Abstract

Uptake of Sr(II) from simulated low level radioactive waste, employing radiotracer 85+89Sr, has been carried out with humic acid by a batch equilibration biosorption study. The process exhibited rapid kinetics and at optimized parameters, Sr(II) was biosorbed from simulated reactor and reprocessing waste by 84 ± 2% and 75 ± 2% respectively. Kinetic modelling revealed that the process follows Ho and McKay’s linear pseudo second order kinetics, indicating chemisorption mechanism of binding. Thermodynamic studies ascertain the exothermic, spontaneous and feasible nature of the process. This work proved the viability of humic acid for Sr(II) removal as an eco-friendly, cost effective alternative to conventional techniques.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

90Sr is a persistent fission product present in our ecosphere due to its long half-life of 28.8 years. Anthropogenic activities such as nuclear fission, past atmospheric nuclear weapons tests, nuclear accidents, spent fuel reprocessing plants and radiation research laboratories are major sources of 90Sr, which, along with 137Cs forms an abundant part of Low Level Radioactive Waste (LLRW). These radionuclides contribute significantly to the overall radiation dose of an LLRW disposal facility [1] and must be treated with caution due to their hazardous nature.

This article focusses on the removal of radioactive Sr(II) from LLRW. The well-known toxic nature [2] of 90Sr, as well as its applications in Radioisotope Thermoelectric Generators (RTGs) [3], medical sciences, and industries, demand its extraction from nuclear effluents of reactor and reprocessing plants by an environmentally cautious and green technique. Out of the existing green methods, there has been a tremendous amount of attention given to the technique of biosorption, which employs natural and modified substances for the removal of radionuclides and heavy metals from solutions [4,5,6,7].

Literature survey reveals that Sr(II) and its radioactive counterparts like 90Sr and 85Sr have been separated from aqueous solutions by employing water imbibed seeds of Ocimum basilicum [8], chemically modified biosorbents derived from Azolla filiculoides [9], immobilized moss [10], lichen like Hypogymnia physodes [11], modified eggshell waste [12], saponified orange juice residue [6], roots of Taraxacum officinale [13] and dry cowdung powder [14]. A diverse range of microbial cultures including Scenedesmus spinosus [15], Aspergillus terreus [16], Saccharomyces cerevisiae [17], Oscillatoria homogenea cyanobacterium [18], among several others [19,20,21] have also been employed for the biosorption of Sr(II). Most of these sorbents require extensive pre-treatment processes and longer durations of reaction time, some require living microbial flora for uptake of metal ions, which adds on to the sludge produced, questioning the green nature of the process. From the aforementioned biosorbents, dry cowdung powder (DCP) [14] is a notch over the others as it is a humified biological waste matter, not requiring any pre-treatment. Its notable high affinity for Sr(II) is intriguing, thus the present investigation attempts to explore the potentiality of humic acid, a prime component of DCP, for the uptake of Sr(II).

Humic substances are ubiquitous in the environment, occurring in all soils, waters, and sediments of the ecosphere. One of their most striking characteristics is the ability to interact with metal ions, oxides, hydroxides, mineral and organic compounds, including toxic pollutants [22], to form water-soluble and insoluble complexes. Humic acid (HA) has been reported to interfere with the biosorption of heavy metals—Pb(II), Cu(II), Zn(II), Cd(II), and Ni(II), on activated carbon [23]. Further, HA as a metal chelator has been applied for the removal of Cr(VI), Cd(II), Al(III), Pb(II) [24, 25] Au(III) [26] and Zn(II) [27]. HA has also been employed for Sr(II) removal [28,29,30] from aqueous systems. Literature studies reveal that HA are rich in aliphatic groups [31] and contain a high percentage of elements like carbon and oxygen [32]. Infrared spectroscopy studies confirmed that carboxyl [33] and phenolic [34] groups play a prominent role in the complexing of metal ions by HAs. Thus, humic acids exhibit an affinity for metal ions by forming complexes, and can be applied for metal remediation.

The following manuscript illustrates the separation technique of Sr(II) from simulated LLRW solutions with a practical outlook to decontaminate such hazardous effluents.

Materials and methods

Adsorbent

Humic acid was procured as pellets from Loba Chemie Pvt. Ltd. (India) and no further purification was carried out. HA pellets were crushed using a mortar–pestle and further sieved to obtain a 100 mesh size.

Preparation of simulated effluent (adsorbate)

All the chemicals used were of analytical grade. Stock solutions of 0.1 mg mL−1 Sr(II), Cs(I), Co(II) and NaI, along with 1 g L−1 solution of NaNO3 were prepared in distilled water (Resistivity 17.9 MOhm.cm at R.T.). Simulated effluent solutions of reactor and reprocessing waste [35] were prepared in accordance to their composition obtained from Tarapur Power Plant, as mentioned below [36]

-

Reactor waste—0.1 mg Cs(I), 0.1 mg Sr(II), 0.1 mg Co(II), 0.1 mg I− and 1 g L−1 NaNO3, pH 7.0 to 8.5.

-

Reprocessing waste—0.1 mg Cs(I), 0.1 mg Sr(II) and 1 g L−1 NaNO3, pH 7.0 to 10.5.

These simulated solutions were used as adsorbates in the batch biosorption experiments.

Radiotracer technique

Radiotracer technique, developed by George de Hevesy and Paneth in 1913 [37], assumes that the fate of radionuclides in the environment follows the behavior of stable elements. Therefore, to facilitate experimental detection of sorption and mobility of radioactive strontium by gamma ray spectrometer, the use of radiotracer 85+89Sr was applied to calculate the total amount of metal biosorbed. This isotope was used as a surrogate for 90Sr, which is a beta emitter. The gamma peak of 85Sr (514 keV, half-life 64.8 days) was measured using single channel NaI(Tl) well type gamma ray spectrometer (PSP649/N, PEA GRS-301) with a minimum resolution of 8%. Radioisotope 85+89Sr (in HNO3) was procured from Board of Radiation and Isotope Technology (BRIT), Trombay, Mumbai.

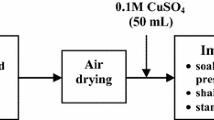

Batch experiments

Radiotracer 85+89Sr was added to simulated reactor and reprocessing waste solution and pH was varied (pH 1 to pH 10) by addition of 0.5 N HNO3 or NaOH. The total volume was adjusted to 15 mL with distilled water. A known amount of HA (3–50 g L−1) was introduced into the resultant solution and equilibrated with mechanical stirrer (Remi RQT 127 A/D) for appropriate time (0–30 min) at suitable agitation speed (500–4000 rpm). The solution was then centrifuged (Remi R-4C) and the supernatant was measured for activity using NaI(Tl) gamma ray spectrometer. A separate reference tube containing 85+89Sr was prepared for the measurement of initial gamma activity of 85Sr.

Percentage biosorption was calculated as follows

where Ai = initial activity measured from the reference tube, Af = final activity in the supernatant

Results and discussion

All the experimental parameters mentioned above were comprehensively studied for optimum biosorption. It was noted that at pH 7, 84 ± 2% of radioactive Sr(II) from reactor waste was adsorbed by 20 g L−1 humic acid at 303 K, within 10 min of agitation at 3000 rpm. With the same contact time and agitation speed, at pH 8 and a sorbent dose of 30 g L−1, 75 ± 2% biosorption was obtained from reprocessing waste.

Effect of pH

On varying the pH from 1 to 10, as shown in Fig. 1, biosorption gradually increased and attained a maximum value of 84 ± 2% for reactor waste at neutral pH and 75 ± 2% for reprocessing waste at pH 8. In the acidic range, the functional groups on HA (primarily carboxylic and phenolic groups) tend to form hydrogen bonds with the excess H+ ions in the solution. The protonated sorbent surface repels the Sr(II) ions, making the adsorption process unfavorable. This repulsion decreases with increasing pH due to reduction of positive charge density on the sorption sites; thus an enhancement of metal uptake is noted. As the alkalinity increases, hydroxyl groups predominate in the solution and compete for the metal ions with the active sites on the surface of HA. Thus, a decrease in metal uptake is noted beyond pH 8.

Effect of sorbent dosage

Upon increasing the dosage of humic acid from 3 to 50 g L−1, biosorption of Sr(II) increased from 40 ± 2% at 3 g L−1 of HA to 84 ± 2% at 20 g L−1 of HA and further remained constant for reactor waste. In the case of reprocessing waste, maximum biosorption of 74 ± 2% was obtained at 30 g L−1 of HA, and upon further increment of adsorbent dose, biosorption remained constant. Initial rise in biosorption with increasing sorbent dosage is attributed to the availability of greater sites for adsorption of Sr(II). After maximum biosorption is attained, further rise in the sorbent dose does not affect the process and Sr(II) removal remains fairly constant.

Effect of agitation speed

Agitation facilitates greater contact and interaction between the adsorbent and adsorbate, leading to an increase in biosorption. As agitation speed is increased from 500 rpm to 4000 rpm, there is a positive impact on biosorption, which increases from 48 ± 2% at 500 rpm to 84 ± 2% at 4000 rpm for reactor waste and from 35 ± 2% at 500 rpm to 75 ± 2% at 4000 rpm for reprocessing waste. Optimized speed used for further experimentation was 3000 rpm as on further increase in speed, there was no substantial rise in biosorption.

Effect of contact time and kinetic modelling

In order to optimize this parameter, all other parameters were kept constant during the study and time of contact was varied from 0 to 30 min. As seen in Fig. 2, from 0 to 5 min, there is a steep rise in biosorption, due to vacant sorbent sites present in the initial period. From 5 to 10 min, there is a gradual rise in Sr(II) biosorption, after which it approached a near-constant value, due to attainment of equilibrium. The standardized contact time was noted to be 10 min.

Sorption kinetic data was fitted to the two important kinetic models—Lagergren pseudo first and Ho and McKay’s pseudo second order model. Out of these, the one with the best fit was found to be the pseudo second order model. Linear form of this model can be expressed by the following equation [38]

where qe and qt are the sorption capacities (mg g−1), at equilibrium and at time t, respectively, and k2 is the equilibrium rate constant (g mg−1 min−1) for pseudo second order model.

Linear regression analysis was carried out by plotting the graph of t/qt versus t, as seen from Fig. 2 (inset). A similar straight line plot illustrating a linear relationship was obtained for Sr(II) removal from reprocessing waste. The regression coefficient, R2 values were close to 1, as seen from Table 1, indicating the applicability of this model to both the systems. This suggests that the biosorption of Sr(II) onto HA is based on chemical interaction between the metal and active sites of the biosorbent.

Effect of temperature and thermodynamics

Temperature studies are an important aspect as biosorption reactions are mostly exothermic, thus percentage adsorption usually drops at higher temperatures. Biosorption experiments were carried out at optimized parameters by varying the temperature from 268 K to 393 K. As temperature rises from 268 K, there is a marginal rise in biosorption, which eventually falls beyond 333 K. This is attributed to excess thermal energy, leading to increased mobility of metal ions and weakening of sorbent–sorbate bonds. The system works well in a low temperature to R.T. range, thus 303 K was optimized for the same.

Temperature dependencies were further evaluated by calculation of thermodynamic parameters. The standard Gibb’s free energy change is an important indication criterion for spontaneity. A sorption process occurs spontaneously if ΔG° is a negative quantity. This free energy of biosorption reaction can be evaluated by the following equations [39]

where ΔG° is the standard Gibb’s free energy change (kJ mol−1), R is the universal gas constant (8.314 J mol−1 K−1), T is absolute temperature (K), Ka is the biosorption equilibrium constant, ∆H° is the enthalpy change (kJ mol−1) and ∆S° is the entropy change (J mol−1K−1).

Equations 3 and 4 can be expressed as

Figure 3 illustrates the thermodynamic relation, where slope and intercept are graphically obtained and used to calculate ∆H° and ∆S°.

As seen from Table 2, Gibbs free energy change is a negative value, indicating spontaneity and feasibility of the system. Enthalpy change is also negative, revealing exothermic nature of the biosorption process. Entropy change is calculated to be positive, which indicates an increase in randomness of the system, implying a favorable reaction with greater affinity of HA for Sr(II) ions.

Effect of initial Sr(II) concentration

In order to understand the metal uptake capacity of humic acid, we have carried out experiments by increasing the concentration of Sr(II), maintaining other parameters constant. Aqueous solutions of Sr(II) were prepared and added to the simulated effluents in the concentration range of 0.1–20.0 mg mL−1 and batch biosorption experiments were performed.

As seen from the graph, percentage biosorption remains fairly constant from 0.1 to 2.0 mg mL−1; after which it starts decreasing drastically. A similar trend was noted by several other researchers [40,41,42]. This decrease in biosorption can be attributed to unavailability of vacant active sites on the surface of the biosorbent and increasing competition amongst Sr(II) ions for the same (Fig. 4).

Selectivity of HA for Sr(II)

As noted from the composition of simulated reactor and reprocessing waste streams, Cs(I) is present in both the systems. Upon monitoring the uptake of Cs(I), employing radiotracer 137Cs, its percentage biosorption was found to be as high as 90 ± 2% and 82 ± 2% for reactor and reprocessing waste respectively. In order to study the effect of salts on the biosorption of Cs(I) and Sr(II), and to understand the selectivity of HA for these ions, salts like iodate, bromide and nitrate were added to the system in varying concentrations.

Results obtained for reactor waste after batch equilibration are illustrated in Fig. 5. As seen from the graph, the presence of these salts improve the selectivity of HA for Sr(II) by reducing the uptake of Cs(I) to the range of 20–30%. Conversely, the uptake of Sr(II) is barely lowered to the range of 70–75%. A similar trend is observed in the case of reprocessing waste with Cs(I) biosorption in the range of 16–20% and Sr(II) at 60–64%. These results indicate that Sr(II) can be separated from Cs(I) in the presence of certain salts. However the nature of HA and its affinity towards metal ions also permits collective adsorption and can be used for waste water clean-up.

Conclusions

Humic acid showed significant uptake of Sr(II) from both simulated reactor and reprocessing waste streams. HA is a readily available soil fraction and as a biosorbent, it works as an economical alternative to conventional techniques. Reactor and reprocessing effluents are of the pH range 7.0–8.5, and 7.0–10.5 respectively. As noted from pH studies, the systems work well in the range of pH 7–8. This negates the need for addition of further chemicals, thereby making the process effectively, ‘chemical-free’. In addition, only 10 min of contact time is required to attain optimum biosorption. Thus advantages of this method include simplicity, rapid kinetics and economic feasibility, in conjunction with the green nature of the process. Our planned future work also takes into account the detailed isotherm studies along with desorptive nature of the biomass.

References

Adams JP (1996) Selected radionuclides important to low level radioactive waste management, 1st edn. U.S. Department of Energy, Idaho

Ojovan MI, Lee WE (2014) An introduction to nuclear waste immobilization, 2nd edn. Elsevier, Amsterdam

Schmidt GR, Sutliff TJ, Dudzinski LA (2011) radioisotope power: a key technology for deep space exploration, radioisotopes—applications in physical sciences In: Singh N (ed) IntechOpen. https://doi.org/10.5772/22041

Giannakopoulou F, Haidouti C, Chronopoulou A, Gasparatos D (2007) Sorption behavior of cesium on various soils under different pH levels. J Hazard Mater 149(3):553–556

Dahiya S, Tripathi RM, Hegde AG (2008) Biosorption of heavy metals and radionuclide from aqueous solutions by pre-treated arca shell biomass. J Hazard Mater 150(2):376–386

Pangeni B, Paudyal H, Inoue K (2014) Development of low cost adsorbents from agricultural waste biomass for the removal of Sr(II) and Cs(I) from water. Waste Biomass Valor 5:1019–1028

Balintova M, Demcak S, Pagacova B (2016) A study of sorption heavy metals by natural organic sorbents. Int J Energy Environ 10:189–194

Chakraborty D, Maji S, Bandyopadhyay A, Basu S (2007) Biosorption of cesium-137 and strontium-90 by mucilaginous seeds of Ocimum basilicum. Bioresour Technol 98(15):2949–2952

Ghorbanzadeh S, Tajer P, Ghazvini M (2009) Bioresource technology biotechnological potential of Azolla filiculoides for biosorption of Cs and Sr: application of micro-PIXE for measurement of biosorption. Bioresour Technol 100(6):1915–1921

Krishna MVB, Arunachalam J, Murali MS, Kumar S, Manchanda VK (2004) Performance of immobilized moss in the removal of 137Cs and 90Sr from actual low-level radioactive waste solutions. J Radioanal Nucl Chem 261(3):551–557

Pipiska M, Hornik M, Kociova M, Augustin J, Lesny J (2005) Radiostrontium uptake by lichen Hypogymnia physodes. Nukleonika 50:39–44

Metwally S, Rizk H, Gasser M (2017) Biosorption of strontium ions from aqueous solution using modified eggshell materials. Radiochim Acta 105(12):1021–1031

Fuks L, Oszczak A, Dudek J, Majdan M, Trytek M (2016) Removal of the radionuclides from aqueous solutions by biosorption on the roots of the dandelion (Taraxacum officinale). Int J Environ Sci Technol 13(10):2339–2352

Barot NS, Bagla HK (2012) Biosorption of radiotoxic 90Sr by green adsorbent: dry cow dung powder. J Radioanal Nucl Chem 294(1):81–86

Liu M et al (2014) Biosorption of strontium from simulated nuclear wastewater by scenedesmus spinosus under culture conditions: adsorption and bioaccumulation processes and models. Int J Environ Res Public Health 11(6):6099–6118

Khani M, Pahlavanzadeh H, Alizadeh K (2012) Biosorption of strontium from aqueous solution by fungus Aspergillus terreus. Environ Sci Pollut Res 19(6):2408–2418

Yin Y, Wang J, Yang X, Li W (2017) Removal of strontium ions by immobilized saccharomyces cerevisiae in magnetic chitosan microspheres. Nucl Eng Technol 49(1):172–177

Dabbagh R, Ghafourian H, Nabi G, Riahi H (2007) Bioaccumulation and biosorption of stable strontium and 90Sr by Oscillatoria homogenea cyanobacterium. J Radioanal Nucl Chem 272(1):53–59

Ghazvini P, Mashkani S, Ghafourian H (2007) Biosorption of strontium from aqueous solution by new strain Bacillus sp. GTG-83. In: WM’07 33rd annual waste management conference, Tucson, AZ

Zhao Y, Dai Q, Dong F, Han L, Yan W (2016) Strontium removal by montmorillonite - pseudomonas fluorescens system. J Microbiol Biotechnol 5(2):39–45

Icgen B, Yilmaz F (2018) Biosorption of strontium from aqueous solutions by Micrococcus luteus Sr02. Geomicrobiol J 35(4):284–293

Wang S, Mulligan CN (2009) Enhanced mobilization of arsenic and heavy metals from mine tailings by humic acid. Chemosphere 74(2):274–279

Sounthararajah DP, Loganathan P, Kandasamy J, Vigneswaran S (2015) Effects of humic acid and suspended solids on the removal of heavy metals from water by adsorption onto granular activated carbon. Int J Environ Res Public Health 12(9):10475–10489

dos Santos A, Botero W, Bellin I, de Oliveira LC, Rocha JC, Mendonca A, Godinho A (2007) Interaction between humic substances and metallic ions: a selectivity study of humic substances and their possible therapeutic application. J Braz Chem Soc 18(4):824–830

Ma M, Wei Y, Zhao G, Liu F, Zhu Y-R (2014) Characterization and adsorption mechanism of Pb(II) removal by insolubilized humic acid in polluted water. Int J Environ Prot Policy 2(6):230–235

Yanti I, Winata WF, Sudiono S Triyono modification of humic acid by ether functional group as biosorbent to Au(III) adsorption in the presence of Sn(II) and Ni(II). In: AIP conference proceedings, 1823(1)

Boguta P, Sokołowska Z (2016) Interactions of Zn(II) ions with humic acids isolated from various type of soils. Effect of pH, Zn concentrations and humic acids chemical properties. PLoS ONE 11(4):e0153626

Paulenova A, Rajec P, Zemberyova M, Sasköiova G, Visšacky V (2000) Strontium and calcium complexation by humic acid. J Radioanal Nucl Chem 246(3):623–628

Macasek F, Shaban IS, Matel L (1999) Cesium, strontium, europium (III) and plutonium (IV) complexes with humic acid in solution and on montmorillonite surface. J Radioanal Nucl Chem 241(3):627–636

Helal AA, Imam DM, Khalifa SM, Aly HF (1998) Effect of some environmental ligands and fertilizers on humic acid complexation with strontium. J Radioanal Nucl Chem 232:9–11

Rupiasih NN, Vidyasagar PB (2009) Analytical study of humic acid from various sources commonly used as fertilizer: emphasis on heavy metal content. Int J Des Nat Ecodyn 4(1):32–46

Kerndorff H, Schnitzer M (1980) Sorption of metals on humic acid. Geochim Cosmochim Acta 44:1701–1708

Vinkler P, Lakatos B, Meisel J (1976) Infrared spectroscopic investigations of humic substances and their metal complexes. Geoderma 3:231–242

Boggs S, Livermore D, Seltz MG (1985) Humic substances in natural waters and their complexation with trace metals and radionuclides: a review. Macromol Chem, Phys

Mani AGS, Paramasivan K, Chitra S, Sinha PK, Lal KB (2005) Improved chemical precipitation process for the treatment of radioactive liquid waste from reprocessing plant. In: Nuclear and radiochemistry symposium (NUCAR), pp 341–342

Kore G, Prasad V, Mishra A (2002) Removal of Ru along with Cs & Sr from the low level radioactive liquid waste of reprocessing plant by chemical treatment method, BARC Newsl (2): 64–69

Hevesy G, Paneth F (1913) The solubility of lead sulphide and lead chromate”. Zeitschrift für Anorg und Allg Chemie 82:323–328

Ho YS, Mckay G (1999) Pseudo-second order model for sorption processes. Process Biochem 34:451–465

Din M, Mirza M, Ata S, Athar M, Mohsin I (2013) Thermodynamics of biosorption for removal of Co(II) ions by an efficient and ecofriendly biosorbent (Saccharum bengalense): kinetics and isotherm modeling. J Chem 2013:1–11

King P, Rakesh N, Beena S, Prsanna Y, Prasad VSRK (2008) Biosorption of zinc onto Syzygium cumini L.: equilibrium and kinetic studies. Chem Eng J 144(2):181–187

Mishraa PC, Patel RK (2009) Removal of lead and zinc ions from water by low cost adsorbents. J Hazard Mater 168(1):31–325

Thavamani SS, Rajkumar R (2013) Removal of Cr(VI), Cu (II), Pb(II) and Ni (II) from aqueous solutions by adsorption on alumina. Res J Chem Sci 3(8):44–48

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Khan, A.N., Bagla, H.K. Application of tracer technique in remediation of Sr(II) from simulated low level radioactive waste. J Radioanal Nucl Chem 322, 193–198 (2019). https://doi.org/10.1007/s10967-019-06514-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-019-06514-9