Abstract

Cr2O3 and MnCr2O4 spinel chromite nanoparticles were synthesized using chemically derived sol–gel technique. Crystal structure was analyzed using X-ray diffraction, and phase transition from a rhombohedral symmetry (R-3c) for Cr2O3 to a spinel cubic symmetry (Fd3 m) for MnCr2O4 has been observed. Data obtained from diffraction were also utilized to evaluate the lattice parameters, crystallite size and unit cell volume. Micrographs obtained using a field emission scanning electron microscope exhibited well-shaped, homogenously distributed 30–70-nm-sized nanoparticles, with well-defined grain. Stoichiometric composition of all the elements present in the samples was confirmed using energy-dispersive X-ray spectroscopy. Dynamic light scattering measurement was performed to corroborate the hydrodynamic diameter and distribution of Cr2O3 and MnCr2O4 nanoparticles. The magnetic behavior of samples was scrutinized as a function of temperature and applied field. It was observed that Cr2O3 exhibited paramagnetic behavior both at room temperature and at 5 K, while a magnetic phase transition from ferro to para was observed in MnCr2O4 with a Curie temperature, T c ~ 50 K.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Nanostructured spinel chromites have emerged as charming materials for potential use in many applications, for example in semiconductor devices, humidity sensors, photocatalysis, removal of impurity from weather and oxidation of chlorinated organic pollutants [1–5]. Owing to these gigantic applications, these materials are mostly studied in bulk form [6]. In the recent years, Cr2O3 clusters have also reaped attention due to their interesting magnetic properties at the nanolevel [7, 8]. Due to a wide range of applications in magnetic storage devices and electronics, etc., materials with such magnetic characteristics are quite exciting among the researchers worldwide. Addition of transition metal ions, such as Mn, Fe or Zn in Cr2O3, results in the structural transformation from one crystalline phase to another, which affects the structural morphology and hence the magnetic properties. For instance, Mn incorporation in Cr2O3 results in MnCr2O4 which behaves as a ferromagnetic material below room temperature (RT). One of the key focuses of the present day research on such chromites is to enhance the magnetic phase transition temperature, so that these materials can be exploited for their potential applications in magnetic energy transformations [9].

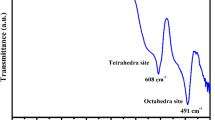

Traditionally, these charming magnetic characteristics arise in spinel structures due to distribution of cations at two distinctive sites, termed as X- and Y-sites [10]. The magnetic moments of cations present at these sites are aligned parallel or partially antiparallel to support net magnetic moment. Hence, the general formula of spinel structure is written as XY2O4, in which divalent X (II) ions occupy the tetrahedral voids, whereas the trivalent Y (III) ions occupy the octahedral voids in the closed packed arrangement of oxygen ions. The spinel unit cell has eight face-centered cubic cells which lead to a big structure, having 32 oxygen atoms, eight X-type and 16 Y-type atoms. Based on the distribution of these atoms within the spinel structure, these compounds exhibit lucrative magnetic properties banking on the composition of cations. In other words, based on the X- and Y-site cations, it exhibits ferromagnetic, antiferromagnetic, spin-glass and paramagnetic behaviors [11–13].

For example, in a recent study, cubic spinel-structured XCr2O4 (X = Mn or Co) has shown frustrated results in the form of nonlinear spiral magnetic order at temperature below the transition temperature. It is also investigated that the spiral order of polycrystalline MnCr2O4 is found to be dormant to the exposure of high magnetic field but can be inflected by external pressure [14]. In addition, the electrical properties of these spinel chromites are also tunable and it is investigated that the dielectric constant of MnCr2O4 is temperature independent, having a value in the range of 2–4, approximately [15]. Magneto-dielectric coupling (MDC) in the polycrystalline samples of MnCr2O4 has also been reported below the ferromagnetic ordering temperature of 43 K [16]. This MDC could be potentially exploited for future multiferroic devices. Another advantage of MnCr2O4 is that it offers much better resistance to carbonaceous attack than Cr2O3, thus making it preferable for use in industrial high-temperature carbonaceous environments [7].

Conventionally, spinel-structured nanoparticles have been synthesized using a variety of techniques. For instance, Yazdanbakhsh et al. [17] reported the synthesis of nanospinel chromites by thermal decomposition of gel obtained via sol–gel method for the removal of azo-dye from the aqueous solution. An oxalate decomposition process has been utilized for the preparation of NiFe2O4 magnetic mesoporous spinel to study its adsorptive property [18]. In addition, the spinel-structured nanoparticles have also been synthesized by assisted co-precipitation [19, 20], spray pyrolysis [21] and solid-state reaction [22].

Although solid-state reaction method is very common for preparing spinels, it requires very high sintering temperatures, often well above 1000 °C for several hours to complete the reaction [23–25]. Other drawbacks of solid-state reaction are inhomogeneity, lack of stoichiometry control and large particle size. In this study, sol–gel-based combustion method is utilized for preparing Cr2O3 and MnCr2O4 nanoparticles to discuss their structural, morphological and magnetic properties, systematically. The reason behind adopting sol–gel-based technique for preparing nanoparticles is high homogeneity, low temperature, controlled shape and size of nano particles [3, 26]. Change in magnetic behavior of Cr2O3 nanoparticles due to Mn incorporation and magnetic phase transition temperature of MnCr2O4 has been determined.

2 Experimental

Cr2O3 and MnCr2O4 samples in powder form were synthesized by sol–gel auto-combustion method. Stoichiometrically weighed appropriate amounts of starting materials, i.e., chromium nitrate [Cr(NO3)3.9H2O, Sigma-Aldrich, ≥99.9], manganese nitrate [Mn(NO3)2.4H2O, Sigma-Aldrich, ≥99.5] and citric acid [C6H8O7, Sigma-Aldrich, ≥99.8], were separately dissolved in deionized (DI) water to earn homogeneous solutions and then mixed together to make 50 mL solution. Initially, the metal nitrates (MN) and citric acid (CA) were weighed using a precision digital balance keeping MN to CA molar ratio of 1:2. The molar ratio of Mn(NO3)2.4H2O to Cr(NO3)3.9H2O, for instance, in the preparation of MnCr2O4 was taken as 1:2, as well, in accordance with (atomic) moles present in one formula unit of MnCr2O4. The mixed solution was placed on a hot plate, and the whole setup was transferred to an ESCO fume hood. The mixture was heated and stirred magnetically at 95 °C for about 45 min until sol was formed. The sol was further heated at this temperature to make gel. As the gel was formed, the magnetic stirrer was removed and the temperature of gel was increased in definite intervals up to 350 °C. After a while, the gel was burnt in a suddenly evolved exothermic reaction and the resultant product was a loose, fluffy and homogenously dried powder. The powder was ground to improve homogeneity by an agate mortar and pestle and subsequently sintered at 600 °C for 2 h, in a muffle furnace (Nabertherm P301, Germany), in order to develop desired crystalline phase. Earlier, stoichiometric proportions of chromium nitrate and citric acid were dissolved in DI water for the preparation of Cr2O3 using the same procedure. Afterward, the powder samples were pelletized using an Apex hydraulic press having diameter 10 mm and thickness of 1.2 ± 0.01 mm.

Phase identification and detailed analysis of crystalline structure were performed using Bruker D/8 Advance X-ray diffractometer (XRD). Grain size was determined using elegant images of samples taken by NovaNano 450-SEM field emission scanning electron microscope (FESEM), and the elemental composition was determined using an Oxford Instruments energy-dispersive X-ray spectroscopy (EDX). Low-temperature magnetic measurements were performed using a cryogen-free measurement system (CFMS).

3 Results and discussion

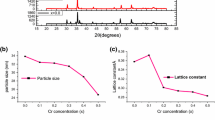

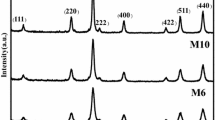

Crystal structure of the samples was identified using XRD in the 2θ range of 20°–80° with Cu-K α radiation (λ = 1.54 Å) operated at 30 kV. The XRD pattern of Cr2O3, as shown in Fig. 1, reveals that all the diffracted peaks belong to rhombohedral crystal structure having space group R-3c, as the peaks were perfectly matched with ICSD file No. 00-038-1479, a characteristics reference pattern of Cr2O3. No impurity peaks were evident in the pattern.

Figure 2 exhibits the XRD pattern of MnCr2O4. The pattern was indexed following the procedure as described by Cullity [27]. Data retrieved from diffraction were plotted, and intensity peaks were identified. Peak positions helped to find sin2θ values and subsequently using the relation, sin2θ ∝ h 2 +k 2 + l 2, hkl values were assigned to the diffracted peaks. The proportionality indicates that planes with lager values of diffraction angles have higher miller indices. The indexed diffracted peaks corresponding to the planes (220), (311), (222), (400), (511) and (440) elaborated that the crystal structure of MnCr2O4 is spinel cubic with space group Fd3 m. It revealed that phase pure MnCr2O4 was obtained as no peaks related to any impurity phase were found. Lattice parameters were determined using the relation, \(a = \lambda \sqrt {h^{2} + k^{2} + l^{2} } /2\text{Sin} \theta\), where λ was the wavelength of X-rays. The indexed pattern was also matched well with ICSD file No. 01-075-1614, a reference pattern of MnCr2O4, with cubic spinel structure. Hence, the evaluated structural parameters were confirmed. Crystallite size of Cr2O3 and MnCr2O4 samples was determined using Scherrer’s formula, \(D = 0.9\lambda /\beta \text{Cos} \theta\) where D, λ, β and θ were the average crystallite size, X-ray wavelength, full width at half maximum (FWHM) in radians and the Bragg’s angle in degrees, respectively. Other structural parameters, such as volume of unit cell (V), bulk density (ρ b = m/πr 2 h, where m is mass, r is radius and h is thickness of the pellet samples), X-ray density (ρ x = 2 M/N A V, where M is molar mass and N A is Avogadro’s number) and porosity (P = 1 − ρb/ρx) of both the samples, were also evaluated. The calculated values of all these parameters are shown in Table 1.

Figure 3 shows FESEM images of both the samples obtained at different magnifications. Figure 3a, b exhibits the structural morphology of Cr2O3 sample which reveals finely dispersed, well-defined grains with sharp grain boundaries, which are mostly spherical in shape and distributed homogenously. Mostly the particles are well separated from each other; however, few agglomerations of grain clusters are also observed. Dark voids represent the porosity of the samples which is estimated well in agreement, as determined from the diffraction data. The average particle size as evaluated using the software Image J is 35 ± 5 nm for Cr2O3. Figure 3c, d exhibits the structural morphology of MnCr2O4 at different magnifications. In this case, the individual nanoparticles are also well defined with sharp boundaries. However, the size of nanoparticles is increased and determined as 65 ± 5 nm. Careful look at magnified image reveals sharp faces of crystalline particles. Density of black spots is also increased contributing more toward porosity.

Size and distribution of hydrodynamic diameter of synthesized powder samples was determined using dynamic light scattering (DLS), as shown in Fig. 4. DLS measures the hydrodynamic diameter of particle which is always larger than the particle size as determined using high resolution (HR) microscopic techniques. This is due to the fact that in hydrodynamic measurements, surfactant or solvent layers adhere to the surrounding of the particle, thus enlarging it as compared to its parent size. The importance of this measurement is that it provides suitability of nanoparticles in biological environments [28]. In DLS, light scatters at different angles after striking with suspended particles in the solution. The scattered light interferes and is detected by light detectors. The interference patterns of light change continuously due to Brownian motion of the particles. In this way, DLS gives information about the size range of particles from minimum to maximum as shown in Fig. 4. Maximum hydrodynamic size of the Cr2O3 particles was observed as 120 and 350 nm for MnCr2O4.

Stoichiometric elemental composition and purity of prepared samples were further confirmed by EDX analysis. The EDX spectra shown in Fig. 5a reveals intensity peaks related to only Cr and O. This confirms the synthesis of impurity-free Cr2O3, as no other element is detected. In Fig. 5b, peaks corresponding to Mn are also observed in addition to Cr and O. This confirms the phase pure synthesis of MnCr2O4. The at% and wt% of all the elements, as shown in Table 2, are in strict accordance with the stoichiometric composition of these elements in their respective formula units.

Magnetic properties of Cr2O3 and MnCr2O4 nanoparticles were determined using CFMS. Conventionally, magnetic characteristics of magnetic nanomaterials depend on elemental composition, lattice parameters, particle size, order of applied field, etc. [29]. Antiferromagnetic materials when reduced to nanoscale, for instance in the form of ultra-thin layers or discrete particles, exhibit weak ferromagnetism. This characteristic behavior normally increases with decreasing particle size [30]. Figure 6 shows the magnetic hysteresis (M–H) loops of Cr2O3, measured at 5 and 300 K. It can be seen that sample presents a paramagnetic behavior both at room temperature and at 5 K, although bulk Cr2O3 is antiferromagnetic [31]. The magnetization curves are essentially linear up to approximately 5 T without any tendency toward saturation. However, at 5 K, the M–H loop shows a minute indication of remanence as shown in inset of Fig. 6. The reason is that, at very low temperature such as 5 K, the disordering effect of thermal agitation is suppressed by aligning tendency of magnetic moments, which leads to a large value of the Langvin variable (a = µH/kT). Besides this, earlier studies have reported that Cr2O3 exhibits weak ferromagnetic behavior in ultra-thin films or discrete particles [32, 33].

On the other hand, MnCr2O4 also exhibits paramagnetic behavior at room temperature (300 K) due to partly aligned magnetic moments in the direction of applied field, but present a ferromagnetic behavior at 5 K, as shown in Fig. 7. As temperature is decreased, maximum number of magnetic moments interact with each other according to Curie–Weiss Law (χ = C/T − θ) and orient themselves in the direction of applied field. Furthermore, according to Langvin theory, at low temperature or at high applied magnetic field (H) saturation occurs due to large value of Langvin function (M/M 0 = L(a)). Therefore, in the consequences of Langvin theory, the loop is saturated at 5 K (Fig. 7) and estimated value of remanence is 26.39 emu/g. Figure 8 shows temperature-dependent field cold (FC) magnetic behavior of MnCr2O4 obtained at an applied filed of 1 T. The Curie temperature (T c) of MnCr2O4, defined by the maxima of –dM/dT of FC curves [34], leading to the ferromagnetic transition is determined as 50 K. This value of Tc is comparable with already reported values of T c for MnCr2O4, which vary between 41 and 55 K [11, 34, 35]. With a decrease in temperature below T c, FC curve shows kink-like anomaly around 50 K.

4 Conclusion

In this study, Cr2O3 and MnCr2O4 nanoparticles have been successfully synthesized via sol–gel auto-combustion technique using citric acid as a fuel. This proposed method has the important advantage of being simple, fast and cost effective. XRD revealed a structural transformation from rhombohedral (Cr2O3) to cubic spinel (MnCr2O4), when Mn is incorporated in Cr2O3. Finely dispersed and symmetrically distributed grains were revealed by FESEM having average sizes as 55 ± 5 and 60 ± 5 nm, for Cr2O3 and MnCr2O4, respectively. EDX spectra confirmed the impurity-free composition of both the samples. Hydrodynamic radii of particles of both the samples were determined using dynamic light scattering. Magnetic characterizations revealed that synthesized Cr2O3 nanoparticles possess paramagnetic characteristics both at room temperature and at 5 K. On the other hand, ferromagnetic transition at 50 K was observed in MnCr2O4.

References

Sun B, Wu J, Jia X, Lou F, Chen P (2015) Preparation and light-controlled resistive switching memory behavior of CuCr2O4. J Sol-Gel Sci Technol 75:664–669

Saha D, Giri R, Mistry KK, Sengupta K (2005) Magnesium chromate–TiO2 spinel tape cast thick film as humidity sensor. Sens Actuators B Chem 107:323–331

Geng Q, Zhao X, Gao X, Yang S, Liu G (2012) Low-temperature combustion synthesis of CuCr2O4 spinel powder for spectrally selective paints. J Sol-Gel Sci Technol 61:281–288

Paul B, Bhuyan B, Purkayastha DD, Dhar SS, Behera S (2015) Facile synthesis of spinel CuCr2O4 nanoparticles and studies of their photo catalytic activity in degradation of some selected organic dyes. J Alloys Compd 648:629–635

Ahmad SS, Rhamdhani M, Pownceby M, Bruckard W (2016) Selective sulfidising roasting for the removal of chrome spinel impurities from weathered ilmenite ore. Int J Miner Process 146:29–37

Kim D, Lhm S (2001) Application of spinel-type cobalt chromite as a novel catalyst for combustion of chlorinated organic pollutants. Environ Sci Technol 35:222–226

Li H, Chen W (2010) Stability of MnCr2O4 spinel and Cr2O3 in high temperature carbonaceous environments with varied oxygen partial pressures. Corros Sci 52:2481–2488

Lau K, Kandalam A, Costales A, Pandey R (2004) Equilibrium geometry and electron detachment energies of anionic Cr2O4, Cr2O5, and Cr2O6 clusters. Chem Phys Lett 393:112–117

Jankovsky O, Sedmidubsky D, Sofer Z, Luxa J, Bartunek V (2015) Simple synthesis of Cr2O3 nanoparticles with a tunable particle size. Ceram Int 41:4644–4650

Tong J, Cai X, Wang H, Xia C (2013) Efficient magnetic CoFe2O4 nanocrystal catalyst for aerobic oxidation of cyclohexane prepared by sol–gel auto-combustion method: effects of catalyst preparation parameters. J Sol-Gel Sci Technol 66:452–459

Masrour R, Hamedoun M, Benyoussef A (2010) Magnetic properties of MnCr2O4 nanoparticle. J Magn Magn Mater 322:301–304

Peelamedu R, Grimes C, Agrawal D, Roy R, Yadoji P (2003) Ultralow dielectric constant nickel–zinc ferrites using microwave sintering. J Mater Res 18:2292–2295

Hossain AKMA, Seki M, Kawai T, Tabata H (2004) Colossal magneto resistance in spinel type Zn1−xNixFe2O4. J Appl Phys 96:1273–1275

Zhou Y, Yang Z, Li L, Xie Y, Lin S, Sun Y, Zhang Y (2012) Magnetic field and external pressure effects on the spiral order of polycrystalline MnCr2O4. J Magn Magn Mater 324:3799–3801

Song S, Yuan Z (2003) Electrical properties of MnCr2O4 spinel. J Mater Sci Lett 22:755–757

Mufti N, Blake GR, Palstra TTM (2009) Magneto dielectric coupling in MnCr2O4 spinel. J Magn Magn Mater 321:1767–1769

Yazdanbakhsha M, Khosravi I, Goharshadi G, Youssefi A (2010) Fabrication of nano spinel ZnCr2O4 using sol–gel method and its application on removal of azo dye from aqueous solution. J Hazard Mater 184:684–689

Gao Z, Cui F, Zeng S, Guo L, Shi J (2010) A high surface area super paramagnetic mesoporous spinel ferrite synthesized by a template-free approach and its adsorptive property. Microporous Mesoporous Mater 132:188–195

Sivakumar P, Ramesh R, Ramanand A, Ponnusamy S, Muthamizhchelvan C (2013) Synthesis and characterization of NiFe2O4 nanoparticles and nanorods. J Alloys Compd 563:6–11

Matulkova I, Holec P, Pacakova B, Kubickova S, Mantlikova A, Plocek J, Nemec I, Niznansky D, Vejpravova J (2015) On preparation of nano crystalline chromites by co-precipitation and autocombustion methods. Mater Sci Eng B 195:66–73

Marinkovic Z, Mancic L, Maric R, Milosevic O (2001) Preparation of nanostructure Zn–Cr–O spinel powders by ultrasonic spray pyrolysis. J Eur Ceram Soc 21:2051–2055

Levy S, Diella D, Pavese V, Dapiaggi A, Sani M (2005) P-V equation of state, thermal expansion and P–T stability of synthetic (ZnCr2O4 spinel). Am Miner 90:1157–1167

Hilczer A, Kowalska K, Markiewicz E, Pietraszko A, Andrzejewski B (2016) Dielectric and magnetic response of SrFe12O19–CoFe2O4 composites obtained by solid state reaction. Mater Sci Eng B Solid 207:47–55

Marinkovic ZV, Mancic L, Vulic P, Milosevi O (2005) Microstructure characterization of mechanically activated ZnO–Cr2O3 system. J Eur Ceram Soc 25:2081–2093

Bayhan M, Hashemi T, Brinkman A (1997) Sintering and humidity-sensitive behavior of the ZnCr2O4–K2CrO4 ceramic system. J Mater Sci 32:6619–6623

Ghafoor I, Siddiqi SA, Atiq S, Riaz S, Naseem S (2015) Sol–gel synthesis and investigation of structural, electrical and magnetic properties of Pb doped La0.1Bi0.9FeO3 multiferroics. J Sol-Gel Sci Technol 74:352–356

Cullity BD (1977) Elements of X-ray diffraction, 2nd edn. Notre Dame

Carvalho JWJ, Carvalho FAO, Batista T, Santiago PS, Tabak M (2014) Cetyltrimethylammonium chloride (CTAC) effect on the thermal stability of oxy-HbGp: dynamic light scattering (DLS) and small angle X-ray scattering (SAXS) studies. Colloid Surf B 118:14–24

Sobhani A, Niasari M (2013) Synthesis, characterization, optical and magnetic properties of a nickel sulfide series by three different methods. Superlattices Microstruct 59:1–12

Anandan K, Rajendran V (2014) Studies on structural, morphological, magnetic and optical properties of chromium sesquioxide (Cr2O3) nanoparticles: synthesized via facile solvo thermal process by different solvents. Mat Sci Semicon Process 19:136–144

Vollath D, Szabo D, Willis J (1996) Magnetic properties of nano crystalline Cr2O3 synthesized in a microwave plasma. Mater Lett 29:271–279

Pokhrel S, Simion C, Quemener V, Barsan N, Weimar U (2008) Investigations of conduction mechanism in Cr2O3 gas sensing thick films by ac impedance spectroscopy and work function changes measurements. Sens Actuators B Chem 133:78–83

Zhang W, Bru E, Zhang Z, Tegus O, Li W, Si P, Geng D, Buschow K (2005) Structure and magnetic properties of Cr nanoparticles and Cr2O3 nanoparticles. Phys B 358:332–338

Jhuang YC, Kuo KM, Chern G (2011) Structural and magnetic characterizations of Mn2CrO4 and MnCr2O4 films on MgO(001) and SrTiO3(001) substrates by molecular beam epitaxy. J Appl Phys 109:07D714

Hastings JM, Corliss LM (1962) Magnetic structure of manganese chromite. Phys Rev 126:556–565

Acknowledgments

Authors are thankful to Higher Education Commission of Pakistan (HEC) for financially supporting this work through research project number NRPU-2471. The authors also extend their sincere appreciations to the Deanship of Scientific Research at King Saud University for funding this Research Group No. RG-1435-004.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Afzal, A., Atiq, S., Saleem, M. et al. Structural and magnetic phase transition of sol–gel-synthesized Cr2O3 and MnCr2O4 nanoparticles. J Sol-Gel Sci Technol 80, 96–102 (2016). https://doi.org/10.1007/s10971-016-4066-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-016-4066-4