Abstract

This article presents the experimental study and comparative performance evaluation of four types of cook stoves using energy and exergy analysis. Analysis of four different types of cook stove models viz. Envirofit, Mangla, Harsha and Vikram were selected and the water boiling test has been carried out. The suitable biomass available from the local market was prepared in the proper size as described in the Bureau of Indian Standards (BIS) and has been used as the fuel for cook stove in this experimental study. The aluminium pots of proper capacity as per BIS standard have been used for different cook stoves. The data from the experiments was collected and evaluated for the energy and exergy efficiencies for different models. Based on the data analysis it is found that the exergy efficiency is much lower than that of the energy efficiency for all the four models. It is also found that the both the efficiencies of Envirofit model are found to be higher than those of other models studied here.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Majority of households in rural India still use biomass as fuel for cooking and heating purposes as the percentage of households using LPG is mere 9% [1]. The biomass is the source of energy for cooking and space heating since time immemorial. Coal or biomass like wood, crop residues, cattle dung and charcoal for their cooking and heating needs is used by almost half of the world population and about 90% of rural population in the developing nation like India. However, biomass is replaced by the gaseous fuels like LPG and natural gas in developed countries and most urban homes in the developing world [2]. Census data 2001 [3] indicated that the traditional energies is being used by approximately 72% of the population of India for their cooking needs, of which over 89% of this population lives in rural areas [4].

Total biomass power potential of entire country is 19,500 MW [5] and a very small percentage it is being tapped till date. Therefore, a huge potential of this energy source is untapped. Large amount of energy is used for the household applications in which energy consumption for cooking plays a major part. Traditional cook stoves or chulhas having thermal efficiencies below 10% emit large amount of pollutants, are used by most rural households in the developing countries for cooking applications. Because of poor thermal efficiencies, traditional chulhas consume large quantity of fuel which ultimately results in a large amount of time spent for collecting fuels. Also due to these in rural households, women and children are often exposed to high levels of pollutants, for 3–7 h daily over many years [6]. The concentration of SPM rises to 3–6 mg/m3 and that of CO is 5–50 ppm [6] according to studies on indoor air pollution. Indoor air pollution is responsible for 2.7% of diseases globally [7]. There are strong evidences to show the relation between exposure to such emissions and acute respiratory infections in children, with estimated two- to three-fold increase in incidence and mortality due to the exposure to these emissions [8]. MacCarty et al. [9] worked on the global warming impact of various types of cook stoves. They found that for sustainable harvesting situations where CO2 emissions are considered neutral, 50–95% overall warming impact from the product of incomplete combustion (PICs) can be reduced from few cook stoves with rocket-type combustion or fan assistance. However, for non-sustainable situations, 40–60% warming impact can be reduced by three types of improved combustion methods. Also they found that the charcoal burning emit less CO2 than that of wood burning. Therefore, there is need of research, development and dissemination of improved cook stoves that leads in the reduction of consumption for cooking, cooking time and indoor air pollution. Also helps in the improvement of quality of life in rural households and reduction in the emission of pollutants in the environment. A detailed design principle for wood burning cook stove is given by Bryden et al. [10].

Owing to the energy crisis in the 1970s, improvement in biomass burning cook stoves to save large quantity of fuel consumed by these cook stoves was considered as an urgent need and many countries across the world started working on the same. Several developing countries started national level programmes on the research, development and dissemination of improved cook stoves. National Program on Improved Cook stoves (NPIC) initiated in the year 1983 by the Ministry of New and Renewable Energy (MNRE), Government of India. Since, than many efforts and researches were conducted to augment the thermal efficiencies of cook stoves and to reduce the indoor air pollution levels. Learning from the experiences of this programme, it is found that there is a need of new initiative on cook stoves with a different approach considering the changes that have taken place in the society, technology and the global concerns. A meeting was organised by MNRE in 2009 to start a programme with a new approach [5, 11].

Several studies on energy and exergy analysis of woody biomass, herbaceous and agricultural biomass were reported in the literature [12]. A study by Zhong et al. [13] revealed that biomass is converted to a liquid fuel with an approximately high energy, which is called bio-crude. The maximum exergy efficiency of this process can be as high 86% and was calculated based on the equations developed by Szargut et al. [14]. An energy analysis of rape seed oil methyl ester was investigated by Kalinci et al. [15] and found that process analysis method is a common method to obtain reasonable data for energy and exergy analysis. Chemical exergy of liquid fuels was calculated and estimated chemical exergy of rape seed oil and RME was reported to be 44.5 and 50.5 MJ/kg. Ojeda et al. [16] evaluated lingo-cellulosic biomass and calculated exergy of main stream process such as re-treatment, fermentation and separation. According to Dincer et al. [17] to harvest good results or to get better thermal efficiencies of any system not only quantity but also the quality of energy should be considered. It was found the energy efficiencies are usually lower than the energy efficiencies as some of input is lost because of inevitable circumstances. Saidur et al. [18] had done the literature survey on the exergy analysis of various biomass viz. herbaceous and agricultural biomass, woody biomass, contaminated biomass and industrial biomass, aquatic biomass. In their study they found that gasification, methanation and CO2 removal are the main sources of exergy losses.

This study deals with the comparative performance evaluation of four different models viz. Envirofit, Mangla, Harsha and Vikram of improved cook stoves using energy and exergy analysis. From the study it is found that the exergy efficiency is much lower than that of the energy efficiency for all the four models. It is also found that the both the efficiencies of Envirofit model are found to be higher than those of other models studied here. Energy analysis of improved cook stoves was done earlier but the work on exergy analysis of improved cook stoves is scant. Therefore, this study is expected to fill this gap of exergy analysis of improved cook stove in order the make them more thermal efficient.

Materials and methods

In this experimental study, the comparative energetic and exergetic analysis of four different types of improved cook stoves has been carried out for which following materials were used.

Materials

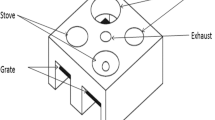

Four improved cook stove models selected in this study are given as below:

-

1.

Envirofit Place a smaller demand on their forest and emit less green house gases [19].

-

2.

Vikram This model dose not requires specialised fuel as it is affordable for rural households, abundant oxygen supply ensures smoke-free heating [20].

-

3.

Mangala Having two opening/mouth to keep the cooking pots and helpful for cooking two meals at a time.

-

4.

Harsha A variety of solid fuels, wood, twigs, leaf, dung cake, agricultural waste, raw coal, briquettes, etc., can be burnt in the stove at high thermal efficiency [21]

As per the Bureau of Indian Standards [22], water boiling test of all above mentioned four cook stoves were performed and the following instruments/equipments have been used:

-

(a)

Glass cylinders for measuring water

-

(b)

Platform balance

-

(c)

Aluminium vessels with lids of proper volumes as per BIS standard

-

(d)

Kerosene oil to ignite the process

-

(e)

Match stick

-

(f)

Selected models of improved cook-stove

-

(g)

Stopwatch

-

(h)

Thermometer/Thermo-couple

-

(i)

Bomb calorimeter

-

(j)

Wood fuel in proper size

Methods

Thermal efficiency of a cook stove is defined as the ratio of heat actually utilized to the heat theoretically produced by complete combustion of a given quantity of fuel wood, which is based on the calorific value of a particular fuel wood. To carry out thermal efficiency of a cook stove few measurements were carried out as below:

Determination of burning capacity rate

If the fuel burning rate per hour is not given by the manufacturer, it need to be determined in order to chose the capacity of cooking pot and the amount of water to be taken at a time as per BIS standard. To do so, we stacked the combustion chamber with test fuel in honey-comb fashion up to third-forth of the height of the cook stove in the pattern recommended. To ignite the fire 10–15 ml of kerosene oil has been sprinkled on the fuel wood from the top of the cook stove and fire lighted using match stick box. The weight of the cook stoves along with wood fuel was measured before igniting the fire and again it was done after half an hour of burning the wood fuel as per the procedure given in BIS standard [22]. To calculate the burning capacity of the cook stove, the following equation was used [22]:

where M 1 is the initial mass of the cook stove with test fuel in kg, M 2 is the mass of the cook stove, after burning the test for half an hour in kg and CV f is the calorific value of the test fuel wood in kcal/kg, and this weighing applies only to portable metal stoves, like the present one.

Determination of size of vessel and quantity of water

The size and dimensions of the vessel and the quantity of water to be taken in each vessel at a time for the thermal efficiency test shall be selected from the table given in BIS standard [22], depending upon the burning capacity rate of the cook stove. After doing preliminary calculations for each cook stove model using Eq. 1, it is found that the quantity of water to be taken in each pot for water boiling test for the present cases is to be 8 l for the Vikram model and 10 l for others cook stoves viz. Envirofit, Harsha and Mangla models.

Calculation for the thermal efficiency

As mentioned above, the thermal efficiency of a cook stove is defined as the ratio of heat actually utilized to the heat theoretically produced by complete combustion of a given quantity of fuel wood, which is based on the calorific value of a particular fuel wood and is given as below:

where the utilized heat is the amount of total heat gained by the water in individual experiment and the heat produced is the amount of heat produced after the complete combustion of the fuel wood consumed in a particular experiment and given as below:

The specific heat of aluminium is taken to be 0.896 kJ/kg °C and the other parameters used in the above equations are defined as below: where w is mass of water in vessel, in kg; W is mass of vessel complete with lid and stirrer, in kg; X is mass of fuel consumed, in kg; c 1 is calorific value of wood, in kcal/kg; x is volume of kerosene consumed, in ml; c 2 is calorific value of kerosene, in kcal/kg; d is density of kerosene, g/cc; f 1 is initial temperature of water in °C; f 2 is final temperature of water in last vessel at the completion of test °C and n total number of vessels used.

Before starting the experiment, some measurements like volume of water, weight of wood, volume of kerosene for the ignition of wood, weight of empty aluminium vessel were measured. Then the fuel wood available from the saw mill cut in proper dimension as per BIS standard afterwards, the wood logs (1–2 kg) of proper dimensions were arranged in honey-comb manner inside the improved cook stove models to be analysed. A known minimum volume of kerosene (which varies for different models) was poured over the wood logs to initiate the ignition process and fire was lighted with a match stick. Aluminium vessels having known volume of water were placed on the cook stove after igniting the fire in the wood log placed in honeycomb fashion inside the cook stove. The readings of water temperature, pot temperature, pot cover temperature, outer surface temperature of the cook stove, etc., were taken periodically after an interval of 5 min. As the first pot reaches to the test temperature of about 80 °C, the second pot placed on the cook stove and the data was measured in the similar way as for the first pot. The experiment was continued and the pot being replaced until the complete fuel wood consumed properly for water boiling/heating process. The calorific value of wood and kerosene were determined with the help of Bomb calorimeter to make results more precise.

Energy and exergy analysis

Basic equations used in the analysis are given in the earlier section and the performance evaluation of four different types of cook stoves has been carried out using energy and exergy analysis following earlier authors [23–25] as below:

Energy analysis

An energy balance for the overall process can be written as:

Energy input is given by:

where \( m_{\text{wd}} \) is mass of wood, \( c_{1} \) is calorific value of wood, and \( c_{2} \) is calorific value of kerosene, \( x \) is volume of kerosene, \( d \) is density of keroseneEnergy output is given by

where Cp is specific heat of water, T fw is final temperature of water, T iw is initial temperature of water, Cp Al is specific heat of Aluminium, m pot is mass of pot, T fp is final temperature of pot and T ip is initial temperature of pot.

Exergy analysis

An overall exergy balance can be written as:

Exergy input is given by:

where T a is ambient temperature, T fuel is temperature of burning fuel.

However, exergy input can also be by chemical exergy of solid industrial fossil fuel, which can be expressed as follows:

where h fg is enthalpy of evaporation of H2O at standard temperature, for water substance at T = 298.15 K, h fg = 2442 kJ/kg, w is mass fraction of moisture in fuel, NCV0 is net calorific value of moist fuel.For dry organic substances contained in solid fossil fuel consisting of C, H, N and O with mass ratio to carbon 2.67 > o/c > 0.667, which in particular includes wood.

where c, h, n and o are the mass fractions of C, H, N and O, respectively.

The exergy input can be given by both the Eqs. 8 and 9, whichever is more appropriate is yet to be ascertain and further work in this direction going on in this research group.

The energy output is given by:

In general energy efficiency is defined as the ratio of output energy to input energy and given by:

In general, exergy efficiency is defined as the ratio of output exergy to the input exergy and given by:

Results and discussion

The performance evaluation and experimental study of four different cook stove models such as Envirofit, Mangla, Harsha and Vikram have been carried out for water boiling test following BIS standard [22]. All these cook stove models were evaluated for water boiling test with specific quantity of water in the Aluminium container using the same type of fuel wood prepared as per the BIS standard. The photographic view of various cook stove models during study is given in Fig. 1. The quantity of water in the container was calculated using heating capacity rate of the individual cook stove given in Eq. 1, while the fuel wood was taken arbitrarily available at the time of each experiment. For example, Envirofit model was tested and evaluated using 1.98 kgs of wood fuel prepared as per the manual having 10 l of water in each aluminium container and total 40 l of water has been used as per the test procedure. The Mangla model was studied with 10 l of water in each pot and 1.34 kgs of wood fuel, while the Vikram model was evaluated using 8 l of water in each pot and 2.0 kgs of wood fuel. On the other hand, Harsha model was evaluated with 10 l of water in each pot and a total wood fuel of 1.48 kgs.

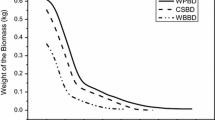

As the quantity of water in each pot was chosen as per the burning rate and power output of the individual cook stove given in the BIS standard and the quantity of wood is taken arbitrarily as per the availability of prepared wood fuel at the time of each experiment. So more than one pot was used for each cook stove and the data for all pots for each cook stove was collected. The instantaneous energy and exergy efficiencies have been evaluated and plotted against the heating time in the graphs as shown in Figs. 2, 3, 4, 5 and 6 and the discussion of results for each cook stove is given individually along with the comparison among them as below:

Envirofit model

As mentioned above, the Envirofit cook stove has been evaluated experimentally with 10 l of water in each pot and total four pots were used consuming 1.98 kgs of wood fuel prepared as per BIS standard [22]. The temperatures of the pot, pot cover, ambient air, water and the outer surface of the cook stove were measured at an interval of 5 min. The energy and exergy efficiencies were evaluated and plotted against the heating time in Fig. 2. It is seen from Fig. 2 that the energy efficiency increases with time for the first pot, while it decreases first sharply and then slightly and again sharply for the last pot (pot 4). On the other hand, for second pot (pot 2) the energy efficiency first sharply decreases then gradually increases, attains its peak and then slightly decreases as the heating/boiling time increases. Whereas, for the third pot (pot 3) the energy efficiency first slightly decreases and then increases, attains its peak and again decreases with the heating time.

Similar results were observed for the exergy efficiency with a slight difference than that of the energy efficiency for the third pot (pot 3). The exergy efficiency for the third pot first increases sharply, attains its peak and then decreases sharply as can bee seen from Fig. 2. Also the peaks in the energy and exergy efficiencies for second and third pots are found to be at almost the same time as can be seen from Fig. 2, however, the peak for the third pot (pot 3) is found to be higher than that of the second pot (pot 2) for both the cases. Again, the energy efficiency for all the cases is found to be much higher than that of exergy efficiency, which can be explained in terms of the quality of energy gained by the hot water during the testing procedure of our experimental study.

Mangla model

This model was studied with 10 l of water in each pot and 1.34 kgs of prepared fuel wood and as mentioned earlier, two pots can used at a time in this particular model. A smaller quantity of wood fuel (1.34 kgs) was taken and total four numbers of pots were used due to the fact that only limited number of pots are available in our laboratory at the time of experimental study of these cook stoves. The energetic and exergetic performance of Mangla model cook stove are shown in Fig. 3. It is seen from this figure that energetic efficiency for pots 1 and 2 first increases sharply, attains its peak and then decreases sharply and again increases sharply, attains its second peak and finally decreases slowly. The exergetic efficiency for pots 1 and 2 first increases sharply, attains its peak and then decreases sharply and again increases first sharply and then slowly. On the other hand, the energy efficiency first decreases and then increases, attains its peak and then fluctuates and finally goes down, while the exergy efficiency for the third and forth pots (pots 3 and 4) first fluctuates and then increases, attains its peak and then fluctuates and finally goes down as the heating time increases.

Also the peaks for the second and fourth pots (pots 2 and 4) for both the efficiencies are found to be higher than those of first and third pots (pots 1 and 3) as can be seen from Fig. 3. This is due to the fact that the maximum energy gain is observed in the second opening (mouth), as there is no option for the passage of the exhaust in the first opening (mouth) of this dual pot Mangla model cook stove and the flue gas passes through the second opening (mouth) only because the first opening is completely covered by the pot. As a result, we obtained the better performance for the pots kept on the second opening (mouth) of the cook stove viz. for pots 2 and 4 as can be seen from Fig. 3.

Vikram model

In this particular model 10 l of water in each pot with total four numbers of pots along with a total quantity of 1.48 kgs of prepared fuel wood were used in the experimental study. The energetic and exergetic performances of Vikram model cook stove are shown in Fig. 4. For the first pot the energy efficiency first decreases slightly and then increases sharply, while the exergy efficiency first slightly increases, then decreases slightly and finally increases sharply with time as can be seen from Fig. 4. On the other hand, the exergy efficiency for the forth pot (pot 4) first increases sharply and then slightly with time. Except the two cases mentioned above, it is clear from Fig. 4 that both the efficiencies first sharply increase, attain their peaks and then sharply decrease with respect to time. The peak for the energy efficiency is almost at the same time for different pots, while it is slightly at different time for the exergy efficiency in the case of the forth pot (pot 4) as can be seen from Fig. 4.

It is also found that the heating time for the last three pots is much lesser than that of the first pot, which is due to the fact that the Vikram model took more time in the ignition at the starting of the experiment. However, due to openings all around for inlet air the combustion occurs at a faster pace and hence, the heating time for other pots decreases which can also be clearly seen from the energy and exergy efficiencies graph (Fig. 4) for the first pot in the last phase.

Harsha model

For Harsh model cook stove 10 l of water in each pot with total three numbers of pots along with a total quantity of 1.48 kgs of prepared fuel wood were used in the experimental study and the observations are plotted graphically in Fig. 5. Figure 5 shows the variation of the energetic and exergetic performance of the Harsha model cook stove against the heating time for 10 l of water in each pot with three numbers of pots as mentioned above. For the first pot (pot 1) it is seen from this graph that the energy efficiency first slightly decreases and then sharply increases, attains its peak and then goes down sharply, while the exergy efficiency first slightly and then sharply increases attains its peak and then goes down sharply. On the other hand, both the efficiencies first increase sharply, attain their peaks and then goes down sharply towards the last phase of the experiment for the second pot (pot 2). Whereas for third pot (pot 3) both the efficiencies first decrease and then increase, attain their peaks and then goes down in a fluctuating manner as can be seen from Fig. 5.

Also for the first and second pots, the peaks for both energy and exergy efficiencies are at larger interval unlike other cook stove models mentioned above, however, the peak for the exergetic efficiency is found to be in the similar range qualitatively unlike the energy efficiency peak as can be seen from Fig. 5. Again the exergetic performance is found to be much lower than that of the energetic performance for all the pots used in this particular model and hence, in the similar trend those of other cook stoves. It is also observed that the heating/boiling time for the first pot in this particular model is found to be the shortest than those of other model, which shows the fast ignition process and merit of this particular model over other type of cook stove models.

The results obtained for this particular model are mixed but slightly different from other models. For example, for the first pot (pot 1) there is a similarity in the energy and exergy efficiencies with other models as can be seen from Figs. 2, 3, 4 and 5, while towards the end of the experiment these results are different from other models. In other words, the energy and exergy efficiencies for all models increases slowly for longer period of time, while it is not the case for Harsha model as can be seen from these graphs mentioned above. This is may be due to the fact that in the Harsha model cook stove the ignition process is faster than other types of cook stove models. As a result, we get the shorter curve for the first two pots (pots 1 and 2), while for the third pot (pot 3) the heating power rate of the cook stove decreases slowly and hence, the heating time prolongs as can be seen from Fig. 5.

Comparison among different cook stoves

The comparison for total energy and exergy efficiencies among all four cook stove models is shown in Fig. 6 for a typical set of operating parameters mentioned above. It is seen from this figure that the energetic performance of all cook stove models is much higher than that of exergetic performance, which is due to the fact that the quantity of energy gained in the hot water for each model is much lesser than the quality of energy gained due to temperature constrained and hence, it is an obvious fact in all thermal energy systems. Also both the energetic and exergetic performances of the Envirofit model cook stove are found to be much better than other types of cook stove models followed by the Harsha model cook stove as can be seen from Fig. 6. Again the energetic performance of the Vikram model cook stove is found to be the lowest whereas the exergetic performance of the Mangla model is found to be the lowest among all cook stove models studies here.

In other words, the Mangla model is found to be better than that of the Vikram model as far as energetic performance is concerned, while it is found to be reverse in the case of exergetic performance. Since exergetic performance is the true measure of any thermal energy system and hence, the Vikram model is found to be better over the Mangla model cook stove, whereas the Environfit model is found to be the best and the Harsha model falls somewhere in the middle from the point of view of thermodynamics as well from the point of view of economics.

Also for the Envirofit model the heating/boiling time for the first pot (pot 1) is found to be the longest followed by the Mangla model, while it is found to be the least in the case of Vikram model, whereas, it is found to be the second lowest in the case of Harsha model cook stove. This shows that the ignition time for Vikram model is the shortest followed by Mangla and Harsha models, while it is found to be the longest in the case of Envirofit model.

Conclusions

This study deals with the comparative exergetic and energetic analysis of four different types of cook stove models based on the experimental observation using different size of pots described in the BIS standard and quantity of well prepared fuel wood arbitrarily available at the time of experiment. From the above discussion, the merits and demerits of each cook stove model evaluated experimentally has been narrated in detail and it is found that each model has some specific quality over the other models. From this experimental study and based on the discussion of results the following conclusions are drawn.

-

Both the efficiencies of Envirofit model is found to be the higher than that of rest of the three models, i.e. performance of Envirofit model is found to be the best among the all four models. The average exergetic and energetic efficiencies of second and third pot is always higher than that of first and fourth pot in case of Envirofit and Vikram models of cook stoves. However, In case of Envirofit model both the efficiencies for second pot are higher than that of first pot and that of fourth pot is higher than that of third pot.

-

For all cook stove models, the energy efficiency is found to be much higher than that of exergy efficiency, which can be explained in terms of the quality of energy gained in the hot water. In other words, the energy gained by the hot water is much higher that the exergy gained by the hot water at that particular temperature and hence, we gets the results obtained in these figures.

-

The energetic performance of the Vikram model cook stove is found to be the lowest whereas the exergetic performance of the Mangla model is found to be the lowest among all cook stove models studies here. Also both the energetic and exergetic performances of the Envirofit model cook stove are found to be much better than other types of cook stove models followed by the Harsha model cook stove.

-

The Mangla model is found to be better than that of the Vikram model as far as energetic performance is concerned, while it is found to be reverse in the case of exergetic performance. Since exergetic performance is the true measure of any thermal energy system and hence, the Vikram model is found to be better over the Mangla model cook stove, whereas the Environfit model is found to be the best and the Harsha model falls somewhere in the middle from the point of view of thermodynamics as well from the point of view of economics.

-

In the case of Envirofit model the heating/boiling time for the first pot (pot 1) is found to be the longest followed by the Mangla model, while it is found to be the least in the case of Vikram model, whereas, it is found to be the second lowest in the case of Harsha model cook stove. This shows that the ignition time for Vikram model is the shortest followed by Mangla and Harsha models, while it is found to be the longest in the case of Envirofit model.

-

For Harsha model cook stove, both the efficiencies for second pot are higher than that of first and third pot which may be due to the fact that in this particular case only three pots have been used. Also for the first and second pots, the peaks for both energy and exergy efficiencies are at larger interval unlike other cook stove models mentioned above, however, the peak for the exergetic efficiency is found to be in the similar range qualitatively unlike the energy efficiency peak for this particular model.

Abbreviations

- \( c_{1} \) :

-

Calorific value of wood (kcal/kg)

- \( c_{2} \) :

-

Calorific value of kerosene (kcal/kg)

- \( Cp \) :

-

Specific heat of water (J/kg K)

- \( Cp_{\text{Al}} \) :

-

Specific heat of Aluminium (J/kg K)

- \( d \) :

-

Density of kerosene (g/cc)

- \( {\rm Ex}_{\text{in}} \) :

-

Exergy input (J)

- \( {\rm Ex}_{\text{o}} \) :

-

Exergy output (J)

- \( E_{\text{in}} \) :

-

Energy input (J)

- \( E_{\text{o}} \) :

-

Energy output (J)

- \( f_{1} \) :

-

Initial temperature of water for thermal efficiency test (°C)

- \( f_{2} \) :

-

Final temperature of water in last vessel at the completion of test (°C)

- \( M_{1} \) :

-

Initial mass of the cook stove with test fuel in (kg)

- \( M_{2} \) :

-

Mass of the cook stove, after burning the test for half an hour (kg)

- \( m_{\text{wd}} \) :

-

Mass of wood (kg)

- \( m_{\text{pot}} \) :

-

Mass of pot (kg)

- \( n \) :

-

Total number of vessels used

- \( P_{1} \) :

-

First pot

- \( P_{2} \) :

-

Second pot

- \( P_{3} \) :

-

Third pot

- \( P_{4} \) :

-

Fourth pot

- \( T_{\text{fw}} \) :

-

Final temperature of water (K)

- \( T_{\text{iw}} \) :

-

Initial temperature of water (K)

- \( T_{\text{fp}} \) :

-

Final temperature of pot (K)

- \( T_{\text{ip}} \) :

-

Initial temperature of pot (K)

- \( T_{\text{a}} \) :

-

Ambient temperature (K)

- \( T_{\text{fuel}} \) :

-

Temperature of burning fuel (K)

- \( w \) :

-

Mass of water in vessel (kg)

- \( W \) :

-

Mass of vessel complete with lid and stirrer (kg)

- \( X \) :

-

Mass of fuel consumed (kg)

- \( x \) :

-

Volume of kerosene consumed (ml)

- \( \eta \) :

-

Energy efficiency (%)

- \( \psi \) :

-

Exergy efficiency (%)

- 1:

-

Initial state

- 2:

-

Final state

- a:

-

Ambient

- Al:

-

Aluminium

- in:

-

Input

- ip:

-

Initial state of pot

- iw:

-

Initial state of water

- fp:

-

Final state of pot

- fw:

-

Final state of water

- o:

-

Output

- wd:

-

Wood

References

Teri Energy Data Directory Yearbook (TEDDY), TERI, 2011.

WRI (World Resources Institute), UNEP, UNDP, World Bank. 1998–99 world resources: a guide to global environment. Oxford: Oxford University Press; 1998.

Census of India 2001: Fuel Used for Cooking. http://censusindia.gov.in/Census_Data_2001/Census_data_finder/HH_Series/Fuel_used_for_cooking.html.

Bhattacharyya SC. Energy access problem of the poor in India: Is rural electrification a remedy? Energy Pol. 2006;34(18):3387–97.

Ministry of New and Renewable Energy (MNRE). www.mnre.gov.in. Accessed 2011.

Bruce N, Perez-Padilla R, Albalak R. Indoor air pollution in developing countries: a major environmental and public health challenge. Bull World Health Organ. 2000;78(9):1078–92.

World Health Organisation. 2004. www.who.int.

Smith KR, Samet JM, Romieu I, Bruce N. Indoor air pollution in developing countries and acute lower respiratory infections in children. Thorax. 2000;5(6):518–32.

MacCarty N, Still D, Ogle D, Bond T, Roden C. A laboratory comparison of the global warming impact of five major types of biomass cooking stoves. Energy Sustain Dev. 2008;XII(2):5–14.

Bryden M, Still D, Scott P, Hoffa G, Ogle D, Bailis R, Goyer K. Design principles for wood burning cook stoves. Aprovecho Research Center/Shell Foundation/Partnership for Clean Indoor Air, USEPA EPA-402-K-05_004. 2005.

Final Report, new initiative for development and deployment of improved cook stoves: recommended action plan, IIT Delhi and TERI New Delhi. 2010. www.winrockindia.org/mnre/doc/Final_Report_Cookstove.doc.

Obara S, Tanno I, Kito S, Hoshi A, Sasaki S. Exergy analysis of the woody biomass Stirling engine and PEM-FC combined system with exhaust heat reforming. Int J Hydrog Energy. 2008;33:2289–99.

Zhong C, Peters CJ, DE Swaan Arons J. Thermodynamics modelling of biomass conversion process. Fluid Phase Equilib. 2002;194–197:805–15.

Szargut J. Exergy method: technical and ecological applications. Southampton: WIT Press; 2005.

Kalinci Y, Hepbasli A, Dincer I. Efficiency assessment of an integrated gasifier/boiler system for hydrogen production with different biomass types. Int J Hydrog Energy. 2010;35:4991–5000.

Ojeda K. Sanchez E, Kafarov V. Sustainable ethanol production from lignocellulosic biomass-application of exergy analysis. Energy. 2010.

Dincer I, Rosen MA. Exergy, energy, environment and sustainable development. London: Elsevier; 2007.

Saidur R, BoroumandJazi G, Mekhilef S, Mohammed HA. A review on exergy analysis of biomass based fuels. Renew Sustain Energy Rev. 2011 (in press).

Envirofit. www.envirofit.org. Accessed 2011.

Winrock International India. www.winrockindia.org. Accessed 2011.

Institute of Mineral and Material Technology. www.immt.res.in. Accessed 2011.

Bureau of Indian Standards. www.bis.org.in. Accessed 2011.

Tyagi SK, Wang W, Kaushik SC, Singhal MK, Park SR. Exergy analysis and parametric study of concentrating type solar collectors. Int J Therm Sci. 2007;46:1304–10.

Pandey AK, Tyagi VV, Park SR, Tyagi SK. Comparative experimental study of solar cookers using exergy analysis. J Therm Anal Calorim. 2011 (in press).

Tyagi VV, Pandey AK, Kaushik SC, Tyagi SK. Thermal performance evaluation of a solar air heater with and without thermal energy storage: an experimental study. J Therm Anal Calorim. 2012;107:1345–52.

Acknowledgements

Sincere thanks are due to Dr. A.K. Jain, Director, Sardar Swaran Singh National Institute of Renewable Energy, Kapurthala (Punjab) India for the fruitful discussions, suggestions and overall guidance in the testing and evaluation of cook stove. Thanks are also due to Ministry of New and Renewable Energy, Govt. of India for the overall financial support in the R&D activities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tyagi, S.K., Pandey, A.K., Sahu, S. et al. Experimental study and performance evaluation of various cook stove models based on energy and exergy analysis. J Therm Anal Calorim 111, 1791–1799 (2013). https://doi.org/10.1007/s10973-012-2348-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-012-2348-9