Abstract

Copper hexacyanoferrate was imbued on pores of synthetic zeolite and the formation of needle shaped copper hexacyanoferrate microcrystals was confirmed by XRD and SEM. Batch equilibrations showed that the sorbent has good affinity for Cs and Sr which was further confirmed from column studies. It is established that a substantial amount (>8000 bed volumes) of low level waste contaminated with 137Cs and 90Sr can be treated in fixed bed column. The sorbent, owing to its low cost, simple preparation process and excellent 137Cs and 90Sr removal performance, is expected to find wide spread application in nuclear industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Large volumes of low level radioactive waste effluents containing a very low amount of dissolved solids (few hundred ppm) and traces (about 5–20 Bq/ml) of radioactivity are generated from day to day operations of various plants in a nuclear installation. These effluents are treated to concentrate radionuclides (mainly 137Cs and 90Sr) into a small volume and the large volume of decontaminated effluents are discharged to environment. According to IAEA guidelines and activity limit prescribed by AERB India, effluents with activity below 3.7 × 106 Bq/M3 qualify for discharge from plant to environment [1]. Efforts are also being made to reduce the activity release to as low as reasonably achievable (ALARA), towards zero-discharge.

Treatment of the waste usually involves in situ precipitation of transition metal hexacyanoferrate coupled with barium sulphate/phosphate and ferric hydroxide for removal of 137Cs, 90Sr and actinides [2, 3]. Ferric hydroxide precipitation serves twin objectives i.e., as a flocculating agent and as a carrier for lanthanides and actinides. This precipitation based process is not very effective for the treatment of very low active (<15 Bq/mL) effluent. Ultra filtration in combination with chemical treatment improves decontamination performance [4]. Reverse osmosis, an alternative option, has been tested on pilot plant scale in India, resulting in a decontaminated effluent (permeate) containing <1 Bq/mL from 5–20 Bq/mL waste feed [5].

Ion exchange removal of 137Cs using transition metal (Cu, Ni and Co) hexacyanoferrates (HCF) is widely investigated [6–10]. These sorbents possess very high distribution coefficient for 137Cs (~105 mL/g) [11]. However, direct applicability of these sorbents in fixed bed column mode is limited, because of their powdery consistency. Nevertheless, the sorbent has been prepared in column usable form by various techniques including in situ formation of the precipitates on porous materials like silica gel [12, 13], activated charcoal [14], PU (polyurethane) foam [15, 16], synthetic zeolite [17–20], ion exchange resins [21], etc. and in situ polymerization like PAN [22]. PU-foam loaded Cu-hexacyanoferrate (Cu-HCF) has been tested in India for the treatment of low level waste [16]. Although loading of sorbent on PU-foam is more than 80% by weight, the voluminous nature of foam limits waste processing throughput. At the Loviisa NPS, Finland, a full scale system for industrial scale removal of Cs was used with HCF exchanger and Cs decontamination factor of >2000 was obtained [9]. In a recent work in authors’ laboratory, 137Cs removal by nano sized crystals of cobalt hexacyanoferrate on anion exchange resin support has been reported [21]. But the sorbent suffers compatibility issues when spent resin immobilization in cement is considered. In this respect, inorganic matrices are the best choice and synthetic zeolite has attracted the most attention. Impregnation of Ni- hexacyanoferrate on pores of a chabazite type synthetic zeolite was reported by Mimura et al. [17]. A similar study was carried out in author’s laboratory using synthetic zeolite of 13X which has good affinity for 137Cs [23]. In addition, crystalline silicotitanate is another candidate for the said applications [24, 25]. However, its application is limited perhaps due to difficulties in bulk preparation and cost constraints.

Removal of 90Sr from low level waste streams has been attempted using inorganic sorbents like hydrous titanium oxide [26], monosodium titanates [27], sodium nonatitanates [28], hydrous manganese oxide (HMO) [29], and synthetic zeolite type 4A [18]. All these sorbents are obtained in powder form. The Sr affinity of the powder was found to reduce significantly when made into a composite and hence its application in column mode has been limited. In India, HMO loaded on PU-foam has been used successfully in column mode [16]. Synthetic zeolite of type 4A has good affinity for Sr and was used in column for treatment of about 6000 bed volumes of waste [30]. These results motivated us to attempt incorporation of Cu-HCF into the pores of 4A zeolite so that a single column can be used for simultaneous removal of 137Cs and 90Sr from low level waste streams.

Present paper reports preparation and characterization of Cu-HCF loaded on to the pores of synthetic zeolite of type 4A. It is conclusively established that a column of modified synthetic zeolite is adequate for simultaneous removal of 137Cs and 90Sr from low level waste stream.

Experimental

Materials and methods

Zeolite 4A, a synthetic zeolite of type A, was locally procured in bead form (0.3–0.8 mm) and used as such. Solutions of Copper sulphate, Potassium ferrocyanide, Sodium nitrate, Cesium nitrate and Strontium nitrate, were prepared using AR grade salts. The 137Cs used as tracer was separated from alkaline intermediate level waste as CsNO3 in 0.5 M HNO3. The 85+89Sr tracer as SrNO3 was obtained from Board of Radiation and Isotope Technology (BRIT), Mumbai.

Preparation of sorbents

Preparation of Cu-HCF on zeolite 4A pores was done as per the procedure by Mimura et al. [17]. In brief, the zeolite beads were equilibrated with 0.5 M CuSO4 solution for 24 h including solution impregnation under reduced pressure for about 15 min. The beads were then separated and air dried. Later the Cu-loaded beads were impregnated with 0.5 M K4Fe(CN)6 solution under reduced pressure for 15 min and left standing overnight. Finally, the beads, after water washing, were stored under water in a plastic bottle. This is designated as conventional procedure and the product obtained is tagged ‘4A-IC’.

A similar product, ‘4A-IM’ was synthesized after changing the procedural steps and solution concentrations. This process is designated as modified process. As compared to conventional process, two major changes have been made viz., (i) impregnation step is reversed and (ii) a reduced concentration of CuSO4 is used. A thumbnail view of the preparation process is presented in Fig. 1.

Characterization of sorbent

XRD study

Identification of crystalline phases in virgin zeolite and their modified products was carried out using X-ray diffraction studies. The X-ray diffractograms were recorded on crushed powder samples employing Cu Kα (40 kV, 30 mAmp) radiation using a Siemens D-500 X-ray diffractometer.

SEM analysis

The morphology of the precipitate loaded onto zeolite beads was determined by SEM analysis using Philips XL-30 ESEM, coupled with EDAX. All beads were cut and cross section was analyzed after gold coating. The EDX analysis of the precipitate was carried out to determine elemental constituents.

Batch equilibration tests

Initial batch equilibration tests were carried out to assess the Cs and Sr uptake performance of the pristine zeolite and its two modified products. In all tests, a known amount (0.1 g, air-dried) of sorbent was equilibrated with 10 mL of test solution at ambient conditions in stoppered glass vial. The test solution (pH 7–8) was prepared by addition of a radiotracer (137Cs or 85+89Sr) in NaNO3 (5 g/L) solution. pH was adjusted by addition of requisite amount of sodium hydroxide, when required. Sodium nitrate was added mainly to avoid uptake of radionuclides by the vials. No inactive salt of Cs and Sr was added. The estimated Cs and Sr concentration in the feed solution is about 0.001 and 0.5 ppm, respectively. The equilibration was done by shaking for 6 h in a wrist action shaker followed by overnight standing. After 24 h, the solution was filtered through 0.45 micron paper and the concentration of the radionuclides was measured radiometrically using a well-type NaI (Tl) scintillation detector coupled to a single channel analyzer and counter assembly. Based on the measured initial and final concentration of the radioelement, Batch distribution coefficient (K d, mL/g) was calculated as follows:

where C i and C f are the radioelement activity in solution before and after equilibration (counts/min/mL), V is the volume of equilibrating solution (mL) and W is the weight of sorbent (g).

Batch test for kinetic studies was carried out employing 0.5 g sorbent and 50 mL of test solution (pH 7–8). The solution was stirred magnetically. At periodic time intervals 2 mL sample was withdrawn, filtered through 0.45 micron paper and analyzed. For Sr uptake studies, a test solution containing 1 ppm Sr, 85Sr radiotracer and 5 g/L NaNO3 was used. Similarly, test solution containing 1 ppm Cs and 137Cs radiotracer in 5 g/L NaNO3 was used for Cs uptake studies.

Column tests

All column experiments were conducted using a glass column (I.D. = 1.0 cm) fitted with a PTFE stopcock and sintered glass disc. A peristaltic pump (Watson–Marlow, Model 532 U) was used for metering the solution. Each run was conducted with a 10 mL fresh sorbent bed by loading about 9.0 g of the sorbent. Sorbents employed include pristine zeolite 4A, 4A-IC and 4A-IM. The feed solution was passed through the column from bottom to top at the flow rate of about 40 bed volumes per hour. Effluent samples were collected periodically and analyzed radiometrically.

The simulated waste solution (pH:8) used in column studies was prepared in 25 L batches by addition of a known volume of 137Cs and 85Sr in sodium nitrate (5 g/L) solution. No inactive salt of Cs and Sr was added.

A column run was carried out with actual waste solution (Table 1) collected from effluent treatment plant. It may be noted that the major gross β activity is due to 137Cs and 90Sr. In addition, a trace amount of 106Ru was also found to be present. The Total Dissolved Solids (TDS) is accounted for by the presence of NaNO3.

Results and discussion

The synthetic Zeolite 4A has an extended three dimensional network of [SiO4]4− and [AlO4]5− connected to each other by oxygen atom. Typical oxide formula for the zeolite can be represented as Na2O Al2O3 2SiO2 5H2O. It has high aluminium content (Si/Al = 1) and possesses maximum Na ion exchange capacity (~5 meq/g) [31]. Further geometric arrangements of the secondary building units are such that small face sharing β-cages characteristic of sodalite are linked through double 4-member rings. Presence of Al (which holds negative charge), on the corners of 4-member rings facilitates strong affinity for divalent atoms. Without compromising its affinity for Sr2+, efforts were made to impart Cs affinity, making it suitable for simultaneous removal of Sr and Cs ions from low level waste solution. This was done by incorporating Cu-HCF onto macro pores of the zeolite as discussed below.

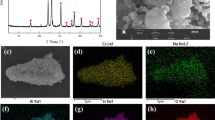

Two products viz, 4A-IC and 4A-IM were obtained after impregnation of Cu-HCF by conventional and modified procedure, respectively. Powder X-ray diffraction pattern of the pristine zeolite (Fig. 2) indicates that the material is highly crystalline. Further, peaks matched well with the standard pattern of zeolite-A, ensuring the quality of the starting zeolite. The XRD pattern of the product 4A-IM shows the peaks of crystalline Cu-HCF (‘*’ marked peaks in Fig. 2) and the peaks of the virgin zeolite (unmarked peaks in Fig. 2) [32]. It shows that the Cu-HCF formed into zeolite pores is crystalline in nature.

Figure 3 compares the XRD pattern of the two impregnated zeolite products. The 4A-IC sample is poorly crystalline and even the zeolite 4A reflexes are weaker. This, in conjunction with the SEM results presented subsequently indicates that Cu-HCF formed in conventional procedure is less crystalline as compared to the product obtained through the modified procedure. This may be attributed to hindered precipitation between Cu2+ and HCF as part of Cu2+ is bound through ion exchange reaction.

SEM micrographs of the beads (cross sectional view) and their EDX profile is presented in Figs. 4, 5, and 6. Figure 4 depicts the microstructure of zeolite 4A. The microstructure consists of rounded, granular aggregates typical of such zeolites. The packing of these aggregates in turn results in the macropores that are targeted for Cu-HCF loading.

Figure 5 represents the microstructure of 4A-IC. The rounded granules visible in the microstructure of the pristine zeolite are covered with copper HCF precipitate. This is further confirmed from the EDX profile wherein strong peaks of copper, potassium and Fe appeared. This in conjunction with the XRD pattern for 4A-IC indicates Cu-HCF crystallization is inhibited and the amorphous Cu-HCF is coating the zeolite aggregates. The preparation route and the presence of Cu in the structure have strong implications for Sr uptake performance as will be described subsequently.

Figure 6 shows the microstructure of 4A-IM in the vicinity of a macropore. The granular structure of the zeolite (similar to Fig. 4) is evident in the sample. In addition, fine needle like crystals appears in the macro pores of the zeolite. The inset of the Fig. 6 shows the finer details of the needle like crystals, which are about 2 μm in length and 100 nm in thickness. EDX profile of the crystals confirmed that these are the crystals of copper HCF. This observation (Fig. 6) is in excellent agreement with higher sample crystallinity resulting from modified process, as also evident in Fig. 3.

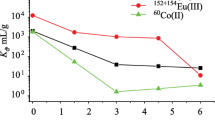

Table 2 shows the results of Cs and Sr uptake studies by the zeolite samples. Excellent Cs removal performance was obtained by both the Cu-HCF impregnated zeolites. On the other hand, reduced Sr uptake by the impregnated product, as compared to the pristine zeolite, was noted. Unlike the results reported by Nakai et at [20], only a negligible amount of Sr uptake was observed by 4A-IC. This reduced Sr uptake was expected as some sites into which Sr2+ could be accommodated were already occupied by Cu2+ used in step-1 of impregnation process. In the modified method, the macro pores of zeolite were filled with K4Fe(CN)6 and when Cu2+ solution was added in step-2, it was mostly utilized for the formation of Cu-HCF. Therefore, the resultant product did not sacrifice significant Sr uptake performance.

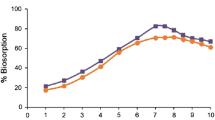

In addition to high sorption performance, for practical application, faster kinetics for both Cs and Sr uptake is desirable. Thus it was of interest to study the rate of uptake, particularly for Sr, as presence of Cu-HCF may slow down the rate of diffusion. Figure 7 shows the variation in Cs uptake by 4A-IM as a function of time. All Cs was adsorbed quickly by Cu-HCF. Presence of Cu-HCF on the outer periphery of the zeolite beads (as seen in SEM micrograph) may have led to rapid Cs pickup. A similar study for Sr uptake was also carried out and the results are presented in Fig. 8. The Sr uptake by the pristine zeolite was also carried out under similar conditions for comparison. It can be seen that nature of Sr uptake by both the zeolites are similar and it took only about 6 h to attain a plateau corresponding to the equilibrium conditions. This indicates that the rate of Sr uptake by 4A-IM remained same even after incorporation of Cu-HCF.

The batch equilibration results presented above showed that 4A-IM is superior for simultaneous removal of Cs and Sr from low level waste. Further confirmation of the fact was obtained by conducting a series of column tests and the results are discussed below.

Figure 9 shows the results of column test carried out with 4A-IC. The simulated waste containing 137Cs and 85+89Sr tracer in NaNO3 (5 g/L) solution was used as feed for the column. As indicated in batch results, excellent Cs removal performance was observed in column run also. No breakthrough for Cs occurred till run termination during which 4000 bed volumes of waste was passed. The column did not show good Sr removal performance. About 10% breakthrough of Sr was observed in the first sample and thereafter Sr concentration in the effluent was found to increase progressively. From the column results, it can conclusively be stated that impregnation of Cu-HCF on 4A through conventional method is not suitable for simultaneous removal of Cs and Sr from low level waste effluent.

Figure 10 shows the column performance of 4A-IM for removal of Cs and Sr from simulated waste. Almost complete removal of Cs and Sr occurred till 5000 bed volumes of waste treatment, after which effluent Sr concentration increased slowly, but no Cs breakthrough occurred till 9000 bed volumes of waste treatment. This confirmed that concurrent removal of Cs and Sr from low level waste effluent is more effective when Cu-HCF is impregnated by modified process.

Figure 11 shows a comparative view of Sr removal by the three sorbents (4A, 4A-IC and 4A-IM). The Sr removal study by 4A was carried out with simulated waste as used above except for the absence of 137Cs radiotracer. In line with batch results, better Sr removal by 4A was observed. Since the column run was carried out at the initial stages of the study, it was continued only for about 5000 bed volumes. About 5% breakthrough of Sr was observed in the last sample collected at run termination. Interestingly, Sr removal performance by 4A-IM is comparable with 4A, even though a wide difference in K d values was obtained in batch tests. The good column characteristic can be attributed to the high affinity for Sr, which remains unaffected even in presence of Cu-HCF.

Good batch uptake of of 137Cs and 90Sr together by 4A-IM, encouraged us to conduct a column run with actual low level effluent. The feed solution (Table 1) used was actual low level effluent collected from effluent treatment plant and of reprocessing plant origin. The column results can therefore be directly applied to assess its utility in treatment of low level waste. Like earlier, the column run was also carried out with 10 mL bed and feed was passed at the flow rate of 40 bed volumes/hour. For easy evaluation, the column results are presented in Fig. 12 in terms of the effluent gross β activity. It is seen that an effluent containing <3.7 Bq/mL of gross β activity was generated after about 8000 bed volumes of waste. A typical gamma spectrum of the column feed and effluent collected after about 8000 bed volumes of waste treatment is shown in Fig. 13. The detailed radiochemical analysis of some samples revealed that this gross β activity is due to the presence of 106Ru and 125Sb. The peaks for 125Sb were barely visible in sample and it accounted about 0.4 Bq/mL in beta activity. At this stage also, a negligible Cs leakage from the column was seen. The 137Cs peak in gamma spectrum is due to background. It may be noted that column performance of 4A-IM with actual waste is superior as compared to simulated waste, possibly owing to the lower concentrations of 137Cs and 90Sr in actual waste. If 106Ru and 125Sb were not present, the column of 4A-IM could have been used to treat large volumes. Nevertheless, a throughput of 8000 bed volumes is much higher than any process reported so far.

Based on the column results described above, it can undoubtedly be stated that 4A-IM is a promising candidate for the treatment of low level waste effluent contaminated with traces of 137Cs and 90Sr. Feasibility of using the sorbent for treatment of higher Cs and Sr contaminated effluent was also examined. Two series of batch tests were carried out utilizing test solutions containing varying concentration of Cs and Sr. As seen earlier, all test solutions contained 5 g/L of NaNO3. Results of the batch tests were presented in Fig. 14 as percentage removal in a single batch contact as a function of initial concentration of the metal ion. The sorbent is quite efficient for Cs and Sr removal even when high concentrations of the radionuclides are present. The Cs and Sr removal efficiency of the sorbent remains same within the concentration range of the metal ion studied. Though initial concentration of Cs and Sr taken for equilibration was same (0.3 mmol/L), the equilibration concentration of Cs and Sr was found to be 8.8 × 10−4 mmol/L and 0.02 mmol/L, respectively. Assuming specific activity of 137Cs and 90Sr in waste is 30 and 70 Ci/g, this concentration corresponds to 3.5 mCi/L of 137Cs and 126 mCi/L of 90Sr respectively. Since equilibrium concentration in batch test is considered as the feed concentration for column studies, it can be stated that the sorbent is also suitable for decontamination of intermediate level waste solution that are generated in nuclear industry.

When the above batch uptake data were plotted in Fig. 15 against the equilibrium concentration of the metal ion in log–log plot, a straight line was obtained both for Cs and Sr uptake by 4A-IM. This linear relationship suggests that Freundlich absorption isotherm holds good for both the metal ions within the concentration range studied. The Freundlich isotherm equation can be written as follows:

where q is the amount of the metal ion sorbed by the unit weight of the sorbent in mmol/g, [M]eq is the equilibrium concentration of the metal ion in mmol/L, K and n are constants. From the intercept and slope of each of the straight lines, log K and n were calculated and tabulated in Table 3.

It can be seen that the value of ‘n’ is almost the same for metal ions. This unit value of ‘n’ suggests monolayer adsorption, even though the surface coverage as per Freundlich equation is unlimited. The values of K can be related to the exchange capacity of the sorbent. This result can be used for calculating Cs and Sr exchange capacities of the sorbent under dynamic conditions. Using Freundlich equation, the Cs and Sr exchange capacity of the sorbent, in equilibrium with 8.8 × 10−4 mmol/L Cs and 0.02 mmol/L Sr, was calculated and the values were found to be 0.03 mmol/g both for Cs and Sr. The corresponding column loading is about 120 Ci of 137Cs and 190 Ci of 90Sr per litre of the sorbent.

Conclusions

A simple process has been evaluated for impregnation of Copper hexacyanoferrate on pores of synthetic zeolite 4A. This impregnated sorbent has good affinity for both Cs and Sr ions. The Cs and Sr sorption by the sorbent follows Freundlich adsorption isotherm. In fixed bed column mode, the sorbent can remove both 137Cs and 90Sr simultaneously from low level liquid waste effluents generated in nuclear industry. The sorbent is particularly useful for reduction of gross β activity from low level waste to below specified limits prescribed by regulatory authority (<3.7 Bq/mL) before environmental discharge. It is established that more than 8000 bed volumes of low level waste contaminated with 137Cs and 90Sr can be treated by the sorbent bed at flow rate of 40 bed volumes per hour. Adoption of the process will not only reduce environmental discharges, but also be a cost effective solution for the management of low level waste generated by the nuclear industry.

References

Classification of radioactive waste: AERB safety guide (2011) AERB/NRF/SG/RW-1

Raj K, Prasad KK, Bansal NK (2006) Radioactive waste management practices in India. Nucl Eng Des 236:914–930

Sinha PK, Amalraj RV, Krishnasamy V (1993) Flocculation studies on freshly precipitated copper ferrocyanide for the removal of caesium from radioactive liquid waste. Waste Manag 13:341–350

Rao SVS, Paul B, Lal KB, Narasimhan SV, Ahmed J (2000) Effective removal of cesium and strontium from radioactive wastes using chemical treatment followed by ultra filtration. J Radioanal Nucl Chem 246:413–418

Pancholi KC, Gaikwad GD, Rao NS, Dandekar MP, Pawaskar CS, Pente AS, Jain S (2013) Operational experience of spiral wound reverse osmosis module for treatment of low level radioactive liquid waste. Symposium on membrane separation (MEMSEP-2013), BARC, Mumbai, INDIA, Sept 16–18, 2013

Vincent T, Vincent C, Guibal E (2015) Immobilization of metal hexacyanoferrate ion-exchangers for the synthesis of metal ion sorbents—a mini-review. Molecules 20:20582–20613

Semenischev VS, Voronina AV, Bykov AA (2013) The study of sorption of caesium radionuclides by “T-55” ferrocyanide sorbent from various types of liquid radioactive wastes. J Radioanal Nucl Chem 295:1753–1757

Haas PA (1993) A review of information on ferrocyanide solids for removal of cesium from solutions. Sep Sci Technol 28:2479–2506

Tusa EH, Paavola A, Harjula R, Lehto J (1994) Industrial scale removal of cesium with hexacyanoferrate exchanger—process realization and test run. Nucl Technol 107:279–284

Technical report series No. 408 (2002) Application of ion exchange process for the treatment of radioactive waste and management of spent ion-exchangers. International Atomic Energy Agency, Vienna

Chen R, Tanaka H, Kawamoto T, Asai M, Fukushima C, Na H, Kurihara M, Watanabe M, Arisaka M, Nankawa T (2013) Selective removal of cesium ions from wastewater using copper hexacyanoferrate nanofilms in an electrochemical system. Electrochim Acta 87:119–125

Terada K, Hayakawa H, Sawada K, Kiba T (1970) Silica gel as a support for inorganic ion-exchangers for the determination of caesium-137 in natural waters. Talanta 17:955–963

Sangvanich T, Sukwarotwat V, Wiacek RJ, Grudzien RM, Fryxell GE, Addleman RS, Timchalk C, Yantasee W (2010) Selective capture of cesium and thallium from natural waters and simulated wastes with copper ferrocyanide function-alized mesoporous silica. J Hazard Mater 182:225–231

Lalhmunsiama CL, Tiwari D, Lee SM (2014) Immobilized nickel hexacyanoferrate on activated carbons for efficient attenuation of radio toxic Cs(I) from aqueous solutions. Appl Surf Sci 321:275–282

Rao SVS, Narasimhan SV, Lal KB (2003) Composite CFC-PU foam ion-exchanger in the removal radio active cesium-pilot plant scale studies using simulated and actual plant waste. J Radioanal Nucl Chem 256:137–141

Rao SVS, Lekshmi R, Mani AGS, Sinha PK (2010) Treatment of low level radioactive liquid wastes using composite ion-exchange resins based on polyurethane foam. J Radioanal Nucl Chem 283:379–384

Mimura H, Kimura M, Akiba K, Onodera Y (1999) Selective removal of cesium from sodium nitrate solutions by potassium nickel hexacyanoferrate-loaded chabazites. Sep Sci Technol 34:17–28

El-Kamash AM (2008) Evaluation of zeolite for the sorptive removal of Cs+ and Sr2+ ions from aqueous using batch and fixed bed column operations. J Hazard Mater 151:432–445

Borai EH, Harjula R, Malinen L, Paajanen A (2009) Efficient removal of cesium from low-level radioactive liquid waste using natural and impregnated zeolite minerals. J Hazard Mater 172:416–422

Nakai T, Wakabayashi S, Mimura H, Niibori Y, Tanigawa H, Ishizaki E, Kurosaki F, Matsukura M (2013) Evaluation of adsorption properties for Cs and Sr selective adsorbents-13171, WM2013 Conference, Feb 24–28, Phoenix, Arizona, USA

Valsala TP, Roy SC, Shah JG, Gabriel J, Raj K, Venugopal V (2009) Removal of radioactive cesium from low level radioactive waste (LLW) streams using cobalt ferrocyanide impregnated organic anion exchanger. J Hazard Mater 166:1148–1153

Faghihian H, Iravani M, Moayed M, Maragheh MG (2013) Preparation of a novel PAN–zeolite nanocomposite for removal of Cs+ and Sr2+ from aqueous solutions: kinetic, equilibrium, and thermodynamic studies. Chem Engn J 222:41–48

Banerjee D, Rao MA, Samanta SK (2007) Proceedings in Nuclear and Radiochemistry Symposium (NUCAR 2007), Vadodara, India, pp 371–372

Anthony RG, Dosch RG, Gu D, Philip CV (1994) Use of silicotitanates for removing cesium and strontium from defense waste. Ind Eng Chem Res 332:702–2705

Solbra S, Allison N, Waite S, Mikhalovsky SV, Bortun AI, Bortun LN, Clearfield A (2001) Cesium and strontium ion exchange on the framework titanium silicate M2Ti2O3-SiO4.nH2O(M = H, Na). Environ Sci Technol 35:626–629

Samanta SK (1996) Hydrated titanium(IV) oxide as a granular inorganic sorbent for removal of radiostrontium-I. Batch equilibration studies. J Radioanal Nucl Chem 209:235–242

Peters TB, Barnes MJ, Hobbs DT, Walker DD, Fondeur FF, Norato MA, Fink SD, Pulmano RL (2006) Strontium and actinide separations from high level nuclear waste solutions using monosodium titanate 2. Actual waste testing. Sep Sci Technol 41:2409–2427

Merceille A, Weinzaepfel E, Barre Y, Grandjean A (2012) The sorption behaviour of synthetic sodium nonatitanate and zeolite A for removing radioactive strontium from aqueous wastes. Sep Purif Technol 96:81–88

Valsala TP, Joseph A, Sonar NL, Sonavane MS, Shah JG, Raj K, Venugopal V (2010) Separation of strontium from low level radioactive waste solutions using hydrous manganese dioxide composite materials. J Nucl Mater 404:138–143

Jain S, Ramaswamy M, Theyyunni TK (1994) Removal of cesium and strontium from low level active waste solutions by zeolites. BARC Report (BARC/1994/E/042)

Sinha PK, Panicker PK, Amalraj RV, Krishnasamy V (1995) Treatment of radioactive liquid waste containing caesium by indigenously available synthetic zeolites: a comparative study. Waste Manage 15:149–157

Loos-Neskovic C, Ayrault S, Badillo V, Jimenez B, Garnier E, Fedoroff M, Jones DJ, Merinov B (2004) Structure of copper-potassium hexacyanoferrate (II) and sorption mechanisms of cesium. J Solid State Chem 177:1817–1828

Acknowledgements

Authors thank Shri Kalyan Banerjee, AD, Nuclear Recycle Group, for encouragement during the course of the work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Banerjee, D., Sandhya, U., Pahan, S. et al. Removal of 137Cs and 90Sr from low-level radioactive effluents by hexacyanoferrate loaded synthetic 4A type zeolite. J Radioanal Nucl Chem 311, 893–902 (2017). https://doi.org/10.1007/s10967-016-5097-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-016-5097-6