Abstract

Recently, displays and optoelectronics have made remarkable development because they are the most frequently exposed applications to humanity. The pixel size has become smaller and a new form factor is needed for displays and optoelectronics beyond rigid ones. New material breakthroughs enabling new form factors with plastic-like flexibility, mechanical toughness as well as glass-like thermal/mechanical resistance and low thermal expansion are required. Sol–gel-derived siloxane hybrid material (Hybrimer), showing synergetic properties of organic and inorganic (O–I) materials, can be realized by chemical hybridization and dense O–I co-networks. In addition, the characteristics of hybrimer can be easily optimized via control of organic functional groups, sol–gel reaction, and polymerization steps. First, a sol–gel reaction and polymerization, which enables chemical hybridization of O–I groups, are introduced. Then, the various display and optoelectronic applications using hybrimer achieved by control of properties are provided: (i) patterning, (ii) passivation, (iii) glass-fabric reinforced film, and (iv) color conversion films. This paper includes a brief overview of fabrication process and applications using hybrimer developed over the past decades.

Highlights

-

Sol–gel-derived siloxane hybrid material (hybrimer) is composed of a chemical hybridization between organic and siloxane phase.

-

Hybrimer can be simply fabricated using sol–gel reaction and polymerization.

-

Properties of hybrimer can be easily tuned by controlling the organic groups and sol–gel reaction.

-

Hybrimer can be applied to various display and optoelectronics.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Over recent decades, display and optoelectronic applications have gained much attention because humans are the most exposured in daily life [1, 2]. People generally spend more than 3 h a day on their smartphones [3]. In addition, wearable device and foldable smartphones have been released as commercialized products; then, human exposure to displays and optoelectronics has increased. Recent displays have gradually required smaller pixel size and applications have new form factors (flexible application) beyond those of rigid device [4, 5]. Despite their portability and unique form factor, high-performance flexible electronics will need technological advances in materials and device structures if they are to be successfully commercialized [6,7,8]. In particular, replacing glass, which serves as a substrate and protective layer in flat panel display, is essential for flexible applications [9].

Silicate glass, based on siloxane (Si-O-Si) networks, exhibits high hardness, low water vapor/oxygen transmission rate, superior thermal/chemical stability, and excellent optical transparency [10, 11]. However, glass is weak against bending force and forms cracks easily; that is, glass is no longer an option for flexible devices. Fabrication of thin (< a few hundred micro-meters) and large scale (>3 m) glass substrates need high technology and induce cost problems. In addition, as nanoparticles are difficult to be dispersed in glass, areas of application using glass have limitations. Polymer film, on the other hand, shows mechanical toughness and flexibility as well as being lightweight [12]. Due to their flexibility, various polymer films such as polyethylene terephthalate (PET) and polyimide (PI) films have been applied as substrate films in displays [13]. Nonetheless, polymer films have limitations in standalone use as a substitute of glass, including high thermal expansion and poor thermal/mechanical resistance [14]. That is, polymers are unsuitable in LED encapsulation, barriers, and protection of nanoparticles. Development of innovative materials beyond current materials is essential for new generation applications.

Organic–inorganic (O–I) hybrid materials have received considerable interest as candidates to overcome the limits of organic and inorganic materials [15, 16]. In particular, organically modified ceramics (ORMOCER) and sol–gel derived siloxane hybrid materials (hybrimers) have been the siloxane-based O–I hybrid materials of focus over the few decades [17,18,19,20]. Hybrimer, which can be classified into class-II, has a covalent bond between organic and siloxane phase formed by hydrolysis/ condensation of silane precursors. The chemical hybridization causes the hybrimer to exhibit synergetic characteristics of polymer and siloxane materials, including high transmittance, easy thickness control, flexibility, and superior thermal/mechanical resistance. Properties of the hybrimers are intimately related to organic groups, and various applications in displays and optoelectronics have been demonstrated by changing the silane precursor and polymerization method, as shown in Fig. 1 [21,22,23,24,25,26,27,28,29,30,31].

Schematic illustrations of fabrication of hybrimers and their possible applications for displays and optoelectronics. Photo-patterning (upper left): self-developing method for waveguides (left image). Reproduced with permission [21]. Copyright 2004, Royal Society of Chemistry. UV-based nanoimprinting technique (middle image). Reproduced with permission [22]. Copyright 2005, Royal Society of Chemistry. Photo-lithography for color filters (right image). Passivation and Barrier layer (upper right): LED encapsulation (left image). Reproduced with permission [23]. Copyright 2014, American Chemical Society. Passivation layer on thin-film transistors (middle image). Reproduced with permission [24]. Copyright 2020, Wiley-VCH. Hard coating for foldable display (right image). Reproduced with permission [25]. Copyright 2017, Wiley-VCH. Glass-fabric reinforced siloxane hybrid (GFRH) film (lower left): flexible substrate (left image). Reproduced with permission [26]. Copyright 2010, Wiley-VCH. Transparent conducting electrodes (middle image). Reproduced with permission [27]. Copyright 2017, American Chemical Society. Large-scale triboelectric nanogenerators (right image). Reproduced with permission [28]. Copyright 2020, Wiley-VCH. Color conversion film (lower right): white light-emitting diodes using quantum dot (left image). Reproduced with permission [29]. Copyright 2019, American Chemical Society. Barcodes using upconversion nanoparticle (middle image). Reproduced with permission [30]. Copyright 2019, American Chemical Society. Quantum dot-color filters (right image). Reproduced with permission [31]. Copyright 2019, American Chemical Society

Herein, we report the fabrication of hybrimers using sol–gel reaction, and following polymerization curing and their applications in displays and optoelectronics. In Section 2, we introduce the sol–gel reaction to synthesize organo-oligosiloxane resin using organo-silane precursors. Two main sol–gel reactions are presented: hydrolytic and non-hydrolytic sol–gel reactions. Next, heat or UV curings to link the siloxanes by organic polymerization are introduced to fabricate hybrimers. The polymerization mechanisms depend on the organic functional groups of the oligosiloxane resin. In Section 3, we introduce recent types of displays and optoelectronics using the hybrimers and involving control of the organic groups, ratio of organic/siloxane contents, and sol–gel reaction. Micro-sized patterns are obtained using UV-initiated polymerization of the carbon double bond in the hybrimer. The photo-lithography and imprinting processes are introduced in Section 3.1 (upper left in Fig. 1). In Section 3.2, we introduce light-emitting diode (LED) encapsulation and a passivation layer that can protect devices from external heat and mechanical degradation (upper right in Fig. 1). This layer can play important roles in long-term use of LEDs, thin-film transistors (TFTs), and displays. In Section 3.3, we introduce a glass-fabric reinforced siloxane hybrimer (GFRH) film that enables flexible electronics with thermal/mechanical superiority and low thermal expansion (lower left in Fig. 1). The GFRH films were demonstrated as substrate films, in flexible and transparent conducting electrodes (TCEs), and in triboelectric nanogenerators (TENGs). Finally, in Section 3.5 (lower right in Fig. 1), we introduce a long-term stable color conversion siloxane resin that dispersed color converting materials such as dyes, upconversion nanoparticles, and colloidal quantum dots in siloxane matrix. The siloxane matrix encapsulates the conversion materials and protects them from heat and moisture for long-term use of color conversion layers in displays.

2 Fabrication of siloxane hybrid materials (hybrimers)

2.1 Sol–gel synthesis of organo-oligosiloxane resin

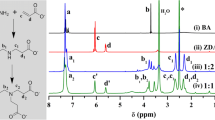

Organo-oligosiloxane resin is synthesized using sol–gel hydrolysis and a condensation process of silane precursor containing organic groups; a new siloxane network (Si-O-Si) is formed by the sol–gel reaction, which can be largely divided into two methods of hydroltic and non-hydrolytic sol–gel reactions [32,33,34,35,36].

First, the hydrolytic sol–gel reaction is appropriate for the formation of highly condensed oligosiloxane resin using alkoxy groups (−OCnH2n+1)-containing silane precursor [37]. Before sol–gel condensation, alkoxy groups are hydrolyzed under acidic or basic aqueous condition; then, the hydroxyl groups (-OH) condense with other hydroxyl and alkoxy groups in processes referred to as water and alcohol condensations, respectively. Synthesis of oligosiloxane resin is confirmed by Fourier-transform infrared spectroscopy with the formation of a siloxane bond in the range of 1100-1000 cm-1 [38]. The sol–gel reaction has an advantage of low-temperature process under 100 °C; the synthesized resin shows appropriate viscosity for use under room temperature. Using the molds, we can fabricate the hybrimers with the desired thickness and shape, without an additional binder [29]. Degree of condensation and kinetics of hydrolysis/ condensation are intimately affected by the factors such as alkoxy length, ratio of water to Si, and pH level [39]. However, in the case of the non-hydrolytic sol–gel reaction, hydroxyl silane or chloride is used for sol–gel condensation [40]. Diphenyl silanediol (DPSD) is commonly utilized as the silane precursor; it improves the refractive index and thermal stability and allows applications to substrate films and encapsulation materials [26, 41, 42]. Hydroxyl groups in DPSD directly react with alkoxy groups in oragano alkoxysilane precursors. The non-hydrolytic sol–gel reaction is a simple method; however, a lower degree of condensation occurs compared to that of the hydrolytic reaction.

The residual hydroxyl groups cause to decrease of hydrophobicity, and solubility in non-polar sovent. During fabrication of hybrimers, however, the oligosiloxane resins show high degree of condensation over 90% via simple sol–gel reaction under low temperature (<100 °C); thus, the problem derivated from the residual hydroxyl groups is not observed in the hybrimers.

2.2 Polymerization curing of organo-oligosiloxaen resin

To obtain three-dimensional organic-siloxane co-networks, the organic groups in oligo-siloxane resin are connected through a polymerization process. Usually, organic groups having polymerizable sites are used, including acrylate, epoxy, vinyl, thiol, and amine groups [25, 31, 41, 43,44,45,46,47,48,49]. As mentioned previously, thermal and photopolymerization are the widely used methods with heat and UV light, respectively. The methods of polymerization according to organic groups are listed in Table 1.

Photo-polymerization is a chain reaction in which free radicals or photo-ions initiate a photochemical reaction [50, 51]. UV light easily excites initiators at room temperature; thus, photo-polymerization has high reactivity and allows fast formation of hybrimer. Free-radical polymerization is applicable to carbon double bond (C = C) in acrylate and vinyl oligosiloxane resin; cationic ring-opening polymerization (CROP) is used for epoxy oligo-siloxane resin. Despite of the fast rate of free-radical polymerization, the reaction shows oxygen inhibition in the presence of oxygen gas, and steric hindrance limits the polymerization rate [34, 52]. Thiol functional groups enable photo-polymerization with thiol-ene reaction under normal atmosphere, which is applied for photo-lithography [53]. In general, the CROP is slower than free-radical polymerization; however, CROP is possible in the presence of atmospheric oxygen and the living polymerization achieves a high degree of polymerization [54, 55].

Thermal polymerization is a heat-initiated polymerization for a formation of vinyl and methacrylate hybrimer. For free-radical polymerization, unstable peroxide groups (O–O) are decomposed by elevated temperature; the created free radicals induce the polymerization [56]. On the other hand, hydrosilylation is a reaction between unsaturated carbon bonds and hydride silicone; it shows an advantage of no byproducts compared to the case of free-radical polymerization [57]. Despite of the high transmittance obtained using hydrosilylation due to the lack of byproducts, the high cost of platinum catalyst is a problem. Compared to photo-polymerization, thermal polymerization requires high temperature and a long time; however, the high temperature overcomes steric hindrance and termination step simultaneously occurs with propagation step. In the case of photo-polymerization, additional thermal or moisture annealing processes are necessary to decrease yellowness with the termination of polymerization [58].

To retain appropriate characteristics of the hybrimers for applications to specific displays and optoelectronics, discreet selections of sol–gel reaction, organic groups, and polymerization method are essential.

3 Display and optoelectronic applications

Hybrimers show characteristics of both polymer-like flexibility and glass-like thermal/chemical stability and good mechanical properties. Hybrimer, with chemical hybridization of organic and siloxane groups is a promising candidate in future display and optoelectronic applications as a substitute for glass. In this section, we summarize the studies that have been done to apply hybrimers into micro-sized patterning, LED encapsulation, passivation, GFRH films, and color conversion layers.

3.1 Photo-patterning of micro-structures

Micro-optical components such as micro-patterned passivation layer, optical films, waveguides, etc., which have micro-scale patterning or topological surface modulation are very important, because pixels in the displays have become micro-sized and micro-optical elements are increasing in optoelectronics [59,60,61,62]. For micro-optical elements, certain factors are important, including clear patterning, good resolution, and high aspect ratio [63]. In usual, the fabrication of micro-scale patterns has been achieved using UV radiation on photosensitive material (photoresist) [64]. Acrylate and epoxy groups are widely used as photosensitive materials for UV-initiated free-radical polymerization and CROP, respectively. To obtain micro-scale patterns, UV imprinting and photo-lithography are methods that are well-known for their simplicity and high sensitivity. In this section, we introduce some micro-optical applications using methacrylate or epoxy hybrimers: waveguides, prism sheets, and color filters.

Waveguides, having large core structures on clad layers, have received great attention to guide waves in integrated optical circuit devices [65,66,67]. By restricting the transmission to one direction, minimizing the loss of energy, and transparent and low-loss planar waveguides can be fabricated using silicon, glass, and polymers. However, the etching and developing processes incur problems of cost and complexity. Direct photo-patterning fabrication of waveguides was reported using a photo-initiator of benzyldimethylketal (BDK) incorporated in methacrylate hybrimer [68]. Figure 2a shows the mechanism for photo-locking of photochemical species with UV irradiation [69]. BDK was activated by UV irradiation and used to make free-radical polymerization of methacrylate groups. After polymerization, BDK migrated outward and evaporated during baking at 150 °C for a few hours. As photo-polymerization progressed, the refractive index of the exposed region increased by 43 × 10−3 compared to unexposed area; it was appropriate for core structures in waveguides for low loss during transfer of light. Ridge waveguides with smooth surfaces obtained using a photo-locking process are represented in Fig. 2b [70]. The waveguides were simply fabricated by direct laser exposure and a self-developing process without use of wet-etching and photo-mask. Using the direct laser patterning, a 1 × 4 splitter was simply fabricated and all the channels were well defined (Fig. 2c). Light with wavelength of 1550 nm was transmitted through the channels and output light showed uniform intensity.

Micro-sized pattern using UV irradiation on photo-active hybrimer. a Schematic illustration of photochemical self-development. Reproduced with permission [69]. Copyright 2004, Springer. b 3-D AFM image and 2-D line profile of channel waveguide using self-development. c Low magnification optical microscope image and near field mode profile of output in waveguide 1 ×4 splitter. b, c Reproduced with permission [70]. Copyright 2003, Springer. d SEM image of UV-imprinted waveguide array. e Optical propagation loss of the waveguide. d, e Reproduced with permission [71]. Copyright 2005, Royal Society of Chemistry. f AFM image of concave (upper) and convex (lower) pattern using imprinting. Reproduced with permission [72]. Copyright 2006, IOP Publishing, Ltd. g SEM image of prism sheet using UV-imprinting process. Reproduced with permission [43]. Copyright 2020, American Chemical Society. h Mechanism of thiol-ene reaction between thiol and vinyl oligosiloxane resin. Reproduced with permission [118]. Copyright 2011, Royal Society of Chemistry. i SEM image of 50 × 50 μm2 pattern using photo-lithography

More recently, to obtain sophisticated and well-defined patterns, imprinting of hybrimer has been demonstrated [43]. Fluoro-methacrylate hybrimer shows a clear imprinting property with a crack-free structure for multimode optical waveguide, as shown in Fig. 2d [71]. Fluoro-methacrylate oligosiloxane resin was synthesized by non-hydrolytic sol–gel process, using 3-(tri-methoxysilyl)propyl methacrylate (MPTMS), (heptadeca-fluorodecyl)trimethoxysilane (PFAS), and diphenylsilanediol (DPSD). The non-hydrolytic process produced oligosiloxane resin without additional solvent; thus, no cracks formed after the UV imprinting process. UV illumination to the imprinting hybrimer using the rubber mold like polydimethylsiloxane (PDMS) polymerized the methacrylate groups, and replicated hybrimer waveguides were obtained. The fluorinated hybrimer showed increase of hydrophobicity and flexibility, and controlled the refractive index according to contents of PFAS. As shown in Fig. 2e, at a wavelength of 850 nm, the fabricated waveguide shows low propagation loss of 0.25 dB cm-1, which is less than the absorbance of hybrimer. To confirm the superior imprinting feasibility of the fluorinated hybrimer, sub-50 nm scale imprinting was demonstrated and confirmed by atomic force microscope (AFM) analysis [72]. Figure 2f represents the AFM image of the imprinted pattern; both images for concave and convex patterns show exact replication with nanoscale features.

For some display applications, methacrylate and vinyl hybrimer, having carbon double bonds, were demonstrated as optical sheets, such as prism and diffuser sheets, and color-filters [73, 74]. As mentioned earlier, hybrimer shows appropriate viscosity and photo-sensitivity for imprinting; thus, the methacrylate-phenyl hybrimer showed a clear transfer for use in microlens and prism sheets (Fig. 2g) [43]. In addition, the methacrylate-phenyl hybrimer has high refractive index of 1.55, and the replicated prism sheets dramatically enhanced luminance, refracting incident light in the vertical direction. However, UV-initiated free-radical polymerization suffers from oxygen inhibition, which causes poor propagation of the polymerization [52]. Oxygen absorbs the free radicals and unreactive peroxy radical forms. As thiol oligosiloxane resin was added to the vinyl/methacrylate resin, photo-induced patterning was possible under ambient atmospheric condition; this is known as thiol-ene reaction (Fig. 2h) [49]. The thiol group acts as chain transfer agent and the removal of the hydrogen radical from the thiol causes a propagation of radicals to alkene. Due to the patternability of methacrylate hybrimer using the thiol-ene reaction, we reported a quantum dot (QD)/siloxane composite, with advantages of long-term stability and fine patterning, as a QD color filter (QD-CF) (Fig. 2i) [31]. The secondary thiol monomer was used due to its moderate reactivity and lower odor issue; QD-CF with Bayer arrays was obtained with high resolution (50 × 50 μm2).

3.2 LED encapsulation and passivation layer

Light-emitting diodes (LEDs) are fundamental components for lighting and display due to their environmental friendliness with low energy consumption, long lifetime, and high light efficiency [75,76,77]. For high-performance LEDs with long-term stability under heat and moisture, development of LED encapsulation has become an important issue [78, 79]. LED encapsulants having high transparency, thermal/photo-stability, and high refractive index (n) are critical to establish thermal resistance against yellowing and to enhance the light extraction efficiency from LED chips (n≈2.4) to air (n ≈ 1.0) [80].

UV-curable epoxy-phenyl hybrimer was demonstrated to have advantages of simple photo-polymerization and high refractive index of 1.54 [81]. Though thermally curable siloxane-based LED encapsulants exhibit high thermal stability, they have thermal shrinkage and poor manufacturing productivity. To suppress the yellowish color problem of UV-curable hybrimer, additional antioxidants were added to prevent oxidative degradation of hydrocarbon (Fig. 3a). The UV-curable epoxy hybrimer maintained its initial transparency after thermal aging at 120 °C for 1008 h in air (88.6% → 87.8% at 450 nm). These values are comparable to those of commercial thermally curable silicon (OE-6630, 89.6% → 87.7% at 450 nm). With the use of OE-6630, changes of electroluminescence (EL) intensity of epoxy hybrimer encapsulated blue LEDs showed a similar tendency.

LED encapsulation and passivation layer. a Photographs of UV-curable epoxy hybrimer before and after thermal aging. Reproduced with permission [81]. Copyright 2012, Royal Society of Chemistry. b Photographs and optical transmittance of vinyl-phenyl hybrimer before and after thermal aging. Reproduced with permission [82]. Copyright 2010, American Chemical Society. c Refractive index and luminous flux of zirconium-phenyl hybrimer and commercial OE-6630. Reproduced with permission [23]. Copyright 2014, American Chemical Society. d Trace of transmittance at 300 nm of methyl hybrimer and PDMS during thermal and UVB aging. Reproduced with permission [88]. Copyright 2015, American Chemical Society. e Trace of transmittance at UVA, UVB, and UVC during UVB aging. Reproduced with permission [89]. Copyright 2016, Royal Society of Chemistry. f Area of residual Mg versus time plot of fluorinated epoxy hybrimer and organic films during Mg soaking test. Reproduced with permission [24]. Copyright 2020, Wiley-VCH. g Epoxy hybrimer in Ashby plot of Young’s modulus against strength. h Photograph of epoxy hybrimer coating on PET film. g, h Reproduced with permission [25]. Copyright 2017, Wiley-VCH. i Dielectric constant of fluorinated methacrylate hybrimer as function of fluoro silane contents. Reproduced with permission [94]. Copyright 2010, American Chemical Society. j Dissipation factor of vinyl-phenyl hybrimer at various frequency. Reproduced with permission [47]. Copyright 2016, American Chemical Society

To improve the thermal stability, vinyl-phenyl hybrimer is a promising encapsulant due to its low portion of short hydrocarbon [82]. Polydimethylsiloxane (PDMS) shows superior thermal resistant even under 200 °C. Nevertheless, its low refractive index of 1.43 bring a limitation of light extraction efficiency. Vinyl-phenyl hybrimer was prepared by hydrosilylation reaction between vinyl-phenyl oligosiloxane resin and phenyltris(dimethoxy)silane (PTDMSS) at 180 °C in air atmosphere. The vinyl-phenyl oligosiloxane resin had a high degree of condensation of 96.6%; thus, a highly dense vinyl-siloxane co-network was obtained. Compared to PDMS with low density of 0.96 g mL−1, the density of vinyl-phenyl hybrimer was 1.24 g mL−1. As shown in Fig. 3b, vinyl-phenyl hybrimer retains excellent optical transmittance and yellowness index (YI) when aged at 180 °C for 1152 h. A slight decrease of transmittance (6%) and change of YI of 12 occur after aging at 200 °C. To increase the refractive index of phenyl hybrimer, we chemically incorporated zirconium atoms into the vinyl-phenyl and hydrogen-phenyl oligosiloxane resins during sol–gel condensation process [23]. A zirconium-phenyl hybrimer was achieved with a high refractive index of 1.58; the light extraction efficiency increased 12.7% compared to that of a bare LED chip (Fig. 3c). In addition to no yellowness after aging at 180 °C, the zirconium-phenyl hybrimer was stable under harsh thermo-hygrostat conditions (85 °C/85% RH) and had higher rubbery state storage modulus (~70 MPa) than that of OE-6630 (~40 MPa).

UV-LEDs have been studied for various applications of counterfeit detection, sensors, UV curing, and water purification [83,84,85]. For organic UV-LED encapsulant, high UV absorbance deteriorates the transparency in the UV region [86]. Silica glass (SiO2), as thin glass plate or monolithic silica with sintering, is a widely used encapsulant for the UV-LEDs [87]. Despite of the excellent UV transparency and gas barrier performance, the high sintering temperature damages the LED chips. We reported a methyl hybrimer using hydrolytic sol–gel reaction and hydrosilylation; there was no phenyl group leading to high transparency in UVB region (280-320 nm) [88]. Figure 3d shows a trace of transmittance of the methyl hybrimer and PDMS during thermal aging at 200 °C and UVB irradiation; methyl hybrimer, because it has a hyper-brancehd co-networks, few radical sources, and robust siloxane groups, shows superior thermal resistance and long-term UVB stability. To apply the hybrimer to long-term operating UV-LEDs even for the deep UV region (UVC: 200-280 nm), a fluorine group was incorporated in the methyl hybrimer [89]. As shown in Fig. 3e, the fluoro-methyl hybrimer shows high UV transmittance from the deep UV (<300 nm) to near UV regions. When the fluorine group was incorporated, the higher bonding energy of fluorine led to formation of co-networks; that is, generation of methyl radical, forming UV absorbing hydroperoxide, drastically diminishes.

Recently, fluorinated epoxy and neat epoxy hybrimer have been reported as passivation layers of thin-film transistors (TFTs) and displays [24]. First, the fluorinated epoxy hybrimer was designated to obtain low water vapor transmission rate compared to those of conventionally used organic barrier such as parylene, polyimide, and SU-8 (Fig. 3f). The fluorine increased the hydrophobicity and the epoxy groups enabled photo-patterning at a size as 10 μm. We demonstrated fluorinated epoxy for bio-fluidic barriers on flexible electronics with oxide TFTs, and confirmed the durable barrier performance of over 16 h of the passivated TFTs in phosphate-buffered saline (PBS) environment. Second, a ladder-like structured epoxy hybrimer was reported as a flexible hard coating for foldable display [25]. This epoxy hybrimer, having glass-like wear resistance (strength: 544.09 MPa), yet plastic-like compliance (Young’s modulus; 10.8 GPa), is realized using new characteristic in Ashby’s plot, as shown in Fig. 3g. For real application as the hard coating, a flexible coating of 50 μm-thick epoxy hybrimer on polyethylene terephthalate (PET) film showed excellent optical transparency, and endured a folding test (radius: 1 mm) of over 10,000 cycles and an industrial steel-wool abrasion test (Fig. 3h).

For TFTs in display applications, a low dielectric constant of the passivation layer is an important factor for low RC time delay, capacitive coupling, and power dissipation [90,91,92]. Despite the good protection of SiO2 and SiNx, the high dielectric constants of 4 and 7, respectively, cause capacitive coupling and are a limitation for large-sized TFT-LCDs [93]. Meanwhile, methacrylate hybrimer with inserted fluoro silane allows a low dielectric constant of 2.54 at 1 MHz for the passivation layer (Fig. 3i) [94]. As the fluoro contents increase, the expansion of the free volume and reduction of the electronic polarization decrease the dielectric constant. In addition to the low dielectric constant, methacrylate hybrimer shows transparency and thermal stability as well as low leakage current and loss tangent. As shown in Fig. 3j, vinyl-phyenyl hybrimer exhibits the excellent dielectric performance with low values of dielectric constant (2.75) and dielectric loss (0.0015 at 1 GHz); the hybrimer is stable at high temperatures up to 275 °C [47]. As a matrix for copper-clad laminates (CCLs), in particular, the vinyl hybrimer shows stable frequency dependence of low dielectric loss (0.0033) up to 10 GHz.

3.3 Glass-fabric reinforced siloxane hybrimer (GFRH) film

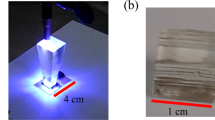

To replace the glass substrate in flat electronics, polymer films are used as substitute material due to their excellent flexibility, light weight, and mechanical toughness [13, 95]. However, conventional polymer films have critical limits when used in place of glass, including high coefficient of thermal expansion (CTE) and poor thermal/ mechanical stability. We have reported glass-fabric reinforced siloxane hybrimer (GFRH) film as transparent conducting electrodes (TCEs), substrates, and triboelectric nanogenerators (TENGs); these are possible because the glass-fabric shows durability at high temperature, chemical inertness, cost-effectivity, and high strength [95,96,97]. As shown in Fig. 4a, the GFRH film is simply fabricated by vacuum pressing method and the haze value is controlled by refractive index contrast between the glass fabric and hybrimer [43]. When the refractive index of hybrimer (nh) matches that of glass fabric (nf), transparent GFRH film, in which the glass fabric is uniformly embedded in the hybrimer (matrix), is obtained with low haze of less than 1 (Fig. 4b) [26]. In this section, we introduce examples of using GFRH film for flexible optoelectronic devices.

Glass-fabric reinforced siloxane hybrid (GFRH) film. a Fabrication of GFRH film using vacuum pressing. Reproduced with permission [43]. Copyright 2020, American Chemical Society. b Cross-sectional SEM image of GFRH film. c Photograph of rolled-up GFRH film. b, c Reproduced with permission [26]. Copyright 2010, Wiley-VCH. d Surface SEM image of AgNW-embedded GFRH film. e Chemical stability of AgNW-GFRH film and AgNW on glass against K2S. d, e Reproduced with permission [101]. Copyright 2014, Royal Society of Chemistry. f Normalized power conversion efficiency of c-ITO/metal NW-GFRH film as a function of bending cycle with bending radius of 2.5 and 5 mm. Reproduced with permission [102]. Copyright 2016, Springer Nature. g Photograph of emitted light from OLED device using AgNF-GFRH film. Reproduced with permission [27]. Copyright 2017, American Chemical Society. h External quantum efficiency of OLEDs on transparent and hazy GFRH substrate. Reproduced with permission [104]. Copyright 2018. Wiley-VCH. i Large-scale yellow QD-GFRH film. Reproduced with permission [105]. Copyright 2020, Wiley-VCH. j 3D schematic illustration of triboelectric nanogenerators using surface-textured GFRH film. Reproduced with permission [28]. Copyright 2020, Wiley-VCH

Transparent GFRH film was demonstrated as a flexible substrate film that was compatible with atomic layer deposition (ALD) and photo-assisted chemical vapor deposition (PECVD) systems [26]. Methacrylate-phenyl hybrimer was synthesized by controlling the refractive index while varying the ratio of methacrylate and phenyl silane precursor to match with nf of 1.55. The GFRH film showed a high transparency (>89%) and a low CTE of 13 ppm K−1, while the CTE of hybrimer for the matrix was over 200 ppm K−1. In addition, the 5% weight loss temperature of the GFRH substrate exceeded 370 °C; that is, the GFRH film exhibited superior thermal resistance. Using the GFRH film as a transparent substrate, arrays of flexible indium gallium zinc oxide TFTs and a-Si-based solar cells were successfully fabricated at 250 °C (Fig. 4c).

Using embedment of conducting materials in the GFRH film during the vacuum pressing process, we fabricated TCEs, which are the most important component of thin-film optoelectronic devices, such as organic light-emitting diodes (OLEDs), touch screen panels (TSPs), photovoltaics, and displays [98,99,100]. Figure 4d shows silver nanowire-embedded GFRH (AgNW-GFRH) film for TCEs with excellent optoelectrical properties [101]. The AgNWs, a promising material to replace indium tin oxide (ITO) because of their excellent figure of merit, flexibility, and low cost, were embedded in GFRH substrate with smooth surface topology (<2 nm). The AgNWs were passivated by a hybrimer with superior thermal stability; then, AgNW-GFRH maintained its initial sheet resistance (Rsh) value of 20 Ω sq−1 during the long annealing time (6 h), even at temperature up to 250 °C. In addition to thermal resistance of AgNW-GFRH, the AgNWs showed stability against chemicals. As shown in Fig. 4e, in contrast to AgNW on glass, the low sheet resistance of AgNW-GFRH was retained against K2S solution. Figure 4f shows the normalized power conversion efficiency of flexible perovskite devices on TCE using GFRH film and PET film as a function of various bending radii [102]. Due to its embedment, the conducting material maintains its excellent electronic property in bending condition. The synergetic combination of superior electrical property and stability has led to the use of metal nanowire-embedded GFRH substrate in flexible optoelectronic applications such as perovskite solar cells, wearable touch screen panels, sensors, and OLEDs (Fig. 4g) [27].

A high haze value of GFRH film can be easily obtained using the refractive index contrast between the glass fabric and hybrimer, without any additional light scattering layer or embedding of nanoparticles [103]. Methacrylate or epoxy hybrimer without phenyl groups showed lower refractive index (1.50) than that of glass fabric (1.55); thus, high haze of over 80% in the visible range is obtained. The hazy GFRH film uniformly diffuses incident light; the external quantum efficiency (EQE) of OLEDs exhibits an increment of 74% when the hazy GFRH film is used as the TCE (Fig. 4h) [104]. Figure 4i is a photograph of large-scale yellow quantum dot-embedded GFRH (QD-GFRH) film (210 × 297 mm2) with high haze. Because color conversion material is inserted in the hazy GFRH film, photoluminescence (PL) increases twofold and the color conversion material shows superior stability against heat and moisture (Fig. 4i) [105]. Finally, using a cost-effective roll-to-plate and UV curing process, we demonstrated large-scale and surface-textured GFRH film for TENGs (Fig. 4j) [28]. Using the GFRH film, enhanced output power was obtained due to the surface texture with high durability during 105 cycles of TENG operation.

3.4 Color conversion siloxane resin

White LEDs are energy-efficient lightings to replace pre-existing light sources, such as incandescent bulbs and fluorescent lamp, due to their long lifetime, light efficiency, and reliability [76]. In general, a yellow converting phosphor such as Y3Al5O12:Ce3+ (YAG:Ce) is combined with a blue LED to realize white photoluminescence [106]. However, the broad PL emission from the yellow phosphors, having a full width at half-maximum (FWHM) over 50 nm, causes a low color-rendering index and waste of energy (>2/3) through the color filter layer [107]. When individual red and green color converting materials are used instead of yellow phosphors, displays can further realize natural colors of objects with wide color gamut [108]. We reported red and green dye/siloxane composites in which the dyes were covalently bridged in the epoxy-phenyl hybrimer to enhance the thermal stability of dyes [109]. The end groups of the dyes, which were alkoxy groups, bonded with hydroxyl groups in phenyl silane during sol–gel condensation, resulting in a dye-bridged oligosiloxane resin. Figure 5a shows the trace of PL intensity of the dye/siloxane and dye/commercial epoxy composites during thermal annealing at 120 °C in an air atmosphere. Compared to epoxy resin with physical dispersion of dyes, the dye/siloxane composites showed improved thermal stability and maintenance of initial PL intensity for 600 h. This was because the epoxy-phenyl hybrimer, having good thermal resistance and low oxygen gas transmission ratio, encapsulated the dye and protected it against heat and oxidation. In addition, by controlling the ratio of red to green dye/siloxane composites, white LEDs were fabricated with high color rendering index of 88 and the CIE coordinates (0.301, 0.252) were unchanged at 120 °C for 1200 h.

Color conversion film with long-term stability. a Photographs of red and green dye/siloxane composite at 365 nm (left) and relative intensity of red and green PL depending on temperature. Reproduced with permission [109]. Copyright 2011, Wiley-VCH. b Molecular structure and c trace of PLQY at 85 °C and 85% relative humidity condition of red QD/siloxane composite. b, c Reproduced with permission [115]. Copyright 2016, American Chemical Society. d CIE coordinates of white QD-LED using QD/siloxane composite and blue LEDs, and NTSC. Reproduced with permission [29]. Copyright 2019, American Chemical Society. e Florescence OM image of OA-QD and MS-QD/siloxane ink after drying. f Florescence OM image of fabricated QD-color filters. e, f Reproduced with permission [31]. Copyright 2019, American Chemical Society. g Encoded upconversion nanoparticle/siloxane composite by mobile phone camera under NIR exposure (980 nm). Reproduced with permission [30]. Copyright 2019, American Chemical Society

Semiconductor-based quantum dots (QDs) have attracted great interest for next-generation color converting materials due to their size-dependent emission, narrow FWHM, and high PL quantum yield compared to dyes and phosphors [110,111,112,113]. However, the high surface area from the nano-sized particles leads to poor thermal and chemical stability as well as poor dispersion stability in the polymeric matrix [114]. We reported oleic acid-capped QD/siloxane (OA-QD/siloxane) composite for a film type QD-display [115]. During polymerization of C = C in the methacrylate-phenyl hybrimer, the C = C in oleic acid also bonded with the methacrylate; thus, additional cross-linkages caused rigid encapsulation of QDs by the siloxane matrix, as represented in Fig. 5b. The siloxane-encapsulation enhanced the thermal and chemical stability of the QDs; we then obtained long-term (>30 days) stable QD/siloxane film under 85 °C/5% relative humidity (RH) condition. The film also showed an increase of PL QY in high temperature/high humidity condition (85 °C/85% RH), which are the harsh testing conditions in the manufacturing industry (Fig. 5c). This increase of PL QY was the result of water molecules passivation of trap state on the surface of the QDs; the solvated trap state induced the preferred radiative behavior [116]. Finally, we realized white LEDs using a mixture of red and green QD/siloxane composites with blue LEDs, resulting in a wide color gamut of 107%, related to the National Television System Committee (NTSC) as shown in Fig. 5d [29].

To realize white PL with a thinner QD-embedded film, an increase of QD concentration in the matrix or enhancement of color conversion ability is possible [117]. Despite the presence of nano-sized QDs, the long alkyl chain in oleic acid causes the QDs to aggregate when the QD concentration increases. When OA-QD is physically dispersed in oligosiloxane resin, the limit of concentration without aggregation is 1 wt%. Figure 5e and f display mercaptosilane-capped QD (MS-QD)/siloxane composite, in which the concentration of QDs is 20 wt% in the methacrylate-phenyl hybrimer using ligand exchange [31]. Due to the differences of surface affinity, the ligand of oleic acid can be easily exchanged to 3-mercaptopropyl-methyldimethoxysilane (MPMDMS) by stirring at room temperature. The end groups of MPMDMS have methoxy groups that react with hydroxyl groups in DPSD during sol–gel condensation. MS-QD is chemically dispersed in oligosiloxane resin and the uniform dispersion is maintained during the drying process (Fig. 5e). Using highly concentrated QD/siloxane ink, we demonstrated long-term stable QD-incorporated color filters (QD-CFs). The methacrylate groups with secondary thiol monomer enable photo-patterning (50 × 50 μm2), as shown in Fig. 5f. The QD-CFs, with thickness of 10 μm, converted incident blue light at a rate of over 90%, and showed stability against heat and moisture. Without increase in the QD concentration, the color conversion ability of QD-embedded film also increased by diffusion or total internal reflection of incident blue light when using a hazy QD-GFRH film or integration of a microlens array on film surface [43, 105]. In addition to display applications, there have been efforts to investigate the upconversion nanoparticle/siloxane composite as a barcode and photo-sensor for IR detection, as shown in Fig. 5g [30].

4 Conclusion

Displays and optoelectronics have dramatically evolved as their sizes have become smaller and they can provide unique form factors. To overcome the pre-existing rigid form factor and superior thermal/mechanical resistance of glass, material breakthroughs are essential. Herein, we have provided an overview of sol–gel-derived siloxane hybrid materials (hybrimers), formed by chemical hybridization between organic and inorganic (siloxane) materials. The chemical hybridization can lead to synergetic properties of polymer and siloxane materials (glass), such as excellent transparency, formability, flexibility, and good thermal/mechanical resistance. The hybrimer can be simply fabricated using polymerization of organo-oligosiloxane resin synthesized by sol–gel-derived hydrolysis and a condensation process from silane precursor. Using a photo-active hybrimer such as methacrylate or epoxy hybrimer, micro-sized patterns can be obtained by self-developing, UV-imprinting, and photo-lithography. The micro-sized patterns of hybrimer show high resolution and excellent optical transmittance for use in waveguides, optical sheets, and color-filters. High refractive index can be obtained by incorporating phenyl groups in the hybrimer molecular structure, and the phenyl hybrimer exhibits high thermal stability in LED encapsulation. In addition, hybrimers having low dielectric loss and water vapor transmission rate, as well as glass-like hardness and polymer-like modulus, can be obtained to apply to the passivation and hard coating layers for flexible optoelectronics. Transparent and hazy glass-fabric reinforced siloxane hybrimer (GFRH) film can be produced using simple vacuum pressing and control of refractive index of hybrimer compared to glass-fabric. The GFRH film shows a smooth surface, flexibility, and superior thermal stability. With the embedment of electrical conducting material in GFRH film, transparent conducting electrodes can be fabricated for flexible optoelectronic applications such as perovskite solar cells, wearable touch screen panels, sensors, and OLEDs. Color conversion film, with superior stability against heat and moisture, can be fabricated using the insertion of color converting material such as dyes, upconversion materials, and quantum dots in the hybrimer during sol–gel condensation. The color converting material/siloxane composite can be used in long-term stable barcode, white LEDs, and color filters. These novel properties of hybimer allow this material to be applied in emerging display and optoelectronic applications.

References

Huitema E (2012) The future of displays is foldable. Inf Disp (1975) 28:6–10

Cima MJ (2014) Next-generation wearable electronics. Nat Biotechnol 32:642–643

Roberts JA, Yaya LHP, Manolis C (2014) The invisible addiction: cell-phone activities and addiction among male and female college students. J Behav Addict 3:254–265

Seong J, Jang J, Lee J, Lee M (2020) CMOS backplane pixel circuit with leakage and voltage drop compensation for an micro-LED display achieving 5000 PPI or higher. IEEE Access 8:49467–49476

Lim HR, Kim HS, Qazi R et al. (2020) Advanced soft materials, sensor integrations, and applications of wearable flexible hybrid electronics in healthcare, energy, and environment. Adv Mater 32:1–43

Nishimura J, Hara K, Daitoh T et al. (2020) 3‐1: Invited paper: super bright 8K LCD with 10,000 nit realized by excellent light‐resistance characteristics of IGZO TFT backplane. SID Symp Dig Tech Pap 51:1–4

Monickam S, Newman T, Szychowski B et al. (2020) 8‐2: invited paper: high refractive index materials for display and lighting applications. SID Symp Dig Tech Pap 51:86–89

Liu W, Linjia M, Aichen X et al. (2020) 17‐6: invited paper: 4K HDR “Stacked‐Panel” TV based on dual‐cell LCD. SID Symp Dig Tech Pap 51:243–245

Crawford GP (2005) Flexible flat panel displays. John Wiley & Sons, Ltd, Chichester, UK

Mauro JC (2014) Grand challenges in glass science. Front Mater 1:20

Mauro JC, Philip CS, Vaughn DJ, Pambianchi MS (2014) Glass science in the United States: current status and future directions. Int J Appl Glas Sci 5:2–15

Kaltenbrunner M, Sekitani T, Reeder J et al. (2013) An ultra-lightweight design for imperceptible plastic electronics. Nature 499:458–463

Sekitani T, Zschieschang U, Klauk H, Someya T (2010) Flexible organic transistors and circuits with extreme bending stability. Nat Mater 9:1015–1022

Choi MC, Kim Y, Ha CS (2008) Polymers for flexible displays: from material selection to device applications. Prog Polym Sci 33:581–630

Sanchez C, Arribart H, Guille MMG (2005) Biomimetism and bioinspiration as tools for the design of innovative materials and systems. Nat Mater 4:277–288

Ritchie RO (2011) The conflicts between strength and toughness. Nat Mater 10:817–822

Kang ES, Bae JY, Bae BS (2003) Measurement of thermo-optic coefficients in sol-gel hybrid glass films. J Sol-Gel Sci Technol 26:981–984

Yang S, Kim J-S, Jin J et al. (2010) Thermal resistance of cycloaliphatic epoxy hybrimer based on sol-gel derived oligosiloxane for LED encapsulation. J Appl Polym Sci 117:2140–2145

Buestrich R, Kahlenberg F, Popall M et al. (2001) ORMOCERs for optical interconnection technology. J Sol-Gel Sci Technol 20:181–186

Haas KH, Wolter H (1999) Synthesis, properties and applications of inorganic-organic copolymers (ORMOCER®s). Curr Opin Solid State Mater Sci 4:571–580

Park OH, Kim SJ, Bae BS (2004) Photochemical reactions in fluorinated sol-gel hybrid materials doped with a photolocking agent for direct micropatterning. J Mater Chem 14:1749–1753

Kim WS, Yoon KB, Bae BS (2005) Nanopatterning of photonic crystals with a photocurable silica-titania organic-inorganic hybrid material by a UV-based nanoimprint technique. J Mater Chem 15:4535–4539

Kim YH, Bae JY, Jin J, Bae BS (2014) Sol-gel derived transparent zirconium-phenyl siloxane hybrid for robust high refractive index LED encapsulant. ACS Appl Mater Interfaces 6:3115–3121

Lee I, Ho Kim Y, Jang J et al. (2020) Solution-processed, photo-patternable fluorinated sol-gel hybrid materials as a bio-fluidic barrier for flexible electronic systems. Adv Electron Mater 6:1901065

Choi G-M, Jin J, Shin D et al. (2017) Flexible hard coating: glass-like wear resistant, yet plastic-like compliant, transparent protective coating for foldable displays. Adv Mater 29:1700205

Jin J, Ko JH, Yang S, Bae BS (2010) Rollable transparent glass-fabric reinforced composite substrate for flexible devices. Adv Mater 22:4510–4515

Park J, Hyun BG, An BW et al. (2017) Flexible transparent conductive films with high performance and reliability using hybrid structures of continuous metal nanofiber networks for flexible optoelectronics. ACS Appl Mater Interfaces 9:20299–20305

Lee H, Lee HE, Wang HS et al. (2020) Hierarchically surface-textured ultrastable hybrid film for large-scale triboelectric nanogenerators. Adv Funct Mater 30:2005610

Kim YH, Lee H, Kang SM, Bae BS (2019) Two-step-enhanced stability of quantum dots via silica and siloxane encapsulation for the long-term operation of light-emitting diodes. ACS Appl Mater Interfaces 11:22801–22808

Kuk SK, Jang J, Han HJ et al. (2019) Siloxane-encapsulated upconversion nanoparticle hybrid composite with highly stable photoluminescence against heat and moisture. ACS Appl Mater Interfaces 11:15952–15959

Kim YH, Koh S, Lee H et al. (2020) Photo-patternable quantum dots/siloxane composite with long-term stability for quantum dot color filters. ACS Appl Mater Interfaces 12:3961–3968

Kang E-S, Park J-U, Bae B-S (2003) Effect of organic modifiers on the thermo-optic characteristics of inorganic-organic hybrid material films. J Mater Res 18:1889–1894

Kim YH, Choi GM, Kim YH, Bae BS (2019) Mechanically improved sol-gel derived methacrylate-siloxane hybrid materials with urethane linkage. J Sol-Gel Sci Technol 89:111–119

Kim YH, Choi GM, Shin D et al. (2018) Transparent urethane-siloxane hybrid materials for flexible cover windows with ceramic-like strength, yet polymer-like modulus. ACS Appl Mater Interfaces 10:43122–43130

Kim YH, Choi G-M, Bae J et al. (2018) High-performance and simply-synthesized ladder-like structured methacrylate siloxane hybrid material for flexible hard coating. Polym (Basel) 10:449

Jin J, Yang S, Bae BS (2012) Fabrication of a high thermal-stable methacrylate-silicate hybrid nanocomposite: Hydrolytic versus non-hydrolytic sol-gel synthesis of methacryl-oligosiloxanes. J Sol-Gel Sci Technol 61:321–327

Brinker CJ, Scherer GW (1990) Sol-gel science: the physics and chemistry of sol-gel processing. Academic press, San Diego, p. 96

Sassi Z, Bureau JC, Bakkali A (2002) Spectroscopic study of TMOS-TMSM-MMA gels: Previously identification of the networks inside the hybrid material. Vib Spectrosc 28:299–318

Pierre AC (1998) Introduction to sol-gel processing. Springer US, Boston, MA

Styskalik A, Skoda D, Barnes C, Pinkas J (2017) The power of non-hydrolytic sol-gel chemistry: a review. Catalysts 7:168

Kim JS, Yang SC, Kwak SY et al. (2012) High performance encapsulant for light-emitting diodes (LEDs) by a sol-gel derived hydrogen siloxane hybrid. J Mater Chem 22:7954–7960

Lee TH, Kim JH, Bae BS (2006) Synthesis of colorless imide hybrid nanocomposites using amine functionalized oligosiloxane nano-building clusters. J Mater Chem 16:1657–1664

Kim YH, Lee H, Kang S-M et al. (2020) Long-term stable microlens array-integrated quantum dot/siloxane film for thin white backlight units. ACS Appl Nano Mater 3:10261–10269

Kim H, Bae J, Kim YH et al. (2014) Low temperature curable epoxy siloxane hybrid materials for LED encapsulant. J Appl Polym Sci 131:39968

Yang S, Kwak SY, Jin J, Bae BS (2009) Highly condensed epoxy-oligosiloxane-based hybrid material for transparent low- k dielectric coatings. ACS Appl Mater Interfaces 1:1585–1590

Kim JS, Lee S, Hwang YH et al. (2012) Photo-curable sol-gel hybrid film as a dielectric layer by a thiol-ene reaction in air or N 2 for organic thin film transistors. Electrochem Solid-State Lett 15:G13

Kim YH, Lim YW, Kim YH, Bae BS (2016) Thermally stable siloxane hybrid matrix with low dielectric loss for copper-clad laminates for high-frequency applications. ACS Appl Mater Interfaces 8:8335–8340

Bae JY, Kim YH, Kim HY et al. (2013) Sol-gel synthesized linear oligosiloxane-based hybrid material for a thermally-resistant light emitting diode (LED) encapsulant. RSC Adv 3:8871–8877

Kim JS, Yang SC, Park HJ, Bae BS (2011) Photo-curable siloxane hybrid material fabricated by a thiol–ene reaction of sol–gel synthesized oligosiloxanes. Chem Commun 47:6051–6053

Phillips R (1984) Photopolymerization. J Photochem 25:79–82

Crivello JV, Reichmanis E (2014) Photopolymer materials and processes for advanced technologies. Chem Mater 26:533–548

Ligon SC, Husár B, Wutzel H et al. (2014) Strategies to reduce oxygen inhibition in photoinduced polymerization. Chem Rev 114:577–589

Kim J-S, Kim Y, Ko J-H, Bae B-S (2013) Thiol-Ene reaction derived sol-gel hybrid dielectric layer for oragnic thin film transistors. ECS Trans 50:83–88

Penczek S, Cypryk M, Duda A et al. (2007) Living ring-opening polymerizations of heterocyclic monomers. Prog Polym Sci 32:247–282

Crivello JV, Malik R (1997) Synthesis and photoinitiated cationic polymerization of monomers with the silsesquioxane core. J Polym Sci Part A Polym Chem 35:407–425

Warley RL, Feke DL, Manas-Zloczower I (2005) Effect of peroxide crosslinking on the dynamic modulus of silicone rubber. J Appl Polym Sci 97:1504–1512

Bae JY, Jang J, Bae BS (2017) Transparent, thermally stable methyl siloxane hybrid materials using sol-gel synthesized vinyl-methyl oligosiloxane resin. J Sol-Gel Sci Technol 82:253–260

Yang S, Kim J-S, Jin J et al. (2011) Cycloaliphatic epoxy oligosiloxane-derived hybrid materials for a high-refractive index LED encapsulant. J Appl Polym Sci 122:2478–2485

Kim WS, Lee JH, Shin SY et al. (2004) Fabrication of ridge waveguides by UV embossing and stamping of sol-gel hybrid materials. IEEE Photonics Technol Lett 16:1888–1890

Ko YH, Prabhakaran P, Choi S et al. (2020) Environmentally friendly quantum-dot color filters for ultra-high-definition liquid crystal displays. Sci Rep. 10:15817

Il KimT, Kim RH, Rogers JA (2012) Microscale inorganic light-emitting diodes on flexible and stretchable substrates. IEEE Photonics J 4:607–612

Jiang H (2013) Nitride microLEDs and beyond - a decade progress review. Opt Express 21:A475–A484

Kim WS, Kim KS, Kim YC, Bae BS (2005) Thermowetting embossing nanoimprinting of the organic-inorganic hybrid materials. Thin Solid Films 476:181–184

Ovsianikov A, Viertl J, Chichkov B et al. (2008) Ultra-low shrinkage hybrid photosensitive material for two-photon polymerization microfabrication. ACS Nano 2:2257–2262

Usui M, Hikita M, Yoshimura R, et al (1998) An optical coupling technique for parallel optical interconnection modules using polymeric optical waveguide films. In: 2nd 1998 IEMT/IMC Symposium. Institute of Electrical and Electronics Engineers Inc., pp 127–132

Chandross EA, Pryde CA, Tomlinson WJ, Weber HP (1974) Photolocking-A new technique for fabricating optical waveguide circuits. Appl Phys Lett 24:72–74

Uchimura H, Takenoshita T, Fujii M (1998) Development of a “laminated waveguide.”. IEEE Trans Micro Theory Tech 46:2438–2443

Bae BS, Park OH, Charters R et al. (2001) Direct laser writing of self-developed waveguides in benzyldimethylketal-doped sol-gel hybrid glass. J Mater Res 16:3184–3187

Bae BS (2004) High photosensitive sol-gel hybrid materials for direct photo-imprinting of micro-optics. J Sol-Gel Sci Technol 31:309–315

Jung JI, Park OH, Bae BS (2003) Fabrication of channel waveguides by photochemical self-developing in doped sol-gel hybrid glass. J Sol-Gel Sci Technol 26:897–901

Kim WS, Kim KS, Eo YJ et al. (2005) Synthesis of fluorinated hybrid material for UV embossing of a large core optical waveguide structure. J Mater Chem 15:465–469

Kim WS, Choi DG, Bae BS (2006) Ultraviolet-nanoimprint of 40 nm scale patterns using functionally modified fluorinated hybrid materials. Nanotechnology 17:3319–3324

Park JU, Kim WS, Bae BS (2003) Photoinduced low refractive index in a photosensitive organic-inorganic hybrid material. J Mater Chem 13:738–741

Jung KH, Bae BS (2008) Synthesis and characterization of photopatternable epoxy hybrid materials for the fabrication of thick and thermally stable microstructures with a high aspect ratio. J Appl Polym Sci 108:3169–3176

Patel P (2011) Solid-state lighting: the future looks bright. MRS Bull 36:678–680

Matyba P, Yamaguchi H, Chhowalla M et al. (2011) Flexible and metal-free light-emitting electrochemical cells based on graphene and PEDOT-PSS as the electrode materials. ACS Nano 5:574–580

Tao P, Li Y, Siegel RW, Schadler LS (2013) Transparent dispensible high-refractive index ZrO2/epoxy nanocomposites for LED encapsulation. J Appl Polym Sci 130:3785–3793

Narendran N, Gu Y, Freyssinier JP et al. (2004) Solid-state lighting: failure analysis of white LEDs. J Cryst Growth 268:449–456

Narendran N, Gu Y (2005) Life of LED-based white light sources. J Disp Technol 1:167–171

Chhajed S, Lee W, Cho J et al. (2011) Strong light extraction enhancement in GaInN light-emitting diodes by using self-organized nanoscale patterning of p -type GaN. Appl Phys Lett 98:071102

Yang S, Kwak SY, Jin J et al. (2012) Thermally resistant UV-curable epoxy-siloxane hybrid materials for light emitting diode (LED) encapsulation. J Mater Chem 22:8874–8880

Kim JS, Yang S, Bae BS (2010) Thermally stable transparent sol-gel based siloxane hybrid material with high refractive index for light emitting diode (LED) encapsulation. Chem Mater 22:3549–3555

Würtele MA, Kolbe T, Lipsz M et al. (2011) Application of GaN-based ultraviolet-C light emitting diodes - UV LEDs - for water disinfection. Water Res 45:1481–1489

Asif Khan M (2006) AlGaN multiple quantum well based deep UV LEDs and their applications. Phys status solidi 203:1764–1770

Shatalov M, Jain R, Saxena T et al. (2017) Development of deep UV LEDs and current problems in material and device technology. Semicond Semimet 96:45–83

Huang W, Zhang Y, Yu N, Yuan Y (2007) Studies on UV-stable silicone-epoxy resins. J Appl Polym Sci 104:3954–3959

NAKAMURA N, SEKINE M, MATSUMOTO S et al. (2008) Optical characteristics of spherical glass encapsulated LEDs. J Ceram Soc Jpn 116:1075–1078

Bae JY, Kim YH, Kim HY et al. (2015) Ultraviolet light stable and transparent sol-gel methyl siloxane hybrid material for UV Light-Emitting Diode (UV LED) encapsulant. ACS Appl Mater Interfaces 7:1035–1039

Bae JY, Kim HY, Lim YW et al. (2016) Optically recoverable, deep ultraviolet (UV) stable and transparent sol-gel fluoro siloxane hybrid material for a UV LED encapsulant. RSC Adv 6:26826–26834

Rathore JS, Interrante LV, Dubois G (2008) Ultra low- k films derived from hyperbranched polycarbosilanes (HBPCS). Adv Funct Mater 18:4022–4028

Lee B, Park YH, Hwang YT et al. (2005) Ultralow-k nanoporous organosilicate dielectric films imprinted with dendritic spheres. Nat Mater 4:147–151

Lee HJ, Lin EK, Wang H et al. (2002) Structural comparison of hydrogen silsesquioxane based porous low-k thin films prepared with varying process conditions. Chem Mater 14:1845–1852

Matsumura H (1989) Silicon nitride produced by catalytic chemical vapor deposition method. J Appl Phys 66:3612–3617

Oh JH, Kwak SY, Yang SC, Bae BS (2010) Highly condensed fluorinated methacrylate hybrid material for transparent low- k passivation layer in LCD-TFT. ACS Appl Mater Interfaces 2:913–918

Li Y, Meng L, Yang Y et al. (2016) High-efficiency robust perovskite solar cells on ultrathin flexible substrates. Nat Commun 7:10214

Sampath S, Ramachandra GS (2008) Effects of glass fibers on light transmittance and color of fiber-reinforced composite. Dent Mater 24:34–38

Dangtungee R, Somchua S, Siengchin S (2012) Recycling glass fiber/epoxy resin of waste printed circuit boards: Morphology and mechanical properties. Mech Compos Mater 48:325–330

Jin J, Lee J, Jeong S et al. (2013) High-performance hybrid plastic films: a robust electrode platform for thin-film optoelectronics. Energy Environ Sci 6:1811–1817

Im HG, Jung SH, Jin J et al. (2014) Flexible transparent conducting hybrid film using a surface-embedded copper nanowire network: A highly oxidation-resistant copper nanowire electrode for flexible optoelectronics. ACS Nano 8:10973–10979

Im HG, An BW, Jin J et al. (2016) A high-performance, flexible and robust metal nanotrough-embedded transparent conducting film for wearable touch screen panels. Nanoscale 8:3916–3922

Im HG, Jin J, Ko JH et al. (2014) Flexible transparent conducting composite films using a monolithically embedded AgNW electrode with robust performance stability. Nanoscale 6:711–715

Im HG, Jeong S, Jin J et al. (2016) Hybrid crystalline-ITO/metal nanowire mesh transparent electrodes and their application for highly flexible perovskite solar cells. NPG Asia Mater 8:e282

Yao Y, Tao J, Zou J et al. (2016) Light management in plastic-paper hybrid substrate towards high-performance optoelectronics. Energy Environ Sci 9:2278–2285

Lim Y-W, Kwon OE, Kang S-M et al. (2018) Built-in haze glass-fabric reinforced siloxane hybrid film for efficient organic light-emitting diodes (OLEDs). Adv Funct Mater 28:1802944

Lee H, Kim YH, Lim Y et al. (2020) Flexible but mechanically robust hazy quantum dot/glass fiber reinforced film for efficiently luminescent surface light source. Adv Opt Mater 8:1902178

Liu Z, Liu S, Wang K, Luo X (2010) Measurement and numerical studies of optical properties of YAG:Ce phosphor for white light-emitting diode packaging. Appl Opt 49:247–257

Wang X, Zhou G, Zhang H et al. (2012) Luminescent properties of yellowish orange Y 3Al 5-xSi xO 12-xN x:Ce phosphors and their applications in warm white light-emitting diodes. J Alloy Compd 519:149–155

Zhao M, Zhang Q, Xia Z (2020) Narrow-band emitters in LED backlights for liquid-crystal displays. Mater Today 40:246–265

Kwak S-Y, Yang S, Kim NR et al. (2011) Thermally stable, dye-bridged nanohybrid-based white light-emitting diodes. Adv Mater 23:5767–5772

Lee J, Sundar VC, Heine JR et al. (2000) Full color emission from II-VI semiconductor quantum dot-polymer composites. Adv Mater 12:1102–1105

Zhao B, Yao Y, Gao M et al. (2015) Doped quantum dot@silica nanocomposites for white light-emitting diodes. Nanoscale 7:17231–17236

Klimov VI, Mikhailovsky AA, Xu S et al. (2000) Optical gain and stimulated emission in nanocrystal quantum dots. Science 290:314–317

Klein DL, Rotht R, Lim AKL et al. (1997) A single-electron transistor made from a cadmium selenide nanocrystal. Nature 389:699–701

Shirasaki Y, Supran GJ, Bawendi MG, Bulović V (2013) Emergence of colloidal quantum-dot light-emitting technologies. Nat Photonics 7:13–23

Kim HY, Yoon DE, Jang J et al. (2016) Quantum dot/siloxane composite film exceptionally stable against heat and moisture. J Am Chem Soc 138:16478–16485

Pechstedt K, Whittle T, Baumberg J, Melvin T (2010) Photoluminescence of colloidal CdSe/ZnS quantum dots: The critical effect of water molecules. J Phys Chem C 114:12069–12077

Liu C, Li Z, Hajagos TJ et al. (2017) Transparent ultra-high-loading quantum dot/polymer nanocomposite monolith for gamma scintillation. ACS Nano 11:6422–6430

Kim J-S, Yang S, Park H, Bae B-S (2011) Photo-curable siloxane hybrid material fabricated by a thiol–ene reaction of sol–gel synthesized oligosiloxanes. Chem Commun 47:6051

Acknowledgements

This work was supported by the Wearable Platform Materials Technology Center (WMC) supported by a National Research Foundation of Korea (NRF) Grant funded by the Korean Government (MSIP) (NRF-2016R1A5A1009926).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, Y.H., Lee, I., Lee, H. et al. Sol–gel synthesized siloxane hybrid materials for display and optoelectronic applications. J Sol-Gel Sci Technol 107, 32–45 (2023). https://doi.org/10.1007/s10971-021-05491-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-021-05491-4