Abstract

Quaternary Cu2ZnSnS4 (CZTS) thin films, a promising absorber material for solar cells has been successfully deposited on glass substrates by cost effective simple dip-coating method without using either polluting chemicals or expensive vacuum facilities. X-ray diffraction pattern reveals the formation of CZTS films with tetragonal type kesterite structure. The Raman spectra of the prepared films exhibited resonance peaks corresponding to the CZTS phase. The scanning electron microscopic image shows the formation of films with smooth surface. The surface topography studied using atomic force microscope gives an rms roughness of 1.6 nm. The Hall effect studies indicate that the prepared films are p-type with a carrier concentration of 4.77 × 1020 cm−3. The energy dispersive X-ray analysis result indicate the presence of Cu, Zn, Sn and S in the film. The absorption coefficient was found to be the order of 104 cm−1 and the band gap has been found to be 1.5 eV.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Quaternary photo voltaic material Cu2ZnSnS4 (CZTS) is turning out to be the most ideal candidate for solar cell application because of its suitable strong optical absorption coefficient of about 104 cm−1 and even a very thin layer of about 1–2 μm can absorb over 90 % of the incident photons in the spectrum having photon energy higher than the band gap. Copper zinc tin sulphide (CZTS) is emerging as a potential material for use in low-cost, environment friendly and efficient thin film solar cells. It has an optimal band gap of about 1.5 eV which enables a generation of 33 % power conversion efficiency according to Shockley–Queisser theory, which makes CZTS as a promising cost effective material for solar cells [1–3]. The crystal structure of CZTS is similar to that of the leading photovoltaic material CuIn1−xGaxSe2 (CIGS) which is considered as the most promising solar cell absorber layer material in terms of solar cell efficiency. However, the constituent elements of CIGS are expensive (In and Ga) and toxic (Se). In contrast to CIGS material, CZTS has attracted much attention in recent years because of its abundant availability and non-toxic nature. In order to replace rare or toxic elements in a compound semiconductor, isoelectronic alteration can be made to obtain a new compound semiconductor with the same electronic structure. In CIGS compound semiconductor indium and gallium can be replaced by Zn and Sn, as they are non toxic and abundantly available materials. Replacing Se with S converts CIGS into CZTS. CZTS has an absorption coefficient in the order of 104 cm−1 and a direct band gap of 1.5 eV and makes it a suitable candidate to replace CIGS as an absorber layer in thin film solar cells. Barkhouse et al. [4] have reported the highest conversion efficiency of 10.1 % for CZTS based solar cells. The quaternary Cu2–II–IV–VI4 compound is considered to be a novel material for thin film solar cells (TFSC).

The aim of the present work is to deposit CZTS film from non-toxic precursor solution using a simple chemical method so that the processing parameters can be easily controlled and it can be used for large-scale low-cost fabrication. Fischereder et al. [5] have used a toxic pyridine-based solution containing Cu, Zn and Sn salts along with thioacetamide as a sulphur source. However, pure CZTS films were formed only by annealing the precursor film above 250 °C in vacuum atmosphere. Thiourea is a another sulphur popular source that can easily form complexes with Cu, Zn and Sn, which yield sulphides on thermal decomposition [6]. The non-toxic precursor solution of Cu, Zn, Sn and thiourea in methanol can easily produce kesterite type CZTS film.

CZTS thin films can be prepared by using several techniques such as spray pyrolysis technique [6], spin coating method [7], d.c magnetron sputtering [8], sol–gel sulfurization method [9], pulsed laser deposition [10], co-evaporation technique [11], and electron beam evaporation [12]. So far, the absorber layer of CZTS has been mainly deposited by thermal evaporation, sputtering or hydrazine slurry-based methods. The main drawback of the physical deposition method is that it requires vacuum chambers and large power supplies and the hydrazine based method requires specifically designed equipment for hydrazine, which is toxic and flammable.

In the present work Cu2ZnSnS4 thin films have been prepared using copper nitrate and zinc nitrate as the precursor material using simple dip coating method. Zinc nitrate and copper nitrate have been used for the first time as a precursor material for the preparation of Cu2ZnSnS4 films and as far as the knowledge of the authors go no other earlier reports are available stating the use of copper nitrate and zinc nitrate as starting materials for preparing Cu2ZnSnS4 films.

2 Experimental details

Analytical reagent grade (AR) chemicals Cu(NO3)2, Zn(NO3)2, SnCl2 and thiourea were used as precursor materials and they were dissolved in methanol. Few drops of monoethanolamine (MEA) was added as a stabilizer. The solution was stirred for 1 h at room temperature to yield a homogeneous, clear and transparent solution using magnetic stirrer. The possible reaction mechanism for the formation of CZTS film is as follows.

The over all ionic reaction is

The precursor solution consists of metal ions. Thiourea complex and thiourea interacts with metal ion via sulphur atom.

Hence the Cu2ZnSnS4 formation is according to the below equation

CZTS thin films were deposited on well cleaned glass substrate by dip-coating method. The prepared CZTS thin films were annealed at 200 °C for 1 h. The aqueous approach used in the present study is based on chemical bath deposition and ion exchange of Chalcogenide film. The annealed films are uniform and have a good adherence with the substrate.

Structural properties of CZTS thin films were studied using X-ray diffractometer SHIMADZU (Model 6000) with CuKα radiation (kα = 1.54056 Å) and Raman spectroscopy studies were carried out using Raman spectrometer (BRUKER RFS 27). Surface morphology and compositional study of the thin films were carried out using scanning electron microscopy (JEOL, JSM-6360, Japan) attached with an energy dispersive X-ray analysis (EDAX) analyzer and the surface topography has been studied using Atomic force microscopy (Nanosurf Easyscan2). Hall effect studies were carried out by Hall effect measurement system (ECOPIA HMS-2000). Optical properties were studied using the absorbance spectra recorded using UV–Vis–NIR spectrophotometer (Jasco V-570).

3 Result and discussion

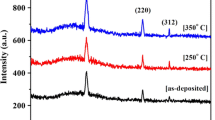

Figure 1 shows the X-ray diffraction pattern of the CZTS thin film annealed at 200 °C. Broad peaks were obtained at the 2θ positions 28.26°, 47.28°, 55.24° for the annealed films which corresponds to the (1 1 2), (2 2 0), (3 1 2) planes of CZTS thin films and they are characteristic of tetragonal type kesterite structure of Cu2ZnSnS4 (JCPDS [13], card no. 26-0575). No secondary phase is observed, suggesting that the CZTS films are close to stoichiometric. It is also important to note that no extra phase corresponding to oxide or hydroxide is seen in the diffraction pattern. Being quaternary compound CZTS often contains other binary and ternary phase and it is difficult to control the stoichiometry. Thus it requires good control over synthesis parameters to obtain the desired phase of the material. The grain size of the CZTS thin film was calculated using Scherer’s equation

where λ is the wavelength of X-ray radiation, β is the FWHM and θ is the bragg angle. The average grain size was found to be 23 nm. The diffraction studies reveals that CZTS thin films has been formed with kesterite structure at an annealing temperature 200 °C which is considerably lower than 250, 280 and 500 °C reported by Fischereder et al. [5]. Yeh et al. [7] and Jiang et al. [14], respectively. The obtained lattice constants were a = 5.432 Å and c = 10.852 Å. These values are in good agreement with reported lattice parameters a = 5.427 Å and c = 10.848 Å (JCPDS [13], card no. 26-0575).

Most of the secondary phases which are formed during the formation of CZTS have peaks which lie close to the peaks of CZTS due to similar crystal structure and this makes it hard to distinguish CZTS from the secondary phase in a X-ray diffractogram. Raman spectroscopy can give a better indication of the presence of secondary phase, because each phase in CZTS will give a peak position in Raman scattering which is more distinct than in X-ray diffraction pattern. The Raman spectra of CZTS film is shown in Fig. 2. In the Raman spectra peaks are observed at 282, 297, 334, 355, 364 and 376 cm−1. The maximum intensity peak at 334 cm−1 and other peaks observed at 282, 355, 364 and 376 cm−1 corresponds to CZTS and are in agreement with the reported results [15–19] and it confirms the formation of CZTS phase. The peak observed at position 297 cm−1 corresponds to the tetragonal Cu2SnS3 secondary phase [8, 20]. Usually tetragonal Cu2SnS3 phase are observed to form at low temperature [8, 20]. The absence of peak at 271 cm−1 and 352 cm−1 confirms that β-ZnS phase has not been formed. The CZTS Raman spectrum did not show any evidence for the presence of binary phases SnS, SnS2, CuS and Cu2S.

Figure 3 shows the of atomic force microscope (AFM) image of CZTS film. The root mean square (rms) roughness was found to be 1.6 nm indicating the formation of smooth and compact film. Figure 4 shows the SEM image of CZTS thin film. The image shows that the surface morphology of the film is smooth, and the film is compact and dense in nature.

The elemental composition of CZTS thin film was determined by Energy Dispersive X-ray Analysis and the spectra is shown in Fig. 5. The chemical composition of the film is Cu—13.90 at %, Zn—12.15 at %, Sn—21.72 at %, S—52.7 % at %, and the ratios, Cu/(Zn + Sn) is 0.41 %, Zn/Sn is 0.55 % and S/[Cu] + [Zn] + [Sn] is 1.08 %. Tanaka et al. [9] have reported that higher efficiencies can be obtained using Cu poor, Zn rich absorber layer in solar cells.

Carrier concentration and mobility are the important parameters for the absorber layer of solar cell and it was determined by Hall measurements. The carrier concentration of the CZTS film was found to be 4.77 × 1020 cm−3 and the Hall mobility was 4.94 cm2 V−1 s−1. The resistivity of the CZTS film was found to be 2.13 × 10−7 Ω cm. The films were observed to exhibit p-type conductivity.

The absorbance spectra of the CZTS film is shown in Fig. 6. The absorption coefficient of the CZTS film was found to be the order of 104 cm−1. The band gap of the CZTS film has been determined using the relation,

where, α is the absorption coefficient, A is the constant, Eg is the energy gap and hυ is the incident photon energy. The optical band gap is deduced by extrapolating the straight line portion of the (αhυ)2 versus (hυ) plot (Fig. 7) to meet the hυ axis. The band gap energy was found to be 1.5 eV, which is in good agreement with previously reported value [9]. This band gap value is quiet close to the optimum band gap required for a solar cell absorber layer.

4 Conclusion

In conclusion, CZTS film has been successfully synthesized by simple sol–gel dip coating method. The X-ray-diffraction pattern revealed the formation of tetragonal type kesterite structure CZTS films. The synthesis process results in smooth, compact and dense films with the root mean square roughness (rms) of 1.6 nm and the optical band gap has been found to be 1.5 eV. The films are p-type semiconductor and the charge carrier concentration is 4.77 × 1020 cm−3. Fabrication of CZTS film based solar cell is the next part of this work.

References

Guo QJ, Hillhouse HW, Angrawal R (2009) Synthesis of Cu2ZnSnS4 nano crystal ink and its use for solar cells. J Am Chem Soc 131:11672

Steinhagen C, Panthani MG, Akhavan V, Goodfellow B, Koo B, Korgel BA (2009) Synthesis of Cu2ZnSnS4 nanocrystals for use in low-cost photovoltaics. J Am Chem Soc 131:12554

Riha SC, Parkinson BA, Prieto AL (2009) Solution-based synthesis and characterization of Cu2ZnSnS4 nano crystals. J Am Chem Soc 131:12054

Barkhouse DAR, Gunawan O, Gokeman T, Torodov TK, Mitzi TB (2012) Device characterization of 10.1% hydrazine processed Cu2ZnSn(Se, S)4 solar cell progress in photovoltaics. Res Appl 20:6

Fischereder A, Rath T, Haas W, Amenitsch H, Albering J, Meischler D, Larissegger S, Edler M, Saf R, Hofer F, Trimmel G (2010) Investigation of Cu2ZnSnS4 formation from metal salts and thioacetamide. Chem Mater 22:3399

Madarasz J, Bombicz P, Okuya M, Kaneko S (2001) Thermal decomposition of thiourea complexes of Cu(I), Zn(II), and Sn(II)chlorides as precursors for the spray pyrolysis deposition of sulfide thin films. Solid State Ionics 439:141

Yeh MY, Lee C, Wuu DS (2009) Influences of synthesizing temperatures on the properties of Cu2ZnSnS4 prepared by sol–gel spin-coated deposition. J Sol-Gel Sci Technol 52:65

Fernandes PA, Salomé PMP, da Cunha AF (2010) CuxSnSx+1 (x = 2,3) thin films grown by sulphurization of metallic precursors deposited by d.c magnetron sputtering. Phys Status Solidi C 7:901

Tanaka K, Fukui Y, Moritake N, Uchiki H (2011) chemical composistion dependence of morphological and optical properties of Cu2ZnSnS4 thin films deposited by sol–gel sulphurization and Cu2ZnSnS4 thin films solarcell efficiency. Sol Energy Mater Sol Cells 95:838

Moriya K, Tanaka K, Uchiki H (2008) Cu2ZnSnS4 thin films annealed in H2S atmosphere for solar cell absorber prepared by pulsed laser deposistion. Jpn J Appl Phys 47:602

Tanaka T, Kawasaki D, Nishio M, Guo Q, Ogawa H (2006) Fabrication of Cu2ZnSnS4 thin films by co-evaporation. Phys Status Solidi C 3:2844

Katagiri H, Sasaguchi N, Hando S, Hoshino S, Ohashi J, Yokota T (1996) Preparation and evaluation of Cu2ZnSnS4 thin films by sulphurization of E-B evaporated precursors. Sol Energy Mater Sol Cells 49:745

JCPDS, card no. 26-0575

Jiang M, Li Y, Dhakal R, Thapaliya P, Mastro M, Caldwell JD, Kub F, Yan X (2011) Cu2ZnSnS4 polycrystalline thin films with large densely packed grains prepared by sol–gel method. J Photonics Energy 1:019501-1

Altosaar M, Raudoja J, Timmo K, Danilson M, Grossberg M, Krustok J, Mellikov E (2008) Cu2Zn1–x Cd x Sn(Se1–y S y )4 solid solutions as absorber materials for solar cells. Phys Status Solidi A 205:167

Yoo H, Kim JH (2010) Growth of Cu2ZnSnS4 thin films using sulphurization of metallic film. Thin Solid Films 518:6567

Yoo H, Kim JH (2011) Comparitive study of Cu2ZnSnS4 film growth. Sol Energy Mater Sol Cells 95:239

Fernandes PA, Salomé PMP, da Cunha AF (2009) Growth and Raman scattering of Cu2ZnSnS4 thin films. Thin Solid Films 517:2519

Fernandes PA, Salomé PMP, da Cunha AF, Schubert B-A (2011) Cu2ZnSnS4 solar cells prepared with dc-sputtered stacked metallic precursor. Thin Solid Films 519:7382

Fernandes PA, Salomé PMP, da Cunha AF (2010) A study of Terenary Cu2SnS3 and Cu3SnS4 thin films prepared by sulphurizing stacked metal precursors. J Phys D Appl Phys 43:215403

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rajesh, G., Muthukumarasamy, N., Subramaniam, E.P. et al. Synthesis of Cu2ZnSnS4 thin films by dip-coating method without sulphurization. J Sol-Gel Sci Technol 66, 288–292 (2013). https://doi.org/10.1007/s10971-013-3006-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-013-3006-9