Abstract

Retention of Pa(V) on the extraction chromatographic resins (DGA, TRU, TEVA, UTEVA and octanol resin) produced by Triskem International Company has been studied. The capacity factor k′ values of Pa(V) were determined in static experiments (batch technique) for a wide concentration range of nitric and hydrochloric acid solutions. The obtained data are useful to devise chromatographic separation of Pa(V) from other actinides.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Protactinium has a wide spectrum of applications. For example, the 231Pa/230Th ratio may be used for evaluation of migration processes in deep water circulation in Atlantic Ocean, providing a link between climate change and the rate of meridional circulation [1]. Pa is attractive for geology [2–4], nuclear forensics [5, 6]. Recently the interest in application of 230Pa for nuclear medicine has been demonstrated.

230Pa partially (branching ratio is 7.8 %) decays to 230U, which has a potential for targeted alpha-therapy (TAT) [7, 8] due to the decay chain of 230U providing multiple alpha-particle emissions. 230U may be utilized directly or as a parent of 226Th (T 1/2 = 31 min) in a generator system. However, resources of 230Pa production are limited. One of the most perspective methods is irradiation of natural Th by protons. In [9] estimated the production yield for 230Pa based on cross section measurements. It was shown, that clinically relevant amounts of 230U can be produced at lower (<40 MeV) proton energies. At (70–200 MeV) energies 230U can be produced together with 225Ac and 223Ra which are regarded as the most promising alpha-emitting radionuclides for TAT application. Besides 225Ac, 223Ra and 230Pa/230U the irradiation results in the formation of a large number of spallation and fission products including lanthanides needed to be eliminated.

Separation methods liquid–liquid extraction and ion exchange chromatography are usually used for isolation of Pa radioisotopes. Extraction behavior of Th(IV), Pa(V), U(VI) and Np(VI) from mineral acid solutions by trilaurylamine (TLA) was investigated in [10]. It was shown, that Th(IV), Pa(V), U(VI) demonstrate low distribution coefficients (<0.1) at high concentrations of H2SO4. Addition of HCl and HBr to H2SO4 solutions enhances significantly the extraction of these elements. The authors [11] studied the extraction of Pa(V) by tributylamine (TBA) from oxalic, tartaric and phosphoric acid solutions. It was shown that Pa(V) may be effectively separated in a form of oxalic complex. Pa(V) is also quantitatively extracted by di-(2-ethylhexyl)phosphoric acid (HDEHP) from chloric and hydrochloric acid solutions [12].

Anion exchange is also used for Pa separation [13], because the protactinium anionic complexes are formed in strong mineral acid solutions [14]. One of the most effective methods for Pa(V) separation is based on silica gel sorption [11]. The capacity factor of Pa(V) decreased three times in the presence of Th(IV) ions [15]. Water–alcohol solutions were investigated for separation of Pa(V), U(VI), Th(IV) and Np(VI) on silica gel [16].

Extraction chromatography combines advantages of liquid–liquid extraction and chromatography. However, experimental data describing Pa(V) separation using extraction chromatography from mineral acids are limited. Some of them are presented in [17, 18]. A novel approach to efficient separation of Pa(V) and Np(VI) was described in [19] with 1-octanol as an extracting agent. This approach significantly reduces waste (acidic and organic) and eliminates the need for HF and H2SO4. The present paper focuses on Pa extraction chromatographic behavior using DGA, TEVA, TRU, UTEVA, octanol resins (TrisKem Int.). Capacity factors of Pa were obtained for HNO3 and HCl solutions in a wide range of acid concentration.

Experimental

Chemicals

All chemicals and reagents were of p.a. quality or higher and used without additional purifications. Nitric acid (HNO3), hydrochloric acid (HCl), perchloric acid (HClO4) were obtained from Merck. Silicagel with particle size 100–160 and 100–400 µm were used. Extraction chromatographic resins DGA (N,N,N′,N′ tetroctyldiglicolamide as extracting agent), TRU (octylphenyl-N,N-di-isobutyl carbomoylphosphine oxide dissolved in TBP as extracting agent), TEVA (mixture of trioctyl and tridecyl methyl ammonium chloride as extracting agent), UTEVA (diamyl, amylphosphonate as extracting agent) with 100–150 µm particle size and octanol (alcohols as extracting agent) with 50–100 µm particle size were used (all resins are produced by Triskem Int.).

233Pa

237NpO2 was used for obtaining of 233Pa as decay product of 237Np. A sample of 20 mg 237NpO2 was dissolved in concentrated HNO3 and then evaporated to moist salts. The oxidation of 237Np+5,+4 to Np+6 was performed with concentrated HClO4. Then neptunium was transferred to pentavalent state with small amount of sodium nitrite and an aliquot was measured on gamma-spectrometer and qualified by UV vis spectrophotometry. The total volume of 237Np solution was 20 mL and the activity ≈500 kBq.

Methods of 233Pa isolation

233Pa was separated from 237Np by extraction chromatography using TEVA and octanol resin and by sorption onto silica gel. Column conditions: r = 0.4 cm, h = 8.5 cm, V = 4.3 cm3. Silica gel [16], TEVA and octanol resin [19] were taken as sorbents for separation. All the sorbents were equilibrated with corresponding acid solutions during several hours.

Silica gel

Method 1

The silica gel (fraction 100–160 µm) was placed in 4 M HCl solution. Then the column was filled by pre-conditioned silica gel and of 1 mL of 237Np/233Pa stock solution was added. 237Np passed through the column in 4 M HCl with the flow rate of 0.08 mL/min. 233Pa was quantitatively adsorbed on the column under these conditions. The column was washed with 15 mL of 4 M HCl to remove the traces of 237Np. 233Pa was then eluted by 10 mL of 1:3 mixture of 4 M HCl and C3H7OH.

Method 2

The silica gel (fraction 100–400 µm) was placed in 6 M HCl solution. Then the column was filled by pre-condition silica gel and 1 mL of 237Np/233Pa stock solution was added. 237Np passed through the column in 6 M HCl with the flow rate of 0.3 mL/min. The column was washed with 15 mL of 4 M HCl to remove the traces of 237Np. 233Pa was eluted by 15 mL of mixture 6 M HNO3: 0.6 M HF.

TEVA resin

The column was filled with TEVA resin and washed with 15 mL 9 M HNO3. 1 mL of 237Np stock solution was added in the column. Then 60 mL of 9 M HNO3 was passed through the column with the flow rate 0.4 mL/min to elute 237Np. The protactinium was eluted by 20 mL of 0.1 M HCl solution.

Octanol resin

The octanol resin was placed in 4 M HCl solution and left for several hours. 237Np was eluted by 30 mL of 9 M HCl solution at the flow rate of 0.2 mL/min [19]. Afterwards 233Pa was quantitatively eluted by 1 M HCl solution.

Capacity factors

Weight distribution ratios D w for TRU resin, DGA resin, UTEVA, TEVA, octanol resin in wide range of acid concentration (from 0.01 to 9 M of nitric and hydrochloric acids) were determined in static conditions. The weight of sorbent sample was 50 mg. The aqueous phase containing known concentration of mineral acid solution and radioactive tracer was added to the sorbent and shaken during 3 h. After equilibration and filtration through a glass wool filter, aliquot 1 mL was measured by gamma-spectroscopy and the value of D w was calculated:

In extraction chromatography, the capacity factor k′ is commonly used instead of D:

where \(A_{0}\)—activity of aqueous phase before equilibration (cpm), \(A_{\text{s}}\) activity of aqueous phase after equilibration (cpm), \(W\)—weight mass of chromatographic material (g), \(V\)—volume of solution (mL), d ext—density of extracting agent, w ext—weight fraction of extracting agent. Details for converting D w to k′ are given in [18, 20].

Blank experiments

A sample of aqueous phase containing known concentration of mineral acid solution and radioactive tracer was shaken during 3 h without sorbents. After passing through a glass wool filter, 1 mL of solution was measured by gamma-spectroscopy. A part of activity lost anywhere (the surface of labware, the filter, etc.) was obtained and then taken into account for calculation of k′ measured under the same conditions.

Gamma-ray spectroscopy

Gamma-ray spectroscopic measurements were performed using a high purity Ge-detector GR 3818 Canberra Ind. (USA). Software Genie 2000 for spectrum processing was applied. Eluate from each column was collected in 1 mL flasks and 237Np and 233Pa were registered via gamma-peaks 86.47 and 311.90 keV, respectively.

Results and discussion

In aqueous solutions, Pa(V) forms mono-oxo cation PaO3+ having strong tendency to hydrolysis, polynuclear species formation as well as complexation with various anions. In general, formation of Pa complexes in nitric acid may be presented as Pa(OH) x (NO3) 5−x−y y (x + y ≤ 8, where 8 is coordination number of Pa(V)). Cationic complexes Pa(OH)3NO3 + or Pa(OH)2NO3 2+ are dominant in 1–2 M HNO3 and gradually transform to neutral and anionic species [21] with Pa(OH)2(NO3) −4 as a main species in concentrated HNO3 [22]. In case of hydrochloric acid, complexes PaOx(OH)yCl 5−x−y−zz (x = 0–2, y = 0–4, z = 0–8, x + y + z ≤ 8) were considered [11, 23]. Positive charge of complexes was observed up to 3–4 M HCl [24, 25]. In more concentrated HCl, oxo-chloride ions PaOCl4 −, PaOCl5 2− and PaOCl6 3− were regarded as more probable rather than chloride complexes PaCl6 −, PaCl7 2− and PaCl8 3− [26, 27]. Variety of Pa speciation results in a lack of reliable published data necessary for common separation techniques (liquid extraction, ion exchange, extraction chromatography).

According to the earlier published data [28] TEVA, TRU, DGA and UTEVA resins could be applied for protactinium separation. Since Pa(V) can adsorb not only onto the resins but also onto any surface of labware, the blank experiments were carried out. The losses of Pa(V) up to 15 % was found in both HCl and HNO3 solutions of concentration range 0.01–0.1 M. Then the values of losses diminished gradually to 10 % along with increasing the acidity of solution. The obtained Pa(V) losses were taken into account when the values of capacity factor k′ were calculated.

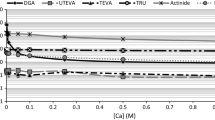

The values of capacity factor k′ for Pa(V) with TEVA resin as a function of HCl or HNO3 concentration are plotted in Fig. 1. The k′ values significantly increase for HCl, as well as HNO3, concentrations above 3–4 M. Such behavior is in the agreement with Pa(V) speciation in highly concentrated mineral acids in which anionic complexes are formed that are sorbed by the positive quaternary ammonium groups of TEVA resin. The data reported are compared to that reported by Mendes et al. [28] recalculated here using the ratio of the density of stationary phase, d ext, and the weight fraction, w ext, of extracting agent impregnated onto the inert support as proposed by Horwitz et al. [29]:

The data from both our study and reported by Mendes [28] demonstrate the similar tendency.

The data of k′ values were used for the choice of conditions of column separation of 233Pa from 237Np (Fig. 2).

It was shown that combination of 9 M HNO3 and 0.1 M HCl solution resulted in a complete isolation of 233Pa. Comparing to the silica gel separation, the present method allows us to avoid using such chemicals as HF or alcohols.

The values of capacity factor k′ for Pa(V) with UTEVA, TRU and DGA depending on HCl or HNO3 concentration are presented in Figs. 3, 4, 5. The resins show strong affinity to Pa(V) in solutions of both acids with concentration above c.a. 5 M. Moreover, the maximal k′ values for TRU and DGA in HCl reach 105, which may be useful for further design of separation schemes. The character of k′ value dependency in HNO3 medium is similar, excepting that maximal k′ values are systematically lower for TEVA and UTEVA than ones in HCl medium. This could be explained by the fact that the equilibrium in strong HCl solutions is essentially shifted towards formation of strong multi-charged anionic complexes [26, 27], whereas in concentrated HNO3 solutions, a noticeable part of cationic and neutral complexes exist together with anionic ones.

A new extraction chromatographic sorbent octanol resin was tested and the k′ values for Pa in HCl solutions were obtained (Fig. 6). Moderate growth of k′ values in the range of diluted HCl solutions may be attributed to the bonding of hydroxo-chloride complexes of Pa(V) with a hydroxyl group of 1-octanol while the increased k′ values in concentrated HCl solutions correspond to effective interaction via chelating mechanism.

Conclusions

Despite of that behavior of various lanthanides and actinides on extraction chromatographic resins are well studied and reported, the reliable published data for Pa(V) remain scarce. The present work were determinined the capacity factor \(k^{\prime }\) for Pa(V) on extraction chromatographic resins, namely, TRU, DGA, UTEVA, TEVA and octanol resin at different HCl and HNO3 concentrations (from 0.01 to 9 M). The obtained k′ values were compared to ones available in literature. The data allow choosing the optimal conditions for chromatographic separation of Pa(V) from elements with similar chemical properties, and the separation of Pa(V) from Np(V) on TEVA was demonstrated. Extraction chromatographic resins are also promising for development of radionuclide generator, for example, 230Pa/230U/226Th having practical potential for TAT.

References

Gherardi J, Labeyrie L, Nave S, Francois R, McManus J, Cortijo E (2009) Glacial-interglacial circulation changes inferred from 231Pa/230Th sedimentary record in the North Atlantic region. Paleoceanography 24:PA2204. doi:10.1029/2008PA001696

Nerge C, Thomas A, Mas J, Garcia-Orellana J, Henderson G, Masgue P, Zahn R (2009) Separation and measurement of Pa, Th, and U isotopes in marine sediments by microwave-assisted digestion and multiple collector inductively coupled plasma mass spectrometry. Anal Chem 81(5):1914–1919

Regelous M, Turner S, Elliott T, Rostami K, Hawkesworth C (2004) Measurement of femtogram quantities of protactinium in silicate rock samples by multicollector inductively coupled plasma mass spectrometry. Anal Chem 76(13):3584–3589

Morgenstern A, Apostolidis C, Moyer K (2002) Age determination of highly enriched uranium: separation and analysis of 231Pa. Anal Chem 74(21):5513–5516

Keegan RP, Gehrke RJ (2003) A method to determine the time since last purification of weapons grade plutonium. Appl Radiat Isot 59(2–3):137–143

Geibert W, Usbeck R (2004) Adsorption of thorium and protactinium onto different particle types: experimental findings. Geochim Cosmochim Acta 68(7):1498–1513

Capote R, McGinley J, Rasmussen G, Sin M, Zielinska B, Apostolodis C (2008) Production of 230U/226Th for targeted alpha therapy via proton irradiation of 231Pa. Anal Chim Acta 80(22):8763

Duchemin C, Guertin A, Haddad F, Michel N, Metivier V (2014) 232Th(d, 4n)230Pa cross-section measurements at ARRONAX facility for the production of 230U. Nucl Med Biol 41:22

Radchenko V, Engle JW, Wilson JJ, Maassen JR, Nortier MF, Birnbaum ER, John KD, Fassbender ME (2016) Formation cross-section and chromatographic separation of protactinium isotopes formed in proton-irradiated thorium metal. Radiochim Acta. doi:10.1515/ract-2015-2486

Souka N, Shabana R, Hafez F (1975) Extraction behavior of thorium, protactinium, uranium and neptunium from mixed mineral acid solutions by TLA. J Radioanal Chem 27:401–410

Palchine ES, Myasoedov BF, Davydov AV (1968) Analytical chemistry of protactinium. USSR, Nayka, p 238

Mason G, Lewey S (1974) Extraction of Pa(V) by a sterically hindered phosphinic acid from an aqueous chloride phase. J Inorg Nucl Chem 36(4):911–915

Kolarich RT, Ryan VA, Schuman RP (1966) Association constants of anionic-protactinium (V) complexes. J Inorg Nucl Chem 29:783–797

Bunney LR, Ballou NE, Pascual J, Foti S (1959) Anion exchange behavior of several metal ions in hydrocloric, nitric, and sulfuric acid solutions. Anal Chem 31(3):324–326

Chang H, Ting G (1975) The chemistry of the actinide and transactinide elements, Taiwan, INER-64-D-0167

Souka N, Farah K, Shabana R (1976) Sorption behavior of some actinides on silica gel from mineral acids and alcoholic solutions. J Radioanal Chem 34:277–284

Horwitz EP, Dietz ML, Chiarizia R, Diamond H (1992) Separation and preconcentration of uranium from acidic media by extraction chromatography. Anal Chim Acta 266:25–37

Horwitz EP, Dietz ML, Chiarizia R, Diamond H, Maxwell SL, Nelson MR (1995) Separation and preconcentration of actinides by extraction chromatography using a supported liquid anion exchanger: application to the characterization of high-level nuclear waste solutions. Anal Chim Acta 310:63–78

Knight AW, Nelson AW, Eitrheim ES, Forbes TZ, Schultz MK (2015) A chromatographic separation of neptunium and protactinium using 1-octanol impregnated onto a solid phase support. J Radioanal Nucl Chem 307:59–67

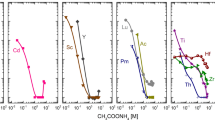

Ostapenko V, Vasiliev A, Lapshina E, Ermolaev S, Aliev R, Totskiy Yu, Zhuikov B, Kalmykov S (2015) Extraction chromatographic behavior of actinium and REE on DGA, Ln and TRU resins in nitric acid solutions. J Radioanal Nucl Chem 306(3):707–711

Hardy CJ, Scargill D, Fletcher JM (1958) Studies on protactinium(V) in nitric acid solutions. J Inorg Nucl Chem 7(3):257–275

Spitcyn VI, Diachkova RA, Khlebnikov VP (1964) Report of academy of sciences. USSR, 157, 135

Myasoedov BF (2006) Protactinium. In: Kirby HW, Tananaev IG (eds) The chemistry of the actinide and transactinide elements, chap 4. Springer, Dordrecht, p 161

Larned B, Barton CJ et al (1963) Chemistry symposium: proceedings of the protactinium. US, Gatlinburg, TID-7675

Scherff HL, Herrmann G (1966) Ionic species of pentavalent protactinium in hydrochloric acid solutions. Radiochim Acta 6:53

Bagnall KW, Brown DJ (1964) Some chloro-complexes of quinquevalent protactinium, niobium, and tantalum. J Chem Soc. doi:10.1039/JR9640003021

Casey AT, Maddock AG (1959) The chemistry of protactinium—VA comparison of the extraction of protactinium, niobium and tantalum. J Inorg Nucl Chem 10(3–4):289–305

Mendes M, Aupiais J, Jutier C, Pointurier F (2013) Determination of weight distribution ratios of Pa(V) and Np(V) with some extraction chromatography resins and the AG1-X8 resin. Anal Chim Acta 780:110–116

Horwitz EP, Choarizia R, Dietz ML (1992) A novel strontium selective extraction chromatographic. Solvent Extr Ion Exch 10:313–336

Acknowledgments

The authors are grateful to TrisKem International Company and personally to Dr. Steffen Happel for providing the samples of extraction chromatography resins. The work was partly supported by the Russian Foundation for Basic Research, (Grant No. 16-33-00656).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ostapenko, V., Sinenko, I., Arefyeva, E. et al. Sorption of protactinium(V) on extraction chromatographic resins from nitric and hydrochloric solutions. J Radioanal Nucl Chem 311, 1545–1550 (2017). https://doi.org/10.1007/s10967-016-4996-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-016-4996-x