Abstract

Higher cost and lower availability of enriched isotopic materials are the major constraints in targets fabrication of isotopes. If the distribution of the vapor flux is not controlled in the evaporation, large amount of material is wasted. Minimizing the material wastage is important in the fabrication of targets of expensive isotopes. Evaporation sources have been designed and machined at Inter-University Accelerator Centre (IUAC) for minimizing the consumption of materials in evaporation. Details of different types evaporation sources used in Target development laboratory at IUAC for minimizing the wastage of target material in target fabrication is discussed in this report.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In physical vapor deposition, most of the targets are prepared by either thermal evaporation or electron beam evaporation. In most cases, the amount of wasted material is very high due to the large solid angle of evaporation. In electron beam evaporation and in thermal evaporations using dimple shaped source, the solid angle of evaporation is approximately 2π. In these two cases, the amount of material collected on the substrate is very low and the collection efficiency is usually lower than 10 %. Wastage of material can be minimized by reducing the solid angle of the vapor flux distribution. Tube shaped sources having narrow opening are very effective in reducing the solid angle of vapor flux distribution and so confines the deposition to a lower area [1]. Different types of evaporation sources are used for confining the area of deposition to a small area and thus increasing the collection efficiency [2]. To improve the vapor collection efficiency, the new crucible was designed and machined out of graphite in IUAC. The source can be heated applying resistant heating or bombardment by beam of electrons provided by electron gun. This graphite crucible can be used for deposition of materials with relatively low melting point and was used at IUAC for such material as silver, gold, nickel, platinum, indium, tin, cadmium, lead, zinc. For evaporation of materials with higher melting temperature we use crucibles of tungsten, molybdenum and tantalum.

Experimental procedure

Following evaporation sources are used in IUAC for improving the collection efficiency.

Graphite crucibles

Availability, low cost and good machinability are the major advantages of graphite. The graphite crucible developed recently at IUAC and its dimensions are shown in Fig. 1.

This crucible is an assembly of a crucible body and a cap. The cap has a hole of 1–2 mm diameter. The inner volume of the crucible assembly (8 mm diameter and 3 mm height) is sufficient for accommodating a volume of 150 mm3 of material. Crucible body and top cover are connected by thread joint. The threaded joint is necessary as otherwise the cap will not be able to withstand the pressure inside the crucible during evaporation and the cap will be ejected. A thread joint of M8 and 5 mm long holds the cap firmly with crucible body. Crucibles with low internal volume of 60 mm3 (5 mm diameter and 3 mm height) is also in use for target material available in small amount.

The newly developed crucible was recently tested. The design of the graphite crucible allows heating the material either by beam of electrons provided by electron gun or by resistant heating using tungsten basket heater (Fig. 2).

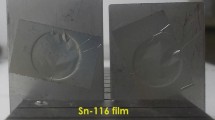

Figure 3 shows the scheme of evaporation using the described graphite crucible heated by electrons provided by electron gun. Significant improvement of collection efficiency was shown in various evaporation attempts. Table 1 shows the details of recent evaporations using graphite crucible.

The collection efficiencies achieved with this newly designed crucible were better than the ones obtained when using tantalum tubular sources (R. D. Mathis make) recommended by Heagney JM [3] for thermal evaporation. The crucibles of this tubular type are regularly used in IUAC for minimizing the wastage of isotopic material. Evaporations of cadmium, copper, lead, silver, tellurium, thallium, tin and zinc have successfully been done from tubular source with as well satisfactorily high vapor collection efficiency.

Tantalum crucible

At temperature above 2,000 °C, graphite crucible becomes very soft. Tantalum is found more suitable for evaporations requiring higher temperature. Tantalum crucibles of various internal volumes (3–6 mm diameter and 7–12 mm height) are frequently used in electron beam evaporation of rare earth isotopes. Evaporations of gadolinium, terbium, neodymium and samarium have successfully been done from tantalum crucible described above. Targets prepared by this method have been used in various nuclear physics experiments in IUAC and contamination by crucible material was not seen in any experiments. An in-house machined tantalum crucible used for these evaporations and schematic of the evaporation set-up are shown in the Fig. 4.

Conclusion

In-house developed crucibles and custom made evaporation sources are very effective in restricting the vapor within a narrow solid angle and thus improving the collection efficiency in vacuum evaporation technique. Minimizing the distance between the source and substrate with a cooling arrangement for substrate can further improve the collection efficiency.

References

Greene JP, Thomas GE (1989) Nucl Instr Meth A282:71

Maier HJ, Grossmann R (1987) Nucl Instr Meth A257:11

Heagney JM (1972) Nuclr Instr Meth 102:451

Acknowledgments

We would like to thank Dr. D. K. Avasthi, Program Leader, Target Development Laboratory, IUAC, for his encouragement and constant support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abhilash, S.R., Saini, S.K. & Kabiraj, D. Methods adopted for improving the collection efficiency in vacuum evaporation technique. J Radioanal Nucl Chem 299, 1137–1139 (2014). https://doi.org/10.1007/s10967-013-2674-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-013-2674-9