Abstract

A simple one-step micelle-mediated extraction, commonly called cloud point extraction, method was developed for the preconcentration of vanadium in red, brown and green seaweeds. The recovery of vanadium under the optimized conditions of pH 3.7, [PAN/TAN] = 1×10−4 M, [PONPE-20] = 0.1% (m/v), ionic strength = 0.05 M KNO3, and a temperature of 41 °C was > 99%. Vanadium was assayed by neutron activation analysis using the Dalhousie University SLOWPOKE-2 reactor facility. The detection limits for vanadium varied from 0.6 to 3.9 µg kg−1 depending on the sample. The method was validated using certified reference materials. Mass fractions of vanadium in seaweeds ranged from 0.009 to 55.4 mg kg−1.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Vanadium is the 20th most abundant element in earth’s crust. It is present almost everywhere in nature as well as in many man-made materials. Anthropogenic sources of vanadium include fossil fuel combustion, steel manufacturing, and usage as a catalyst in many industrial processes. It is yet to be recognized as an essential trace element for humans [1], although its role for animals has been known for some time [2, 3]. In humans, vanadium is reported to influence glucose and carbohydrate metabolism, insulin receptivity, serve as a cofactor for enzymes such as haloperoxidase and nitrogenase, inhibit lipid breakdown, and prevent vascular diseases, among other beneficial features [4,5,6]. Vanadium can bioaccumulate and undergo biomagnification thereby increasing its toxic effects. The toxicity of vanadium at relatively high levels in animals is known but its biochemical, hematological, mutagenic and carcinogenic effects on humans have not yet been that extensively reported. It is known that the inorganic physicochemical forms of vanadium are more toxic than their organic counterparts, and the order of toxicity for inorganic vanadium is V(V) > V(IV) > V(III). Extensive reviews and articles of the essentiality and toxicity of vanadium and its compounds have been published such as in [7,8,9]. Analytical methods of high accuracy, precision, and sensitivity are required for the measurement of very low mass fractions of vanadium in diverse matrices to assess its background values and essentiality as well as its extent of contamination and toxicity.

In many countries, particularly in Asia, seaweeds are commonly used as dietary condiments and supplements. For example, the average daily dietary intakes of seaweeds by Japanese men and women have been quoted as 10.5 and 10.2 g (wet weight), respectively. Fukushima and Chatt measured vanadium levels of 22.2 and 19.7 mg kg−1 (wet weight) in Japanese tangle and hijiki seaweeds, respectively [10]. On the other end of the spectrum, seaweeds are being considered as biomonitors of toxic pollutants in water [11,12,13]. Brown seaweeds are of particular interest in the present work for monitoring vanadium pollution around the southern shore of Ghana [14].

Among the non-destructive (i.e. without any chemical pretreatment) techniques neutron activation analysis (NAA), X-ray fluorescence (XRF) [15], and particle-induced X-ray emission (PIXE) [16] have been successfully used in the past for measuring vanadium mass fractions in archaeological, biological, biomedical, environmental and industrial materials. Vanadium can be conveniently determined by various forms of NAA. The 51V isotope (natural abundance 99.75%, cross section of 4.88 ± 0.04 b) can absorb thermal neutrons to produce the short-lived nuclide 52V (3.74 min) which emits the interference-free 1434.1-keV (100% intensity) gamma-ray. Instrumental NAA (INAA) is perhaps the most frequently used non-destructive technique for the determination of vanadium in a variety of materials [17,18,19,20,21,22,23,24,25,26,27]. However, conventional INAA methods cannot be easily applied to measure nanogram levels of vanadium in presence of percentage levels of elements such as Na, Cl, Al, and Mn due to spectral interferences. Alternatively, INAA in conjunction with anticoincidence counting (INAA-AC) can be advantageously used. Several INAA-AC methods have previously been successfully developed in our laboratory for the determination of elements including vanadium with high precision, accuracy, sensitivity, and rapidity [28,29,30,31,32,33,34,35,36,37,38]. Zhang and Chatt reported that “the detection limits for vanadium were decreased by factors of 3–5 in INAA-AC (0.61–9.4 µg kg−1) compared to conventional INAA (1.9–79 µg kg−1)” [36] for samples containing high levels of the interfering elements mentioned above. Several excellent radiochemical NAA (RNAA) methods have also been reported in the literature [39,40,41,42,43,44]. The main advantage of RNAA of course is its freedom from reagent blanks. The short half-life (3.74 min) of 52V makes routine chemical separation of radioactive samples within a short time difficult. Alternatively, a number of preconcentration NAA (PNAA) methods have been developed to separate vanadium from interfering elements prior to irradiation [45,46,47,48,49,50]. In PNAA, like all other pretreatment methods, one may encounter reagent blanks which can adversely affect vanadium determination at very low levels if proper precautions are not taken. Although cloud point extraction (CPE) to preconcentrate trace elements is attractive, in the past it has not been used much in combination with NAA [51].

The theory and applications of CPE have been reviewed by several authors [52,53,54] and covered in our own publications [14, 51, 55,56,57] as well as by others, and therefore will not be further dealt with here. It is important to note that CPE is a green method. Several CPE methods coupled to NAA (CPE–NAA) have been developed in our laboratory for both single-element and simultaneous multielement determinations which include antimony, arsenic, cadmium, chromium, cobalt, copper, lead, manganese, mercury, nickel, zinc and the lanthanides. There are many papers in the literature dealing with vanadium such as in [58,59,60,61,62,63]. Although several techniques such as HPLC-ICP-MS, ICP-MS, IDMS, ICP-AES, ICP-OES, F-AAS, ET-AAS, spectrophotometry, etc. have been used in the past for measuring vanadium and ICP-MS/MS [64] for lanthanide levels in diverse matrices, spectrophotometry appears to be the choice of many researchers. The advantages of using spectrophotometry are well documented; however, it cannot be used for multielement determination, and lower detection limits for vanadium can be achieved by other techniques such as NAA. The objective of the study described here was to develop a simple one-step CPE–NAA method for the determination of sub-ppb levels of vanadium in seaweed samples.

Materials and methods

Chemicals, reagents, standards, reference materials, irradiations, and gamma-ray spectrometry systems

The purity and suppliers of all chemicals and reagents used in the CPE procedure have been described elsewhere in detail [14, 56]. For the sake of completeness of this paper only the relevant items are repeated below. The high-purity chemicals used were: polyoxyethylene nonylphenylether with 20 oxyethylene units (PONPE-20), 1-(2-pyridylazo)-2-naphthol (PAN), 1-(2-thiazolylazo)-2-naphthol (TAN), citric acid, diammonium hydrogenphosphate, tris-[hydroxymethyl]aminomethane (TRIZMA base), redistilled 70% HNO3 (99.999 purity), ammonia solution, sucrose, and KNO3. All chemicals and reagents were analyzed by INAA for reagent blanks.

High-purity vanadium plasma emission grade standard solution of 1 000 mg kg−1 was used to prepare a stock solution with 2 M HNO3 in a 100-mL volumetric flask. The working comparator vanadium standard solutions were prepared from the stock solution at pH < 3 in order to avoid adsorption problems [51]; they were placed in dark bottles with Teflon caps; and stored at 4 °C to avoid evaporation. Finally, the comparator vanadium standard was prepared by transferring 200 µL of the working standard directly onto a finely ground sucrose support in a precleaned 1.5-mL polyethylene vial using a calibrated Eppendorf pipette. The vial with its content was dried for 2 days in a fumehood. All samples and standards were irradiated in precleaned polyethylene vials which were cleaned by soaking them in 2 M ultrapure HNO3 for 2 days, rinsing thoroughly with DDW and drying at 30 °C. A temperature-controlled water bath with an absolute standard deviation of ± 0.1 °C and a pH meter with a precision of ± 0.2 pH units at 25 °C were used for the cloud point experiments.

Three certified reference materials (CRM), namely NIES-CRM No. 9 Sargasso, NIST-SRM 1547 Peach Leaves and NIST-SRM 1515 Apple Leaves were obtained from the National Institute for Environmental Studies (NIES) Japan and the National Institute of Standards and Technology (NIST) U.S.A. in this work to validate the CPE–NAA method.

All samples, vanadium comparator standards, and reference materials were irradiated in a fission neutron flux of 2.5 × 1011 cm−2 s−1 in an inner pneumatic site of the Dalhousie University SLOWPOKE-2 Reactor (DUSR) facility. The timing parameters for vanadium determinations were: irradiation time (ti) of 1 min, decay time (td) of 1 min and the counting time (tc) of 10 min.

All irradiated materials were counted using a conventional gamma-ray spectrometry system consisting of a 60-cm3 APTEC Ge(Li) detector with a resolution of 1.9 keV at the 1332-keV photopeak of 60Co, a peak-to-Compton ratio of 35:1, and relative efficiency of 9.5%. This detector was used in conjunction with an ORTEC D-spec Plus multichannel analyzer. The vanadium content was assayed using the interference-free 1434.1-keV gamma-ray of 52V, as mentioned above.

Seaweed samples, and digestion, generalized extraction and drying procedures

The details of the sample collection procedure are given elsewhere [14, 65]. Briefly, 15 samples of seaweed were collected between 2003 September and 2004 November from Ghanaian coast. The samples were washed with distilled deionized water (DDW), dried in an oven at 40 °C, homogenized using a pre-cleaned milling machine, and sieved through an 85-mesh USA standard testing sieve.

The seaweed samples and CRMs needed to be digested prior to CPE. The microwave digestion procedure has previously been developed by Rao and Chatt [66] and also described by the present coauthors [14, 56]. Briefly, about 250 mg of dried material were digested with 5 mL of concentrated HNO3 in a precleaned 45-mL Teflon cup of a microwave acid digestion bomb. The contents were transferred to a precleaned 500-mL beaker with DDW, evaporated to dryness under an infrared lamp, redissolved in about 100 mL DDW, and used for CPE.

In order to study the influence of various parameters on the CPE of trace elements of interest, a generalized procedure was developed and followed [56]. For the sake of completeness of this paper this procedure is repeated below with minor modification for vanadium. The procedure for vanadium consisted of the following steps: (1) addition of 0.2 g of 20% (m/v) PONPE-20 surfactant solution, 0.75 mL of Trizma-HNO3 buffer containing 0.05 M KNO3, 0.5 mL of each of PAN and TAN ligand solutions, 0.1 mL of the vanadium comparator standard solution, 20–30 mL of the microwave-digested sample solution, and DDW up to a total volume of 40 mL; (2) equilibration of the mixture for 2 min on a mechanical shaker; (3) keeping it in a constant-temperature bath at 41 °C for 10 min; (4) centrifugation at 3500 rpm for 10 min; and (5) cooling it in an ice-NaCl bath for 5 min. The upper aqueous phase was pipetted off and its pH measured. The surfactant-rich phase, which settled at the bottom of the centrifuge tube, was transferred to a 1.5-mL polyethylene irradiation vial.

The volume of the surfactant-rich phase was reduced. First, freeze-drying of samples for 20 h was tried and found to be effective; however, a little bit of solution spilled out of the vials during drying. The loss of analyte and possibility of cross-contamination were considered as the main disadvantages of the freeze-drying process. In the second option, the surfactant-rich extract in 1.5-mL polyethylene vials was dried under infrared light for about 3 h, cooled for 8 h followed by drying in a fumehood for 8 h. This combined method of sequential heating and cooling gave satisfactory results and was used regularly. The dried samples were analyzed by NAA for vanadium.

Results and discussion

Optimization of parameters affecting CPE

In order to obtain the maximum extraction efficiency of vanadium by the CPE method, a number of experimental factors was investigated using vanadium standard solutions. The parameters of interest were: pH, ionic strength, equilibration temperature, concentrations of chelating agents (PAN and TAN), concentration of surfactant (PONPE-20), sample volume, and type as well as concentrations of foreign ions. In the studies detailed below factors such as vanadium concentration (20 µg mL−1), total volume (40 mL), stirring time (2 min), and centrifugation speed (3500 rpm) as well as time (10 min) were kept constant. Mass fractions of vanadium were determined by NAA.

For ionizable solutes, the charge of the solute can greatly influence its extent of binding to micellar assembly. The ionic form of a molecule normally does not interact and bind with the micellar aggregate as strongly as its neutral form. The formation of a hydrophobic metal complex which can be extracted in the surfactant-rich phase is essential. Thus, the selection of the solution pH is of special importance when controlling the experimental variables in CPE. For these reasons, the pH of the sample solution was one of the factors to be evaluated first. A general study of the influence of pH on extraction recovery was done keeping other variables constant. The pH was varied from 1.0 to 9.0 and five measurements were done at each pH value. The variation of the extraction recovery (± 2σ) on pH for vanadium is shown in Fig. 1. It is obvious from the graph that the recovery was generally poor at high pH values perhaps due to the hydrolysis of vanadate ions but was quantitative at pH between 3 and 4 with the highest recovery at 3.7. It agrees with the earlier studies done on vanadium [62]. The pH of 3.7 was therefore selected to optimize other factors for the CPE of vanadium.

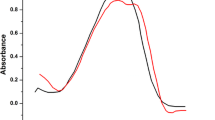

Since one of the primary requirements of a good CPE method is the formation and subsequent extraction of a stable hydrophobic metal complex in the surfactant-rich phase, it is important that the chelating agent(s) be selected carefully. There are several chelating agents, such as 8-hydroxyqinoline, bromopyrogallol red, 2-(5-bromo-2-pyridylazo)-5-diethylaminophenol (5-Br-PADAP), and oxalate ions, which can form stable complexes with vanadium and they have been used for CPE of vanadium. We knew from our previous work on CPE [51] that both TAN and PAN can form stable complexes with several metals. We were also aware of the studies which indicated that the rate of extraction for mixed hydrophobic complexes is higher compared to that of a single chelating agent [67, 68]. Therefore, it was decided to use a mixture of TAN and PAN in this work. The influence of the concentrations of TAN and PAN on the recovery of vanadium was evaluated. Concentrations of the TAN/PAN ratio was varied from 2.5 × 10−5 M to 3.5 × 10−4 M, keeping all other experimental factors constant. The results (± 2σ) are shown in Fig. 2. There was a very high percent recovery of vanadium (99.8 ± 2.0%) at a [TAN/PAN] ratio of 1 × 10−4 M which was selected for this work.

Among the micellar systems used by various researchers, perhaps Triton X-114 followed by Triton X-100 are most popular for CPE of trace elements. For the extraction of vanadium Triton X-114, PONPE-7.5, Brij35 and Tween20 have been used. We had very good experience with PONPE-20 for the extraction of several trace elements from water [51]. It has a low cloud point temperature, and the surfactant-rich phase has a high density which becomes viscous on cooling which in turn makes the phase separation by centrifugation rather simple and very effective. So it was selected for studies on CPE of vanadium. The effect of PONPE-20 on the extraction efficiency was investigated for the concentration range of 0.05–0.30% with an interval of 0.05%. The results (± 2σ) presented in Fig. 3 clearly show a sharp increase in the percent recovery of vanadium (99.7 ± 2.0%) from 0.05 to 0.1%. The recoveries at other concentrations show only a slight decrease but were always above 90% perhaps due to a large capacity of the micelle and the surfactant-rich phase for the vanadium-TAN-PAN mixed ligand complex. A concentration of 0.1% of PONPE-20 was selected for the optimization of other parameters.

There exists a difference of opinion among researchers regarding the effect of ionic strength on CPE. Some suggested that ionic strength had negligible effect [51], others reported poor phase separation [69] while the rest preferred to use high concentrations (1–5 M) of salts as clouding agents [70]. In the present study, the ionic strength of the solutions was varied from 0.005 M to 0.25 M with respect to KNO3. The results (± 2σ) shown in Fig. 4 indicate that an order of a magnitude increase in the electrolyte strength from 0.005 M to 0.05 M gave the highest percent recovery (99.6 ± 2.8%) of vanadium; then the recovery remained constant within experimental errors but later decreased by about 10% at the highest concentration of 0.25 M KNO3. Very high concentrations of KNO3, viz. 0.10 and 0.20 M, created problems for NAA. The radioactivity due to the 1525-keV gamma-ray of 42K produced by the reaction 41K(n,γ)42K increased the background of the gamma-ray spectrum substantially making it difficult to determine low vanadium levels through the 1434.1 keV gamma-ray of 52V. For this reason, the concentration of KNO3 was kept at 0.05 M in the present work.

The effect of temperature on CPE has been discussed detail in our previous publications [14, 51, 55,56,57] as well as by others [68, 71], and will not be repeated here. To study the influence of temperature on the efficiency of the extraction procedure for vanadium using PONPE-20 micellar solution, six temperature values, namely 25, 30, 36, 41, 46 and 50 °C, were selected in this work. As the results (± 2σ) in Fig. 5 show, the percent recovery of vanadium (99.2 ± 1.3%) was quantitative and reproducible at 41 °C; it was therefore chosen for the extraction of vanadium.

It is evident from the above experiments, results and discussions that the optimized CPE method for vanadium is to carry out the extractions at a pH of 3.7, temperature of 41 °C, ionic strength of 0.05 M KNO3, concentration ratio of 1 × 10−4 M of the chelating agents (PAN/TAN) and the surfactant concentration PONPE-20 of 0.1% (m/v).

Analytical quality control parameters

Vanadium content of the blanks and chemical reagents were determined by NAA. Reagents could be sources of contamination in any analytical measurement. All reagents used in this work were of the highest commercially available purity, as mentioned above. Additionally, empty vials, sucrose, chemical reagents, and deionized–distilled water (Milli-Q grade) were all irradiated, allowed to decay and counted using the same timing schemes as used for the seaweed samples, and no vanadium was detected in any one of them. The total reagent blank for the entire CPE method was also below the detection limit (viz. 0.6 µg kg−1) for vanadium under the experimental conditions used.

Sample handling could be another source of contamination. Strict precautions were taken to minimize sample handling as much as possible. It has already been mentioned that all apparatus was thoroughly washed and rinsed prior to use. The CPE method developed in this work involves only one step where a contamination may possibly occur. This is during the transfer of the extracted sample in the surfactant-rich phase form the centrifuge tube to the 1.5-mL polyethylene vial. This phase was poured directly into the vial without using any pipette. The centrifuge tube was washed with DDW using a pipette, which may be another source of contamination. Since the total blank for vanadium was below its detection limit, the possible contribution from contamination was considered insignificant.

Internal quality assessment was routinely undertaken in this work. Vanadium standard solutions were irradiated along with the samples. Irradiations were done on per batch basis and in between samples. The precision of the sets of replicate samples was evaluated with the use of quality control (QC) charts, namely Schewart control chart. Vanadium standard solutions were analyzed using the same irradiation, decay and counting conditions employed in the analysis of the seaweed samples, i.e. ti:td:tc = 1:1–10:10 min. The mean (X) and the standard deviation (σ) were calculated, and the control and warning limits were set as the X ± 2σ and X ± 3σ intervals, respectively. It was found that 80% of the 20 measurements were within ± 1σ while 20% were within ± 2σ. It is evident that the system operated under a very good statistical control.

In order to validate the CPE–NAA method, five replicate analyses of the following three certified reference materials were carried out: BCR-CRM No. 9 Sargasso, NIST-SRM 1547 Peach Leaves, and NIST-SRM 1515 Apple Leaves. The precision (expressed as % relative standard deviation) of the methods were within ± 10%. The measured results along with the certified values for each of the reference materials are presented in Table 1. The agreement between the results obtained in this work and the certified values form the issuing agencies was very good.

The sensitivity for vanadium under the NAA experimental conditions given above was 1072 counts µg−1. The detection limit, LD, as defined by Curie [72] was 0.01 mg kg−1 by INAA. The detection limits for vanadium after CPE varied from 0.6 to 3.9 µg kg−1 depending on the sample. The average detection limit after CPE was 1.51 µg kg−1. These suggest that CPE using two chelating agents and NAA can be a useful tool for the determination of very low levels of vanadium in environmental samples with complex matrix. Detection limits reported recently by other researchers include 16 µg kg−1 for vanadium using ICP-OES [62] and 1.4 ng mL−1 by spectrophotometry [58].

Preconcentration factor is an important parameter for evaluating the extraction capability of a micellar system for metal species. Assuming a quantitative transference (recovery) of analyte(s) into the micellar phase, this parameter can represent a convenient way to assess the preconcentration process. The preconcentration factor (PF) can be defined as the ratio between the original matrix sample volume (Vmatrix) and the surfactant-rich phase volume (Vs), i.e. PF = (Vmatrix/Vs). However, if the mass transference of the metal into the micellar phase is not quantitative, it would be better to use enrichment factor, EF [73]. Typical PFs reported in the literature for trace elements varied from 10 to 100 [51]. An average preconcentration factor of 89 was obtained for the CPE method developed in this work for vanadium.

CPE-NAA method for vanadium in seaweeds

Based on successful results obtained for the optimization procedure, the CPE method developed was applied to preconcentrate vanadium from the seaweed samples. The gamma-ray spectrum of Polycavernosa dentata seaweed after CPE (ti:td:tc = 1:1:10 min) is presented in Fig. 6. It is evident from the spectrum that the separation is extremely efficient where the 1434.1-keV gamma-ray of 52V is the only quantifiable photopeak. The barely detectable photopeak of 28Al at 1779 keV was from the polyethylene irradiation vials used in this work.

It has been mentioned before that foreign ions can interfere with the extraction of the element of interest. The Polycavernosa dentata is a Rhodophyta (red) species of seaweed which was collected from industrial areas of the Ghanaian coast and analyzed by INAA in a previous study [65]. This seaweed is known to concentrate many elements at fairly high levels. The average mass fractions (mg kg−1 unless otherwise noted, dry weight, n = 5) of some of the elements determined by INAA [65] were: Al (1950 ± 80), As (20.2 ± 0.9), Br (935 ± 64), Ca % (0.35 ± 0.01), Cl % (8.95 ± 0.05), Co (12.2 ± 0.3), Cr (0.55 ± 0.02), Cu (10.7 ± 0.4), Fe (3950 ± 89), Hg (0.20 ± 0.01), I (410 ± 19), K % (6.2 ± 0.2), Mg % (1.42 ± 0.09), Mn (1.42 ± 0.09), Na % (1.86 ± 0.07), Ni (20.1 ± 0.3), and Zn (28.5 ± 2.2). The gamma-ray spectrum (Fig. 6) of this seaweed does not show the photopeaks of the neutron activation products of any of these elements. The vanadium recovery of the CPE of this seaweed was > 99%. Therefore it can be safely concluded that even the high concentrations of the ions of the above elements do not interfere with the vanadium recovery.

The real advantage of using the CPE-NAA method for vanadium determination in seaweeds is evident from the three lowest values (mg kg−1) obtained: 0.009 ± 0.001 (Enteromorpha flexuosa), 0.038 ± 0.002 (Sargassum vulgare), and 0.042 ± 0.003 (Hypnea musciformis), as shown in Table 2. These three species of green, brown and red seaweeds, respectively, perhaps do not accumulate vanadium or were not exposed to contaminated water. Nevertheless, their concentrations could not have been measured by INAA and other instrumental techniques. A chemical separation prior to detection is obviously necessary. The CPE–NAA method developed here is simple and provides a very low detection limit.

A discussion on the relevance of elemental concentrations of seaweed species in relation to marine pollution studies is beyond the scope of this paper and has been done elsewhere [14, 65]. With the exception of three very low values mentioned above, the range of mass fractions for vanadium was 3.0–55.4 mg kg−1 (Table 2). These values were found to be comparable to that reported in other polluted oceans of the world [74,75,76,77]. Values 8–104 mg kg−1 for vanadium found were considered as high and indicative of industrial pollution in their respective marine environments.

Conclusions

The simple one-step CPE method developed in this work for the preconcentration of vanadium using a mixture of PAN and TAN chelating agents and PONPE-20 surfactant was very useful for its determination in seaweeds. The parameters affecting the separation, namely pH, temperature, ionic strength, and concentrations of PAN/TAN and PONPE-20, were optimized. The recovery of vanadium under the optimized conditions was > 99%. Vanadium was assayed rapidly using the 1434.1-keV photopeak of the 3.75-min radionuclide 52V. The CPE-NAA method was found to give values of high precision and accuracy, and a detection limit of 1.51 µg kg−1 on the average. So the CPE-NAA method can be routinely used whenever needed.

References

Harland BF, Harden-Williams BA (1994) J Am Diet Assoc 94:891–894

Hopkins LL, Mohr HE Jr (1971) The biological essentiality of vanadium, newer trace elements in nutrition. Wiley, New York

Nielson FH (1980) In: Martell AE (ed) Inorganic chemistry in biology and medicine. American Chemical Society, Washington DC, pp 32–35

Winter JM, Moore BS (2009) J Biol Chem 28:284

Sarkar AR, Mandal S (2000) Met Based Drugs 7(3):157

Sakurai H (2008) Yakugaku Zasshi 128(3):317

Ghosh R, Banik S (2016) Dual effects of vanadium: toxicity analysis in developing therapeutic lead-ups. In: Bagshi D, Swaroop A (eds) Food toxicology. CRC Press, Boca Raton, pp 337–354

Gruzewska K, Michno A, Pawelczyk T, Bielarczyk H (2014) J Physiol Pharmacol 65:603–611

Rehder D (2013) Vanadium: its role for humans. In: Sigel RKO, Sigel A, Sigel H (eds) Interrelations between essential metal ions and human diseases. Springer, Berlin, pp 139–169

Fukushima M, Chatt A (2012) J Radioanal Nucl Chem 294:471–478. https://doi.org/10.1007/s10967-012-1713-2

Taylor SW, Kammeree B, Bayer E (1997) Chem Rev 97:333

Khristoforva NK, Kozhenkova SI (2002) Ocean Polar Res 24:325

Bryan GW (1976) Heavy metal contamination in the sea, in marine pollution. Academic Press, London, p 185

Serfor-Armah Y (2006) Studies of seaweeds as indicators of toxic element pollution in Ghana using neutron activation analysis. Ph.D. Thesis, Department of Chemistry, University of Ghana, Accra-Legon, Ghana

Buláneka R, Kaluzová A, Setnicka M, Zukal A, Cicmanec P, Mayerová J (2012) Catal Today 179:149–158. https://doi.org/10.1016/j.cattod.2011.08.044

Tamilarasu S, Velraj G, Ray DK, Acharya R (2016) J Radioanal Nucl Chem 310:363–370. https://doi.org/10.1007/s10967-016-4842-1

Nyarko BJB, Akaho EHK, Fletcher JJ, Zwicker B, Chatt A (2006) J Radioanal Nucl Chem 270:243–248

Fukushima M, Suzuki H, Saito K, Chatt A (2009) J Radioanal Nucl Chem 282:85–89

Kučera J, Bennett JW, Oflaz R, Paul RL, De Nadai Fernandes EA, Kubešová M, Bacchi MA, Stopic AJ, Sturgeon RE, Grinberg P (2015) Anal Chem 87:3699–3705. https://doi.org/10.1021/ac504094n

Bitewlign TA, Chaubey AK, Beyene GA, Melikegnaw TH, Mizera J, Kamenık J, Krausova I, Kucera J (2017) J Radioanal Nucl Chem 311:2047–2059. https://doi.org/10.1007/s10967-017-5187-0

Kamenık J, Dragounova K, Kucera J, Bryknar Z, Trepakov VA, Strunga V (2017) J Radioanal Nucl Chem 311:1333–1338. https://doi.org/10.1007/s10967-016-5101-1

Juichang R, Freedman B, Coles C, Zwicker B, Holzbecher J, Chatt A (1995) J Air Waste Manag Assoc 45:461–464

Seo D, Vasconcellos MBA, Catharino MGM, Moreira EG, de Sousa ECPM, Saiki M (2013) J Radioanal Nucl Chem 296:459–463. https://doi.org/10.1007/s10967-012-2048-8

Alsabbagh A, Khalayleh L, Dbissi M, Landsberger S (2017) J Radioanal Nucl Chem 314:141–147. https://doi.org/10.1007/s10967-017-5355-2

Mildenberger F, Mauerhofer E (2017) J Radioanal Nucl Chem 311:917–927. https://doi.org/10.1007/s10967-016-5098-5

Ho VD, Ho MD, Ha TV, Tran QT, Cao DV (2018) J Radioanal Nucl Chem 315:703–719. https://doi.org/10.1007/s10967-017-5673-4

Acharya R, Swain KK, Shinde AD, Bhamra NS, Chakrabarty K, Karhadkar CG, Singh T, Rana YS, Pujari PK, Shukla DK, Reddy JAVR (2014) J Radioanal Nucl Chem 302:1525–1530

Zhang W (1997) Ph.D. Thesis, Dalhousie University, Halifax, NS, Canada

Zhang WH, Chatt A (2000) Trans Am Nucl Soc 83:486–487

Nyarko BJB, Akaho EHK, Fletcher JJ, Chatt A (2008) Appl Rad Isot 66:1067–1072

Acharya R, Chatt A (2009) J Radioanal Nucl Chem 282:991–996

Zhang W, Chatt A (2009) J Radioanal Nucl Chem 282:139–143

Isaac-Olive K, Chatt A (2012) J Radioanal Nucl Chem 294:479–486

Zhang W, Chatt A (2013) J Radioanal Nucl Chem 296:495–501

Fukushima M, Chatt A (2013) J Radioanal Nucl Chem 296:563–571

Zhang W, Chatt A (2014) J Radioanal Nucl Chem 299:1777–1789. https://doi.org/10.1007/s10967-013-2854-7

Zhang W, Chatt A (2018) J Radioanal Nucl Chem. https://doi.org/10.1007/s10967-018-6031-x

Isaac-Olive K, Kyaw TT, Chatt A (2018) J Radioanal Nucl Chem. https://doi.org/10.1007/s10967-018-6086-8

Damsgaard E, Heydorn K, Rietz B (1973) Symposium on nuclear activation techniques in life sciences (CONF 720425), Bled, Yugoslavia, IAEA (Vienna), pp. 119–128

Orvini E, Gallorini M (1982) J Radioanal Chem 71:75–95

Byrne AR, Kucera J (1991) Fresenius J Anal Chem 340:48–52

Becker DA, Anderson DL, Lindstrom RM, Greenberg RR, Garrity KM, Mackey EA (1994) J Radioanal Nucl Chem 179:149–154

Zeisler R, Tomlin BE, Murphy KE, Kucera J (2009) J Radioanal Nucl Chem 282:69–74. https://doi.org/10.1007/s10967-009-0141-4

Kucera J, Kamenık J, Povinec PP (2017) J Radioanal Nucl Chem 311:1299–1307. https://doi.org/10.1007/s10967-016-4930-2

Blotcky AJ, Falcone C, Medina VA, Rack EP (1979) Anal Chem 51:178–182

Milley JE, Chatt A (1987) J Radioanal Nucl Chem 110:345–363

Kulathilake AI, Chatt A (1992) Trans Am Nucl Soc 65:172–173

Jayawickreme CK, Chatt A (1987) J Radioanal Nucl Chem 110:583–593

Beazley PI, Rao RR, Chat A (1994) J Radioanal Nucl Chem 179:267–276

Smolinski T, Wawszczak D, Deptula A, Lada W, Olczak T, Rogowski M, Pyszynska M, Chmielewski AG (2017) J Radioanal Nucl Chem 314:69–75. https://doi.org/10.1007/s10967-017-5383-y

Pérez-Gramatges A (1999), Simultaneous preconcentration of trace metals by cloud point extraction with 1-(2-pyridylazo)-2-naphthol and determination by neutron activation analysis. Ph.D. Thesis, Department of Chemistry, Dalhousie University, Halifax, NS, Canada

Yazdi AS (2011) Trends Anal Chem 30:918–929

Bosch Ojeda C, Sánchez Rojas F (2012) Microchim Acta 177:1–21. https://doi.org/10.1007/s00604-011-0717-x

Melnyk A, Namiesnik J, Wolska L (2015) Trends Anal Chem 71:282–292. https://doi.org/10.1016/j.trac.2015.03.013

Perez-Gramatges A, Chatt A (2006) J Radioanal Nucl Chem 269:491–497

Serfor-Armah Y, Chatt A, Carboo D, Akuamoah RK (2008) J Appl Sci Technol (JAST) 13:48–54

Perez-Gramatges A, Chatt A (2012) J Radioanal Nucl Chem 294:163–170. https://doi.org/10.1007/s10967-012-1708-z

Stefanova-Bahchevanska T, Milcheva N, Zaruba S, Andruch V, Delchev V, Simitchiev K, Gavazov K (2017) J Mol Liquids 248:135–142. https://doi.org/10.1016/j.molliq.2017.10.046

Gürkan R, Korkmaz S, Altunay N (2016) Talanta 155:38–46. https://doi.org/10.1016/j.talanta.2016.04.012

López-García I, Marín-Hernández JJ, Hernández-Córdoba M (2018) Spectrochim Acta, Part B 143:42–47. https://doi.org/10.1016/j.sab.2018.02.013

Souza VS, Teixeira LSG, Bezerra MA (2016) Microchem J 129:318–324. https://doi.org/10.1016/j.microc.2016.06.029

Wuilloud GM, de Wuilloud JCA, Wuilloud RG, Silva MF, Olsina RA, Martinez LD (2002) Talanta 58:619–627

Madrakian T, Afkhami A, Siri R, Mohammadnejad M (2011) Food Chem 127:769–773. https://doi.org/10.1016/j.foodchem.2010.12.144

Labrecque C, Lebed PJ, Lariviere D (2016) J Environ Radioact 155–156:15–22. https://doi.org/10.1016/j.jenvrad.2016.02.002

Serfor-Armah Y, Carboo D, Akuamoah RK, Chatt A (2006) J Radioanal Nucl Chem 269:711–718

Rao RR, Chatt A (1993) Analyst 118:1247–1251

Freiser BS, Freiser H (1970) Talanta 17:540–542

Paleologos EK, Giokas DL, Karayannis MI (2005) Trends Anal Chem 24:426–436

Akita S, Rovira M, Sastre AM, Takeuchi H (1998) Sep Sci Technol 33:2159–2177

Chen X, Li G, Hu Z (1996) Mikrochim Acta 122:143–149

Hancock RI (1984) Surfactants, Tadros TF (Ed) Academic Press Inc, p 297–299

Curie LA (1995) Pure Appl Chem 67:1699–1723

Bezerra MA, Arruda MAZ, Ferreira SLC (2005) Appl Spectrosc Rev 40:269–299

Vlachos V, Critchley AT, Bannatyne TE, von Holy A (1998) S Afr J Bot 64:233–237

Vasques JA, Guerra N (1996) Hydrobiologia 326(327):327–333

Sanchez-Rodriguez I, Huerta-Diaz MA, Choumiline E, Holguin-Quinones O, Zertuche-Gonzalez JA (2001) Environ Pollut 114:145–160

Wang W-X, Dei RCH (1999) Mar Biol 135:11–23

Acknowledgements

The authors would like to acknowledge with thanks the (1) award of a Fellowship by the International Atomic Energy Agency (IAEA) to Yaw Serfor-Armah for a sandwich Ph.D. program at Dalhousie University, (2) award of Discovery and Infrastructure Grants to A. Chatt by the Natural Sciences and Engineering Research Council of Canada, and (3) cooperation of the Dalhousie University SLOWPOKE-2 Reactor (DUSR) facility in carrying out the project. This paper was presented at the Eleventh International Conference on Methods and Applications of Radioanalytical Chemistry (MARC-XI) held at Kailua-Kona, Hawai’i, USA, during 2018 April 08–13.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Serfor-Armah, Y., Carboo, D., Akuamoah, R.K. et al. Micelle-mediated extraction and neutron activation determination of nanogram levels of vanadium in seaweeds. J Radioanal Nucl Chem 318, 2039–2047 (2018). https://doi.org/10.1007/s10967-018-6194-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-018-6194-5