Abstract

Six magnetic spinel-type CoFe2O4 samples were prepared in the form of powder by a simple sol–gel auto-combustion method from precursor solutions with different metal concentrations (0.1–0.3 mol L−1) and pH values (<1–10). The samples were characterized by X-ray diffractometry, Fourier transform infrared spectrophotometry, transmission electron microscopy and N2-physisorption. Their catalytic performances for oxidation of cyclohexane were evaluated using oxygen as oxidant in the absence of solvents. The results show that pH values and metal concentrations of precursor solutions play important roles in the sizes, dispersions and morphologies of the CoFe2O4 nanoparticles, and thus in their catalytic performances. The sample resulted from precursor solution under the conditions of pH = 7 and metal concentration = 0.1 mol L−1 with the largest surface area, exhibited the best catalytic performance with the highest cyclohexane conversion of 13.7 % and selectivity of 93.9 % for cyclohexanol and cyclohexanone. The CoFe2O4 nanocrystal is also found an efficient catalyst for oxidation of aliphatic and aromatic alkenes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Although there have been numerous advances in oxidation of hydrocarbons using molecular oxygen, the development of more effective and selective catalysts for oxidation of inactive carbon–hydrogen bonds, in saturated hydrocarbons, remains a challenge in oxidation chemistry [1, 2]. Oxidation of cyclohexane is of great importance due to large demand for the products of cyclohexanone and cyclohexanol (K/A oil), which are important raw materials for the production of adipic acid and caprolactam. Adipic acid and caprolactam are most often used in the manufacture of nylon-6 and nylon-66 polymers [3, 4]. However, oxidation of cyclohexane has shown the least efficiency in almost all major industrial processes [5]. Oxidation of cyclohexane in the present industrial process is carried out at ~150 °C and 1–2 MPa pressure using metal cobalt salt or metal–boric acid as homogeneous catalyst. The drawback of this process is that very low conversion of cyclohexane (3–6 %) is achieved in order to maintain high selectivity (75–80 %) for the K/A oil [6]. Great efforts have been made to enhance the efficiency of this process in the past years [7–11]. However, owing to the use of large amounts of solvents and/or reducing agents as well as harsh reaction conditions, it is still difficult to apply the techniques developed at laboratory to industrial processes [7, 8, 12]. So, it becomes very necessary to develop a more effective catalyst and apply to the current industrial process. Oxidation of cyclohexane heterogeneously using molecular oxygen without any solvents or reducing agents is particularly desirable in both economical and environmental aspects.

Magnetic nanoparticles of complex metal oxides such as spinel ferrites become more important in recent years due to both their unique properties and broad range of applications in diverse areas such as magnetic recording and separation, ferrofluid, magnetic resonance imaging, biomedicine, catalysts, gas sensors, high quality ceramics and super paramagnetic materials [13–18]. A great advantage of using magnetic ferrite nanoparticles as catalysts in liquid–phase reactions is that the catalysts are not only thermally and chemically stable in the solution medium, but also easy to be recovered because of their magnetic property. As a matter of fact, these catalysts can be separated from the reaction medium by simply placing a magnetic field on the surface of the flask [15, 16]. As a well-known spinel ferrite an hard magnetic material, Cobalt ferrite, CoFe2O4 has attracted much attention because of its very high cubic magnetocrystalline anisotropy, high coercivity, and moderate saturation magnetization [13, 14, 19]. Furthermore, the properties of this material (CoFe2O4) are highly related to their shapes and sizes, which can be adjusted through the synthesizing processes. Significant number of methods have been developed to prepare cobalt ferrite nanomaterials with with different magnetic behaviors, for instance, sonochemical reactions [20, 21], mechanochemical synthesis [22–24], hydrolysis of precursors [25, 26], flow injection synthesis [27], aqueous co-precipitation [28], hydrothermal method [14] and sol–gel auto-combustion method [29, 30]. Among these techniques, sol–gel auto-combustion synthesis has been proved to be a simple and economical way to prepare nanopowders [30, 31]. Combining the advantages of chemical sol–gel and combustion processes, sol–gel auto-combustion synthesis gives rise to a thermally induced anionic redox reaction. The energy released from the reaction between oxidant and reductant is adequate to form a desirable phase within very short time [32]. The process exhibits the advantages of inexpensive precursors, a simple preparation process, and can produce highly reactive nano-sized powder [32, 33].

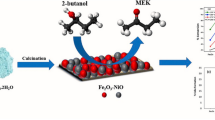

In our previous work [34], CoFe2O4 nanocrystal synthesized by sol–gel auto-combustion method was proved to be highly active and easily recovered catalyst for the oxidation of cyclohexane by molecular oxygen without addition of solvents or reductants. Since the efficiencies of this kind of catalysts closely depends on their shapes, sizes, and structures, which can be adjusted by controlling the conditions of sol–gel auto-combustion processes, the present work focuses on exploring the effects of pH values and metal concentrations of precursor solutions on the properties and catalytic performances of the CoFe2O4 nanoparticles.

2 Experimental

2.1 Preparation of CoFe2O4 nanoparticles

Nanoparticles of CoFe2O4 spinels were prepared based on a modified procedure described in the literature [22]. Keeping 1:1 molar ratio of metal cations to citric acid, Fe (NO3)3·9H2O, Co (NO3)3·6H2O and citric acid were completely dissolved in distilled water under magnetically stirring to form a transparent solution. The solution was allowed to evaporate in an oil bath under continuous stir at 80–90 °C until a brown gel appeared. The gel was dried at 110 °C till a spumous xerogel was obtained. Produced xerogel was ignited at 650 °C, a self-propagating combustion process occurred and dark grey loose product was obtained after the combustion was completed. The product was pulverized in an agate mortar to obtain CoFe2O4 nanoparticles. pH value of the original solution is <1, and concentrated ammonia (25–28 %) was added slowly under constant stir to adjust the pH value. Six samples (A, B, C, D, E and F) from different precursor solutions were prepared as listed in Table 1 to investigate the effects of pH values and metal concentrations on the as-prepared CoFe2O4 nanoparticles.

The xerogels produced from different precursor solutions showed different combustion behaviors. The xerogels, except D, showed a fast flaming auto-combustion reaction producing large amounts of gases: the combustion started in the hottest zones of the crucible and propagated from the bottom to the top like the eruption of a volcano. The reaction was completed in 10–30 s giving rise to a dark grey voluminous product with a structure similar to a branched tree. In the case of xerogel D, the thermal treatment brought about a slow reaction that leads, in about 5 min, to a product of a grey dark powder. In this case the volume did not change during the reaction. The similar phenomena have also been described in the literature [31].

2.2 Catalysts characterization

X-Ray powder diffraction (XRD) of the samples was performed on a PANalytical X’Pert Pro diffractometer using Cu Kα radiation with a scanning angle (2θ) of 10–80° and a voltage and current of 40 kV and 30 mA.

Fourier transform infrared (FT-IR) spectra of samples in KBr wafer were collected using a Nicolet Nexus 870 FT-IR spectrometer. Spectra were recorded in the 4,000–400 cm−1 range with a resolution of 4 cm−1.

Transmission electron microscopy (TEM) micrographs of the samples were obtained using a Hitachi H-600 microscope.

The BET surface area measurements were performed on a Micromeritics ASAP 2010 instrument at liquid nitrogen temperature.

2.3 Oxidation tests

Oxidation of cyclohexane was performed in a 30 mL stainless steel autoclave equipped with a magnetic stirrer and an automatic temperature controller. In a typical reaction, 5.0 mg catalyst and 7.0 mL (65.3 mmol) cyclohexane were added to the autoclave. The autoclave was flushed three times with O2 and pressurized to the desired pressure, then placed in the oil bath under desired temperature and stirring. After the reaction, the autoclave was cooled to room temperature and slowly depressurized. The products were identified by GC–MS and quantified by GC using toluene as the internal standard. The main by-products of the reaction are hexanedioic acid, hexanoic acid, dicyclohexyl adipate and cyclohexyl caproate (Scheme 1). Due to magnetic properties of the prepared nanoparticles, they can be attracted to the stirrer. This may somewhat lower dispersity and consequently catalytic performance of the catalyst.

3 Results and discussion

3.1 XRD analysis

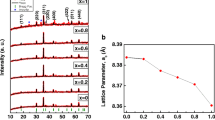

Figure 1 shows the XRD patterns of the as-synthesized samples. For samples A–D, the position and relative intensity of all diffraction peaks match well with standard cobalt ferrite spinel XRD data (JCPDS NO. 22-1086). For samples E and F, however, low intensity reflections that can be ascribed to Co2O3 phase were observed besides of the spinel reflections.

The mean particle sizes of the samples calculated by applying the Sherrer equation to [311] reflections are 24, 26, 28, 16, 21 and 30 nm for the samples A–F, respectively (Table 1). It is clear that precursor solutions with high pH values and metal concentrations are in favor of resulting in big nanoparticles. Furthermore, it shows that the particle size is more sensitive to pH value than to metal concentration.

3.2 FT-IR analysis

Fourier transform infrared spectra of the samples were displayed in Fig. 2. For each sample, a strong band associated with the Fe–O stretching vibration at around 580 cm−1 is presented. It confirms the presence of the cobalt ferrite phase [31]. No characteristic bands corresponding to citric acid or NO3 − appeared, and this indicates that no citric acid or NO3 − is residual in the sample.

3.3 TEM analysis

Transmission electron microscopy micrographs and size distribution histograms of the samples are shown in Figs. 3 and 4, respectively. The sample A shows irregular particles with diameters about 15–40 nm, and most particles with diameters about 25 nm. The sample B shows chain-like aggregations of spherical particles and most of them with uniform size about 25 nm. The morphology of sample C exhibits a majority of irregular particles with diameters about 30 nm and a minority of the spherical analogues with diameters about 15 nm. Consideration the differences among the samples A–C in metal concentrations of precursor solutions, it can be concluded that the sizes of the nanoparticles increase with increasing of metal concentrations (Fig. 4).

The pH values of the precursor solutions seem to have more significant effects on the sizes and morphologies of the resulted nanoparticles. As can be seen from Figs. 3 and 4, the sample D, produced from the precursor solution with the lowest pH value, shows the most serious aggregations about 50–200 nm formed mostly by small particles about 15 nm. The sample E, resulted from the precursor solution with pH 3, consists of smaller aggregations about 50–80 nm formed mostly by particles about 20–27 nm. When the pH value was improved to 10, the resulted sample F is mostly composed of nanoparticles with diameters of ~30 nm. Based on above facts, it can be concluded that the precursor solutions with higher pH values can produce much bigger but more uniform nanoparticles.

3.4 N2-physisorption analysis

N2-physisorption measurements were performed for the as-prepared samples. The BET surface areas of the samples were summarized in Table 1 together with the average particle sizes calculated by the formula d = 6/ρA, where ρ is the theoretical density of the material (5.20 g cm−3 for CoFe2O4 bulk) and A is the specific surface area [31]. As for samples D and E resulted from precursor solutions with low pH values, the average particle sizes determined by BET method are much larger than those based on XRD measurements, indicating that much agglomerations exists in the samples. As a result, the sample D has the smallest particles and, however, the lowest BET surface area because of the most extent of agglomeration. For the other samples, which were prepared from the solutions with high pH values, the average particle sizes calculated based on BET and XRD measurements are similar, indicating low degree of agglomerations in the samples. The facts are consistent with the statistical analysis of the TEM images.

According to the literature [32], when NH3·H2O is added to the precursor solution, the excess NH4 + groups exists in the gel as NH4NO3 when the pH value is above 4. In the cases of high pH values, most of NH4NO3 remains in dried gels. During the drying and combustion process, the remaining NH4NO3 may decompose to liberate NOx and O2. The produced oxygen can accelerate the combustion process and a great amount of heat releases in this reaction. This may be responsible for the increase in the crystallite sizes with increasing pH values. On the other hand, as a lot of gasses will be liberated from the precursors during drying and combustion, it enhances the particle dispersions and enlarges the specific surface areas.

3.5 Catalysis of the prepared catalysts for oxidation of cyclohexane

The performances of the prepared samples on oxidation of cyclohexane were evaluated under optimum conditions in our previous work [34] and the results were presented in Fig. 5. As expected, pH values and metal concentrations of precursor solutions have evident effects on catalytic performances of the resulted samples. As a result, increase of pH or decrease of metal concentration of precursor solution seems to enhance the catalytic performance of the sample when conversion of cyclohexane is concerned (Fig. 5). However, when pH is too high, as for the sample F (pH = 10), the conversion of cyclohexane dropped slightly. The same correlation is observed between BET surface areas of the samples and precursor solution parameters (Table 1). That is, cyclohexane conversions increased with the increase in the BET surface areas of the samples, possibly due to the enhancement of the contact of cyclohexane with the catalyst surface. Among the catalysts tested, the sample A, with the largest surface area, exhibited the best catalytic performance with the highest cyclohexane conversion of 13.7 % and selectivity of 93.9 % for cyclohexanol and cyclohexanone. Since Co2O3 is less active than CoFe2O4 for aerobic oxidation of cyclohexane under our experiments conditions according to our previous investigations, as for the samples E and F, the presence of minor Co2O3 may somewhat reduce their catalytic performances [34].

Oxidation of cyclohexane catalyzed by A the samples A, D, E and F prepared from precursor solutions with different pH values; B the samples A, B and C prepared from precursor solutions with different metal concentrations. Reaction conditions: cyclohexane 7.0 mL (65.3 mmol); catalyst 5.0 mg; initial oxygen pressure = 1.6 MPa; temperature = 145 °C; reaction time = 6.0 h

3.6 Catalysis of the prepared catalysts for oxidation of alkenes

In order to expand the applicable substrate scope of the CoFe2O4 nanocrystal, the sample A was chosen as a representative to investigate the activation in the oxidation of alkenes and the results were collected in Table 2. The CoFe2O4 sample proved to be also efficient in oxidation of both aliphatic and aromatic olefins. Especially in the oxidation of cyclopentene with H2O2, high conversion of 62.9 % for cyclopentene and selectivity of 76.7 % for epoxide were achieved at 60 °C for a 6-h reaction (Table 2, Entry 1). The optimization of the reaction conditions are under investigation.

4 Conclusion

In conclusion, pH values and metal concentrations of the precursor solutions play important roles in controlling the particle sizes, dispersions, and morphologies of the final products of CoFe2O4. The special surface areas and catalytic performances are therefore affected by the parameters of the precursor solutions. The sample obtained from the precursor solution with 0.1 mol L−1 metal concentration at pH 7 manifests moderate particle size and the highest BET surface area, and thus the highest catalytic activities. The CoFe2O4 sample was also efficient for oxidation of both aliphatic and aromatic olefins. High conversions and selectivities were achieved in the oxidation of cyclopentene and α-methyl styrene. Both our previous and present work [34] has shown that this kind of catalysts exhibit excellent reusability and can be easily recovered.

References

Labinger JA (2004) J Mol Catal A 220:27–35

Crabtree RH (1995) Chem Rev 95:987–1007

Schuchardt U, Carvalho WA, Spinace EV (1993) Synlett 10:713–718

Schuchardt U, Cardoso D, Sercheli R, Pereira R, Cruz RS, Guerreiro MC, Mandelli D, Spinace EV, Fires EL (2001) Appl Catal A 211:1–17

Kesavan V, Sivanand PS, Chandrasekaran S, Koltypin Y, Gedanken A (1999) Angew Chem Int Ed 38:3521–3523

Sawatari N, Yokota T, Sakaguchi S, Ishii Y (2001) J Org Chem 66:7889–7891

Narayan RV, Kanniah V, Dhathathreyan A (2006) J Chem Sci 118:179–184

Wang HL, Li R, Zheng YF, Chen HN, Wang FS, Ma JT (2008) Catal Lett 122:330–337

Perkas N, Wang YQ, Koltypin Y, Gedanken A, Chandrasekaran S (2001) Chem Commun 11:988–989

Yuan HX, Xia QH, Zhan HJ, Lu XH, Su KX (2006) Appl Catal A 304:178–184

Tong JH, Li Z, Xia CG (2005) J Mol Catal A 231:197–203

Yu KMK, Abutaki A, Zhou Y, Yue B, He HY, Tsang SC (2007) Catal Lett 113:115–119

Xiao SH, Jiang WF, Li LY, Li XJ (2007) Mater Chem Phys 106:82–87

Zhao LJ, Zhang HJ, Xing Y, Song SY, Yu SY, Shi WD, Guo XM, Yang JH, Lei YQ, Cao F (2008) J Solid State Chem 181:245–252

Faungnawakij K, Kikuchi R, Shimoda N, Fukunaga T, Eguchi K (2008) Angew Chem Int Ed 47:9314–9317

Menini L, Pereira MC, Parreira LA, Fabris JD, Gusevskaya EV (2008) J Catal 254:355–364

Wang X, Lin Y, Zhang ZC, Bian JY (2011) J Sol–Gel Sci Technol 60:1–5

Li L (2011) J Sol–Gel Sci Technol 58:677–681

Wang Z, Fei W, Qian H, Jin M, Shen H, Jin M, Xu J, Zhang W, Bai Q (2012) J Sol–Gel Sci Technol 61:289–295

Shafi K, Gedanken A, Prozorov R, Balogh J (1998) Chem Mater 10:3445–3450

Srivastava DN, Perkas N, Gedanken A, Felner I (2002) J Phys Chem B 106:1878–1883

Ennas G, Marongiu G, Marras S, Piccaluga G (2004) J Nanopart Res 6:99–105

Manova E, Tsoncheva T, Paneva D, Mitov I, Tenchev K, Petrov L (2004) Appl Catal A 277:119–127

Shi Y, Ding J, Yin H (2000) J Alloys Compd 308:290–295

Ammar S, Helfen A, Jouini N, Fievet F, Rosenman I, Villain F, Molinie P, Danot M (2001) J Mater Chem 11:186–192

Ben Tahar L, Smiri LS, Artus M, Joudrier AL, Herbst F, Vaulay M, Ammar S, Fievet F (2007) Mater Res Bull 42:1888–1896

Hyeon T (2003) Chem Commun 0:927–934

Paike VV, Niphadkar PS, Bokade VV, Joshiw PN (2007) J Am Chem Soc 90:3009–3012

Barati MR (2009) J Sol–Gel Sci Technol 52:171–178

Zhang RJ, Huang JJ, Zhao HT, Sun ZQ, Wang Y (2007) Energy Fuels 21:2682–2687

Cannas C, Falqui A, Musinu A, Peddis D, Piccaluga G (2006) J Nanopart Res 8:255–267

Yue Z, Guo W, Zhou J, Gui Z, Li L (2004) J Magn Magn Mater 270:216–223

Ma N, Yue YH, Hua WM, Gao Z (2003) Appl Catal A 251:39–47

Tong JH, Bo LL, Li Z, Lei ZQ, Xia CG (2009) J Mol Catal A 307:58–63

Acknowledgments

This work was supported by the National Science Fund for Distinguished Young Scholars of China (20625308), Scientific Research Fund of Northwest Normal University (NWNU-LKQN-10-28) and Program for Changjiang Scholars and Innovative Research Team in University (IRT1177).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tong, J., Cai, X., Wang, H. et al. Efficient magnetic CoFe2O4 nanocrystal catalyst for aerobic oxidation of cyclohexane prepared by sol–gel auto-combustion method: effects of catalyst preparation parameters. J Sol-Gel Sci Technol 66, 452–459 (2013). https://doi.org/10.1007/s10971-013-3031-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-013-3031-8