Abstract

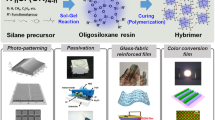

A current trend of applied research in the field of nanomaterials is the integration of bottom up and top down fabrication methods. Sol–gel chemistry is widely applied to obtain different functional materials from a bottom up route, especially in the case of thin films. To fabricate devices based on sol–gel films, which include nanocomposites and mesoporous ordered materials, application of lithography technologies is mandatory. Among the different lithographic approaches, photolithography is widely used by companies using micro-fabrication processes. In this context, photolithography is a typical top down method that requires to be integrated as much as possible with deposition of thin films from a liquid phase. Recently we have developed a new integrated fabrication method which uses high energy photons, such as hard X-rays, which typically have energies between 2.5 and 12 keV, for the manipulation and production of a large variety of functional materials and devices. In the present review a short overview of such achievements is presented.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Sol–gel films, just after the deposition, are in a peculiar state which is generally defined as xerogel, a dense gel which is formed by an interconnected solid network, even if not fully condensed, and a liquid phase generally the residual solvent and water [1]. This state, with just a little change of perspective, could be also defined soft matter which means that at this stage sol–gel films, which include a large family of materials and compositions from inorganic to hybrid organic–inorganic and mesoporous ordered templated films, are quickly responsive to external stimuli inducing physical–chemical modifications. For instance, thermal processing of as deposited films produces, via drying and firing, a dense final material. However, a top down approach is also feasible for sol–gel coatings processing; the advantage is that the films can be cured and simultaneously patterned in a single fabrication step.

Many examples of top down processes applied to as deposited sol–gel films have been reported so far in the literature and several of them have been used for industrial processing; a well known example is UV curing for photo-annealing of inorganic thin sol–gel coatings [2–4] and photopolymerization of hybrid organic–inorganic films [5–9]. An example of industrial application of UV annealing of sol–gel films is the production of antireflective silica–titania coatings on cathode ray tubes [10, 11]. Another UV patterning method which has been developed is the selective irradiation of films by acetylacetonate modified alkoxide precursors; this process has been applied to write zirconia and titania films [12]. Not only UV light can be applied for top down processing, also laser light [13], X-ray irradiation [14, 15] γ-rays [16] or an electron beam [17] have shown to be able of inducing structural modification and film densification upon exposure. Different photolithographic methods which are based on the direct interaction of the light source with sol–gel films have been developed.

In general these top down routes are based on the direct irradiation of fresh sol–gel films by different light sources which generate hydroxyl radicals when water or hydroxyl groups are present; these species produce a condensation reaction which allows for the selective densification in the irradiated regions of the film. The material response to irradiation depends on several parameters (e.g. composition, thickness, energy of the radiation, presence of photoactivators); several side effects may also contribute to the material modifications such as secondary electrons generated from the film substrates [18] and the formation of radical species upon light exposure [19].

Soft X-rays lithography has been also widely used for patterning sol–gel films [15]; however, a possible alternative method is the exposure to hard X-rays which are characterized by a higher energy. Whereas a synchrotron source is used to generate X-rays, the intensity of flux is an additional crucial parameter to achieve high quality pattern in a short time [20]. This encounter between hard X-rays and soft matter, such as sol–gel films, has shown to be a successful marriage not only for lithography but also for manipulating the material itself. In this article we will show a few achievements reached by our research team in the field.

2 The X-ray source

Hard X-rays have a typical energy in the 2.5–12 keV range (Fig. 1a), which is much higher with respect to X-rays for soft lithography (0.5–2 keV); the advantage of irradiating the material by high-energy photons is the higher penetration depth and the possibility of fabricating high-aspect-ratio microstructures in thick films. Figure 1a shows the power density spectrum of synchrotron light at the deep X-ray lithography (DXRL) beamline of Elettra Synchrotron facility in Italy which has been used for the experiments; the spectrum shows that the power density is peaking around 5 keV with a longer tail at higher energies. More recently other experiments have been also performed at the Beijing Synchrotron Radiation Facility showing a good reproducibility of the results when different radiation sources are employed. An intrinsic advantage in using hard X-rays is the high penetration depth, this value depends on the absorption coefficient of the material, which is on turn a function of the radiation wavelength [21]. The dose contrast is a indication of the capability of penetration of the radiation within the material and is defined as the ratio between the energy per unit area incident at the surface and that at the bottom of the film; a dose contrast of one indicates that all the film profile has been irradiated. A simple simulation allows giving an example, the theoretical transmission as a function of photon energy in eV for silica dense films (2.2 g cm−3 density) of different thickness [0.1 μm (black line), 0.5 μm (red line) and 1 μm (blue line)] has been calculated and plotted in Fig. 1b. With the increase of the film thickness higher energies are necessary to obtain a dose contrast close to unit, in fact the thicker is the film and the higher is the absorption of the low-energy photons.

a Power density spectrum of synchrotron radiation at the Elettra DXRL beamline. b Normalized transmittance of photons as a function of incident photon energy (eV) calculated for a silica dense film of thickness 0.1 μm (black line), 0.5 μm (red line) and 1 μm (blue line). Reprinted with permission from Ref. [14] (Color figure online)

3 Effect of exposure to X-rays on sol–gel film structure

The exposure of sol–gel films to hard X-rays produces several effects which depend on their composition and microstructure. In purely inorganic films, densification as a function of the exposure dose is the direct effect produced by the films exposure to hard X-rays. All the changes in the films are due to free radicals, H· and OH·, which are formed by dissociation of water molecules exposed to ionizing radiation; the densification of the metal oxide M (MxOy) via condensation of Mx(OH)y species (e.g. Si(OH)4) is then realized. Even if other effects can not be excluded, such as the production of photoelectrons [22], the Compton effect [23], and X-ray ablation [24], the production of free radicals is considered the main cause of the changes induced in the sol–gel films; this has been well demonstrated comparing the material response in presence of radical sponges.

The densification induced in silica sol–gel films as a function of X-ray dose can be directly followed by FTIR analysis of the films exposed to different doses; Fig. 2 shows the FTIR spectra in the wavenumber range where the main silica absorption band [νas(Si–O–Si)] together with the silanol (Si–OH) stretching band fall. The spectra show a simultaneous decrease of the silanol band and an increase of the silica one, which indicates progressive densification of the films exposed to increasing doses. The decrease in thickness and the increase of refractive index give also a direct indication of film densification upon exposure to X-rays [14].

FTIR absorption spectra in the 1,275–850 cm−1 range of silica films exposed to different X-ray doses. The arrows in the figure show the directions of change in intensity with the increase of dose. Colours of the curves: magenta as-deposited (unexposed sample); red 94 J cm−2; cyan 188 J cm−2; blue 377 J cm−2; black 754 J cm−2; green 1,508 J cm−2; navy 3,015 J cm−2. Reprinted with permission from Ref. [14] (Color figure online)

In the case of hybrid organic–inorganic films the effect of the radical species formed by X-rays is not limited to densification because organic species are affected as well. For the organic moiety the radiation damage induced by the X-rays can either modify the functional groups, [25] or remove the organic species [26].

4 Radical effects and radical sponges

As we have pointed out the formation of free radicals plays a primary role to modify the structure of soft sol–gel films upon irradiation by hard X-rays. To obtain an experimental evidence about the effect of free radicals we have doped the films with C60. Among the different functional properties of the fullerene [27, 28], we used it because of the radical sponge ability [25, 29]. Fullerene and its derivatives have antioxidant and radical scavenging properties under UVA irradiation; fullerenes can sponge up and neutralize 20 or more free radicals per molecule as shown by their performances with vitamin C and vitamin E. The radical scavenging property of C60 has origin in its electronic structure, the low lying lowest unoccupied molecular orbital can easily taking up an electron, which is capable of reacting with radicals. This property has been mostly explored with UV light but could be also exploited at higher energy ranges, such as the X-ray and γ-ray ranges.

C60 molecules at different concentrations have been introduced in hybrid sol–gel films containing covalently bonded phenyl groups as organically modifiers. The first important observation is that the fullerenes in the films are not affected by X-rays until a certain threshold level is reached, beyond this limit they polymerize to form dimers or trimers [30]. On the other hand, the presence of the fullerenes when the as deposited hybrid films are exposed to hard X-rays enhances the resistance threshold of organic bond damage and reduces the condensation of the inorganic network. This effect is shown in Fig. 3a and b, the content of silanols increases with the increase of fullerenes while the amount of phenyl groups which is not degraded increases with the increases of C60 in the films. These data well support the hypothesis that free radical formation is the main cause of condensation of the inorganic network and removal of organic species in hybrids when the sol–gel films is exposed to high energy photons.

a FTIR absorption spectra, in the 1,440–1,420 cm−1 range, of phenylsilane-doped films exposed to a 1,054 J cm−2 dose and containing decreasing amounts of C60 in the sol used for films deposition: 4 mg (black line), 2.5 (red line) and 0 mg (blue line). The unexposed sample without fullerene (green line) is also shown as a reference. b FTIR absorption spectra, in the 950–840 cm−1 range, of phenylsilane-doped films exposed to a 1,054 J cm−2 dose and containing decreasing amounts of C60 in the sol used for films deposition: 4 mg (black line), 2.5 (red line) and 0 mg (blue line). Reprinted with permission from Ref. [29] (Color figure online)

5 Functionalization of carbon nanotubes for sol–gel processing

Functionalization of carbon nanotubes (CNTs) is a critical synthesis step for improving the surface affinity and the chemical reactivity [31]; the application of physical methods, such as plasma, γ-rays or ozone, has shown some limitations because they can cause extensive damage of the nanotubes with wall collapse. In addition, these techniques are unable to functionalize large material amounts due to the limited penetration (20–50 nm). On the other hand functionalization in solution has also several limitations because is a multistep process which employs strong acids and it is necessary to reach a good dispersion of the nanotubes to obtain a homogeneous surface modification.

The high penetration of hard X-rays has suggested that they could represent an alternative method for large scale functionalization of CNTs. Preformed self-supporting CNT structures, with individually entangled in a non-woven fashion CNTs, (buckypaper, BP) have been exposed to different doses of hard X-rays and resulted in an effective surface functionalization by hydroxyl groups (Fig. 4) [32]. The exposure to an intense source of X-rays causes only a small reduction of wall crystallinity without the extensive damage observed after treatment in ozone (Fig. 5) while the functionalization can reach a depth of 50 μm. The silanol groups can then be used for a further functionalization for instance with fluoro-silane (FAS-13) to make the surface CNTs hydrophobic, as we have experimentally demonstrated.

Schematic of buckypaper surface functionalization through hard X-rays. The preformed self-supporting CNT structures (a) which have been exposed to hard X-rays (b) resulted in an effective surface functionalization by hydroxyl groups (c). At this stage a further functionalization with fluoro-silane (FAS-13) can be performed to make hydrophobic the buckypaper surface (d)

TEM image of CNTs after exposure to 262 J cm−2 X-ray dose (left) and after 30 min treatment in ozone (right). Severe damage is observed in the ozone treated sample. Reprinted with permission from Ref. [32]

6 Processing of hybrid films and polymers

The capability of free radicals of removing the organic groups bonded to the silica network in hybrid films can be well exploited for patterning organic–inorganic coatings as well polymer films. In general DXRL has been applied to pattern thick polymeric resist layers (such as SU8 and PMMA) for LIGA [23] micromechanical fabrication but direct exposition of polymeric layers, such as block copolymers [33], allows an easy patterning of the material. The advantage in using lithographic techniques based on hard X-rays is the possibility of producing high quality patterns up to 100 μm thick with high aspect ratio without additional resist, photoinitiator or any chemical modification; the patterns show sharp edges and high homogeneity. Another advantage is that the curing and lithographic process by hard X-rays can be extended to any type of hybrid materials doped with functional molecules allowing the preparation of devices in a few fabrication steps [25]. The decomposition of the organic functionalities in the exposed part of the film has also the advantage of producing a direct change of the material properties in controlled areas (e.g. wettability, etching rate, luminescence). Depending on the composition and structure, the material can also be used as a positive or a negative resist; in general, hybrids behave as negative resist, i.e. the part which is exposed remains on the substrate after etching. This is an indication that the densification induced by X-rays in the exposed is enough to allow an easy removal of the unexposed one. Well defined high aspect ratio patterned structures (1–100 μm range) have been obtained using a phenyl based hybrid film; these coatings have been also used for introducing functional devices by doping with optically active organic molecules such as anthracene, pentacene, and fullerene C60 [25].

However, we found that such behaviour depends on the type of organic functionality. Methyl–silica hybrid coatings prepared through plasma enhanced chemical vapour deposition (PECVD) are an example of positive resist; in general the condition to be a positive resist is a high degree of condensation of the film. In the exposed side the structure of the film is weakened by the removal of the organic groups whose removal rate and efficiency depend on the exposure dose which can be used to control the final structure and composition [26].

7 Mesoporous films preparation and lithography

Mesoporous ordered films are generally prepared combining sol–gel and supramolecular chemistry; the organic micelles which form and eventually ordered during solvent evaporation are the templates of the pores while the inorganic or hybrid network form via controlled condensation reactions of the oligomers at the interface [34]. Removal of the organic template allows obtaining a final inorganic or hybrid ordered porous material with pores which are commonly in the range of 2–10 nm [35, 36].

Several lithographic methods have been proposed to pattern mesoporous films which are based on different types of technologies, such as UV light, soft X-rays, electron beam deposition [37]. DXRL, however, has shown an unprecedented capability, with respect to other techniques, of integrating the material processing from bottom to up. The self-assembly driven by evaporation is the bottom up synthesis which leaves, just immediately after the film deposition, an organized micelles array; however, the final material is obtained only after template removal and densification of the pore walls. This last step can be easily done using DXRL as a top-down effective tool for modification in controlled areas, which is able to modify the material exactly as required (Fig. 6). Exposure of mesoporous films, which are indeed in a truly soft state, produces multiple effects such as the removal of the organic template, densification of the inorganic network of the pore walls and removal of the covalently bonded organic groups in a hybrid organic–inorganic material. A remarkable point of the process is that after exposure to hard X-rays the unexposed part can be easily etched from the substrate leaving well defined and sharp patterns [38]. Mesoporous material processing which generally requires a multistep process involving thermal treatment and lithography can now be done through a single step process (i.e. exposure to X-rays). The process is versatile and can be applied to a large variety of mesoporous materials of different compositions (titania, silica, hafnia, hybrids) as such as to hierarchical porous films [39]. As well as the organic moiety, biological species can be inactivated within mesoporous materials thanks to the selective exposure to hard X-rays. This has been recently reported showing how a film of enzymes confined in mesoporous materials can be patterned using the DXRL [40].

Microfabrication of mesoporous thin films by DXRL. Fresh as-deposited films (a) are exposed to hard X-ray through a lithographic mask (b). The exposures causes densification of the inorganic framework and removal of the templating agent (c). After development, only the exposed parts remained on the substrates while not-exposed parts are selectively dissolved (d)

A preliminary investigation has shown how DXRL can produce not only high quality patterns, but can change the chemical-physical properties of the free volume in polymers. DXRL has been used to improve permselective membranes of thermally rearranged polymers [41]. The exposure to hard X-rays of the thermally responsive membrane reduces the pore dimensions inducing a gas permeability that depends on the irradiation dose.

8 Surface modification

Sol–gel chemistry, besides allowing preparation of a large variety of films in terms of composition and structure, is widely used for surface modification. Different types of substrates can be easily modified using several commercially available alkoxides which allows changing the surface properties and its chemical composition. Some examples are fluorosilanes and aminosilanes which make the surface hydrophobic or allow easy grafting of functional molecules. The patterning by hard X-rays of a highly hydrophobic coating based on tetraethylorthosilicate (TEOS), silica nanoparticles, and 1H,1H,2H,2H-perfluorooctyltriethoxysilane forms microfluidic circuits produced in one fabrication step [42]. The unexposed areas retain the original hydrophobicity (contact angle around to 136°) whilst the patterned regions exhibit a high hydrophilicity (contact angle around 10°) (Fig. 7). The same process can be applied to surface functionalization of a silica slide with a mixture of TEOS, methyltriethoxysilane (MTES) and 3-aminopropyltriethoxysilane; the X-ray patterned surface is modified by immersing the film in a solution containing fluorescein isothiocyanate as fluorescent molecule. The patterned areas show a strong contrast between exposed (black colors) and unexposed regions (red color) which are due to the photoluminescent dye bonding. These examples show that DXRL can be also used for producing highly controlled patterned regions for nucleation of crystals, immobilization of biological molecules or binding of functional molecules.

Microfluidic device produced combining soft chemistry with deep X-ray lithography. a Optical microscope image of patterned circuit. b Optical microscope image zoom of the circuit mixing zone. c Contact angle measurement on exposed areas (10°, high hydrophilicity). d Contact angle measurement on unexposed areas (136°, high hydrophobicity). Reprinted with permission from Ref. [42] (Color figure online)

Prepatterning of a fluorinated substrate to write hydrophilic/hydrophobic circuits is also another route to produce mesoporous channels via selective dewetting [43]. Deposition of films on the prepatterned areas gives mesoporous ordered regions of specific geometry and dimensions. The evaporation of the solution in the constrained conditions given by the small pre-patterned circuits gives layers with thicker edges because of pinning at the pattern edges. This edge effect appears dependent upon the dimension of the pre-patterned hydrophilic/hydrophobic layer; in smaller patterns, the evaporation is too fast and thickening of the edges is not observed. Concave of convex channels are therefore obtained as a function of the pre-patterned area dimensions (Fig. 8).

Schematic of the concave and convex shapes that can be obtained by DXRL on hydrophobic surfaces. Patterns of larger dimensions give concave shapes, while convex structures are obtained using contact pinning effects at the film edge in the case of patterns smaller than around 10 μm. Reprinted with permission from Ref. [43]

9 Nanocomposites: metallic and oxide nanoparticles

The application of DXRL to nanocomposites mesoporous films allows for the fabrication of functional micro-devices made by specifically designed multi-component structures. This approach is straight since it involves two stages only; deposition of a nanocomposite mesostructured film (bottom-up) and exposure to hard X-rays (top-down). A recent example is the formation of array on mesoporous nanocomposite films made by titania and exfoliated graphene [44]. This approach, however, is fully exploited

for the microfabrication of mesoporous nanocomposites containing nanoparticles. In fact, the same radicals responsible for the inorganic densification and removal of organic molecules can be used for generating in situ metallic or semiconductor nanoparticles. The nanoparticle formation is very much similar to the γ-ray irradiation process, however, by means of DXRL the nanoparticles, whose shape, topology and dimension is templated by the pores, directly form within the porous matrix. The hydrogen radicals produced by exposure to X-rays act as electron donors to reduce the HAuCl4 to metallic gold, with a process which is the same for other nanoparticles [45]. The same protocol has been, in fact, successfully applied to obtain mesoporous films containing silver nanoparticles for SERS applications [46].

The DXRL fabrication of nanocomposites is not limited to metallic nanoparticles and has been also extended to prepare oxide nanoparticles (NPs) within a mesoporous ordered matrix; one example is cerium oxide nanoparticles within a titania mesoporous ordered film, as shown in Fig. 9 [47]. To produce the ceria NPS the titania mesopores have been impregnated with a ceria precursor solution and then exposed to hard X-rays, which triggered the formation of crystalline cerium oxides within the pores inducing the in situ growth of nanoparticles with average size of 4 nm. DXRL produces different patterns with a spatial control of the nanoparticle growth on the micrometer scale.

Schematic of the DXRL patterning by in situ nucleation and growth of ceria nanoparticles in mesoporous matrixes. Reprinted with permission from Ref. [47]

10 Other materials, other cases

An interesting example of hard X-rays used to integrated different materials and synthesis is the patterning of Metal–Organic-Framework (MOF). Micropatterns on a zeolitic imidazolate framework (ZIF) layer deposited on a sol–gel surface have been produced by hard X-rays, the exposure produces hardening of the sol–gel substrate by inducing crosslinking while leaving the frameworks intact. A phenyltriethoxysilane solution is drop-cast onto a silicon wafer and thermally treated, ZIF-9 powder is then spread across the PhTES surface and heated to adhere the crystals. The material is then exposed to hard X-rays and rinsed by alcohol to obtain patterns of MOFs [48].

Deep X-ray lithography has been combined with self-assembly to produce nano-in-micro-patterned heterogeneous substrates and Pt electrodes. Nanoperforated titania membranes obtained via evaporation induced self-assembly using block copolymer micelles as templating agent have been selectively exposed to the X-ray radiation which gives structural local densification and selective etching of the unexposed layer. The final material shows micrometric features of a sub-10 nm thick perforated titania membrane that guarantees the accessibility to the substrate and when applied to a conductive platinum-coated silicon surface micrometric nanoelectrode arrays can be finally obtained [49].

11 Outlook

The several examples that we have presented in the present review show how much “soft” materials, especially those prepared via sol–gel, are easily processed using hard X-rays. The exposition to high energy photons is not only a lithographic process but indeed becomes a tool for manipulating the materials, which means changing the chemical physical properties in a controlled manner. The possibility of integration of bottom up (sol–gel) and top-down (deep X-ray lithography) processes is another plus of the method which also allows producing nanocomposites and complex materials in less steps with respect to other methods. The main drawback remains the scarce availability of commercial sources of hard X-rays beside the synchrotron facilities, but the technology has still the potentiality of a larger application.

Many other fields have still to be explored, such as multi nanocomposites, integration in industrial processes while still much basic research has to be done to understand the details of the hard X-rays/soft-matter interactions.

References

Brinker CJ, Scherer GW (1990) Sol–gel science. Academic Press, Waltham

Van de Leest RE (1995) Appl Surf Sci 86:278

Bohannan EW, Gao XR, Gaston KR, Doss CD, Sotiriou-Leventis C, Leventis N (2002) J Sol–Gel Sci Technol 23:235

Ma JH, Wu GM, Shen J, Wang J (2001) J Inorg Mater 16:1174

Soppera A, Feullade M, Croutxé-Barghon C, Carré C (2005) Prog Solid State Chem 33:233

Innocenzi P, Brusatin G (2004) J Non-Cryst Solids 333:137

Costacurta S, Malfatti L, Falcaro P, Innocenzi P (2007) J Sol–Gel Sci Technol 44:59

Kang DJ, Park GU, Lee HH, Park HY, Park J-U (2013) Curr Appl Phys 13:1732

Brusatin G, Della Giustina G, Guglielmi M, Innocenzi P (2006) Prog Solid State Chem 34:223

Asahi Glass Co. Ltd. (1993) Jpn Pat 05080205-A

Hitachi Ltd. (1992) Eur Pat Appl No. 0533030 A2

Kintaka K, Nishii J, Tohge N (2000) Appl Opt 39:489

Lasagni AS, Seyler M, Holzapfel C, Maier WF, Mucklich F (2005) Adv Mater 17:2228

Innocenzi P, Malfatti L, Kidchob T, Costacurta S, Falcaro P, Marmiroli B, Cacho-Nerin F, Amenitsch H (2011) J Synchrotron Radiat 18:280

Brusatin G, Della Giustina G, Romanato F, Guglielmi M (2008) Nanotechnology 19:175306

Tirumala VR, Divan R, Mancini DC, Caneba GT (2005) Microsyst Technol 11:347

Hikemet RAM, Thomassen R (2003) Adv Mater 15:115

Kruk M, Jaroniec M, Sakamoto Y, Terasaki O, Ryoo R, Ko H (2000) J Phys Chem B 104:292

Werst DW, Vinokur EI (2001) J Phys Chem B 105:1587

Falcaro P, Innocenzi P (2011) J Sol–Gel Sci Technol 57:236

Cheng Y, Kuo N-Y, Su H (1997) Rev Sci Instrum 68:2163

Wang J, Morin C, Li L, Hitchcock AP, Scholl A, Doran A (2009) J Electron Spectrosc Relat Phenom 170:25

Saile V, Wallrabe U, Tabata O, Korvink JG (2009) Advanced micro and nanosystems, LIGA and its application. WILEY-VCH, Weinheim

Weon BM, Kwon YB, Won KH, Yoo J, Je JH, Li M, Hahn JH (2010) Chem Phys Chem 11:115

Falcaro P, Costacurta S, Malfatti L, Buso D, Patelli A, Schiavuta P, Piccinini M, Grenci G, Marmiroli B, Amenitsch H, Innocenzi P (2011) ACS Appl Mater Interfaces 3:245

Costacurta S, Malfatti L, Patelli A, Falcaro P, Amenitsch H, Marmiroli N, Grenci G, Piccinini M, Innocenzi P (2010) Plasma Process Polym 7:459

Innocenzi P, Brusatin G (2001) Chem Mater 13:3126

Innocenzi P, Falcaro P, Schergna S, Maggini M, Menna E, Amenitsch H, Grosso D, Soler Illia G, Sanchez C (2004) J Mater Chem 14:1838

Pinna A, Malfatti L, Piccinini M, Falcaro P, Innocenzi P (2012) J Synchrotron Radiat 19:586

Cataldo F (1993) Fuller Sci Technol 8:577

Fam DWH, Palaniappan A, Tok AIY, Liedberg B, Moochhala SM (2011) Sens Actuators B 157:1

Dumée LF, Sears K, Marmiroli B, Amenitsch H, Duan X, Lamb R, Buso D, Huynh C, Hawkins S, Kentish S, Duke M, Gray S, Innocenzi P, Hill AJ, Falcaro P (2013) Carbon 51:427

Innocenzi P, Kidchob T, Costacurta S, Falcaro P, Marmiroli B, Cacho-Nerin F, Amenitsch H (2010) Soft Matter 6:3172

Innocenzi P, Malfatti L, Kidchob T, Costacurta S, Falcaro P, Piccinini M, Marcelli A, Morini P, Sali D, Amenitsch H (2007) J Phys Chem C 111:5345

Soler-Illia GJAA, Innocenzi P (2006) Chem Eur J 12:4478

Soler-Illia GJAA, Crepaldi EL, Grosso D, Sanchez C (2003) Curr Opin Colloid Interface Sci 8:109

Innocenzi P, Kidchob T, Falcaro P, Takahashi M (2008) Chem Mater 20:607

Falcaro P, Costacurta S, Malfatti L, Takahashi M, Kidchob T, Casula MF, Piccinini M, Marcelli A, Marmiroli B, Amenitsch H, Schiavuta P, Innocenzi P (2008) Adv Mater 20:1864

Falcaro P, Malfatti L, Kidchob T, Giannini G, Falqui A, Casula MF, Amenitsch H, Marmiroli B, Grenci G, Innocenzi P (2009) Chem Mater 21:2055

Doherty CM, Gao Y, Marmiroli B, Amenitsch H, Lisi F, Malfatti L, Okada K, Takahashi M, Hill AJ, Innocenzi P, Falcaro P (2012) J Mater Chem 22:16191

Han SH, Doherty CM, Marmiroli B, Jo HJ, Buso D, Patelli A, Schiavuta P, Innocenzi P, Lee YM, Thornton AW, Hill AJ, Falcaro P (2013) Small 9:2277

Falcaro P, Malfatti L, Vaccari L, Amenitsch H, Marmiroli B, Grenci G, Innocenzi P (2009) Adv Mater 21:4932

Costacurta S, Falcaro P, Malfatti L, Marongiu D, Marmiroli B, Cacho-Nerin F, Amenitsch H, Kirkby N, Innocenzi P (2011) ACS Appl Mater Interfaces 27:3898

Malfatti L, Falcaro P, Pinna A, Lasio B, Casula MF, Loche D, Falqui A, Marmiroli B, Amenitsch H, Sanna R, Mariani A, Innocenzi P (2013) ACS Appl Mater Interfaces. doi:10.1021/am4027407

Malfatti L, Marongiu D, Costacurta S, Falcaro P, Amenitsch H, Marmiroli B, Grenci G, Casula M, Innocenzi P (2010) Chem Mater 22:2132

Malfatti L, Falcaro P, Marmiroli B, Amenitsch H, Piccinini M, Falqui A, Innocenzi P (2011) Nanoscale 3:3760

Pinna A, Lasio B, Piccinini M, Marmiroli B, Amenitsch H, Falcaro P, Tokudome Y, Malfatti L, Innocenzi P (2013) ACS Appl Mater Interfaces 5:3168

Dimitrakakis C, Marmiroli B, Amenitsch H, Malfatti L, Innocenzi P, Grenci G, Vaccari L, Hill AJ, Ladewig BP, Hill MR, Falcaro P (2012) Chem Commun 48:7483

Faustini M, Marmiroli B, Malfatti L, Louis B, Krins N, Falcaro P, Grenci G, Laberty-Robert C, Amenitsch H, Innocenzi P, Grosso D (2011) J Mater Chem 21:3597

Acknowledgments

The RAS is kindly acknowledged for funding through CRP 26449 P.O.R. FSE 2007–2013, L.R.7/2007.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Innocenzi, P., Malfatti, L., Marmiroli, B. et al. Hard X-rays and soft-matter: processing of sol–gel films from a top down route. J Sol-Gel Sci Technol 70, 236–244 (2014). https://doi.org/10.1007/s10971-013-3227-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-013-3227-y