Abstract

Ammonium niobium oxalate was prepared and characterized by elemental analysis, XRD and FTIR spectroscopy analysis, which confirmed that the molecular formula of the complex is NH4(NbO(C2O4)2(H2O)2)(H2O)3. Dynamic TG analysis under air was used to investigate the thermal decomposition process of synthetic ammonium niobium oxalate. It shows that the thermal decomposition occurs in three stages and the corresponding apparent activation energies were calculated with the Ozawa–Flynn–Wall and the Friedman methods. The most probable kinetic models of the first two steps decomposition of the complex have been estimated by Coats–Redfern integral and the Achar–Bridly–Sharp differential methods.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Niobium chemistry is not widely known despite increasing interest in the application of niobium compounds within many fields. Niobium materials are presently of great interest in heterogeneous catalysis where they are used as catalyst active ingredient, carrier or auxiliary agent [1]. In these niobium-contain materials, the excellent water-soluble ammonium niobium oxalate is the optimum selection [2]. It is fairly inexpensive and does not suffer from the drawbacks of halides or orthoniobates [3]. However, niobium compounds exhibit special properties, which are not shown by the compounds of neighboring elements of niobium in the periodic table. Some prosperities of ammonium niobium oxalate, such as thermal stability or decomposition mechanism, are very important for the preparation of a good niobium-containing catalyst [4]. Thus, it is desirable to understand the decomposition process as well as the factors influencing the morphology of the decomposition products.

Thermal decompositions of metal oxalates have contributed to establishing the theoretical concepts of solid-state decomposition. The decomposition of transition metal oxalates has been the subject of numerous studies, e.g. Fe [5, 6], Cu [7], Ni, Co and Mn oxalates [8]. Some studies were conducted using the isothermal technique [5–7], while others were performed using non-isothermal methods [9]. Several articles were concerned with the mechanistic aspects and kinetics of the nucleation and growth behavior, including microscopic examination. Boldyrev et al. [10] concluded that the first step in the decomposition of all oxalates is the cleavage of the C–C bond in the anion C2O4 2−. The residual solid product may be the metal oxide or the metal depending on the electropositivity of the cation [11].

In the present study, ammonium niobium oxalate has been synthesized and characterized by elemental analysis, X-ray powder diffraction (XRD) analysis, FTIR spectroscopy and thermogravimetric (TG) analysis. Kinetic methods, such as the Ozawa–Flynn–Wall [12] (OFW, utilizing the dependence lg of heating rate vs. 1/T) and Friedman [13] (FR, utilizing the dependence lndα/dt vs. 1/T) were used in this study to evaluate the apparent activation energy. The most probable kinetic model of thermal decomposition of the compound has been suggested according to Coats–Redfern (C–R) [14] integral method and Achar–Bridly–Sharp (ABS) [15] differential method.

Experimental

Sample preparation

All materials were commercially available and were of analytical grade.

The method of preparation of ammonium niobium oxalate is similar to CN1935772 [2]. Oxalic acid (200 g) was added to 250 mL of water under stirring and the oxalic acid solution with the concentration of 0.48 g L−1 was obtained. Niobic acid (100 g, water content: 25%) was added after the solution was heated to 100 °C. Ammonium oxalate (10 g) was added after reacting for 25 min at 100 °C. Stop heating until ammonium oxalate was completely dissolved. The solution was vaporized to the concentration of 1.5 g L−1 and then cooled to room temperature, causing the desired ammonium niobium oxalate to precipitate out of the solution. The precipitate was filtered off and died at 150 °C. Recrystallization from water yielded the pure ammonium niobium oxalate.

Elemental analysis for C4H14NO14Nb found (%): C, 12.01; H, 3.45; N, 3.83; calc. (%): C, 12.22; H, 3.56; N, 3.56. The content of niobium was determined by thermogravimetry analysis.

Methods

Elemental analysis was carried on Perkin–Elmer PE-2400 II Series CHNS/O analyzer.

X-ray power diffraction patterns were obtained with a D/max-RB diffractometer in the 2θ range using graphit-monochromated CuKα radiation (40 kV, 100 mA). The step scan mode was performed with a step width of 0.02°, at a rate of 4° (2θ) per min.

FTIR spectrum was obtained in KBr discs on a Perkin–Elmer Spectrum GX. Sixteen scans were co-added with a resolution of 4 cm−1, in the range of 4,000–400 cm−1.

Thermal degradation kinetics studies were carried out on a Perkin–Elmer Pyris 1 TGA. The atmosphere was air with a flow rate of 20 ml min−1. The selected heating rates were 1, 2, 5, 10 and 20 K min−1. The sample mass is about 2.2 ± 0.02 mg and temperature range is from 30 to 700 °C. TG analysis of niobic acid (Nb2O5·2H2O) was performed at 20 K min−1 under air with 2.219 mg sample. To verify the reproducibility of obtained mass loss curves, two sample runs were performed under the same experimental conditions for each sample at each selected heating rate first. The approximate overlapping of two mass loss curves from two separate test runs was considered as reasonable agreement; otherwise, another two runs were performed then to determine which one should be chosen.

Results and discussion

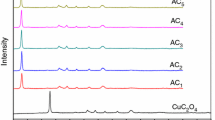

X-ray diffraction analysis

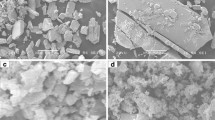

Figure 1 shows the XRD pattern of the synthetic ammonium niobium oxalate. The XRD pattern matched well with the standard data complied in the PDF card no. 83-1993 of ammonium niobium oxide oxalate hydrate (NH4(NbO(C2O4)2(H2O)2)(H2O)3), which agree with the elemental analysis results of the synthetic ammonium niobium oxalate. Therefore, the stoichiometry of the complex has been established as NH4(NbO(C2O4)2(H2O)2)(H2O)3. The molecular structure is exhibited in Fig. 2.

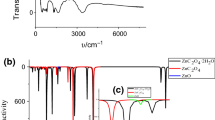

FTIR spectrum of ammonium niobium oxalate

The main infrared bands for the synthetic ammonium niobium oxalate are summarized in Table 1.

Thermogravimetric analysis

Figure 3 shows TG curves of ammonium niobium oxalate (a) and niobic acid (b) (Nb2O5·2H2O) at heating rate of 20 K min−1 under air environment. And the FTIR spectra of ammonium niobium oxalate in different decomposition temperature are exhibited in Fig. 4.

It shows from Fig. 3a that the decomposition of the synthetic complex proceeds through three steps with TG curves closely corresponds to the theoretical mass loss.

The 21.59% mass loss between 30 and 145 °C is attributed to the dehydration of ammonium niobium oxalate and formation of anhydrous complex. It also can be conformed by the disappearing of the absorption peaks of 3588, 3438 and 1626 cm−1 (Fig. 4). The 38.81% mass loss between 145 and 330 °C is due to the decomposition of oxalate ligands and the release of ammonia, which produce Nb2O5·H2O. The absorption peaks of oxalate disappear at a temperature above 330 °C. TG curve shows the second step is consecutive with the first one. Therefore, there is less carbon dioxide at about 145 °C, which adsorbs on amorphous powder phase niobic acid. The third step occurs at about 560 °C with a mass loss of 4.98% due to the formation of anhydrous Nb2O5 and the adsorbed CO2 was deadsorbed. At this stage, niobic acid undergoes a transition from amorphous to hexagonal or orthorhombic phase (TT or T, respectively) crystallization. This conclusion can be confirmed by the thermal decomposition process of niobic acid (Fig. 3b). They have the same temperature range of mass loss. Furthermore, as shown in Fig. 4, at 500 °C, niobic acid shows three broad bands: ~900, 655, and a small shoulder at 511 cm−1. These bands can be assigned to Nb=O in highly distorted NbO6 groups, symmetric stretching of the niobia polyhedra, and ν(Nb–O) in slightly distorted NbO6 octahedra, respectively. At 700 °C, Nb2O5 shows finer characteristics in the same spectral region. There is a large band with a maximum of ~860, three bands at 722, 610, and 566, and a band at 500 cm−1, which are attributed to the main above-mentioned vibrations [16]. This process also can be followed up by XRD patterns at different temperatures as seen in literatures [1, 16].

Kinetic studies

The decomposition kinetics study is important to know the decomposition mechanism, rate of reaction, reaction parameters and to predict the products distribution. This in turn helps in proper selection of reactor, optimization of the reactor design and operating conditions [17].

Model-free estimation of activation energy

All kinetic analyses of non-isothermal data are based on the rate equation [18, 19]:

(where α is the conversion, f(α) is the differential conversion function, β = dT/dt = const. is the linear heating rate in K min−1, A is the pre-exponential factor in min−1, T is temperature in K, R is the gas constant, E α is the activation energy in kJ mol−1). The subscript α indicates the values related to a particular extent of conversion.

In the constant condition of other parameters, the TG curves for decomposition of ammonium niobium oxalate at various heating rates (β = 1, 2, 5, 10 and 20 K min−1) are shown in Fig. 5. The basic data (β, α, T) are taken from the TG curves.

Two typical isoconversional methods of integral Ozawa–Flynn–Wall and differential Friedman have been widely applied to estimate the apparent activation energy without having to presuppose a certain kinetic model. OFW method is in fact a “model-free” method which assumes that the conversion function f(α) does not change with the variation of the heating rate for all values of degree of conversion α. It involves measuring the temperatures corresponding to fixed values of α from experiments at different heating rates β. Therefore, plotting ln β against 1/T in the form of

where \( g(\alpha ) = \int_{0}^{\alpha } {f(\alpha )^{ - 1} {\text{d}}\alpha } \) is the integral conversion function should give a straight line whose slope is directly proportional to the activation energy (−1.0516E α/R).

Friedman proposed the use of the logarithm of the conversion rate dα/dt as a function of the reciprocal temperature, in the form of

It is obvious from Eq. 3 that if the function f(α) is constant for a particular value of α, then dα/dt is also constant. By plotting ln(dα/dt) against 1/T, the value of the −E α/R for a given value of α can be directly obtained. Using this equation, it is possible to obtain values for E α over a wide range of conversions.

OFW plots for the dehydration step of the complex at different α (0.2 ≤ α ≤ 0.8) are exhibited in Fig. 6.

For three decomposition stages, the apparent activation energy can be calculated at different extent of conversion (0.2 ≤ α ≤ 0.8) using both Eqs. 2 and 3, and the results are presented in Figs. 7 and 8, respectively.

It is well known that Friedman method is very sensitive to experimental noise, and tends to be numerically unstable because of employing instantaneous rate value. But OFW method produces a systematic error in E α when the activation energy varies with α. This error does not appear in Friedman method [20, 21]. It is shown from Figs. 7 and 8 that the activation energies calculated by OFW method are higher than those of Friedman method. It is due to that Friedman method is very sensitive to experimental noise, but OFW method leads to meaningful result assuming that E α invaries with α, which is just for OFW method. The approximately constant value of E α for α also suggests that the rate-limiting step of each reaction probably obey a single kinetic mechanism [22, 23].

Lin et al. [24] calculated the average activation energies for the decomposition of nickel oxalate and magnesium oxalate are 205.72 and 152.60 kJ mol−1 by OFW methods, respectively. While the average activation energy for the decomposition of ammonium niobium oxalate is about 139.62 kJ mol−1. Dollimore et al. [25] showed that there is a decrease in decomposition temperature with increase in the ionic radius. The radius of Nb(V) (7.0 nm) is bigger than that of Ni(II) (6.9 nm) and Mg(II) (6.5 nm) and based on Coulombic attraction, the Nb(V) will have a weaker metal–oxygen bond (M–O bond) than that of Ni(II) and Mg(II). A decrease in M–O bond strength would, thus lead to a decrease in decomposition temperature. Moreover, the effect of activation energy of the decomposition cannot be ignored.

Determination of the most probable kinetic model

In order to confirm the exact mechanism in each stage, mathematical analysis was performed by the modified Coats–Redfern integral method and Achar–Bridly–Sharp differential method.

The values of E, ln A and the linear correlation coefficients r are calculated from the linear least-squares plot of ln[g(α)/T 2] vs. 1/T, which the slope is equal to −E/R and the intercept is equal to ln(AR/βE).

Plotting ln{[1/f(α)][dα/dt]} vs. 1/T, a straight line is given. The activation energy E and ln A can be obtained from the slope −E/R and the intercept ln(A/β).

The basic data α, T and dα/dt of the three decomposition steps and forty-one reaction models [26] were inserted into Eqs. 4 and 5. When the values of E and ln A obtained by the two methods are approximately equal with those of OFW and Friedman methods and the linear correlation coefficient is higher, it can be concluded the relevant function is the probable mechanism.

For the first step of dehydration, the results and the reaction function number are listed in Table 2. Comparing the activation energies data in Table 2, the possible kinetics models and respective kinetic parameters at various heating rates are tabulated in Table 3.

From Table 3, we can see that function 14, namely, g(α) = (3/2)(1 − α)ln(1 − α)2/3 and f(α) = (3/2)(1 − α)ln(1 − α)1/3, is the most probable mechanism function of the dehydration of ammonium niobium oxalate. Therefore, the first stage of the decomposition mechanism is controlled by assumed random nucleation and its subsequent growth (Avrami-Eerofeevn, n = 2/3). Function 19 (Avrami-Eerofeevn, n = 3), namely, g(α) = ln(1 − α)3 and f(α) = (1/3)(1 − α)[−ln(1 − α)]−2, is the most probable mechanism function of the decomposition of ammonium niobium oxalate.

However, no reasonable kinetic model can be obtained for the third step by means of above model-fitting methods. The results suggest that the third step could not be interpreted by the forty-one reaction models in this study, or the thermal decomposition step could be multi-step kinetics [27].

Conclusions

This work synthesized ammonium niobium oxalate and determined the molecular formula as NH4(NbO(C2O4)2(H2O)2)(H2O)3. According to TG measurements, the thermal decomposition of ammonium niobium oxalate occurs in three steps. Based on model-free method, the apparent activation energies for the three steps are calculated. For the model-fitting method, the most probable kinetic model of the first step decomposition is described by Avrami-Eerofeevn, n = 2/3, while the second one is fitted by Avrami-Eerofeevn, n = 3.

References

Nowak I, Ziolek M. Niobium compounds: preparation, characterization, and application in heterogeneous catalysis. Chem Rev. 1999;99:3603–24.

Wang W, Li J, Li H, Lu D, Mi XX, Zhong M, Liu J. The preparation of niobium oxalate. CN patent, CN1935772, 2007.

Narendar Y, Messing GL. Synthesis, decomposition and crystallization characteristics of peroxo-citrato-niobium: an aqueous niobium precursor. Chem Mater. 1997;9:580–7.

Ziolek M. Niobium-containing catalysts – the state of the art. Catal Today. 2003;78:47–64.

Galwey AK, Mohamed MA. Kinetic and thermodynamic studies of the nonisothermal decomposition of anhydrous copper(II) formate in different gas atmospheres. Thermochim Acta. 1993;213:279–91.

Mohamed MA, Galwey AK. Kinetic and mechanistic study of the isothermal decomposition of ferric oxalate dihydrate. Thermochim Acta. 1993;213:269–78.

Mohamed MA, Galwey AK. A kinetic and mechanistic study of the thermal decomposition of copper(II) oxalate. Thermochim Acta. 1993;217:263–7.

Mohamed MA, Halawy SA, Salem MA. Non-isothermal decomposition of potassium ferrioxalate trihydrate. J Anal Pyrolysis. 2000;55:55–67.

Macklen ED. Influence of atmosphere on the thermal decomposition of ferrous oxalate dehydrate. J Inorg Nucl Chem. 1967;29:1229–34.

Blodyrev VV, Nev’yantsev IS, Mikhailov YI, Khairetdinov EF. On the mechanism of thermal decomposition of oxalates. Kinet Katal. 1970;11(2):367–73.

Viswanathan B, Gopalakrishnan J, Srinivasan V, Sastri MVC. Thermal decomposition of hydrated iron(II) oxalate and manganese(II) oxalate in vacuum. J Therm Anal. 1971;3:429–31.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn. 1965;38:1881–6.

Friedman HL. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. J Polym Sci Part C. 1964;61:183–95.

Coats AW, Redfern JP. Kinetic parameters from thermogravimetric data. Nature. 1964;201:68–9.

Achar BN. Thermal decomposition kinetics of some new unsaturated polyesters. J Proc Int Clay Conf. 1969;1:6.

Braga VS, Dias JA, Dias SCL, Macedo JL. Catalyst materials based on Nb2O5 supported on SiO2-Al2O3: preparation and structural characterization. Chem Mater. 2005;17:690–5.

Saha B, Ghoshal AK. Model-free kinetics analysis of ZSM-5 catalyzed pyrolysis of waste LDPE. Thermochim Acta. 2007;453:120–7.

Guinesi LS, Ribeiro CA, Crespi MS, Veronezi AM. Tin(II)-EDTA complex: kinetic of thermal decomposition by non-isothermal procedures. Thermochim Acta. 2004;414:35–42.

Jankovic B, Mentus S. Model-fitting and Model-free analysis of thermal decomposition of palladium acetylacetonate [Pd(acac)2]. J Therm Anal Calorim. 2008;94(2):395–403.

Zhang J, Zeng JL, Liu YY, Sun LX, Xu F, You WS, et al. Thermal decomposition kinetics of the synthetic complex Pb(1,4-BDC) (DMF)(H2O). J Therm Anal Calorim. 2008;91(1):189–93.

Vyazovkin S. Modification of the integral isoconversional method to account for variation in the activation energy. J Comput Chem. 2001;22:178–83.

Tita B, Marian E, Tita D, Vlase G, Doca N, Vlase T. Comparative kinetic study of decomposition of some diazepine derivatives under isothermal and non-iso-thermal conditions. J Therm Anal Calorim. 2008;94(2):447–52.

Gabal MA. Non-isothermal studies for the decomposition course of CdC2O4–ZnC2O4 mixture in air. Thermochim Acta. 2003;402:199–208.

Lin CM, Chen DH, Tang WJ. Synthesis of MgNi2O3 and kinetics of thermal decomposition of the oxalate precursor. J Anal Appl Pyrolysis. 2006;75:240–4.

Dollimore D, Griffith DL, Nicholson D. The thermal decomposition of oxalates: part II. Thermogravimetric analysis of various oxalates in air and in nitrogen. J Chem Soc. 1963;2707–11.

Hu RZ, Shi QZ. Thermal analysis kinetics. Beijing: Science Press; 2001.

Vyazovkin S. Model-free kinetics: staying free of multiplying entities without necessity. J Therm Anal Calorim. 2006;83:45–51.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Su, T.T., Zhai, Y.C., Jiang, H. et al. Studies on the thermal decomposition kinetics and mechanism of ammonium niobium oxalate. J Therm Anal Calorim 98, 449–455 (2009). https://doi.org/10.1007/s10973-009-0300-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-009-0300-4