Abstract

The properties of silica aerogels are highly dependent on the post-treatment steps like gel washing, gel aging and gel drying. The experimental results of the studies on one of the post-treatment steps i.e. gel aging effect on the physical and microstructural properties of methyltrimethoxysilane (MTMS) based silica aerogels, are reported. These hybrid aerogels were prepared by two step sol–gel process followed by supercritical drying. The molar ratio of MeOH/MTMS (M) was varied from 7 to 35 by keeping the H2O/MTMS (W) molar ratio constant at 4. The as prepared alcogels of different molar ratios were aged from 0 to 5 days. It was observed that 2 days of gel aging period is the optimum gel aging period for good quality aerogels in terms of low density, less volume shrinkage and high porosity. The well tailored network matrix with low density (0.04 g/cm3), less volume shrinkage (4.5%), low thermal conductivity (0.05 W/mK) and high porosity (98.84 %) was obtained for 2 days of gel aging period of M = 35. Further, the gelation time varied from 8 to 1 h depending on the M values. The gelation time was being more for lesser M values. The aerogels were characterized by bulk density, porosity, volume shrinkage, thermal conductivity, Scanning Electron Microscopy and the Fourier Transform Infrared spectroscopy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Silica aerogels are low density solid state porous materials derived from gel in which the liquid component of the gel has been replaced by air. Such a unique morphology modifies the parent molecular mechanism, resulting in exceptional thermal, acoustical, mechanical and electrical properties [1–3]. Hybrid organic–inorganic silica aerogels are generally produced by incorporating organic phase into inorganic precursor sol, before the gelation. However, silica organic-inorganic hybrid aerogels can be obtained by alkylalkoxysilane precursors such as methyltrimethoxysilane (MTMS) and methyltriethoxysilane (MTES) which has one nonhydrolysable organic radical. These hybrid aerogels are open cell polymers with an intricate internal structure and high porosity [4]. Therefore, they exhibit low thermal conductivity (~0.04 W/mK) and high acoustic insulation (~100 m/s) properties [5]. These fascinating properties were made the aerogels as a prime candidate in various fields of applications such as Cerenkov radiation detectors in high energy physics [6–9], thermal insulators in solar energy systems, refrigerators, thermos flasks [10–13], internal confinement fusion (ICF) targets for the heterogeneous catalyst supports [14], storage media for the liquid rocket propellants and radio luminescent devices [15].

It is well established that small variation in the sol–gel preparative conditions can have a profound influence on the structural and other physico-chemical properties of the resulting hybrid aerogels. The chemical reactions (hydrolysis and condensation) which are responsible for the gelation of alcosol continue long after the gel point and results in strengthening, stiffening and coarsening of the gel network structure. This is called aging process [16] and has a great effect on the microstructural properties of the aerogels. Though, there is an extensive literature present on aging process reviewed by Iler [17], Brinker and Scherer [18], some knowledge of the quantitative effect of aging process on the physical and microstructural properties of MTMS based silica hybrid aerogels, is focused in the present paper.

2 Experimental procedure

2.1 Sample preparation

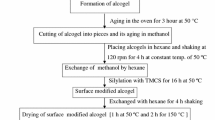

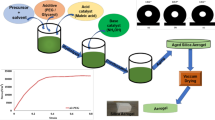

A two stage acid–base catalyzed sol gel process was followed to prepare the alcogel. In the first step, MTMS was diluted in methanol solvent with varying molar ratio of MeOH/MTMS from 7 to 35. The acidic water (oxalic acid, 0.001 M) was added to these solutions, drop by drop, while constant stirring for 15 min. In the second step, after 24 h, basic water (ammonium hydroxide, 10 M) was added to the alcosol, drop by drop, again while stirring for same time interval. The homogeneous alcosols thus obtained were transferred to airtight Borosil glass test tubes of 15 mm outer diameter and 150 mm height. Gelation took place under ambient conditions (temperature ~27 °C). In order to study the effect of gel aging on the properties of the MTMS based aerogels, the as produced hybrid alcogels were aged at various aging periods ranging from 0 to 5 days in the methanol bath.

If the alcogels are dried under ambient conditions, the solvent exerts a capillary pressure on the gels resulting in the collapse of the network structure. Therefore, the monolithic tenuous network structure is preserved using supercritical drying process by lowering the capillary pressure (Pr) and hence the surface tension (γ) of the solvent to zero as per the Laplace’s equation [19]:

where γ is the surface tension of the solvent, θ is the contact angle and r is the pore radius. For supercritical drying, the alcogels were placed in an autoclave (Parr Instruments Company, USA) with an excess amount of MeOH to attain the critical temperature (Tc) and pressure (Pc) (T

c = 240 °C and P

c = 7.9 MPa) of methanol. The temperature of the autoclave was raised to 265 °C at a rate of ~80 °C/h and the corresponding pressure increased to 10 MPa in 3 h. Under these conditions, methanol gets transformed into a supercritical fluid, which was evacuated from the autoclave, slowly, under an isothermal conditions. The complete evacuation took nearly 2 h. The hybrid aerogel so produced was taken out of the autoclave after it was cooled down to the room temperature. The hydrolysis and condensation reactions are as per the following chemical reactions [20].

2.2 Characterization of the aerogels

The aerogels were characterized by studying the physical properties such as the bulk density, volume shrinkage, porosity and thermal conductivity along with the surface morphological studies using Scanning Electron Micrographs (SEM). However, the chemical bondings responsible for the formation of network structure were studied by the Fourier Transform Infrared spectrographs. Some of the above mentioned physical properties of the aerogel samples were studied using the following formulae:

where Va is Volume of aerogel and Vg is Volume of alcogel.

where ρb is the bulk density and ρs is the skeleton density (~1900 kg/m3) which was measured using Helium Pycknometer (Quantachrome).

3 Results and discussion

3.1 Effect of MeOH/MTMS molar ratio (M) on gelation time

In order to determine the effect of MeOH/MTMS molar ratio (M) on the gelation time, M value was varied from 7 to 35 by holding the molar ratios of oxalic acid (0.001 M)/MTMS and NH4OH (10 M)/MTMS constant at 4 for each.

It was observed that the gelation time increased from to 1 to 10 h with an increase in M value from 7 to 35 as shown in Fig. 1. This increase in gelation time with M value is due to the fact that for lower M value, the spacing between the reacting silica species is less which leads to the formation of 3-D silica network within a short period of time. However, with an increase in M value, the spacing between reacting species increases due to more dilution of the precursor in the solvent which leads to decrease in rate of condensation reaction and hinders the formation of gel network, resulting in a longer gelation time.

3.2 Effect of gel aging on the bulk density and volume shrinkage

As the bulk density and volume shrinkage are the prime physical properties of the aerogels, the effect of gel aging on the volume shrinkage and hence on the bulk density of the aerogels have been studied and the results were tabulated in Table 1. The bulk density and the volume shrinkage of the as produced hybrid silica aerogels found to decrease with an increase in aging period upto 2 days. However, further increase in the aging period upto 5 days resulted in more volume shrinkage of the aerogels after the supercritical drying which in turn gives the high bulk density aerogels. The variation in bulk density and volume shrinkage with respect to gel aging period are depicted in Figs. 2 and 3, respectively. From Fig. 2, it is clear that the value of bulk density is least for 2 days of gel aging period for all the M values.

Since, the hydrolysis and condensation reactions are the route reactions for the formation of gel network, the hydrolysis reaction was carried out for 24 h to have the sufficient number of hydroxyl species in the alcosol which are responsible for the formation of Si–O–Si bonds by liberating H2O in the condensation reaction. At the gel point, the network forms sufficiently enough to prevent the solvent flow from the pores of the network. As mentioned in the introduction that the chemical reactions which are responsible for the gelation, will continue long after the gel point. Therefore, though the gel network builds up sufficiently, many of the Si atoms still have unreacted –OR and –OH groups that continue to condense, during the aging process and form Si–O–Si bonds. Therefore, for the less aging period (less than 2 days), most of the Si atoms have unreacted –OR and –OH groups giving rise to very delicate gel which shrinks easily during supercritical drying process because of poor stability in the network structure and turned into high density aerogels. This brings out an automate change in the other physical properties like porosity and thermal conductivity. On the other hand, at higher aging period (more than 2 days), the terminal –OR and –OH groups condense more and more, and the gel network become more hybrid which is pulled-in greatly during the drying process. Therefore, more shrinkage of the gel occurs which automatically leads to the high density aerogels. In this case, though the network becomes more and more hybrid with an increase in the aging time, the stability of the network is very less because of excess condensation. This excess condensation makes the network more brittle and hence the poor stability. The 2 days of aging period of an alcogel is found to be optimum aging period for low density aerogels where the condensation of the hydroxyl species takes place to the appropriate extent with efficient bond strength. Figure 3 clearly depicts the lateral shrinkage in the volume of the as prepared hybrid aerogels. The shrinkage was found minimal for 2 days of gel aging process and went on increasing on both the sides of aging period scale. Therefore, the diameter of the aerogel has been found to be large (i.e. d = 14 mm) for 2 days of gel aging period than the relative aging time. Further, the stability of the network is good since it withstands the thermal stresses developed during the drying process. This gives rise to remarkable improvement in the properties of the final aerogel product in terms of low density.

Specifically, it was observed that the as prepared aerogels at M = 35 have lowest bulk density (0.041 g/cm3) and least volume shrinkage (4.5%), while it was around 0.1 g/cm3 bulk density and nearly 20% volume shrinkage for the other M values, shown in the Table 1. This is due to the fact that though the acid and base catalyst concentrations are constant, the lower dilution of MTMS in methanol solvent results in an enhancement of the catalyst reactivity. Therefore, the rate of hydrolysis and condensation reactions would increase leading to the rapid clusterification of the siloxanes [20]. This would result in the dense network structure with high bulk density. In contrast, an increase in the M value reduces the catalyst concentrations in the alcosol and forms well tailored intricate 3-D porous network structure. Therefore, the bulk density and volume shrinkage were obtained very less. But, the dilution beyond certain limit (M > 35) inhibits the polymerization of silica particles and hence the network structure. In this case, gel did not set due to the large increase in the spacing between the reacting species.

3.3 Effect of gel aging on the thermal conductivity of the aerogels

The effect of gel aging on the thermal conductivity of the as prepared aerogel samples was studied by varying the gel aging period from 0 to 5 days and the result has been shown in Fig. 4. The lowest thermal conductivity, among the respective M values, was observed for the aerogels of 2 days of aging. However, it is the maximum for the lowest as well as highest aging periods i.e. for 0 and 5 days. It is due to the fact that the high thermal resistance in the aerogel is caused by high porosity of the gel network, which constituently has low thermal conductivity. As the less porous network has been obtained for the lower as well as higher aging periods of the alcogel, the heat conducted in the aerogel sample is a bit larger and hence the thermal conductivity is expected to be more. For the 2 days of aging period, the silica network is well tailored with high porosity leading thereby less thermal conductivity varies in between 0.05 and 0.09 W/mK for the M values from 7 to 35 days.

3.4 Effect of gel aging on the microstructure of the aerogels

After gelation but before the drying, the gel structure alters significantly by varying the gel aging period [21]. The effect of gel aging on the microstructure of the aerogel was studied by the SEM. Figure 5a and b show the SEM of the aerogel samples of same molar ratio (M = 35) aged for 2 and 5 days, respectively. Since the silica chains of the alcogel aged for 2 days are quite apart from each other, it shows the highly porous network. However, for the 5 days of aging, the degree of polymerization is increased and extensive cross-linking in three dimensions resulted in the dense structure.

Furthermore, coarsening or ripening process is profoundly more with increase in gel aging period. Therefore, the growth of necks advances the strength and the stiffness of the gel network. As the percentage of volume shrinkage during drying is mainly depends on the stiffness of the gel network [22], the shrinkage of the alcogels is more for higher aging periods. Therefore, the alcogels aged for 5 days resulted in denser network than the 2 days of aging, after the supercritical drying.

3.5 Fourier Transform Infrared (FTIR) spectroscopy studies on the gel aging periods

The effect of gel aging on the chemical bondings present in the aerogels has been studied using Fourier Transform Infrared spectroscopy. Figure 6 shows the normalized FTIR spectra of the aerogels prepared with MeOH/MTMS molar ratio at 28 and at different aging periods, as a function of wave number. The data points obtained were normalized to the percentage transmission of the highest days of aging sample (i.e. (a) shown in the FTIR spectra). Since a non continuous evolution in the intensity of the bonds as a function of aging period has been observed, the FTIR spectra were arranged in the increasing order of the intensity of C–H and Si–C bonds and decrease in the intensity of O–H bonds from (a) to (e). The absorption bands observed at around 3000 and 725 cm−1 are due to the stretching and bending of C–H bonds [23]. The broad absorption bands at around 3500 and 1600 cm−1 are due to asymmetric bending modes of SiO2 [24]. The residual Si–OH groups are the main source of hydrophilicity of the aerogels [25]. It can be seen in the figure that there is an increase in the intensity of C–H and Si–C bonds and decrease in the intensity of the O–H bonds for 2 days of aging period [i.e. spectrum (e)]. However, an increase in the intensity of O–H bonds for higher days of gel aging periods (3–5 days) is due to fact that the polycondensation of the silica species increases with an increase in gel aging period. Therefore, this gave rise to an increase in the number of terminal O–H bonds.

4 Conclusions

The gel aging parameter has been found to strongly affect the physical properties of the hybrid silica aerogels. The remarkable change in the results have been obtained by varying the gel aging period from 0 to 5 days. It has been observed that the 2 days gel aging period is optimum for good quality of the aerogels. The significant alteration in the microstructure of the aerogels has been observed for different gel aging periods. The FTIR spectrographs have been shown the decrease in the concentration of the hydroxylated groups for 2 days of gel aging period. The best quality aerogels in terms of low bulk density (0.04 g/cm3), less volume shrinkage (4.59%) and high porosity (98%) have been obtained for the molar ratio of MTMS/MeOH/Oxalic acid/NH4OH at 1:35:4:4, respectively with 2 days gel aging period.

References

Soleimani Dorcheh A, Abbasi MH (2008) J Mater Process Technol 199:10

Buzykaev AR, Danilyuk AF, Ganzhur SF, Kravchenko EA, Onuchin AP (1999) Nucl Instrum Methods Phys Res Sec A 433:396

Ishino M, Chiba J, En’yo H, Funahashi H, Ichikawa A, Ieiri M, Kanda H et al (2001) Nucl Instrum Methods Phys Res Sec A 457:581

Sarawade PB, Kim J-K, Kim H-K, Kim H-T (2007) Appl Surf Sci 254:574

Reim M, Reichenauer G, Körner W, Manara J, Arduini-Schuster M, Korder S, Beck A, Fricke J (2004) J Non-Cryst Solids 350:358

Pestotnik R, Krizan P, Korpar S, Bracko M, Staric M, Stanovnik A (2001) Ncl Sci Symposium Conf Record 2001 IEEE 1: 372

Cuautle E, Di Bari D, Gorlychev VG, Karavicheva TL, Kurepin AB, Martinez MI et al (2005) Nucl Instrum Methods Phys Res Sec A 553:25

Alfaro R, Martínez MI, Paic G (2007) Nucl Instrum Methods Phys Res Sec A 572:437

Cisbani E, Colilli S, Crateri R, Cusanno F, Fratoni R, Frullani S et al (2003) Nucl Instrum Methods Phys Res Sec A 496:305

Reim M, Körner W, Manara J, Korder S, Arduini-Schuster M, Ebert H-P, Fricke J (2005) Sol Energy 791:31

Reim M, Beck A et al (2002) Sol Energy 72:21

Ackerman WC, Vlachos M, Rouanet S, Fruendt J (2001) J Non-Cryst Solids 285:264

Smith DM, Maskara A, Boes U (1998) J Non-Cryst Solids 225:254

Moussa N, Fraile JM, Ghorbel A, Mayoral JA (2006) J Mol Catal A: Chem 255:62

Pajonk GM, Teichner SJ, Fricke J Proceedings of the 1st Int Symp on Aerogels, Wurzburg, Germany, 23–25, September 1985, p 193

Aegerter MA, Jafelicci M Jr, Souza DF, Zanotto ED (1989) Sol–gel science and technology. In: Proceedings of the winter school on glasses and ceramics from gels, Brazil, 14–19 August, p 153

Iler RK (1979) The chemistry of silica. Wiley, New York

Brinker CJ, Scherer GW (1989) Sol–gel science. Academic press, New York

Hiemenz PC (1977) Principles of colloid and surface chemistry. Marcel Dekker, New York

Venkateswara Rao A, Kulkarni MM, Amalnerkar DP, Seth T (2003) J Non-Cryst Solids 330:187

Iler RK (1979) Methods and compositions for preparing silica aerogels. In: The chemistry of silica, Wiley, New York, pp 222

Brinker CJ, Scherer GW (1985) J Non-Cryst Solids 70:301

Hering N, Shriber K, Riedel R, Lichtenberger O, Woltersodorf J (2001) Appl Organometal Chem 15:879

Yoldas BE (1984) J Non-Cryst Solids 63:145

Shwertfeger F, Glaubitt W, Schubert U (1992) J Non-Cryst Solids 145:85

Acknowledgement

The authors are grateful to the Board of Research in Nuclear Sciences, Department of Atomic Energy (BRNS, DAE), Bhabha Atomic Research Centre (BARC), Government of India, for the financial support for this work through a major research project on “Aerogels” (N0. 2007/37/18/BRNS/604). One of the authors, Mr. Digambar Y. Nadargi, is highly thankful to the BRNS, DAE, Mumbai for the Junior Research Fellowship (JRF) fellowship under the same project. One of the authors, Mr. Sanjay S. Latthe, greatly acknowledges the University Grant commission (UGC), New Delhi, for providing “UGC Research Fellowship in Sciences for Meritorious Students”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nadargi, D.Y., Latthe, S.S. & Venkateswara Rao, A. Effect of post-treatment (gel aging) on the properties of methyltrimethoxysilane based silica aerogels prepared by two-step sol–gel process. J Sol-Gel Sci Technol 49, 53–59 (2009). https://doi.org/10.1007/s10971-008-1830-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-008-1830-0