Abstract

The thermal behaviour of Mg-diclofenac compound was evaluated by simultaneous TG-DTA and DSC. The profile of the DSC curves showed that this compound possesses two transition phases: endothermic and exothermic between 170–180 °C and 185–195 °C, respectively. The endothermic reaction is reversible (enantiotropic). Thus, different experimental conditions, i.e. masses sample, open and crimped lids crucible, static and dynamic atmospheres were utilized for DSC analysis for evaluation of this transition phase. In a static atmosphere the enantiotropic reaction was not observed. The obtained data were utilized to obtain the kinetic parameters, which were calculated by the Capela and Ribeiro method. The results show that the activation energy for the transition phase depends on the different experimental conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Diclofenac deserves special attention because it is a widely marketed anti-inflammatory drug. Some studies have been accomplished regarding the compounds formed with diclofenac [1]. Bucci et al. relate the thermal properties of the solid compounds obtained by the reaction of diclofenac with manganese(II), iron(II), cobalt(II), nickel(II), copper(II) and zinc(II). In this work the first compound of the series of these divalent metals were detailed, but without thermoanalytical discussion of the other complexes [2]. Kenawi et al. investigated the interactions between cetrizine dihydrochloride and diclofenac complexes of Ca(II), Mg(II), Zn(II) and Fe(III) which form stable adducts. As part of this work, it was shown that cetirizine dihydrochloride also interacted with diclofenac sodium and also when the metal ion is linked to diclofenac [3]. Recently, Fini et al. investigated some diclofenac salts, where it was verified that the magnesium compound presents a crystalline transition [4]. However, other characteristics of the thermal behaviour of this compound were not detailed. In a previous work, the preparation and thermal characterization of iron(III)-diclofenac was reported on. In this work we used a sample mass of 2 and 5 mg, which allow a better evaluation of kinetic parameters [5]. Recently, the preparation of calcium-diclofenac was also reported on as well as the thermal behaviour and kinetic evaluation of the dehydration, thermal decomposition and transition phase of this compound [6]. In addition, we also have reported on the synthesis of cobalt-diclofenac complex, which exhibits a transition phase. The objective of this study was the evaluation of the transition phase by DSC method with different sample masses and using a cover on the crucible as well as crimped lids. In these different conditions, the effects of the different masses employed demonstrated that the activation energy becomes lower with an increase in the sample mass [7].

Therefore, as part of our research into understanding the behaviour of the transition phase of complex metals, specially using the diclofenac drug as a ligand, this work reports on the preparation of magnesium(II)-diclofenac compound (Mg(Diclof)2). Thus, the aim of this work was to evaluate the thermal behaviour and obtain the variation of activation energy (E a/kJ mol−1) vs. degree conversion (α) of the transition phase observed in this compound. DSC curves were carried out in an open and crimped aluminium pan and with three different sample sizes under non-isothermal conditions in nitrogen and static atmospheres, in order to determine the effect of changed experimental conditions on the kinetic behaviour and thus to obtain reference values of activation energy. Furthermore, the isoconversional method was used as a way of obtaining reliable and consistent kinetic information and, because the measurements are estimated, the temperatures correspond to fixed values of conversion degree (α) and also avoid the use of explicit kinetics models. Thus, the activation energy (E a/kJ mol−1) data were obtained applying the isoconversional method proposed by Capela and Ribeiro [8–12].

Experimental

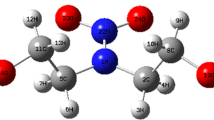

The Mg(Diclof)2 compound was prepared by the stoichiometric addition of magnesium(II) sulphate on potassium diclofenac salt, both in methanol solutions, as described by Fini et al. [4]. The obtained precipitate was filtered, washed with methanol, dried at room temperature and stored in a desiccator over anhydrous calcium chloride until a constant weight was achieved.

Simultaneous TG-DTA and DSC curves were obtained from a SDT 2960 and a DSC 2910, both from TA Instruments, respectively. The TG-DTA analysis experiment was performed using sample sizes of about 7 mg in an a-alumina crucible with heating rates of 20 °C min−1 in synthetic air atmosphere (100 mL min−1). The DSC curves were obtained using several heating rates (5, 10 and 20 °C min−1) from 30 to 220 °C. Powdered samples having a particle size around 250 mm and sample mass of 1, 5 and 10 mg (±0.05 mg) were placed in an aluminium crucible, either open or with crimped lids. The analyses were evaluated at a nitrogen flow of 50 mL min−1, as well as without the flow of gas (static atmosphere). The diffraction patterns were obtained from a Siemens D-500 X-ray diffractometer using Cu Kα radiation (λ = 1.54 Å) and settings of 40 kV and 30 mA.

Kinetic methodology

To perform the kinetic analysis under non-isothermal conditions is usually to consider the integral kinetic equation, defined by

where β = dT/dt is a constant heating rate (T is the temperature and t is the time), g(α) is the integral form of the reaction model as function of the extent of reaction α, A is the pre-exponential factor, E is the activation energy and R is the gas constant.

The estimates of the kinetic parameters are obtained by fitting equation (1) to experimental data. As consequence, is required the evaluation of the integral on the right side of the equation (1), known as temperature integral. A difficulty results from the fact that this integral does not have an exact analytical solution. Thus, is convenient to approximate the integral of temperature for some function that yields suitable estimations to these kinetic parameters.

In this work, the kinetic parameters are obtained through isoconversional method using an approximation to the temperature integral based on the convergent of a Jacobi fraction, proposed by Capela et al. [8]. This approximation is a rational function, given by the following equation:

A characteristic experimental curve presents the conversional fraction, α, as a function of the temperature for a given heating rate, β. For each fixed value of α there are corresponding values T α for temperature, values E α for activation energy and values A α for pre-exponential factor.

Replacing the integral in Eq. 1 by the approximation given in Eq. 2 is obtained the following expression for heating rate β as function of the \( x_{\alpha } = 10^{3} /RT_{\alpha } \):

where the activation energy is in kJ/mol and the parameter B α is defined as:

The estimates of the E α and B α can be obtained by the non-linear fitting of the Eq. 3 to the β values as function of x α.

Once the g(α) function has been determined for each conversional fraction α, the estimation of the Arrhenius pre-exponential factor can be obtained from Eq. 4 and is given by following equation:

Results and discussion

Thermal behaviour

Simultaneous TG-DTA curves of Mg (Diclof)2 are shown in Fig. 1a. The first mass loss (17.76%) between 30 and 120 °C, corresponding to the endothermic peak in DTA curve, is due to methanol loss. The second, third and fourth mass losses occurred from 288 to 375 °C (35.46%), from 375 to 650 °C (22.23%) and from 650 to 820 °C (18.54%), respectively. For both mass losses, the corresponding DTA events were attributed to the thermal decomposition of the ligand. Calculations based on the mass loss up to the final temperature, is in agreement with the formation of MgO as the final residue. An exothermic peak seen between 176 and 215 °C, having its maximum at 195 °C, which did not show a corresponding mass loss at the TG curve, is attributed to the transition phase. This fact was verified by X-ray powder data pattern which revealed to be amorphous, but after this transition phase, became crystalline. The X-ray patterns of this compound are shown in Fig. 2a–c. In Fig. 2a, b, the characteristic of this compound with and without methanol, respectively, is shown where it is demonstrated that there are alterations for the non-crystalline state. In Fig. 2c, after the crystallization step (Fig. 1 and Fig. 3), the presence of some characteristic lines can be seen which are attributed to the weak crystallinity.

The transition phase is a phenomenon that can occur in several organic or inorganic compounds, which consists of a physical or chemical alteration of the molecules. If solid state compounds are considered, such as pharmaceutical compounds, two main types of transition phases will occur: enantiotropic and monotropic. In the first, a reversible transition of the structure occurs, in other words, the compound goes back to its original conformation. In the second, the transition occurs as an irreversible rearrangement of the structure [13–16].

The DSC curves of this compound are shown in Fig. 3. Two events were observed, from 160 to 175 °C and from 175 to 200 °C, which are attributed to transition phases enantiotropic (endothermic peak) and monotropic (exothermic peak) stages, respectively. To certify these facts, a sample mass of about 1 mg was heated up to a little before the exothermic reaction, and after that quickly cooled (dashed line). Then, this sample was again re-heated, as observed in Fig. 3 (solid curve). Therefore, these results (Fig. 3) suggest that the first endothermic peak is an enantiotropic reaction because this event will occur again. Thus, the exothermic reaction (solid curve) was attributed to the irreversible transition process (monotropic reaction), because this event alters the structure of this compound (Fig. 2c).

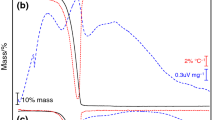

Figures 4 and 5 showed the DSC curves for Mg(Diclof)2 in a nitrogen atmosphere at heating rates of 5, 10 and 20 °C min−1, either with open or with crimped lids, respectively. For the compounds at dynamic atmosphere, the transition steps progressively occur around 160 and 205 °C. As observed in Fig. 4 (open crucibles), in the curves with heating rates of 10 and 20 °C min−1, for the endothermic event, displacement occurs with the increase of the mass of the sample. It has also been observed that with the increase of the heating rate, the endothermic reaction tends to occur early, which makes the curve more accentuated at 20 °C min−1, and therefore, shows a tendency to obtain less sharp peaks. For crimped lids (Fig. 5), the endothermic event tends to decrease with an increase of the mass and of the temperature. Thus, at 20 °C min−1 and with a mass of 5, and 10 mg there is a complete disappearance of this event. Fini et al. [4], working with this compound did not observer the endothermic event shown, probably due to some experimental variation. In the DSC curves in a static atmosphere (no shown the endothermic peaks completely disappear. This indicates that the sample depends on the experimental conditions.

Kinetic parameters

The kinetic parameters of the crystallization stage (exothermic reaction) of this compound were evaluated from the DSC curves, in both dynamic and static atmospheres. In the Fig. 6, the distribution of the heating rate b, in function of 1000/RT α is shown. It can be observed that the linear fit adjustment between the three points have low variation for E a values, which correspond to the linear fit for the activation energy proposed by Capela and Ribeiro [8]. The average values of the activation energy of the kinetic data for all compounds are shown in Table 1, where the resulting correlation coefficient (r) has a good close linear fit.

The activation energy versus degree conversion (α) values, are shown in Fig. 7, curves a, b and c, respectively. From these curves, a tendency can be seen where the plots maintain the same profile and almost run parallel to each other. But the values of E a vary for each compound due to the difference between the mass of the sample and experimental conditions. This indicates that crystallization occurs in a same way for every extension of a, what is probably due to a simultaneous process of diffusion and/or nucleation-growth.

If the sample masses are evaluated comparatively (Fig. 7) and either used in an open or as crimped lid crucible, it can be observed that there is a difference between the plots of activation energy versus the conversion degree. For this compound, these differences observed were attributed to the thermal conductivity of the different masses utilized. For 1 mg, in an open crucible in static or dynamic atmospheres, we can see that the difference great. However, for the same mass of 1 mg, but in a crimped lid crucible condition, the activation energy tends to decrease. Another effect observed was in relation to the increase in mass sample (5 and 10 mg). In these cases, it can be seen that the differences between the values of activation energy in the different conditions utilized tend to approach each other. Thus, for a mass of 10 mg the activation energy in both conditions practically overlap. This indicates that the increase of sample, in both open and crimped lid crucibles, it is possible to obtain activation energy with values close to each other.

Conclusions

Simultaneous TG-DTA curves show the thermal behaviour of Mg(Diclof)2 compound. The X-ray powder diffraction patterns show that the original compound is amorphous before the transition phase, and after this it has a crystalline structure.

The thermal studies carried out by DSC analysis on non-isothermal conditions show that there are two transition phases. The different experimental conditions in dynamic and static atmospheres provide an understanding of the behaviour of the transition phase. Furthermore, the presented results clearly indicate that the use or not of the crimped lid has an influence of an increase or decrease on the activation energy values. On the other hand, the sample mass also determines a decrease of the activation energy values. Therefore, we can see that the different kinetic results are conditioned by the contributions of different experimental factors, which allowed an evaluation of the values of activation energy in a more appropriate way.

References

Kovala-Demertzi D, Hadjikakou SK, Demertzis MA, Deligiannakis Y. Metal ion–drug interactions. Preparation and properties of manganese (II), cobalt (II) and nickel (II) complexes of diclofenac with potentially interesting anti-inflammatory activity: behavior in the oxidation of 3,5-di-tert-butyl-o-catechol. J Inorg Biochem. 1998;69:223–9.

Bucci R, Magri AD, Magri AL, Napoli A. Spectroscopic characteristics and thermal properties of divalent metal complexes of diclofenac. Polyhedron. 2000;19:2515–20.

Kenawi IM, Barsoum NB, Youssef MA. Cetirizine dihydrochloride interaction with some diclofenac complexes. Eur J Pharm Sci. 2005;26:341–8.

Fini A, Fazio G, Rosetti F, Holgado MA, Iruin A, Fuentes JA. Diclofenac salts. III. Alkaline and earth alkaline salts. J Pharm Sci. 2005;94:2416–31.

Kobelnik M, Bernabé GA, Ribeiro CA, Capela JMV, Fertonani FL. Kinetic of decomposition of iron (III)-diclofenac compound. J Therm Anal Calorim. 2009;97:493–6.

Kobelnik M, Cassimiro DL, Ribeiro CA, Dias DS, Crespi MS. Preparation of the Ca–diclofenac complex in solid state: study of the thermal behavior of the dehydration, transition phase and decomposition. J Therm Anal Calorim. 2010;102:1167–73.

Kobelnik M, Ribeiro CA, Dias DS, Almeida S, Capela JMV, Crespi MS. Study of the thermal behavior of the transition phase of Co(II)–diclofenac compound by non-isothermal method. J Therm Anal Calorim. doi:10.1007/s10973-010-1208-8.

Capela JMV, Capela MV, Ribeiro CA. Nonisothermal kinetic parameters estimated using nonlinear regression. J Math Chem. 2009;45:769–75.

Souza JL, Kobelnik M, Ribeiro CA, Capela JMV. Kinetics study of crystallization of PHB in presence of hydroxy acids. J Therm Anal Calorim. 2009;97:525–8.

Kobelnik M, Quarcioni VA, Ribeiro CA, Capela JMV, Dias DS, Crespi MS. Thermal behavior in solid state of Zn(II)-diclofenac complex: dehydration, transition phase and thermal decomposition. J Chin Chem Soc. 2010;57:384–90.

Kobelnik M, Cassimiro DL, Almeida AE, Ribeiro CA, Dias DS, Almeida S, Crespi MS. Study of the thermal behavior of Al(III) and In(III)-diclofenac complexes in solid state. J Therm Anal Calorim. doi:10.1007/s10973-010-1266-y.

Kobelnik M, Cassimiro DL, Dias DS, Ribeiro CA, Crespi MS. Thermal behavior of Jerivá oil (Syagrus romanzoffiana). J Therm Anal Calorim.doi:10.1007/s10973-011-1308-0.

Perrenot B, Widmann G. Polymorphism by differential scanning calorimetry. Termochim Acta. 1994;234:31–9.

Singhal D, Curatolo W. Drug polymorphism and dosage form design: a practical perspective. Adv Drug Deliv Rev. 2004;56:335–47.

Rustichelli C, Gamberini G, Ferioli VA, Gamberini MC, Ficarra R, Tommasini S. Solid-state study of polymorphic drugs: carbamazepine. J Pharm Biomed Anal. 2000;23:41–54.

Olives AI, Martin MA, Castillo BD, Barba C. Influence of the presence of trace amounts of metals on the polymorphism of tolbutamide. J Pharm Biomed Anal. 1996;14:1069–76.

Acknowledgements

The authors thank CAPES/CNPQ Foundations, Brazil, for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kobelnik, M., Cassimiro, D.L., Ribeiro, C.A. et al. Preparation and thermal study of Mg-diclofenac compound in solid state. J Therm Anal Calorim 108, 213–218 (2012). https://doi.org/10.1007/s10973-011-1416-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-011-1416-x