Abstract

Polyurethane was irradiated at various gamma radiation doses up to 1,000 kGy at room temperature in nitrogen. Positron annihilation lifetime spectroscopy, tensile test and dynamic mechanical analysis were used to find the relationship between free volume and mechanical properties. An increase of the free volume fraction in soft segments (SS) and a decrease of the free volume fraction in hard segments (HS) during gamma radiation was observed and analyzed. The results showed that HS in polyurethane had the excellent resistance to gamma radiation, whereas SS had a tendency to degrade. The reason for the decrease of the strain at break and the ultimate tensile strength was analyzed, which showed the changes in the mechanical properties of polyurethane irradiated by gamma rays were mainly determined by the changes of free volume in SS. If the resistance properties of polyurethanes exposed to radiations need to be improved, SS should be paid more attention to.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polyurethane adhesives have been widely used in the areas of aerospace and nuclear energy for their good thermal stability, excellent resistance to radiations and wonderful adhesive properties for almost any solid materials. In such applications, polyurethane adhesives are exposed to various radiations, and some performances, especially mechanical properties will change, which could affect the security of the related systems.

Gamma radiation effects on polyurethane have been reported in some references [1–8]. Bukanoval and Degtyareva [5, 6] investigated polyester polyurethanes consisting of toluene diisocyanate (TDI), dimethy biphenyl diisocyanate or hexamethylene diisocyanate. Their results showed that the main radiation effect on polyurethane was degradation leading to the decrease of tensile strength and elongation with increasing the radiation dose from 50 to 500 kGy. Ozdemir et al. [7] investigated the mechanical properties of poly(carbonate urethane) irradiated by gamma ray. It was concluded that the degradation mechanism at a high radiation dose was the possible reason for the decrease in the toughness of poly(carbonate urethane). Katarzyna Gorna and Sylwester Gogolewski [8] irradiated the polyurethanes with varying hydrophilic-to-hydrophobic content ratios at a dose of 25 kGy, and observed that polyurethane underwent significant degradation resulting in the reduction of tensile strength and modulus.

According to the above researchers’ results, they all have claimed that degradation resulting in the reduction of mechanical properties. However, the answers for how the degradation happens and how the degradation reduces the mechanical properties are not described there.

Polymers irradiated by radiations usually undergo two fundamental processes: degradation and cross-linking [3, 9]. Both the two processes have an important influence on polymer mechanical properties for mechanical properties are decided by micro-structures. Degradation usually results in the break in the polymer molecular chains, leading to the production of the new free volume. Cross-linking can form new bonds between polymer molecules and make the molecules closer to each other, which could increase the interaction between polymer chains and therefore reduce the free volume [10]. PALS is a powerful method for the characterization of free volume [11].

Positron in the polymer will either annihilate directly with an electron or forms a bound state called positronium (Ps) in free volume. Ortho-positronium (o-Ps) as a kind of Ps has an intrinsic lifetime 142 ns in vacuum. In polymers, o-Ps will have a ‘pick-off’ reaction with an anti-parallel spin electron from the wall of free volume, form para-positronium (p-Ps) and annihilate rapidly. Hence, the lifetime of o-Ps reduces to several nanoseconds. The o-Ps lifetime mirrors sensitively the electron density in the nearest surrounding the Ps and the size of free volume where o-Ps is localized [10].

The o-Ps annihilated results can be used to calculate the free volume fraction f using the following Eq (1) [10].

where C is a constant, I is the intensity of o-Ps annihilation from PALS results, and V sph = 4π/3 × R 3 is the average free volume of a single hole. R as the average free volume radius can be obtained from the following semi-empirical Eq. (2).

where o-Ps pick-off lifetime τ is expressed in ns, and R in nm. ΔR is an empirical constant 0.1656 nm.

In this study, in order to study the relationship between free volume and mechanical properties, physical structure was studied by PALS.

Experimental

Materials

Polyurethane was synthesized by two components (A and B) of Tie Mao 101 adhesive from Shanghai Xinguang Chemical Co., Ltd. located at No. 588 Huating Xiangzhu Road, Jiading District, Shanghai, China. Component A contains polyethyleneglycol adipate, and B with a concentration of 11–13 % –NCO groups was the modified toluene diisocyanate (TDI) by trimethylolpropane (TMP). Tie Mao 101 adhesive is usually used with a mass ratio of A:B = 10:1–5. In this experiment, component A was mixed with B uniformly with a mass ratio of A:B = 10:4 by stirring with a glass rod in a glass beaker. Then the glass beaker was transferred to a vacuum oven to remove the gas bubbles. After that 113 g of the mixture was transferred to a polyethylene cup. Then, the weighed mixture was poured onto a horizontal flat glass slice with a size of 200 mm × 200 mm which was environed by the glue strip and kept the upside of the strip at least 5 mm higher than the glass surface. After 7 days’ solidification, a vacuum oven was used to get rid of the remaining solvents (ethyl acetate and acetone) for a month at 30 °C. Finally, the solidified polyurethane was peeled off from the glass slice and was cut into different sizes for the tests of PALS, DMA and mechanical properties.

Gamma radiation

60Co source was used to irradiate the samples at various doses up to 1,000 kGy at an approximate dose rate of 5 kGy/h at room temperature at Institute of Nuclear Physics and Chemistry located at No. 64 Mianshan Road, Mianyang, Sichuan Province, China. The samples were placed in the special glass ampoules. Then, the high temperature acetylene flame was used to seal the mouth of the glass ampoules on the top. After that, the ampoule was vacuumed to get rid of the air and filled with 50 kPa inert gas (pure N2, 99.99 %) from the branch pipe in the side. Finally, the ampoules were sealed by the acetylene flame.

Measurements

PALS were carried out using a fast-slow spectrometer with a time resolution of 194 ps full width at half maximum at room temperature. This lifetime spectrometer employed two BaF2 detectors. The positron source 22NaCl was sandwiched by two specimens with a size of 10 mm × 10 mm × (1 ± 0.1) mm. In order to get a better statistical analysis, the collection of ~2×106 counts was allowed. The acquired lifetime spectra were resolved into four lifetime components (τ 1, τ 2, τ 3, τ 4) by a computer program named LT9 [12]. The source component 382 ps (13 %) was used for source correction.

Dynamic properties were measured using DMA Q800 in single cantilever bending mode. The samples with a size of 20 mm × 10 mm × (1 ± 0.1) mm were subjected to a sinusoidal displacement of 10 μm at the temperature range from −60 to 230 °C with a heating rate of 5 °C/min and a frequency of 1 Hz.

Tensile properties of the specimens were carried out at room temperature. The polyurethane was cut out in a dumbbell shape with dimensions of 5 mm (neck) × 1 mm(thickness) × 75(length). Tensile strength and the elongation at break were measured at a cross-head speed of 50 mm/min. All the given values were the averages of three measurements for each condition.

Results and discussion

DMA and PALS results

The loss tangent (tan δ) versus temperature curves for the irradiated and un-irradiated polyurethanes are shown in Fig. 1. No obvious changes are observed at different radiation doses. Three transition regions throughout the whole heating range: A (−25–0 °C), B (40–100 °C), C (140–200 °C) are observed. Polyurethane usually possesses a segmented structure: HS are formed by a diisocyanate and a chain extender whereas SS are composed of a polyol, polyether or polyester [13]. A and B are the glass transition temperature ranges of SS and HS, respectively, and C is the viscous flow temperature range [14]. The two glass transitions observed in DMA results shows that the polyurethane we used has two phases structure.

For the crystalline polymer, it usually has two phases structure: crystalline region and amorphous region, and the free volumes of these two phases are different. The crystalline region usually has a smaller free volume than the amorphous region. Thus, the crystalline polymer is commonly analyzed with four components results in PALS [10]. The two longer components are due to the pick-off annihilation of o-Ps in crystalline region and amorphous region. Polyurethane also has the two phases: HS and SS. It is certain that HS has the smaller free volume than SS for the strong interaction (high polarity and the hydrogen bonding) between urethane linkages in HS. Therefore, the polyurethane lifetime spectra are analyzed into four components in our experiment. Actually, the PALS results of polyurethane with four components have been reported in some references [15, 16]. Consolati et al. [15] discussed some correlations among macroscopic features of some cross-linked fluorinated polyether-urethanes and their free volume properties as probed by PALS. They observed that PALS was sensitive to the phase separation, the spectra were analyzed into four components and τ 3 corresponds to the Ps state which was associated to the urethane phase. Ferrerira Marques and his partners [16] studied urethane/urea membranes by PALS, two types of free volume with different sizes had been identified, probably corresponding to two separate domains of SS and HS.

The PALS results are shown in Table 1. The shortest component τ 1 (120–150 ps) with intensity I 1, is due to the annihilation of p-Ps [10]. The second shortest component τ 2 (300–335 ps) with intensity I 2, is attributed to the annihilation of free positrons and positrons trapped in various vacancies and interfaces [10]. The two longest components τ 3 (0.8–1.15 ns) and τ 4 (2.08–2.28 ns), are the results of o-Ps annihilation in the free volume of HS and SS respectively.

Changes in the free volume of SS

The lifetime τ 4 and intensity I 4 of the longest component are shown in Fig. 2. The lifetime τ 4 which mirrors the size of free volume decreases a little with increasing the dose. I 4 increases gradually. The intensity of the long component is assumed to be proportional to the number of the free volume for it gives the information on the o-Ps formation probability. Thus, there are more and more free volumes produced in SS, whereas the average free volume size seems to become smaller and smaller.

Lifetime measurements allow the estimation of the free volume fraction f 4 from Eqs (1) and (2). Here, C is a constant. f 4 value must be proportional to the product of V sph and I 4. The results of f 4 values estimation are presented in Fig. 3. It shows that f 4 is dose dependent. f 4 increases with increasing the dose. These results reveal the degradation effects in SS in polyurethane, which is corresponding to our former 2D-TG studies that SS in polyurethane have a tendency to degrade [17]. When the backbone chains are broken by gamma rays, new free volumes are produced at the break position, which is helpful to increase the number of free volume. The reason why τ 4 decreases might be that many smaller new free volumes will be produced when polyurethane is irradiated by gamma rays and these new produced smaller free volumes averaging with the primary free volume causes the mean size of free volume to decrease.

Changes in the free volume of HS

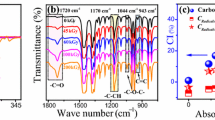

The positron annihilation lifetime τ 3 and intensity I 3 are shown in Fig. 4. τ 3 has a tendency to decrease with increasing the radiation dose, which indicates that the mean size of free volume becomes smaller and smaller. The decrease of I 3 reveals that the number of the free volume decreases. Figure 5 shows the changes in the free volume fraction f 3 in HS. It is observed that f 3 decreases gradually with increasing the radiation dose. Such results reveal that no degradation effects are observed in HS during gamma radiation. Phenyl ring with conjugated structure possesses wonderful resistance to radiations because the absorbed energy can diffuse to the whole ring avoiding the energy concentration in one bond. There are plenty of phenyl rings in HS, which could be helpful in resisting the radiations. Isocyanate (–NCO) in the polyurethane adhesive is usually remanent to keep the adhint ability. We have reported that the content of isocyanate groups would be reduced through the chemical reactions when the polyurethane experiences gamma radiation [17]. Maybe, isocyanate groups have some chemical reactions, produce new chemical bonds occupying free volumes and result in the decrease of free volume fraction in HS.

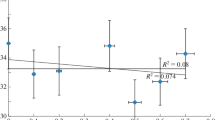

Changes in mechanical properties

The results of tensile test are shown in Fig. 6. Both the strain at break and the ultimate tensile strength decrease gradually, and when radiation dose exceeds 300 kGy they decrease much more slowly. It means that the polyurethane irradiated by gamma ray is more easily to be broken.

Several references have claimed that degradation resulting in the reduction of mechanical properties. Surely, polymer degradation will increase the chain ends, produce new free volume and reduce the interaction between molecules. The mechanical results we observe also reveal the degradation effect is present. PALS results have illustrated that the free volume fraction in SS increases with increasing the radiation dose, whereas in HS decreases. That’s to say, SS have the tendency to degrade whereas HS not when polyurethane is irradiated by gamma ray. Therefore, the decrease of the strain at break and the ultimate tensile strength is most likely due to the more and more produced free volume in SS.

Conclusions

Free volume of polyurethane has been studied by PALS, and four components were obtained. The two longest components τ 3 (0.8–1.15 ns) and τ 4 (2.08–2.28 ns) were analyzed. The free volume fraction in HS reduced gradually with increasing the dose. The increase of the free volume fraction in SS showed the degradation in SS, which was the reason why the strain at break and ultimate tensile strength reduced. Therefore, the changes in the mechanical properties of polyurethane adhesive irradiated by gamma radiation are mainly determined by the properties of SS.

References

Wei H, Xiong J, Chen X, Gao X, Xu Y, Fu Y (2007) Study on the radiation degradation of polyether-polyurethane induced by electron beam. J Radioanal Nucl Chem 274(3):525–530

Ravat B, Gschwind R, Grivet M, Duverger E, Chambaudet A, Makovicka L (2001) Energetic distribution of the electrons from a 200 keV beam in polyurethane layers: EGS4 calculation and FTIR analysis. Radiat Phys Chem 61(3):571–573

Dedgaonkar V, Navle P, Shrotri P (1996) Radiation effects on aging behaviour of oligobutadiene-base urethane polymer. Radiat Phys Chem 48(3):333–335

Pierpoint S, Silverman J, Al-Sheikhly M (2001) Effects of ionizing radiation on the aging of polyester based polyurethane binder. Radiat Phys Chem 62(1):163–169

Bukanova N, Cherkasova L, Sotnikova E, Tarasova Z (1978) Effect of gamma radiation on linear aromatic polyurethanes. In Chem Abstr 88:154002

Degtyareva A, Shrubovich V, Fedorenko O, Meleshevich A (1984) Relation between the structure of urethane thermoplastic elastomers and their radiation resistance. In Chem Abstr 101:24383

Özdemir T, Usanmaz A (2007) Degradation of poly(carbonate urethane) by gamma irradiation. Radiat Phys Chem 76(6):1069–1074

Gorna K, Gogolewski S (2003) The effect of gamma radiation on molecular stability and mechanical properties of biodegradable polyurethanes for medical applications. Polym Degrad Stab 79(3):465–474

Abdel-Hady E, Abdel-Hamid H, Mohamed HF (2004) Electron beam and gamma irradiation effects on conducting polystyrene studied by positron annihilation technique. Radiat Meas 38(2):211–216

Borek J, Osoba W (2001) Free volume changes in physically aged polyethylene by positron annihilation. Polymer 42(7):2901–2905

Ferreira Marques M, Gordo P, Kajcsos Z, Lopes Gil C, de Lima A, Queiroz D, de Pinho M (2007) Positron studies of the temperature-dependence of free volumes in polydimethylsiloxane/poly (propylene oxide) urethane/urea membranes. Radiat Phys Chem 76(2):129–133

Kansy J (1996) Microcomputer program for analysis of positron annihilation lifetime spectra. Nucl Instrum Methods Phys Res Sect A 374(2):235–244

Guignot C, Betz N, Legendre B, Le Moel A, Yagoubi N (2001) Degradation of segmented poly (etherurethane) Tecoflex induced by electron beam irradiation: characterization and evaluation. Nucl Instrum Methods Phys Res Sect B 185(1):100–107

Yen F-S, Lin L–L, Hong J-L (1999) Hydrogen-bond interactions between urethane–urethane and urethane-ester linkages in a liquid crystalline poly(ester-urethane). Macromolecules 32(9):3068–3079

Consolati G, Levi M, Turri S (2001) Positron annihilation and phase separation phenomena in polyurethane crosslinked coatings with different polyether segments. Polymer 42(24):9723–9728

Marques MF, Gordo P, de Lima A, Queiroz D, de Pinho MN, Major P, Kajcsos Z (2008) Free-volume studies in polycaprolactone/poly (propylene oxide) urethane/urea membranes by positron lifetime spectroscopy. Acta Phys Polonica Series A 113(5):1359

Sui H, Liu X, Zhong F, Li X, Ju X (2013) A study of radiation effects on polyester urethane using two-dimensional correlation analysis based on thermogravimetric data. Polym Degrad Stab 98(1):255–260

Acknowledgments

This work was supported financially by Science Foundation of Chinese Academy of Engineering Physics 2011A0302013. We also thank Mr. Jiabin Liu, Mrs. Xiaoying Wang and Mr. Xiaofei Hao for their great help in sample preparation and test.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sui, H., Liu, X., Zhong, F. et al. Relationship between free volume and mechanical properties of polyurethane irradiated by gamma rays. J Radioanal Nucl Chem 300, 701–706 (2014). https://doi.org/10.1007/s10967-014-3048-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-014-3048-7