Abstract

In this paper, a novel photocatalyst, made up of Ag/BiFeO3 nanocomposites activated by visible light, was successfully synthesized using a sol–gel process, followed by a chemical reduction method. The as-prepared BiFeO3 particles and Ag/BiFeO3 nanocomposites were characterized by X-ray diffraction, transmission electron microscopy, scanning electron microscopy and diffuse reflectance spectroscopy. The results showed that the metal Ag nanoparticles with diameter of 20–50 nm are anchored on the surface of BiFeO3. Meanwhile, the photocatalytic experiments demonstrated that the Ag/BiFeO3 composites had excellent photocatalytic activity for the decomposition of methyl orange in visible light, which far exceeded that of the pure BiFeO3. These results revealed Ag loading could significantly improve the photocatalytic property of BiFeO3. Recycle experiments showed the nanocomposites had an excellent recoverability, suggesting stable photoactivity. Finally, we discuss the photocatalytic mechanism of nanocomposites. The enhanced photoactivity of Ag-decorated BiFeO3 photocatalyst is most likely attributed to the electronic effect of Ag nanoparticles including surface plasmon resonance.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Among all the perovskite materials with ABO3 structure studied so far, BiFeO3 (BFO) shows ferroelectric properties with a high Curie temperature (T C ~ 830 °C) and G-type antiferromagnetic properties below the Néel temperature (T N ~ 370 °C) [1–4]. Therefore, it has been widely used in magnetic and ferroelectric devices [5]. Apart from ferroelectric properties, BiFeO3 is one of the materials with the largest known electric polarizations and has a small (≈2 eV) band gap for which it is likely applied in conducting domain walls, catalyst and fuel and/or solar cells [6–11]. Recently, it has also been demonstrated that nano-BFO exhibits photocatalytic activities under visible light irradiation for water splitting and degradation of organic pollutants because of its narrow band gap and excellent chemical stability [12–15]. Li et al. [12] successfully synthesized BiFeO3 microcrystals with various shapes and sizes, suggesting that photocatalytic activity of microcubes was better than that of microspheres for the degradation of Congo red under visible light irradiation. Wang et al. [13] also demonstrated that the BiFeO3 nanoparticles with an average diameter of 35 nm provided the better photocatalytic performance than the bulk in the degradation of rhodamine B. Otherwise, Fei et al. [16] studied {111} dominant pills and rods of BiFeO3 with a significant enhanced visible light response, and their results showed that BiFeO3 with the designed structures could have a better performance in photocatalytic applications.

Although nanocrystallization and controlling of topography can improve properties of BFO over bulk materials, the low photocatalytic activity of BFO hinders its commercialization in photocatalytic field for the degradation of organic pollution. Therefore, an important task is to improve the photocatalytic activity of BFO for practical use. In fact, doping of BFO with a foreign atom at either A or B site of the ABO3 lattice has been proven to be a valuable route to enhancing its properties [17–19]. Guo et al. [20] demonstrated substitution of Bi3+ with Gd resulted in remarkable improvement of the photocatalytic activity of BFO under visible light. Design and construction of heterojunction is another useful method for increasing photocatalytic efficiency [21, 22]. The heterojunction usually is formed between two different semiconductors, whose inner electric field can provide a driving force for the separation of photogenerated charge carriers. Heterojunction, constructed by coating wide-gap semiconductor on narrow-gap semiconductor, can utilize photoresponse ability of both semiconductors. Otherwise, the heterojunction constructed by metal and semiconductor is called Schottky junction. On the ideal condition, because the Fermi level of metal is lower than semiconductor, photogenerated electrons migrate to the surface of metal when irradiated, which inhibit the recombination of electron and hole and promote photocatalytic efficiency. Li’s group fabricated BiFeO3–graphene nanohybrids through a facile hydrothermal treatments, which had a significant enhanced performance in the visible light photocatalytic activity [23]. Sakar et al. synthesized the pure BFO and BFO/γ-Fe2O3 nanocomposite by auto-ignition technique and examined the visible light-driven photocatalytic activity of both. As a result, the pure BFO showed a moderate photocatalytic activity, while BFO/γ-Fe2O3 nanocomposite exhibited enhanced activity by degrading methyl orange dye [24]. But BiFeO3-based Schottky junction has rarely been reported.

In this work, we synthesized Ag/BiFeO3 nanohybrids by sol–gel method followed by a chemical reduction process. UV–Vis diffuse reflectance spectroscopy was employed to study the optical properties of Ag/BiFeO3. Their phase structures and morphologies were characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM) and transmission electron microscopy (TEM). Furthermore, the visible light photocatalytic behaviors of the as-produced Ag/BiFeO3 composites were explored by the degradation of methyl orange (MO) in aqueous solution under visible light irradiation. Due to the surface modification of BiFeO3 by Ag nanoparticles (Ag NPs), the absorption and photocatalytic performance of the as-prepared photocatalyst Ag/BiFeO3 in the visible region was greatly enhanced, which was attributed to surface plasmon resonance effect.

2 Experimental

2.1 Reagents

Ferric nitrate (Fe(NO3)3·9H2O) and bismuth nitrate (Bi(NO3)3·5H2O) were purchased from Sigma-Aldrich, silver nitric (AgNO3) and methyl orange (MO) were obtained from Shanghai Reagents Company (Shanghai, China), and citric acid was obtained from Tianjin Chemical (Tianjin, China). Other reagents were all from commercial sources with analytical purity and used as received. All stock solutions were prepared daily with deionized water treated with a water purification system (Simplicity 185, Millipore Corp., Billerica, MA).

2.2 Preparation of BiFeO3 nanoparticles and nano-Ag/BiFeO3

A preciously reported sol–gel process was modified to prepare BiFeO3 nanoparticles [25]. Simply, Fe(NO3)3·9H2O (0.01 mol) and Bi(NO3)3·5H2O (0.01 mol) were dissolved in acetic acid (20 mL), and a yellowy solution was obtained. Then, citric acid of 10 g was added into the solution under magnetic stirring as a complexant. The mixture was vigorously stirred for 1 h at 50 °C to form the sol, which was then kept at 150 °C for 2–3 h to obtain dry gel. Finally, the dry gel was calcined at 550 °C for 3 h in a muffle furnace.

Ag/BiFeO3 nanocomposites were prepared by chemical reduction method [26]. PVP was used as reductant for the preparation of Ag/BiFeO3 nanocomposites. In a typical procedure, 1.88 g of poly(vinyl pyrrolidone) (PVP, Aldrich, Mw = 30,000 g·mol−1) was added in 8.0 mL of deionized water, and the mixture was heated to 60 °C in air under magnetic stirring until PVP was dissolved completely. Then, 1.5 mmol BiFeO3 was added to the PVP solution which was stirred for 20 min. After that, 3 mL AgNO3 solution was immediately poured to obtain a proper Ag: BiFeO3 ratio. The reaction was carried out for 2 h at 80 °C under magnetic stirring. The product was collected by centrifugation and washed with deionized water. The samples were dried for further use. When the molar ratio between BiFeO3 and AgNO3 was varied from 50, through 30 and 15 to 10, the samples prepared marked with Ag-BFO-1, Ag-BFO-2, Ag-BFO-3, Ag-BFO-4, respectively.

The N-doped TiO2(N-TiO2) reference photocatalyst was prepared by the nitridation of commercially available TiO2 powder (surface area 48 m2 g−1) at 500 °C for 10 h under NH3 flow (flow rate of 350 mL min−1).

2.3 Photocatalytic activity measurement

The photocatalytic activity of Ag/BiFeO3 nanomaterials was evaluated by the degradation of MO in aqueous solution under visible light irradiation with a 450 W Xe lamp (Newport Solar Simulators, Model: 9115X, a cutoff filter of 420 nm). In each experiment, 50 mL of MO (20 mg/L) solution was added to a glass flask containing 50 mg photocatalyst. The glass flask was in the dark for half an hour to ensure that adsorption equilibrium was reached before the measurements. The reaction temperature was kept at room temperature by cooling water for eliminating any thermal catalytic effect. After the degradation of a period of time, the suspensions containing the sample powders and dyes were sampled. The sample powders were then separated by centrifuging, and the absorbance of the dye solutions was measured using a UV–Vis spectrophotometer. The MO concentration was determined according to absorbance and a standard curve.

2.4 Characterization

The crystal structures of products were characterized by PANalytical X’Pert PRO X-ray diffraction (XRD) with Cu Kα radiation (λ = 1.54 Å) in the range of 10°–80°. The micrographs of Ag/BiFeO3 composites were investigated using a scanning electron microscope (SEM) and transmission electron microscope (TEM).

3 Results and discussion

3.1 Component analysis of BiFeO3 particle and Ag/BiFeO3 nanocomposites

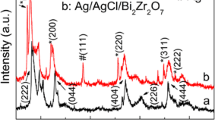

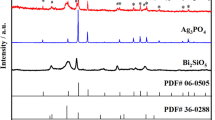

The phase composition and structure of the samples prepared under different conditions were examined by powder X-ray diffraction (XRD). Figure 1 shows the XRD patterns of the prepared BiFeO3 samples at different temperatures. All diffraction peaks of the sample prepared at 550 °C (Fig. 1b) are in excellent accord with JPCDS files No. 86-1518. This indicated single-phase BiFeO3 was completely crystallized into the perovskite phase at 550 °C with lattice constants a = b = 0.5576 and c = 0.13866 nm. From Fig. 1c, we observed the enhanced diffraction peaks of BiFeO3 samples except for a small amount of miscellaneous peak. As increasing the calcination temperature to 600 °C (Fig. 1c), the crystallization of the sample slightly increased. The high heating temperature induced the formation of the impurity Bi2O3 and Bi25FeO40, which was marked with “asterisk” and “filled square box,” respectively. According to the literature, the high heating temperature tends to induce the formation of the impurity when synthesizing of BiFeO3 by sol–gel technique [13]. Furthermore, the lower heating temperature would also induce impurity such as Bi2O3 [27]. Figure 1a is the XRD pattern of sample calcined at 400 °C. From this curve, we can also observe the trace amount of Bi2O3 and Bi25FeO40 with characteristic 2θ values. These results indicate we should choose a proper calcination temperature for obtaining pure phase BiFeO3, which is preferably 550 °C in this method.

3.2 Topography characterization of Ag/BiFeO3 nanocomposites

Figure 2 exhibits the XRD patterns of Ag/BiFeO3 hybrid materials. From curve b to d in Fig. 2, we can see the four diffraction peaks at 38.1, 44.3, 64.2 and 77.5° which are, respectively, corresponding to the (111), (200), (220) and (311) crystalline planes of metallic Ag and are marked with “inverted filled triangle.” The positions of the four peaks are perfectly matched with cubic phase Ag (metallic Ag, JCPDS file: 65-2871). Moreover, the intensity of the four diffraction peaks increases with the growth of AgNO3 dosage. The curve a is the XRD pattern of pure phase BiFeO3 which was prepared at the temperature of 550 °C. The diffraction peaks of BFO marked with “inverted open triangle.” These results illustrate the formation of metallic Ag and BiFeO3 composites and the content of metallic Ag in composites increasing with the growth of AgNO3 dosage.

The morphology of the Ag/BiFeO3 nanocomposites is exhibited in Fig. 3. The SEM image of the Ag/BiFeO3 nanocomposites (Fig. 3a) shows that the size of BiFeO3 is not very uniform, and the Ag NPs are anchored to its surface. To further confirm the presence of the Ag NPs in Ag/BiFeO3 nanocomposites, we presented the TEM image as shown in Fig. 3b. By closely observing Fig. 3b, we find that many small Ag nanoparticles are dispersed on the surface of BiFeO3, and the nanoparticles are irregular and monodisperse with diameters of about 20–50 nm. These results are in good agreement with the XRD data.

3.3 UV–Vis diffuse reflection spectra of Ag/BiFeO3 nanocomposites

The optical properties of the BiFeO3 nanoparticles and its composites with Ag were investigated by UV–Vis diffuse reflection spectroscopy. As shown in Fig. 4, the visible light absorbance of BFO sharp declines when wavelength is longer than 560 nm (curve a), while the absorption of Ag/BiFeO3 at this region is obviously higher than BFO. This could be attributed to surface plasmon absorption of metallic silver on the BiFeO3 surface. BiFeO3 is decorated with the silver nanoparticles with great many different diameters, so Ag/BiFeO3 nanocomposites have the higher absorption in the entire visible light range.

At the range with wavelength shorter than 560 nm, the absorption of all samples is associated with the optical band gap of BiFeO3. In addition, for the Ag/BiFeO3 composites, the absorbance at the range of 560–800 nm increases in the following order: Ag-BFO-1 ‹ Ag-BFO-2 ‹ Ag-BFO-3 ≈ Ag-BFO-4. These results indicate the absorption intensity of the composites increases with the increasing amount of AgNO3 in reaction system. According to the XRD data, the amount of Ag nanoparticles on the surface of BiFeO3 increases with the growth of amount of silver nitric. Therefore, the increment of the absorbance of composites is due to larger LSPR effect from more Ag nanoparticles deposited on the BiFeO3 surface.

3.4 The photocatalytic performance of Ag/BiFeO3 nanocomposites

Many groups have studied the photocatalytic activities of bismuth ferric nanomaterials by degrading rhodamine B [28], Congo red [12], methylene blue [29] and methyl orange [30] and so on. Results demonstrated BiFeO3 micro/nanocrystals can decompose such kind of dyes under visible light irradiation. The photocatalytic efficiency is dependent on the size, morphology, doping and other modification of BFO.

As a typical organic contaminant, MO is commonly chosen as an organic model compound in wastewater photocatalytic degradation studies. There are two reasons. One is that MO is very stable under visible light irradiation without photocatalyst, and the degradation rate of MO could be ignored after a long-time UV–Vis irradiation in the absence of photocatalyst [30, 31]. The other one is that the amount of absorbed on the catalyst surface could be negligible [32, 33].

Visible light photocatalytic activities of the as-prepared bismuth ferritic nanocrystals were monitored through the degradation of methyl orange in aqueous solution. Figure 5 displays the concentration–time plot of MO photodegradation with BFO nanocrystals obtained at different temperatures as photocatalysts. It is clear that all samples have photocatalytic activity, and the time-dependent change of concentration of MO has a similar trend. The MO degradation rates reach only about 26, 36 and 18 % for BFO nanocrystals synthesized at 450, 550 and 600 °C, respectively, indicating that the photodegradation rate of BFO photocatalysts increases with the increase in temperature from 450 to 550 °C. However, the photocatalytic efficiency of BFO nanoparticles calcined at 600 °C is lower than those of other samples. This could be ascribed to more impurities appeared in BFO nanocrystals at higher or lower temperature. The above comparative results signify that the photodegradation efficiency of BFO nanoparticles is not extremely perfect even for pure phase BiFeO3 nanoparticles compared with that of other visible light photocatalysts containing bismuth element under the same conditions, such as BiVO4 and Bi2WO6 [34, 35].

Figure 6 represents the concentration changes of MO as a function of time with various Ag/BiFeO3 photocatalysts under visible light irradiation. For comparison, we also measured the photocatalytic activity of N-TiO2 in the same condition. Obviously, BFO nanoparticles have much lower photocatalytic activity than the Ag/BiFeO3 composites and N-TiO2. After 120-min illumination with photocatalyst, the degradation rate of MO was in the following order: BFO nanoparticles <N-TiO2<Ag-BFO-1<Ag-BFO-2<Ag-BFO-3<Ag-BFO-4, implying that modification with silver nanoparticles can significantly improve the photocatalytic efficiency of BFO, and the activity of the photocatalysts increases further for the more dosage of AgNO3. In addition, MO can be completely decomposed within 90 min under visible light using Ag-BFO-4, which shows that photodegradation performance of Ag-BFO-4 was the best compared with other samples. The kinetic linear simulation curves of photocatalytic degradation of MO with BFO or Ag/BiFeO3 nanocomposites are shown in Fig. 7. The results show a linear relationship between ln(c/c 0) (c 0, the initial concentration of MO before irradiation; c, the concentration of MO after irradiation) and irradiation time, which illustrated the photocatalytic decomposition of MO following first-order kinetics. The apparent first-order rate constant k for BFO or Ag/BiFeO3 nanocomposites is 0.003, 0.0087, 0.018, 0.0353, 0.0483 min−1, respectively. Simply, k(BFO) ≪ k(Ag-BFO-1) < k(Ag-BFO-2) < k(Ag-BFO-3) ≈ k(Ag-BFO-4). The results reveal that metal Ag decoration plays an important role for increasing BFO composites photocatalytic activity, but this effect does not enhance further when the molar ratio of BiFeO3 and Ag was less than 18. This indicates that too much Ag NPs on the surface would block the visible light absorption of BiFeO3. Thus, excessive Ag NPs on the surface would not continue to improve the photocatalytic performance of the nanocomposites. In fact, we immersed the catalyst sample in the MO solution in the dark for half an hour to ensure that adsorption equilibrium was reached before the measurements. The MO concentration decreases ~9 % when adsorption equilibrium was reached. And the photolysis of MO was studied by making a measurement under illumination without the catalyst. From Fig. 6, we can see that MO is only photolyzed by about 3 % in the absence of photocatalyst. Thus, the results are really due to photocatalysis instead of adsorption or photolysis which is negligible.

The photocatalytic stability was studied by the cycling degradation experiments. As shown in Fig. 8, although the photocatalytic activity of the as-prepared Ag/BiFeO3 nanocomposites decreases by ~15 % after five times recycle experiment, the activity of Ag/BiFeO3 (Ag-BFO-3) photocatalyst still maintains a high level. The slight decrease after each cycle would be attributed to the absorption of contamination and the decrease in active spots [36].

On the basis of the above results, we think the Ag/BiFeO3 nanocomposites can work as a stable and effective visible light photocatalyst applied in the decomposition of organic pollutants.

3.5 The photocatalytic mechanism of Ag/BiFeO3 nanocomposites

Figure 9 illustrates the photocatalytic mechanism of the photoinduced charge separation, migration and degradation process under visible light irradiation. Under visible light illumination, the electrons of BiFeO3 could be excited and then injected into the Fermi level of Ag directly or indirectly. This is due to that the metallic silver nanoparticles can accept the photogenerated electrons from the excited semiconductor as an electron reservoir, thereby facilitating dioxygen reduction by suppressing electron–hole recombination and promoting interfacial charge transfer [36, 37]. Whereas hole is stay in the HOMO of BiFeO3 and oxidizes OH− and/or H2O to OH∙. Furthermore, the localized surface plasmon resonance (LSPR) induced by the collective oscillations of surface electrons on Ag nanoparticles could enhance the visible light harvesting of photocatalyst and help electron–hole separation [38]. As a result, Ag/BiFeO3 had a greater visible absorption ability and a quicker charge separation velocity than BiFeO3 nanocrystals and thus had higher photocatalytic efficiency.

4 Conclusions

In conclusion, Ag/BiFeO3 nanocomposites were successfully synthesized through a sol–gel process, followed by a chemical reduction method. The visible light photoactivities of as-prepared Ag/BiFeO3 photocatalyst were evaluated through the decomposition of MO. The Ag-loaded BiFeO3 nanocomposites showed the higher photocatalytic efficiency compared with the pure BFO particles which could be ascribed to electronic effect of Ag nanoparticles including LSPR and Schottky barrier. Moreover, the photocatalytic activity was found to increase with the further growth of the AgNO3 dosage. We have demonstrated that the photocatalytic performance of BiFeO3 was obviously improved by Ag decoration. The composite photocatalyst retained 85 % activity after five runs, suggesting very good recoverability. Otherwise, Ag/BiFeO3 hybrids have some magnetism (data are not showed in paper), so that the photocatalyst can be conveniently separated from aqueous solution through centrifugation. Therefore, noble metal-loaded BiFeO3 composites with high-efficiency photoactivity and magnetism could promisingly expand the scope of the perovskite ABO3-structured materials applied in photocatalysis.

References

Song CY, Xu J, Yimamu A, Wang L (2014) Hydrothermal synthesis of perovskite bismuth ferrite micro/nano powders. Integr Ferroelectr 153:33–41

Zhu X, Zhou J, Jiang M, Xie J, Liang S, Li S, Liu Z, Zhu Y, Zhu J, Liu Z (2014) Molten salt synthesis of bismuth ferrite nano- and microcrystals and their structural characterization. J Am Ceram Soc 97:2223–2232

Ramesh R (2014) Electric field control of ferromagnetism using multi-ferroics: the bismuth ferrite story. Philos Trans R Soc A Math Phys Eng Sci 372:1471–2962

Wang J, Neaton JB, Zheng H, Nagarajan V, Ogale SB, Liu B, Viehland D, Vaithyanathan V, Schlom DG, Waghmare UV, Spaldin NA, Rabe KM, Wuttig M, Ramesh R (2003) Epitaxial BiFeO3 multiferroic thin film heterostructures. Science 299:1719–1722

Hopkins PE, Adamo C, Ye L, Huey BD, Lee SR, Schlom DG, Ihlefeld JF (2013) Effects of coherent ferroelastic domain walls on the thermal conductivity and Kapitza conductance in bismuth ferrite. Appl Phys Lett 102:121903

Seidel J, Martin LW, He Q, Zhan Q, Chu YH, Rother A, Hawkridge ME, Maksymovych P, Yu P, Gajek M, Balke N, Kalinin SV, Gemming S, Wang F, Catalan G, Scott JF, Spaldin NA, Orenstein J, Ramesh R (2009) Conduction at domain walls in oxide multiferroics. Nat Mater 8:229–234

Zhang D, Shi P, Wu X, Ren W (2013) Structural and electrical properties of sol–gel-derived Al-doped bismuth ferrite thin films. Ceram Int 39(Supplement 1):S461–S464

Bu Y, Zhong Q, Xu D, Tan W (2013) Redox stability and sulfur resistance of Sm0.9Sr0.1CrxFe1−xO3−δ perovskite materials. J Alloys Compd 578:60–66

Jeon NJ, Noh JH, Kim YC, Yang WS, Ryu S, Seok SI (2014) Solvent engineering for high-performance inorganic–organic hybrid perovskite solar cells. Nat Mater 13:897–903

Armstrong EN, Duncan KL, Wachsman ED (2013) Effect of A and B-site cations on surface exchange coefficient for ABO3 perovskite materials. PCCP 15:2298–2308

Ryu S, Noh JH, Jeon NJ, Chan Kim Y, Yang WS, Seo J, Seok SI (2014) Voltage output of efficient perovskite solar cells with high open-circuit voltage and fill factor. Energy Environ Sci 7:2614–2618

Li S, Lin Y, Zhang B, Wang Y, Nan C (2010) Controlled fabrication of BiFeO3 uniform microcrystals and their magnetic and photocatalytic behaviors. J Phys Chem C 114:2903–2908

Wang X, Lin Y, Ding X, Jiang J (2011) Enhanced visible-light-response photocatalytic activity of bismuth ferrite nanoparticles. J Alloys Compd 509:6585–6588

Tan G, Zheng Y, Miao H, Xia A, Ren H (2012) Controllable microwave hydrothermal synthesis of bismuth ferrites and photocatalytic characterization. J Am Ceram Soc 95:280–289

Wang W, Li N, Chi Y, Li Y, Yan W, Li X, Shao C (2013) Electrospinning of magnetical bismuth ferrite nanofibers with photocatalytic activity. Ceram Int 39:3511–3518

Fei L, Yuan J, Hu Y, Wu C, Wang J, Wang Y (2011) Visible light responsive perovskite BiFeO3 pills and rods with dominant {111}c Facets. Cryst Growth Des 11:1049–1053

Tholkappiyan R, Vishista K (2014) Effect of niobium on the optical and magnetic properties of bismuth ferrite (BiFeO3). Adv Sci Eng Med 6:311–317

Mukherjee A, Banerjee M, Basu S, Pal M (2014) Electrical and optical properties of gadolinium doped bismuth ferrite nanoparticles. AIP Conf Proc 1591:1339–1341

MacLaren I, Wang LQ, Schaffer B, Ramasse QM, Craven AJ, Selbach SM, Spaldin NA, Miao S, Kalantari K, Reaney IM (2013) Nanorods: novel nanorod precipitate formation in neodymium and titanium codoped bismuth ferrite. Adv Funct Mater 23:654

Guo R, Fang L, Dong W, Zheng F, Shen M (2010) Enhanced photocatalytic activity and ferromagnetism in Gd doped BiFeO3 nanoparticles. J Phys Chem C 114:21390–21396

Zhao G, Liu S, Lu Q, Xu F, Sun H, Yu J (2013) Synthesis of TiO2/Bi2WO6 nanofibers with electrospinning technique for photocatalytic methyl blue degradation. J Sol Gel Sci Technol 66:406–412

Talebian N, Nilforoushan M, Memarnezhad P (2013) Photocatalytic activities of multilayered ZnO-based thin films prepared by sol–gel route: effect of SnO2 heterojunction layer. J Sol Gel Sci Technol 65:178–188

Li Z, Shen Y, Yang C, Lei Y, Guan Y, Lin Y, Liu D, Nan C (2013) Significant enhancement in the visible light photocatalytic properties of BiFeO3-graphene nanohybrids. J Mater Chem A 1:823–829

Sakar M, Balakumar S, Saravanan P, Jaisankar SN (2013) Manifestation of weak ferromagnetism and photocatalytic activity in bismuth ferrite nanoparticles. AIP Conf Proc 1512:228–229

Kim JK, Kim SS, Kim W-J (2005) Sol–gel synthesis and properties of multiferroic BiFeO3. Mater Lett 59:4006–4009

Washio I, Xiong Y, Yin Y, Xia Y (2006) Reduction by the end groups of poly(vinyl pyrrolidone): a new and versatile route to the kinetically controlled synthesis of Ag triangular nanoplates. Adv Mater 18:1745–1749

Farhadi S, Rashidi N (2010) Preparation and characterization of pure single-phase BiFeO3 nanoparticles through thermal decomposition of the heteronuclear Bi[Fe(CN)6]·5H2O complex. Polyhedron 29:2959–2965

Zhu X, Hang Q, Xing Z, Yang Y, Zhu J, Liu Z, Ming N, Zhou P, Song Y, Li Z, Yu T, Zou Z (2011) Microwave hydrothermal synthesis, structural characterization, and visible-light photocatalytic activities of single-crystalline bismuth ferric nanocrystals. J Am Ceram Soc 94:2688–2693

Huo Y, Jin Y, Zhang Y (2010) Citric acid assisted solvothermal synthesis of BiFeO3 microspheres with high visible-light photocatalytic activity. J Mol Catal A Chem 331:15–20

Gao F, Chen XY, Yin KB, Dong S, Ren ZF, Yuan F, Yu T, Zou ZG, Liu JM (2007) Visible-light photocatalytic properties of weak magnetic BiFeO3 nanoparticles. Adv Mater 19:2889–2892

Romão J, Barata D, Habibovic P, Mul G, Baltrusaitis J (2014) High throughput analysis of photocatalytic water purification. Anal Chem 86:7612–7617

Song L, Li Y, Zhang S, Zhang S (2014) Synthesis and characterization of Bi3+-Doped Ag/AgCl and enhanced photocatalytic properties. J Phys Chem C 118:29777–29787

Yamada Y, Mizutani M, Nakamura T, Yano K (2010) Mesoporous microcapsules with decorated inner surface: fabrication and photocatalytic activity. Chem Mater 22:1695–1703

Yu J, Kudo A (2006) Effects of structural variation on the photocatalytic performance of hydrothermally synthesized BiVO4. Adv Funct Mater 16:2163–2169

Fu H, Pan C, Yao W, Zhu Y (2005) Visible-light-induced degradation of rhodamine B by Nanosized Bi2WO6. J Phys Chem B 109:22432–22439

Yang Y, Wen J, Wei J, Xiong R, Shi J, Pan C (2013) Polypyrrole-decorated Ag–TiO2 nanofibers exhibiting enhanced photocatalytic activity under visible-light illumination. ACS Appl Mater Interf 5:6201–6207

Liu R, Wang P, Wang X, Yu H, Yu J (2012) UV- and visible-light photocatalytic activity of simultaneously deposited and doped Ag/Ag(I)-TiO2 photocatalyst. J Phys Chem C 116:17721–17728

Zhang Z, Wang W, Gao E, Sun S, Zhang L (2012) Photocatalysis coupled with thermal effect induced by SPR on Ag-Loaded Bi2WO6 with enhanced photocatalytic activity. J Phys Chem C 116:25898–25903

Acknowledgments

This work was supported by the National Natural Science Foundation of China (51202040, 21363006), Guangxi Natural Science Foundation (2013GXNSFBA019042, 2012GXNSFBA053032) and scientific research projects of Guangxi Education (200103YB059, 201106LX243).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, H., Du, Z., Wang, J. et al. Enhanced photocatalytic performance of Ag-decorated BiFeO3 in visible light region. J Sol-Gel Sci Technol 76, 50–57 (2015). https://doi.org/10.1007/s10971-015-3749-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-015-3749-6