Abstract

CuFe2(C2O4)3·4.5H2O was synthesized by solid-state reaction at low heat using CuSO4·5H2O, FeSO4·7H2O, and Na2C2O4 as raw materials. The spinel CuFe2O4 was obtained via calcining CuFe2(C2O4)3·4.5H2O above 400 °C in air. The CuFe2(C2O4)3·4.5H2O and its calcined products were characterized by thermogravimetry and differential scanning calorimetry, Fourier transform FT-IR, X-ray powder diffraction, scanning electron microscopy, energy dispersive X-ray spectrometer, and vibrating sample magnetometer. The result showed that CuFe2O4 obtained at 400 °C had a saturation magnetization of 33.5 emu g−1. The thermal process of CuFe2(C2O4)3·4.5H2O experienced three steps, which involved the dehydration of four and a half crystal water molecules at first, then decomposition of CuFe2(C2O4)3 into CuFe2O4 in air, and at last crystallization of CuFe2O4. Based on KAS equation, OFW equation, and their iterative equations, the values of the activation energy for the thermal process of CuFe2(C2O4)3·4.5H2O were determined to be 85 ± 23 and 107 ± 7 kJ mol−1 for the first and second thermal process steps, respectively. Dehydration of CuFe2(C2O4)3·4.5H2O is multistep reaction mechanisms. Decomposition of CuFe2(C2O4)3 into CuFe2O4 could be simple reaction mechanism, probable mechanism function integral form of thermal decomposition of CuFe2(C2O4)3 is determined to be 1 − (1 − α)1/4.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Spinels of the type M2+M2 3+O4 attract the research interest because of their versatile practical applications [1–3]. In the case of M3+=Fe, the resulting spinel ferrites having a general chemical composition of MFe2O4 (M = Cu, Mn, Mg, Zn, Ni, Co, etc.) are widely used in the field of high-density information storage, ferrofluids, catalysts, drug targeting, magnetic separation, magnetic resonance imaging, and gas sensor [4–11]. Within this group, copper ferrite (CuFe2O4) is very important soft magnetic material. Its properties such as magnetic behavior and gas-sensing properties are highly dependent on the synthesis method.

To date, various methods have been developed to synthesize CuFe2O4 with cubic structure, including ball-milling [12, 13], sol–gel synthesis [14], co-precipitation [15, 16], combustion synthesis [17], microwave synthesis [18], and solid-state reaction at low heat [4]. In the synthesis of CuFe2O4, it was found that crystallite diameter, morphology, and crystalline phases of CuFe2O4 associated with its properties were highly dependent on the synthesis method and temperature. Sun et al. [4] obtained spinel-type CuFe2O4 with a crystallite size of 75 nm by solid-state reaction at low heat when precursor was calcined at 600 °C. Tao et al. [16] studied synthesis of spinel-type CuFe2O4 via sol–gel and co-precipitation methods, respectively. The results showed that spinel-type CuFe2O4 was obtained at 600 °C via calcining precursor obtained by co-precipitation method. However, pure CuFe2O4 was not obtained until 800 °C by a sol–gel process, which might be due to the loose contact between copper and iron ions and the possible low diffusion rate. Therefore, new synthesis methods for CuFe2O4 still need to be studied and innovated further. Besides, the mechanism and kinetics studies of thermal process of precursor are needed in order to obtain high-quality CuFe2O4 for practical applications.

The aim of this work is to prepare polycrystalline CuFe2O4 using CuSO4·5H2O, FeSO4·7H2O, and Na2C2O4 as raw materials via solid-state reaction at low heat [11, 19] and to study magnetic properties of CuFe2O4, the mechanisms, and kinetics of the thermal process of precursor. The kinetics of the thermal process of precursor was studied using TG–DSC techniques. Non-isothermal kinetics of the thermal process of precursor was interpreted by the Kissinger–Akahira–Sunose (KAS) equation [20, 21] and Ozawa–Flynn–Wall (OFW) equation [22–24]. The kinetic (E a mechanism) parameters of the thermal decomposition of CuFe2(C2O4)3·4.5H2O are discussed for the first time.

Experimental

Reagent and apparatus

All chemicals were of reagent-grade purity. TG/DSC measurements were taken using a Netsch 40PC thermogravimetric analyzer. X-ray powder diffraction (XRD) was performed using a Rigaku D/max 2500 V diffractometer equipped with a graphite monochromator and a Cu target. The FT-IR spectra of the precursor and its calcined products were recorded on a Nexus 470 FT-IR instrument. The morphologies of the calcined samples and energy dispersive X-ray spectrometer (EDS) were obtained on S-3400 scanning electron microscopy (SEM). The specific saturation magnetizations (Ms) of the calcined sample powders were carried out at room temperature using a magnetic property measurement system (SQUID-MPMS-XL-5).

Preparation of CuFe2O4

The CuFe2O4 precursor was prepared by solid-state reaction at low heat using CuSO4·5H2O, FeSO4·7H2O, and Na2C2O4 as raw materials at first. In a typical synthesis, CuSO4·5H2O (24.41 g), FeSO4·7H2O (54.37 g), Na2C2O4 (43.24 g), and surfactant polyethylene glycol (PEG)-400 (3.0 mL, 50 vol%) were put in a mortar, and the mixture was fully ground by hand with a rubbing mallet for 40 min. The grinding velocity was about 200 circles/min, and the strength applied was moderate. The reactant mixture gradually became damp, and then, a paste formed quickly. The reaction mixture was kept at room temperature for 2 h. The mixture was washed with deionized water to remove soluble inorganic salts until SO4 2− ion could not be visually detected with a 0.5 mol L−1 BaCl2 solution. The solid was then washed with a small amount of anhydrous ethanol and dried at 86 °C for 4 h. The resulting material was subsequently determined to be the CuFe(C2O4)3·4.5H2O. Nanocrystalline CuFe2O4 with cubic structure was obtained via calcining CuFe(C2O4)3·4.5H2O above 400 °C in air.

Determination of activation energy by KAS equation and OWF equation

Activation energy of thermal decomposition of solid compound can be obtained by KAS equation (Eq. 1) and OWF equation (Eq. 2), respectively.

where q is the heating rate (K min−1), T is the reaction temperature (K) in TG curve, E a is the activation energy (kJ mol−1) of thermal decomposition, R is the gas constant (8.314 × 10−3 kJ mol−1 K−1), A is the pre-exponential factor, and α is called conversion degree. The g(α) is a function of α, and it reveals the mechanism of reaction. The plots of ln(q/T 2) versus 1/T and ln q versus 1/T corresponding to different conversions α can be obtained by a linear regression of least-square method, respectively. Thus, reaction activation energy E a can be obtained from linear slope (−E a/R, Eq. 1) and (−1.0516E a/R, Eq. 2). In order to obtain exact E a values of the thermal decomposition, the iterative equations of Eqs. 1 and 2 can be expressed as Eqs. 3 and 4, respectively [24].

where h(x) is expressed by the fourth Senum and Yang approximation formulae [25]:

where x = E a/RT, and H(x) is equal to [24]:

The iterative procedure performed involved the following steps: (i) assume h(x) = 1 or H(x) = 1 to estimate the initial value of the activation energy E a1. The conventional isoconversional methods stop the calculation at this step; (ii) using E a1, calculate a new value of E a2 for the activation energy from the plot of ln[q/h(x)T 2] versus 1/T or ln[q/H(x)] versus 1/T; (iii) repeat step (ii), replacing E a1 with E a2. When E ai − E a(i−1) < 0.1 kJ mol−1, the last value of E i was considered to be the exact value of the activation energy of the reaction.

Determination of the most probably mechanism function

The probable mechanism function of thermal process, i.e., g(α) function, can be obtained by Eq. 7 [24]:

The procedure performed involved the following steps: (i) the conversion degrees α corresponding to multiple heating rates at the same temperature are put into the left of Eq. 7 at first, combined with twenty-six types of mechanism functions [26], and then the slope k and correlation coefficient r are obtained from the plot of ln [g(α)] versus ln q; (ii) g(α), which the value of the slope k is near to −1.00000 and correlation coefficient r is better, is determined to be the most probably mechanism function of thermal process.

Determination of pre-exponential factor A

The pre-exponential factor A can be estimated from the intercept of the plots of Eq. 2, inserting the most probable g(α) function determined [27].

Results and discussion

TG/DSC analysis of the precursor

Figure 1 shows the TG/DSC curves of CuFe2(C2O4)3·4.5H2O at four different heating rates in air, respectively.

The TG/DSC curves show that thermal process of the CuFe2(C2O4)3·4.5H2O below 450 °C occurs in three well-defined steps. For heating rate of 10 °C min−1, the first step starts at about 50 °C, ends at about 201 °C, and characterized by a strong endothermic DSC peak at about 189 °C, which can be attributed to dehydration of four and a half water molecules from CuFe2(C2O4)3·4.5H2O and the formation of CuFe2(C2O4)3. The observed mass loss in the TG curve is 15.72%, which is in good agreement with 15.58% theoretic mass loss of dehydration of four and a half water molecules from CuFe2(C2O4)3·4.5H2O. The second decomposition step begins at about 201 °C and ends at about 300 °C, which involves an exothermic process with a strong DSC peak at about 248 °C, attributed to the decomposition of CuFe2(C2O4)3 and the formation of CuFe2O4. The thermal decomposition of second step only requires about 22 °C from the beginning to finish, indicating that decomposition of CuFe2(C2O4)3 into CuFe2O4 in air is a fast step, which can be attributed that Fe2+ and Cu2+ ions with d6−9 outer electron configuration have strong polarization force. The corresponding observed mass loss in the TG curve is 36.56%, which is close to 38.45% theoretic mass loss of reaction of CuFe2(C2O4)3 with two O2 molecules. The thermal process of third step is crystallization of cubic CuFe2O4 and characterized by a weak exothermic DSC peak at about 328 °C.

XRD analysis of CuFe2(C2O4)3·4.5H2O and its calcined samples

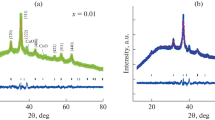

Figure 2 shows the XRD patterns of CuFe2(C2O4)3·4.5H2O dried at 86 °C and the calcined products at different temperatures in air for 1 h.

From Fig. 2a, the results show that strong intensity and smoothed baseline, a wide and low diffraction pattern of the precursor is observed, which indicates that the CuFe2(C2O4)3·6H2O obtained at 86 °C is a crystalline with higher crystallinity. The diffraction peaks in the pattern can be indexed to be in agreement with the orthorhombic FeC2O4·2H2O from PDF card 23-0293, with space group 12/a(15). No diffraction peaks of copper oxalate, such as CuC2O4 or CuC2O4·xH2O, are observed, which implies that Cu2+ ions enter lattice of FeC2O4·2H2O, and CuC2O4 or CuC2O4·xH2O forms a solid solution with FeC2O4·2H2O. It is explained by the fact that Cu2+ ion (72 pm) and Fe2+ ion (75 pm) have same electric charge and similar ionic radius. When the precursor is calcined at 250 °C for 1 h, a part of characteristic diffraction peaks of cubic CuFe2O4 with weak intensity is observed. From Fig. 2b, when the sample was heated at 400 °C in air for 1 h, the diffraction peaks in the pattern are in agreement with those of cubic CuFe2O4, with space group F, lattice parameters: a = b = c = 0.8349 nm, α = β = γ = 90o, density = 5.31 g cm−3, from PDF card 25-0283. Intensity of diffraction peaks of impurities, such as CuO and Fe2O3, increases with increasing calcination temperature.

According to the Scherrer formula [6]: D = Kλ/(βcosθ), where D is crystallite diameter, K = 0.89 (the Scherrer constant), λ = 0.15406 nm (wavelength of the X-ray used), β is the width of line at the half-maximum intensity, and θ is the corresponding angle. The resulting crystallite sizes of the products from calcining precursor can be obtained. Besides, the crystallinity of cubic CuFe2O4 can be calculated via MDI Jade 5.0 software [28]. The results are shown in Fig. 3. From Fig. 3, it can be seen that the crystallite sizes of the products increase with increasing calcination temperature. However, the crystallinity of cubic CuFe2O4 decreases with increasing calcination temperature, which is attributed that the cubic CuFe2O4 can decompose into CuO and Fe2O3 above 400 °C. In other words, cubic CuFe2O4 is thermodynamically more stable at 400 °C.

IR spectroscopic analysis of CuFe2(C2O4)3·4.5H2O and its calcined samples

The FT-IR spectra of CuFe2(C2O4)3·4.5H2O and its calcined sample are shown in Fig. 4. The CuFe2(C2O4)3·4.5H2O exhibits a strong and broad band at about 3,400 cm−1 that can be assigned to the stretching OH vibration of the water molecule. The weak band at about 827 cm−1 is the water libration (hindered rotation). The strong band, which appears at 1,643 cm−1 in the spectrum of the precursor, can be ascribed to the bending mode of the HOH [6, 19, 28]. The bands at 1,338 cm−1 can be assigned to either the appearance of new M–OC2O3 (M = Cu, Fe) bonds and/or to the combinations of OH librations and lattice modes [6, 24]. When CuFe2(C2O4)3·4.5H2O is calcined at 400 °C, the bands at 2,361 and 1,453 cm−1 are attributed to the absorption of CO2 and absorption of water from air, respectively.

SEM and EDS analyses of the calcined samples

The morphologies and EDS spectrum of the calcined samples are shown in Fig. 5. From Fig. 5a, it can be seen that the calcined sample obtained at 600 °C is composed of irregular grains, there is a soft agglomeration phenomenon in the particles of sample, and the observed particles sizes are between 100 and 300 nm. With the increase in calcination temperature, the calcined sample is aggregated into larger grains further. Figure 5c shows the SEM micrographs of sample obtained at 800 °C. It can be seen that the calcined sample obtained at 800 °C becomes lamellar shape. The average crystallite sizes of the calcined samples determined by X-ray diffraction are significantly smaller than the values determined by SEM. This is attributed that values observed by SEM technique give the size of the secondary particles, and the X-ray line broadening analysis discloses only the size of primary particles. Figure 5d shows EDS spectrum of the calcined product obtained at 700 °C, and the result shows that mole ratio of Cu/Fe is equal to 0.95:2.15, which closes to that obtained by XRD analysis.

Magnetic properties of the calcined samples

Figure 6 shows the hysteresis loops of the CuFe2O4 particles obtained at different calcination temperatures. From Fig. 6, it can be observed that specific saturation magnetizations of powders calcined at 400, 600, 700, and 800 °C for 1 h are 33.5, 31.9, 21.8, and 22.0 emu g−1, respectively. That is, specific saturation magnetization decreases with increasing calcination temperature. In other words, the smaller the crystallinity of the particles, the smaller is the specific saturation magnetizations. The smaller Ms values associated with smaller crystallinity can be explained as follows: First, CuFe2O4 can decompose into CuO and Fe2O3 particles with weak magnetic intensity above 400 °C, and weak magnetic CuO and Fe2O3 particles can reduce the net magnetic moment in the samples. Second, the magnetocrystalline anisotropy of the particles is dependent on the crystallinity of CuFe2O4. When the calcination temperature increases, the crystallinity of particles decreases, which increases magnetocrystalline anisotropy distortion and decreases magnetic moment within the particles of CuFe2O4 [10].

Kinetics of thermal decomposition of CuFe2(C2O4)3·4.5H2O

In accordance with TG/DSC and XRD analyses of CuFe2(C2O4)3·4.5H2O and its calcined products mentioned above, thermal process of CuFe2(C2O4)3·4.5H2O below 400 °C consists of three steps, which can be expressed as follows, respectively.

According to non-isothermal method, the basic data of α and T collected from the TG curves of the thermal decomposition of CuFe2(C2O4)3·4.5H2O at various heating rates (5, 10, 15, and 20 K min−1) are illustrated in Tables 1 and 2.

According to Eqs. 1 and 2, the isoconversional calculation procedures of KAS and OFW are used. The corresponding KAS and OFW lines obtained at different conversion degrees α and different heating rates q are shown in Figs. 7 and 8, respectively.

The values of the activation energies associated with the thermal process of CuFe2(C2O4)3·4.5H2O for the first thermal process step corresponding to different conversions α are obtained by the KAS and OFW calculation procedure and the iterative method mentioned above. The results are shown in Tables 3 and 4, respectively.

From Tables 3 and 4, E a values for thermal decomposition of step 1 obtained by iterative method are very close to those obtained by KAS method (differing about 1 kJ mol−1), and those by OFW method is higher than those obtained by iterative method (differing about 2 kJ mol−1). E a values for thermal decomposition of step 2 obtained by iterative method are very close to those obtained by KAS method (differing about 0 kJ mol−1), and those by OFW method is higher than those obtained by iterative method (differing about 3 kJ mol−1). However, it can be discovered that the E a values obtained from the plot of ln[q/H(x)] versus 1/T or ln[q/(h(x)T 2)] versus 1/T by iterative procedure are very close to each other. From Tables 3 and 4, the activation energies change in the step 1 with α is higher than 10%, and that in the step 2 with α is lower than 10%, so that we draw a conclusion that the dehydration of the crystal water of CuFe2(C2O4)3·4.5H2O could be multistep reaction mechanism, and decomposition of CuFe2(C2O4)3 into CuFe2O4 could be simple reaction mechanism [19, 27, 29, 30].

According to Eq. 2 and Table 2, conversion degree and temperature corresponding to heating rate are put into twenty-six types of mechanism functions, respectively. The slope k, correlation coefficient r, and intercept B of linear regression of ln [g(α)] versus ln q are obtained. Mechanism function, in which the value of k is closest to −1.00000 and the correlation coefficient r 2 is higher, is chosen as mechanism function of thermal decomposition of CuFe2(C2O4)3. The results show that probable mechanism function integral form of thermal decomposition of CuFe2(C2O4)3 is determined to be g(α) = 1 − (1 − α)1/4.

The pre-exponential factor A is estimated from the intercept of the plots of Eq. 2 by inserting the most probable g(α) function determined. The results show that the range of pre-exponential factor A is 1.86 × 1010 min−1.

Conclusions

We have successfully synthesized nanocrystalline CuFe2O4 via a novel and simple method. XRD analysis shows that precursor is a solid solution containing CuFe2(C2O4)3·4.5H2O. Crystalline CuFe2O4 with cubic structure is obtained when the precursor is calcined above 400 °C in air for 1 h. Magnetic characterization indicates that the specific saturation magnetization of CuFe2O4 obtained at 400 °C is 33.5 emu g−1. The thermal process of the precursor in the range of ambient temperature to 400 °C experiences three steps, which involves the dehydration of the waters of crystallization at first; then the decomposition of CuFe2(C2O4)3 and formation of amorphous CuFe2O4; and at last crystallization of cubic CuFe2O4. The kinetics of the thermal process of the precursor is studied using TG/DSC technique. The values of the activation energy for the thermal process of CuFe2(C2O4)3·4.5H2O are determined to be 85 ± 23 and 107 ± 7 kJ mol−1 for the first and second thermal process steps, respectively. Dehydration of CuFe2(C2O4)3·4.5H2O is multistep reaction mechanisms, and decomposition of CuFe2(C2O4)3 into CuFe2O4 could be simple reaction mechanism.

References

Sugimoto M. The past, present, and future of ferrites. J Am Ceram Soc. 1999;82:269–80.

Raj K, Moskowitz B, Casciari R. Advances in ferrofluid technology. J Magn Magn Mater. 1995;149:174–80.

McMichael RD, Shull RD, Swartzendruber LJ, Bennett LH, Watson RE. Magnetocaloric effect in superparamagnets. J Magn Magn Mater. 1992;111:29–33.

Sun ZP, Liu L, Jia DZ, Pan WY. Simple synthesis of CuFe2O4 nanoparticles as gas-sensing materials. Sens Actuators B. 2007;125:144–8.

Li JJ, Yuan HM, Li GD, Liu YJ, Leng JS. Cation distribution dependence of magnetic properties of sol–gel prepared MnFe2O4 spinel ferrite nanoparticles. J Magn Magn Mater. 2010;322:3396–400.

Wu XH, Wu WW, Zhou KW, Cui XM, Liao S. Products and non-isothermal kinetics of thermal decomposition of MgFe2(C2O4)3·6H2O. J Therm Anal Calorim. 2011. doi:10.1007/s10973-011-1968-9.

Li FS, Wang HB, Wang L, Wang JB. Magnetic properties of ZnFe2O4 nanoparticles produced by a low-temperature solid-state reaction method. J Magn Magn Mater. 2007;309:295–9.

Wu WW, Cai JC, Wu XH, Li YN, Liao S. Magnetic properties and crystallization kinetics of Zn0.5Ni0.5Fe2O4. Rare Met. 2011. doi:10.1007/s12598-011-0439-6.

Satyanarayana L, Madhusudan Reddy K, Manorama SV. Nanosized spinel NiFe2O4: a novel material for the detection of liquefied petroleum gas in air. Mater Chem Phys. 2003;82:21–6.

Zhang K, Holloway T, Pradhan AK. Magnetic behavior of nanocrystalline CoFe2O4. J Magn Magn Mater. 2011;323:1616–22.

Wu WW, Cai JC, Wu XH, Liao S, Huang AG. Co0.35Mn0.65Fe2O4 magnetic particles: preparation and kinetics research of thermal process of the precursor. Powder Technol. 2011. doi:10.1016/j.powtec.2011.09.048.

Goya GF, Rechenberg HR. Superparamagnetic transition and local disorder in CuFe2O4 nanoparticles. Nanostruct Mater. 1998;10:1001–11.

Jiang JZ, Goya GF, Rechenberg HR. Magnetic properties of nanostructured CuFe2O4. J Phys Condens Mater. 1999;11:4063–78.

Bomio M, Lavela P, Tirado JL. Electrochemical evaluation of CuFe2O4 samples obtained by sol–gel methods used as anodes in lithium batteries. J Solid State Electrochem. 2008;12:729–37.

Pandya PB, Joshi HH, Kulkarni RG. Magnetic and structural properties of CuFe2O4 prepared by the co-precipitation method. J Mater Sci Lett. 1991;10:474–6.

Tao SW, Gao F, Liu XQ, Sørensen OT. Preparation and gas-sensing properties of CuFe2O4 at reduced temperature. Mater Sci Eng B. 2000;77:172–6.

Zhang YS, Stangle GC. Preparation of fine multicomponent oxide ceramic powder by a combustion synthesis process. J Mater Res. 2004;9:1997–2004.

Vanetsev AS, Ivanov VK, Tret’yakov Yu D. Microwave synthesis of lithium, copper, cobalt, and nickel ferrites. Dokl Chem. 2002;387:332–4.

Wu XH, Wu WW, Li SS, Cui XM, Liao S. Kinetics and thermodynamics of thermal decomposition of NH4NiPO4·6H2O. J Therm Anal Calorim. 2011;103:805–12.

Chrissafis K. Kinetics of thermal degradation of polymers. Complementary use of isoconversional and model-fitting methods. J Therm Anal Calorim. 2009;95:273–83.

Chen ZP, Chai Q, Liao S, He Y, Wu WW, Li B. Preparation of LiZnPO4·H2O via a novel modified method and its non-isothermal kinetics and thermodynamics of thermal decomposition. J Therm Anal Calorim. 2011. doi:10.1007/s10973-011-1799-8

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn. 1965;38:1881–6.

Flynn JH. The ‘temperature integral’—its use and abuse. Thermochim Acta. 1997;300:83–92.

Vlaev L, Nedelchev N, Gyurova K, Zagorcheva M. A comparative study of non-isothermal kinetics of decomposition of calcium oxalate monohydrate. J Anal Appl Pyrolysis. 2008;81:253–62.

Senum GI, Yang RT. Rational approximations of the integral of the Arrhenius function. J Therm Anal. 1977;11:445–7.

Liqing L, Donghua C. Application of iso-temperature method of multiple rate to kinetic analysis. Dehydration for calcium oxalate monohydrate. J Therm Anal Calorim. 2004;78:283–93.

Genieva SD, Vlaev LT, Atanassov AN. Study of the thermooxidative degradation kinetics of poly(tetrafluoroethene) using iso-conversional calculation procedure. J Therm Anal Calorim. 2010;99:551–61.

Liu C, Wu XH, Wu WW, Cai JC, Liao S. Preparation of nanocrystalline LiMnPO4 via a simple and novel method and its isothermal kinetics of crystallization. J Mater Sci. 2011;46:2474–8.

Boonchom B, Danvirutai C. Kinetics and thermodynamics of thermal decomposition of synthetic AlPO4·2H2O. J Therm Anal Calorim. 2009;98:771–7.

Wu WW, Li YN, Zhou KW, Wu XH, Liao S, Wang Q. Nanocrystalline Zn0.5Ni0.5Fe2O4: preparation and kinetics of thermal process of precursor. J Therm Anal Calorim. 2011. doi:10.1007/s10973-011-2027-2.

Acknowledgements

This study was financially supported by the National Nature Science Foundation of China (Grant no. 21161002) and the Guangxi Nature Science Foundation of China (Grant no. 2011GXNSFA018036).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, X., Zhou, K., Wu, W. et al. Magnetic properties of nanocrystalline CuFe2O4 and kinetics of thermal decomposition of precursor. J Therm Anal Calorim 111, 9–16 (2013). https://doi.org/10.1007/s10973-011-2104-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-011-2104-6