Abstract

Macroporous Me2-CA-BTP/SiO2-P was used for separating 241Am(III) from lanthanides. Good selectivity towards 241Am(III) was achieved in 0.1–3 M HNO3. Adsorption equilibrium of 241Am(III) was obtained within 1 h in 0.1 M HNO3 solution. 241Am(III) was efficiently separated from lanthanides through column experiment in both 0.1 M HNO3 and 0.01 M HNO3–0.34 M NaNO3 solution. It still performed excellently at 207 kGy under γ irradiation in nitrate medium. In a word, Me2-CA-BTP/SiO2-P is a very promising candidate for separating MA from Ln that even a salt-free Ln&MA separation process may be established such as from 0.1 M HNO3 based on it.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the development of nuclear energy, the accumulated spent fuel increases year by year. For the purpose of sustainable development of nuclear energy and reducing the long-term radioactive waste to a minimum, it is urgent to dispose the spent fuel correctly and efficiently. The potential radiotoxicity of high level liquid waste (HLLW) from the current industrial plutonium uranium recovery by extraction (PUREX) process, which only separates 99.5% of U and Pu from spent fuel, still exceeds 10,000 years to reach the natural uranium ore radiotoxicity level. However, if further removal of minor actinides (MA) from HLLW followed by converting it into short-lived radionuclides, which is the so called Partition and Transmutation strategy (P&T), is performed, the time will reduce to 300–500 years. Before transmutation, minor actinides must be separated from the neutron-absorbing elements from HLLW. Lanthanides (Ln), which account for about one-third of the fission products and are much higher than those of MA in a order of magnitude in contents, are strong neutron-absorbing elements and predominantly exist as trivalent cations in acidic aqueous solutions and have similar ionic radii with MA(III) making their chemistry properties very similar, resulting in the mutual separation of MA(III) and Ln(III) very difficult. The separation of trivalent Ln(III) and MA(III) has therefore become a challenging key issue in HLLW reprocessing.

Various materials have been prepared and used for MA(III) and Ln(III) separation, such as CMPO [1], TODGA [2], TPTZ [3], Cyanex 301 [4], TRPO [5], BTP [6, 7], BTBP [6, 8], BTPhen [9], etc. But as HLLW generated by PUREX process is in high acidity (about 2–5 M, M = mol/L) with strong radioactivity and various elements co-existence, which proposes high requirements for materials used for directly separating MA from HLLW in the aspects of stability and selectivity, few of the extractants mentioned above can meet the demands. For example, CMPO and TODGA exhibits good stability in high acidity solution but poor selectivity between MA(III) and Ln(III) [1, 10,11,12]. Cyanex 301 has high selectivity towards MA(III) over Ln(III) only in very low acid solution such as pH > 3 with NaNO3 added meantime [4]. TRPO exhibits good co-extraction ability towards MA and Ln in 0.8–1.2 M HNO3 but it needs 5 M HNO3 solution to strip MA and Ln from the loaded organic phase into liquid phase [13]. For the ligands of BTP, BTBP, BTPhen [6], good selectivity between MA(III) and Ln(III) is obtained which has been widely recognized, most of which exhibits poor stability in high acid solution under irradiation, but there are some exceptions in the cases of ligands with cyclic side structures at the 5,6 positions of triazinyl rings avoiding α-H which is the weak parts under acid or iradiation [14], such as CyMe4-BTBP [15, 16], CyMe4-BTPhen [15], Me2-CA-BTP [17]. The extraction performance of both CyMe4-BTBP and CyMe4-BTPhen towards Am and Eu show no decrease when the γ absorption dose is 300 kGy in 1 M HNO3 solution [15] and are used as the reference extractants in the SANEX process [16].

Me2-CA-BTP/SiO2-P is a kind of adsorbent prepared in our previous work based on Me2-CA-BTP (Fig. 1) [17,18,19]. It exhibits good adsorption selectivity towards 241Am(III) over other typical fission products including Ln(III) in 3 M HNO3 solution, and good stability in 1 M and 3 M HNO3 solution even under γ irradiation [17]. Moreover, Me2-CA-BTP/SiO2-P also exhibits good adsorption selectivity towards 241Am(III) over Ln(III) in low acid—NaNO3 mediums [19]. In a word, Me2-CA-BTP/SiO2-P is a promising material for MA separation from the aspects of directly separating MA from HLLW and the mutual separation of MA&Ln, so it is worth studied throughly. Furthermore, except the direct separation process, the most widely accepted concept for MA separation nowadays is the two-step separation process, i.e. firstly MA and Ln are co-separated from other fission products from high acid HLLW, and secondly, MA and Ln is mutual separated from each other in low acid medium with salting-out agent added if necessary. So the possible application of Me2-CA-BTP/SiO2-P in the two-step MA separation process (low acid or low acid—NaNO3 medium) is also worth study. The paper would firstly study the adsorption behavior of Me2-CA-BTP/SiO2-P towards other actinides, such as U, Pu, which has not been reported before. Then it would mainly focus on the stability and continuous column separation performance using radionuclides in low acid—NaNO3 mediums. Column experiments using radionuclides is the most intuitive way to reflect the separation effect so it is very important.

Experimental

Reagents

Lanthanide nitrates were of analytical grade purchased from Sinopharm Chemical Reagent Co., Ltd., China. 241Am(III), 152Eu(III), 238U(VI) and 239Pu(IV) were from stock solutions of China institute of atomic energy and its concentration in the solution after dilution for adsorption were 1000 Bq/mL (3.27 × 10−8 M), 1000 Bq/mL (1.02 × 10−9 M), 1.00 × 10−3 M, 50 Bq/mL (9.11 × 10−8 M) respectively. The acetonitrile (CH3CN) used was chromatographically pure. Other reagents such as nitric acid, sodium nitrate, etc. were of analytical grade and used without further treatment. The Me2-CA-BTP/SiO2-P adsorbent was synthesized in our previous study by impregnating Me2-CA-BTP dissolved in CH2Cl2 into macroporous silica polymer under reduced pressure with the content of Me2-CA-BTP about 33 wt% [18, 19]. The liquid solutions were prepared with ultra-pure water of 18 MΩ cm resistance.

Batch adsorption experiment

The effects of HNO3 concentration and contact time on Me2-CA-BTP/SiO2-P adsorption towards actinides and lanthanides were studied by batch experiment. 0.1 g Me2-CA-BTP/SiO2-P was combined with 5 mL aqueous solution in a 10 mL plastic centrifuge tube with screw cap. The mixture was shaken mechanically in an air bath shaker at 300 rpm at 25 °C. The solid and liquid phases were separated by centrifugation. The radioactivities of 241Am(III) and 152Eu(III) were determined by high-purity germanium multichannel gamma spectrometer (CANBERRA) at 59.5 keV and 121.78 keV respectively. The radioactivity of 239Pu(IV) was measured by the Super Low Level Liquid Scintillation Analyzer (PE Tri-Carb 3170). The concentration of 238U(VI) was measured by UV spectrophotometer (Lab Tech UV1000/1100). The distribution coefficient Kd (mL g−1), separation factor SFA/B, and adsorption efficiency E (%) are calculated by Eqs. (1), (2), and (3), respectively:

where A0, Ae denote the radioactivities of metal ions in the aqueous phase before and after adsorption, respectively, Bq mL−1. V (mL) indicates the volume of aqueous phase and W (g) is the mass of dry Me2-CA-BTP/SiO2-P adsorbent.

Column separation experiment

Column separation experiment was carried out using a glass column of Φ5 mm * h500 mm. 5 g Me2-CA-BTP/SiO2-P was transferred to the column in the slurry state under atmosphere with the bed volume about 9.8 mL. The column behaviors of Me2-CA-BTP/SiO2-P towards 241Am(III) and Ln(III) in both 0.1 M HNO3 and pH2—0.34 M NaNO3 solutions were studied respectively. Using the case of 0.1 M HNO3 as the feed solution as an example, firstly, the packed column was pre-equilibrated with 20 mL 0.1 M HNO3 solution. Then 10 mL 0.1 M HNO3 containing 2 mM Ln (La, Ce, Pr, Nd, Sm, Eu, Gd, Dy) for each and 500 Bq/mL 241Am(III) as feed solution flew through the column. Followed by about 40 mL 0.1 M HNO3, about 10 mL 0.01 M HNO3, and finally 0.001 M HNO3–0.01 M DTPA solutions respectively flew through the column to elute the residual or poor adsorbed Ln(III) and strongly adsorbed 241Am(III). The mobile phase was pumped at about 0.1 mL/min and the effluents were collected by a fractional collector. The concentrations of Ln in the effluents were determined by inductively coupled plasma-optical emission spectrometer (ICP-AES: Shimadzu ICPS-7510) while 241Am(III) was determined by high-purity germanium multichannel gamma spectrometer.

Stability evaluation

The gamma-ray irradiation stability of Me2-CA-BTP/SiO2-P in both 0.1 M HNO3 and pH2-nitrate mediums was evaluated by 60Co γ source. 0.3 g Me2-CA-BTP/SiO2-P and 15 mL aqueous solution (e.g., 0.1 M HNO3 solution) were put together in a 40 mL glass vial with a cap and irradiated at the dose rate of 1 kGy/h. The total organic carbon (TOC) in the aqueous solution was determined by TOC analyzer (Shimadzu, TOC-V), which, in some degree, can partly reflect the dissolution of both decomposed and undecomposed Me2-CA-BTP from the adsorbent into the liquid phase. The irradiated Me2-CA-BTP/SiO2-P was analyzed by UV/vis spectra (Shimadzu, UV-3600 Plus) and UPLC/Q-TOF-MS (Waters) to evaluate the changes in structure and content of Me2-CA-BTP in Me2-CA-BTP/SiO2-P after irradiation. UV/vis spectra were performed in a wavelength range from 400 nm to 200 nm. The UPLC/Q-TOF-MS test was performed in the positive mode using ACQUITY UPLC BEH C18 column. Furthermore, the adsorption of Me2-CA-BTP/SiO2-P towards 241Am(III) and 152Eu(III) after irradiation was further evaluated.

Results and discussion

Effect of HNO3 concentration

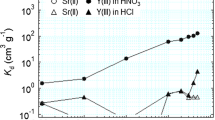

In our previous study, the adsorption behaviors of Me2-CA-BTP/SiO2-P towards stable Ln(III), other typical FPs and trace amount of 241Am(III) were studied that it exhibited good adsorption selectivity towards 241Am(III) over Ln(III) and most other FPs [17,18,19]. Herein, the effect of initial HNO3 concentration (pH4—4 M) on the adsorption of Me2-CA-BTP/SiO2-P towards trace amounts of 238U(VI), 239Pu(IV) was further studied. The results are shown in Fig. 2 combining with the results of 152Eu(III) and 241Am(III) obtained in Ref. [17]. Considering 239Pu(IV) hydrolyzes easily in low acidity solution, the effect of acidity on adsorption was performed in 0.5–4 M HNO3 solution, and its uptake rate was over 97% in 0.5–2 M HNO3 while it decreased as acidity further increased in 3–4 M HNO3, which is similar with that of 241Am(III). The reason may be that the adsorption of Me2-CA-BTP/SiO2-P towards both 239Pu(IV) and 241Am(III) needs the participation of NO3− to keep charge balance. As the radiotoxicity, it is difficult to conduct in-depth analysis with analytical instruments, so stable Ln(III) in the Ref. [7] was used as a simulated elements of MA(III), and XPS analysis was performed on Ln-loaded isoBu-BTP/SiO2-P where NO3− was observed [7]. But as HNO3 concentration further increases, the competition between HNO3 and metal ions also increases which leads to the decrease of metal ion adsorption. In pH4—4 M HNO3 solution, Me2-CA-BTP/SiO2-P exhibited almost no adsorption towards 238U(VI), which is consistent with the results in reference that BTP has no adsorption or extraction ability towards U [20]. The adsorption towards 241Am(III) was much higher than that of 152Eu(III) with SFAm/Eu over 72 in 0.1–3 M HNO3. In a word, Me2-CA-BTP/SiO2-P has good adsorption selectivity towards 239Pu(IV) and 241Am(III) over Eu(III).

Effect of contact time on adsorption towards 241Am(III) and 152Eu(III)

According to the above study, Me2-CA-BTP/SiO2-P exhibits good adsorption selectivity towards 241Am(III) over 152Eu(III) in 0.1 M HNO3 solution without salting-out agent added, which indicates the possibility of establishing a salt-free Ln&MA separation process in 0.1 M HNO3 solution and will decrease the second radioactive waste significantly. The effect of contact time on adsorption towards 241Am(III) and 152Eu(III) in 0.1 M HNO3 solution was studied with the results shown in Fig. 3. The adsorption equilibrium towards 241Am(III) can almost be obtained within 1 h with the uptake rate 241Am(III) about 90% and SFAm/Eu over 75 as time increased indicating fast adsorption kinetics and good selectivity.

Stability evaluation

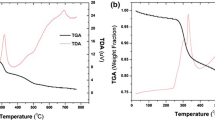

The γ irradiation stabilities of Me2-CA-BTP/SiO2-P in 0.1 M HNO3 and low acid-NaNO3 solutions were studied using 60Co as γ source at the dose rate of 1 kGy/h. The total organic content (TOC) in the liquid phase after irradiation was analyzed with TOC less than 150 mg/L (Fig. 4a). Considering the support particle SiO2-P is very stable [21], so the TOC in the liquid phase is mainly from the dissolution of both decomposed and undecomposed of Me2-CA-BTP from the adsorbent. If all the Me2-CA-BTP was decomposed and dissolved in the liquid phase, the TOC should be 4820 mg/L. Compared with 4820 mg/L, the value of 150 mg/L is very small with the relative value less than 3%, which indicates good stability of Me2-CA-BTP/SiO2-P.

Effect of γ absorption dose on a TOC in the liquid phase, b adsorption towards 241Am(III) and 152Eu(III) after irradiated in 0.01 M HNO3–0.99 M NaNO3 solution (γ irradiation conditions: Co-60 source, dose rate: 1 kGy/h, V/M: 15 mL/0.3 g; TOC test conditions: diluting the liquid solution 50 times before test; Adsorption conditions: V/M: 2.5 mL/0.05 g, [M]: 1000 Bq/mL, Temp.: 25 °C, time: 24 h, shaking speed: 300 rpm, medium: 0.01 M HNO3–0.99 M NaNO3)

Me2-CA-BTP/SiO2-P after irradiation was also used to adsorb 241Am(III) and 152Eu(III) from 0.01 M HNO3–0.99 M NaNO3 solution (Fig. 4b). Compared with fresh Me2-CA-BTP/SiO2-P without irradiation corresponding to the absorption dose of 0 kGy, Me2-CA-BTP/SiO2-P after irradiation exhibited no obvious difference in 241Am(III) and 152Eu(III) adsorption with the uptake rates almost unchanged as the absorption dose increase.

Both UV and UPLC/Q-TOF-MS were further used to analyze Me2-CA-BTP/SiO2-P after irradiation. Fresh Me2-CA-BTP/SiO2-P was used as a standard sample. Acetonitrile (CH3CN) was used to dissolve Me2-CA-BTP in the adsorbent while SiO2-P couldn’t be dissolved. The overall absorption value and intensity increased with initial Me2-CA-BTP concentration shown in Figs. 5a and 6a. For UV analysis, the absorption peak at 232.8 nm is contributed to π → π∗ transition of electrons from aromatic cycles, which is similar with that of CyMe4-BTP, BTP-4Me, and iPr-BTP [22, 23] and is used as a characteristic peak for quantitative analysis. The absorption value at 232.8 nm versus Me2-CA-BTP concentration is shown in Fig. 5b where a linear line is obtained and used for the retention calculation of Me2-CA-BTP after irradiation. The UV spectra of Me2-CA-BTP/SiO2-P after irradiation in 0.1 M HNO3, 0.01 M HNO3–0.49 M NaNO3, 0.01 M HNO3–0.99 M NaNO3 are shown in Fig. 5c–e respectively that the UV spectra of Me2-CA-BTP/SiO2-P are almost consistent with that of fresh Me2-CA-BTP/SiO2-P. The retention contents of Me2-CA-BTP/SiO2-P after irradiation were obtained according to the standard curve in Fig. 5b with the values over 90% shown in Fig. 5f.

UV spectra of Me2-CA-BTP a Effect of Me2-CA-BTP concentration, b absorption value at 232.8 nm versus Me2-CA-BTP concentration, c irradiated in 0.1 M HNO3 solution, d irradiated in 0.01 M HNO3–0.49 M NaNO3 solution, e irradiated in 0.01 M HNO3–0.99 M NaNO3 solution, f effect of γ absorption dose on Me2-CA-BTP/SiO2-P retention (γ irradiation conditions: Co-60 source, dose rate: 1 kGy/h, V/M: 15 mL/0.3 g; UV tests: 13.2 mg/L Me2-CA-BTP in CNCH3)

UPLC/Q-TOF-MS test resuts of Me2-CA-BTP. a Effect of Me2-CA-BTP concentration, b integral area of M/Z = 482.30 versus Me2-CA-BTP concentration, c mass spectra of Me2-CA-BTP, d elution curve of Me2-CA-BTP/SiO2-P irradiated in 0.1 M HNO3 solution, e elution curve of Me2-CA-BTP/SiO2-P irradiated in 0.01 M HNO3–0.49 M NaNO3 solution, f effect of γ absorption dose on Me2-CA-BTP/SiO2-P retention (γ irradiation conditions: Co-60 source, dose rate: 1 kGy/h, V/M: 15 mL/0.3 g; UPLC/MS-Q-TOF test: 13.2 mg/L Me2-CA-BTP in CH3CN)

For UPLC/Q-TOF-MS analysis (Fig. 6), the mass-to-charge ratios of 509.25 and 482.30 shown in Fig. 6c are corresponding to (2Me2-CA-BTP + 3H2O + 2H+)/2 and Me2-CA-BTP + H+ respectively, and herein M/Z = 482.30 is used for the retention calculation of Me2-CA-BTP with the standard curve of integral area versus concentration shown in Fig. 6b. The UPLC/Q-TOF-MS analysis of Me2-CA-BTP/SiO2-P after irradiation in 0.1 M HNO3, 0.01 M HNO3–0.49 M NaNO3 are shown in Fig. 6d, e respectively that the elution curves of Me2-CA-BTP/SiO2-P are almost consistent with that of fresh Me2-CA-BTP/SiO2-P. The retention contents of Me2-CA-BTP are over 90% in different mediums shown in Fig. 6f. In summary, the results above indicate good γ-irradiation stability of Me2-CA-BTP/SiO2-P in 0.1 M HNO3 or low acid-NaNO3 solution.

Column experiments

The column separation behaviors of Me2-CA-BTP/SiO2-P towards 241Am(III) and Ln(III) in the feed solutions of both 0.01 M HNO3–0.34 M NaNO3 and 0.1 M HNO3 mediums were studied with the results shown in Fig. 7, Tables 1 and 2. The effluent was collected since the feed liquid began to be pumped into the column, so the effluent in step A was corresponding to the residual solution in the column used for pre-equilibrium. As seen, Me2-CA-BTP/SiO2-P exhibited almost no adsorption towards Y, La, Ce, Nd, Sm, Eu, Gd that they almost all flew out with the feed solution in step B and scrubbing solution of 0.1 M HNO3 in step C. While it exhibited part adsorption towards Dy, although most of Dy flew out in step B, C, and D, but there were still few parts left in step E. But considering there are almost no Ln(III) heavier than and including Dy in HLLW, so the problem caused by Dy during MA(III) separation is almost negligible [24]. Finnally, Me2-CA-BTP/SiO2-P exhibited good adsorption towards 241Am that almost no 241Am flew out in steps B, C, D. 241Am was completely desorbed and separated from the other fission products Ln in step E using 0.001 M HNO3–0.01 M DTPA (aminopolycarboxylate complexantdiethylenetriamine-N,N,N′,N″,N″-pentaacetic acid). DTPA is a kind of actinide holding hydrophilic reagents and can strong complex with An(III) which has been widely used in the TALSPEAK (Trivalent Actinide Lanthanide Separation by Phosphorus Extractants and Aqueous Complexes) process [14]. A high recovery yield of 241Am was achieved with the value nearly 100% shown in Tables 1 and 2. The results above indicate Me2-CA-BTP/SiO2-P has the possibility to separate MA(III) from Ln(III), especially in the case of 0.1 M HNO3 which makes it possible to establish an almost salt-free Ln&MA separation process.

Column experiment results of separating 241Am(III) from a 0.01 M HNO3–0.34 M NaNO3, b 0.1 M HNO3 simulated HLLW by Me2-CA-BTP/SiO2-P at 308 K (column: Φ5 mm * 50 cm, 5 g Me2-CA-BTP/SiO2-P, Temp.: 308 K, liquid flow rate: about 0.2 mL/min, A: 0.01 M HNO3–0.34 M NaNO3, B: 0.01 M HNO3–0.34 M NaNO3–2 mM Ln(III)–500 Bq/mL 241Am(III) for (a) and 0.1 M HNO3–2 mM Ln(III)–500 Bq/mL 241Am(III) for (b), C: 0.1 M HNO3, D: 0.01 M HNO3, E: 0.001 M HNO3–0.01 M DTPA)

Conclusions

To reduce the long-term radiotoxicity of HLLW, macroporous silica-polymer based adsorbent Me2-CA-BTP/SiO2-P was used for separating 241Am(III) from lanthanides in nitrate medium. It exhibited good adsorption selectivity towards 241Am(III) and 239Pu(IV) over 152Eu(III) with the uptake rates of 241Am(III) and 239Pu(IV) over 97% meantime in a wide nitric acid solution, such as 0.5–2 M, while almost no adsorption towards 238U(VI). In the case of Me2-CA-BTP/SiO2-P adsorbing 241Am(III) in 0.1 M HNO3 solution, it took about 1 h to reach equilibrium and also kept high SFAm/Eu with the value over 75. In both 0.1 M HNO3 and 0.01 M HNO3–0.34 M NaNO3 feed solutions, 241Am(III) was successfully separated from lanthanides by column experiment and high recovery yield over 98.55% was obtained meantime. Furthermore, Me2-CA-BTP/SiO2-P kept high effective content with the value over 90% and exhibited no decrease in adsorption selectivity towards 241Am(III) and 152Eu(III) in 0.1 M HNO3 and 0.01 M HNO3–NaNO3 mediums when the Co-60 γ absorption dose was as high as 207 kGy at the dose rate of 1 kGy/h. In a word, Me2-CA-BTP/SiO2-P is a very promising candidate for separating MA from Ln that even a soft free separation Ln&MA process can be established such as from 0.1 M HNO3 based on it.

References

Ozawa M, Sano Y, Tanaka Y (2000) CMPO-TRUEX process and its application in the separation of actinides from high-level liquid wastes. Min Process Extr Metall Rev 21:249–275

Wang Z, Huang H, Ding S, Hu X, Zhang L, Liu Y, Song L, Chen Z, Li S (2017) Extraction of trivalent Americium and Europium with TODGA homologs from HNO3 solution. J Radioanal Nucl Chem 313:309–318

Ekberg C, Fermvik A, Retegan T, Skarnemark G, Foreman MRS, Hudson MJ, Englund S, Nilsson M (2008) An overview and historical look back at the solvent extraction using nitrogen donor ligands to extract and separate An(III) from Ln(III). Radiochim Acta 96:225–233

Chen J, Zhu Y, Jiao R (1996) The Separation of Am from lanthanides by purified cyanex 301 extraction. Sep Sci Technol 31:2723–2731

Jianchen W, Chongli S (2001) Hot test of trialkyl phosphine oxide (TRPO) for removing actinides from highly saline high-level liquid waste (HLLW). Solv Extr Ion Exch 19:231–242

Panak PJ, Geist A (2013) Complexation and extraction of trivalent actinides and lanthanides by triazinylpyridine N-donor ligands. Chem Rev 113:1199–1236

Ning S, Zhang W, Yu S, Zhang S, Zhou J, Wang X, Wei Y (2019) Selective separation of MA(III) from Ln(III) by highly stable silica-polymer-based N-donor IsoBu-BTP/SiO2-P adsorbent. Extr Ion Exch 37(2):126–139

Ekberg C, Lofstrom-Engdahl E, Aneheim E, Foreman MR, Geist A, Lundberg D, Denecke M, Persson I (2015) The structures of CyMe4-BTBP complexes of americium(iii) and europium(iii) in solvents used in solvent extraction, explaining their separation properties. Dalton Trans 44:18395–18402

Afsar A, Harwood LM, Hudson MJ, Distler P, John J (2014) Effective separation of Am(III) and Eu(III) from HNO3 solutions using CyMe4-BTPhen-functionalized silica-coated magnetic nanoparticles. Chem Commun (Camb) 50:15082–15085

Stefanovsky SV, Skvortsov IV, Belova EV, Rodin AV (2017) Study of thermal and radiation stability of the extractant based on CMPO in fluorinated sulfones. MRS Adv 2:641–647

Yuan W, Wang C, Ao Y, Zhao L, Shi W, Zhai M (2016) γ-Radiation effect on Th4+ extraction behaviour of TODGA/[C2mim][NTf2]: identification and extractability study of radiolytic products. RSC Adv 6:7626–7632

Mincher BJ, Mezyk SP, Elias G, Groenewold GS, Riddle CL, Olson LG (2013) The radiation chemistry of CMPO: part 1. Gamma radiolysis. Solv Extr Ion Exch 31:715–730

Li W, Duan W, Sun T, Liu C, Wang J, Chen J (2017) Denitration of simulated high-level liquid waste by formic acid for the connection of PUREX process with TRPO process. J Radioanal Nucl Chem 314:221–229

Veliscek-Carolan J (2016) Separation of actinides from spent nuclear fuel: a review. J Hazard Mater 318:266–281

Schmidt H, Wilden A, Modolo G, Bosbach D, Santiago-Schübel B, Hupert M, Švehla J, Grüner B, Ekberg C (2016) Gamma radiolysis of the highly selective ligands CyMe4BTBP and CyMe4BTPhen: qualitative and quantitative investigation of radiolysis products. Procedia Chem 21:32–37

Modolo AWG, Kaufholz P, Bosbach D, Geist A (2014) Development and demonstration of innovative partitioning processes (i-SANEX and 1-cycle SANEX) for actinide partitioning. Prog Nucl Energy 72:107–114

Ning SY, Wang XP, Zou Q, Shi WQ, Tang FD, He LF, Wei YZ (2017) Direct separation of minor actinides from high level liquid waste by Me2-CA-BTP/SiO2-P adsorbent. Sci Rep 7:14679

Ning S, Wang X, Liu R, Wei Y, He L, Tang F (2015) Evaluation of Me2-CA-BTP/SiO2-P adsorbent for the separation of minor actinides from simulated HLLW. J Radioanal Nucl Chem 303:2011–2017

Ning S, Zou Q, Wang X, Liu R, Wei Y (2016) Adsorption behavior of Me2-CA-BTP/SiO2-P adsorbent toward MA(III) and Ln(III) in nitrate solution. Sci China Chem 59:862–868

Ning S, Zou Q, Wang X, Liu R, Wei Y, Zhao Y, Ding Y (2016) Evaluation study on silica/polymer-based CA-BTP adsorbent for the separation of minor actinides from simulated high-level liquid wastes. J Radioanal Nucl Chem 307:993–999

Hoshi H, Wei YZ, Kumagai M, Asakura T, Morita Y (2006) Separation of trivalent actinides from lanthanides by using R-BTP resins and stability of R-BTP resin. J Alloys Compd 408–412:1274–1277

Dupont C, Hill C, Suzenet F, Guillaumet G (2013) Influence of an alkoxy group on bis-triazinyl-pyridines for selective extraction of Americium(III). Solv Extr Ion Exch 31:253–268

Sebastian Höfener MT, Koke Carsten, Heuser Johannes, Ekström Ulf, Skerencak-Frech Andrej, Schimmelpfennig Bernd, Panak Petra J (2016) Computing UV vis spectra using a combined molecular dynamics and quantum chemistry approach bis-triazin-pyridine (BTP) ligands studied in solution Phys. Chem Chem Phys 18:7728–7736

Halleröd J, Ekberg C, Authen T, Bertolo L, Lin M, Grüner B, Švehla J, Wagner C, Geist A, Panak P, Aneheim E (2018) On the basic extraction properties of a phenyl trifluoromethyl sulfone-based GANEX system containing CyMe4-BTBP and TBP. Solv Extr Ion Exch 36:360–372

Acknowledgements

This work was supported by the National Natural Science Foundation of China (11705032, 11675102); and the Natural Science Foundation of Guangxi Province (2017GXNSFBA198175); and the Science and Technology Major Project of Guangxi Province (AA17204100).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ning, S., Zhang, S., Zhou, J. et al. Salt-free separation of 241Am(III) from lanthanides by highly stable macroporous silica-polymer based Me2-CA-BTP/SiO2-P adsorbent. J Radioanal Nucl Chem 322, 1023–1030 (2019). https://doi.org/10.1007/s10967-019-06777-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-019-06777-2