Abstract

A macroporous silica-based supramolecular recognition absorbent (Calix[4] + Dodecanol)/SiO2–P, was prepared by successive impregnation and fixing the 1,3-[(2,4-diethylheptylethoxy)oxy]-2,4-crown-6-Calix[4]arene (Calix[4]arene-R14) and its molecule modifier 1-Dodecanol onto SiO2 silica-based polymer support. The characterization of (Calix[4] + Dodecanol)/SiO2–P was examined by thermal gravimetry and differential thermal analysis and electron probe microanalysis. Relatively large separation factors of Cs and other metal ions (α n+Cs/M ) above 60 were obtained in the presence of 3 M HNO3. The adsorption data of Cs(I) fitted well with Langmuir isotherm and the maximum adsorption capacity was estimated to be 0.19 mmol g−1. The Cs(I) in 3 M HNO3 were also effectively adsorption on (Calix[4] + Dodecanol)/SiO2–P in the column operation, and the loaded Cs(I) was successfully eluted with an eluent of H2O. The column packed with (Calix[4] + Dodecanol)/SiO2–P had excellent reusability after three cycles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recently, much attention has been given to the selective separation and recovery of Cs-137 from high level liquid waste (HLLW) in relation to the partitioning of radioactive nuclides and their effective utilization [1–3]. Cesium-137 having relatively long half-life of about 30 years exhibits high radioactivity and heat generation, and large amounts of Cs group (~3.6 kg/1 t HU, 45 GWd/t) are contained in HLLW [4]. Therefore, selective separation of Cs-137 from HLLW is an important environmental issue for nuclear waste management. In addition, the purified Cs is also expected for the reuse as radiation and heat sources in the field of medicine and industry.

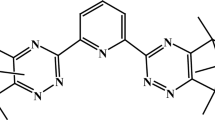

Many methods for the separation of Cs(I) such as co-precipitation [5–8], ion exchange [9–12] and solvent extraction have been studied [13–17]. In the liquid–liquid solvent extraction process, supramolecular recognition agents are well known to have selective extractability to Cs(I) [18–21]. 1,3-[(2,4-Diethylheptylethoxy)oxy]-2,4-crown-6-Calix[4]arene (Calix[4]arene-R14), a kind of supramolecular recognition composite, which shows a high selectivity toward Cs(I) and excellent radiation stability, can act as one of the most promising extractant for the recovery of Cs(I) from HLLW. The Calix[4]arene-R14 compound is composed of chemical bonding of a Calix[4]arene and an 18-crown-6 by phenolic oxygen and polyether chain. It has the ability to extract Cs(I) due to the effective complexion of Cs(I) with the hydrophilic crown ether and high selectively of Calix[4]arene for Cs(I), such as a good match between the cavity of Calix[4]arene and ionic radius of Cs(I) ion, π-bonding interaction with the arene groups, etc. [22]. However, some problems occurred in the liquid–liquid solvent extraction process. For example, the radiolytic degradation of solvent and diluent resulted in the corrosion of equipments and generation of a large amount of organic waste. Furthermore, the solvent extraction process is difficult to commercially employ because the large scale equipments are required for the multi-stage extraction process. These problems can be overcome by using extraction chromatography, and an impregnation method for extraction chromatography has been proposed to immobilize the organic solvents in a macroporous silica/polymer composite support (SiO2–P) [23, 24].

The SiO2–P support is a kind of inorganic material, which prepared by impregnation the copolymer inside the macroporous SiO2 substrate. Impregnation the Calix[4]arene-R14 onto SiO2–P has a number of advantages such as mechanical strength, strong acid and radiation resistance, and ease of solid–liquid separation by simple equipments. Thus, the impregnation of the Calix[4]arene-R14 onto SiO2–P support seems to be one of the most prominent techniques for the practical extraction chromatography operation.

In the previous work, the Calix[4]arene-R14 impregnated on SiO2–P for adsorption of Cs(I) has been investigated [25–28], but few data were reported about the thermal stability, equilibrium and adsorption behavior of continuous column. Most of the literatures reported are limited to the batch process. The column adsorption property should be clarified for the practical use on a large scale because the isotherm batch experimental data are difficult to be applied directly to column at a high flowing rate without attained equilibrium. In this study, we have attempted to load the Calix[4]arene-R14 and a molecule modifier, 1-Dodecanol, into SiO2–P by using its high immobilizing ability for the selective separation of Cs(I) from HLLW. The present paper deals with the preparation of a Calix[4]arene-R14 loaded absorbent, characterization, adsorption equilibrium and breakthrough and elution properties of Cs(I) for the fixed-bed column.

Experimental

Materials

A supramolecular recognition composite, 1,3-[(2,4-diethylheptylethoxy)oxy]-2,4-crown-6-Calix[4]arene (Calix[4]arene-R14, 97 %) was purchased from Rikoh Kagaku Co., Ltd. and used without any further purification. The molecular structure of Calix[4]arene-R14 is shown in Fig. 1. 1-Dodecanol was procured from Wako Pure Chemical Industries, Ltd. The SiO2 silica-based polymer support (SiO2–P) was synthesized by following a method described in a literature [23]. For simplicity, “P” in the SiO2–P particles was abbreviated as styrene–divinylbenzene (SDB) copolymer, which was immobilized inside the macroporous SiO2 substrate by polymerization reaction. Here, SiO2–P was consisted of 82 wt% SiO2 and 18 wt% copolymer. The physical properties of SiO2–P are showed in Table 1. Other chemicals such as CsNO3, Sr(NO3)2, RE(NO3)3·6H2O (RE = La, Nd, Sm, and Gd), ZrO(NO3)2·2H2O and (NH4)6Mo7O24·4H2O were reagent grade supplied by Kanto Chemical Co. Palladium nitrate solution (4.5 wt%) and ruthenium nitrosyl nitrate solution (1.5 wt%) were purchased from Sigma-Aldrich Chemical Co.

Preparation of (Calix[4] + Dodecanol)/SiO2–P

The Calix[4]arene-R14 and a molecule modifier 1-Dodecanol impregnated on SiO2–P support ((Calix[4] + Dodecanol)/SiO2–P) was prepared as follows. First, the Calix[4]arene-R14 and 1-Dodecanol were dissolved in dichloromethane and then mixed with the SiO2–P particles in a glass flask for approximately 1 h at 25 °C. After that the mixture was stirred gently for 2 h at 40 °C under reduced pressure by using rotary evaporator in order to enhance impregnating, and finally vacuum-dried for 1 day at 40 °C.

Characterization

Thermal stability of the (Calix[4] + Dodecanol)/SiO2–P resin was evaluated by thermal gravimetry and differential thermal analysis (TG–DTA, Shimadzu DTG-60) at the operating temperature range from 25 to 600 °C, with a heating rate of 2 °C min−1. The incorporation of Cs(I) ions into (Calix[4] + Dodecanol)/SiO2–P was confirmed by electron probe microanalysis (EPMA, JXA-8200).

Determination of distribution coefficient (K d)

The distribution of metal ions for (Calix[4] + Dodecanol)/SiO2–P was estimated by batch method. An aqueous solution (4 cm3) containing 5 mM metal ions was contacted with 0.2 g of (Calix[4] + Dodecanol)/SiO2–P at 25 ± 1 °C up to 5 h, which was found to be sufficient for attaining equilibrium. The concentrations of Cs(I) and other metal ions were measured by atomic absorption spectrophotometry (AAS, Simadzu AA-660) and inductively coupled plasma atomic absorption spectrometry (Simadzu ICPS-7510).

The distribution coefficient (K d) of metal ions on (Calix[4] + Dodecanol)/SiO2–P and separation factor of Cs and other metal ions (α n+Cs/M ) are defined as:

where C 0 and C f are the initial and equilibrium concentration (mM) of metal ions in solution, respectively, m (g) is the weight of dry (Calix[4] + Dodecanol)/SiO2–P composite and V (cm3) is the volume of aqueous phase.

Column chromatographic separation

The column was prepared by packing about 5.3 g of (Calix[4] + Dodecanol)/SiO2–P resin in a glass column (10 mm in diameter × 150 mm long) with a thermostatic water jacket. Figure 2 show the apparatus for the column experiments. The effluent was every 6.0 cm3 fractionated, and the concentration was determined by AAS. A feed solution ([Cs(I)] = 10 mM) was passed through the column at flow rate of 1.0 cm3 min−1. A breakthrough curve was obtained by plotting the breakthrough ratio (C/C o) against the effluent volume, where C o and C (mM) are the concentration of the initial solution and the effluent, respectively. Elution/regeneration of the column was carried out by using H2O as an eluent at the above-mentioned flow rate, every 7.5 cm3 of the eluent was taken by a fraction collector. The elution chromatogram was obtained by plotting the elution percentage (Elution, %) against the elution volume. The elution percentage is defined as the ratio of the eluted amount of Cs(I) in each fraction to the initial amount loaded on the column.

Results and discussion

Thermal stability

The thermal stability was evaluated by TG–DTA analyses within the temperature range 25–600 °C (Fig. 3). The results of TG and DTA for SiO2–P indicate two different weight loss ranges: 180–320 and 320–500 °C. The first and second weight losses are due to the thermal desorption of SDB copolymer. The overall weight loss of SiO2–P was estimated be about 18 %, indicating that 18 wt% SDB was impregnated inside the SiO2 substrate.

As for (Calix[4] + Dodecanol)/SiO2–P, the endothermic peaks around 310 and 475 °C are observed which was similar to the thermal decomposition of SDB copolymer, indicated that the simultaneous thermal decomposition of SDB copolymer and organic solvents (Calix[4] + Dodecanol) at the same temperature range. The overall weight losses of (Calix[4] + Dodecanol)/SiO2–P was estimated to be 49.6 %, indicated that the absorbent consists of 50.4 wt% of SiO2. Thus, the content of SDB in absorbent can be calculated from the weight percentage of SiO2 (82 %) and SDB polymer (18 %) in fresh SiO2–P, and it was found to be 11.1 wt%. From these results, the content of solvents impregnated in SiO2–P was determined to be 38.5 wt%. The preparation conditions and estimated weight percents of compositions are summarized in Table 2. As can be seen, the SDB polymer was successfully immobilized inside the SiO2 substrate, and the solvents were loaded into the pore of SiO2–P completely. All of these findings has good contributions to the synthesis of absorbent and suggest that the thermal stability of (Calix[4] + Dodecanol)/SiO2–P can be maintained up to 180 °C.

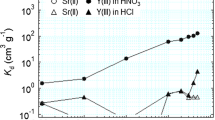

Effect of HNO3 on separation factor (α)

In order to examine the selectivity of Cs(I) for (Calix[4] + Dodecanol)/SiO2–P in various HNO3 concentration, the separation factor of Cs(I) and other metal ions (α n+Cs/M ) was estimated. Figure 4 show the estimated separation factor of Cs(I) and other metal ions (Mn+) for (Calix[4] + Dodecanol)/SiO2–P at different concentrations of HNO3 up to 6 M. As we can see, the separation factor tend to increase with increasing HNO3 concentration of 1–4 M HNO3 and decrease gradually above 4 M HNO3. According to literature, the FP nuclides except for Rb(I) had no adverse impact on the Cs(I) adsorption and separation [25–28]. Therefore, the α n+Cs/M is due to the effect of HNO3 on adsorption of Cs(I), indicated that the Calix[4]arene-R14 extraction with Cs(I) through ion-pair formation in the presence of 1–4 M HNO3 (Eq. 3), but at higher HNO3 concentration (>4 M), the adsorption is governed by solvent extraction of nitric acid with crown ether function group of Calix[4]arene-R14 and the hydrogen bonding become dominant in this process (Eq. 4). As we know, the concentration of HNO3 in HLLW is around 3 M in spent fuel reprocessing. The relatively large α n+Cs/M for (Calix[4] + Dodecanol)/SiO2–P in the presence of 3 M HNO3 were estimated to be 60 to 550. These findings indicate that the (Calix[4] + Dodecanol)/SiO2–P had excellent adsorption ability and high selectivity for Cs(I).

Adsorption isotherm

An adsorption isotherm represents the relationship between the amount of adsorbate on absorbent and adsorbate concentrations at equilibrium, and maximum capacity which was calculated from adsorption isotherm plays an important role for design of adsorption system. In this study, two basically theoretical isotherm models of Langmuir and Freundlich equations are used to compare adsorption mechanism of (Calix[4] + Dodecanol)/SiO2–P. The Langmuir equation assumes that the adsorption reaction is a monolayer adsorption with constant adsorption energy. The Freundlich equation applies to multilayer adsorption and adsorption on a heterogeneous surface. The Langmuir and Freundlich equation are given by:

where C eq (mol/dm3) and Q eq (mol g−1) are the equilibrium concentrations of Cs(I) in the aqueous and solid phases, respectively, Q max (mol g−1) is the maximum amount of Cs(I) taken up, K L (dm3 mol−1) is the Langmuir constant, 1/n is the Freundlich isotherm exponent constant related to the adsorption intensity, K F (mol g−1) is the Freundlich constant, K T (L g−1) is the Tempkin constant, b T (kJ mol−1) is the Tempkin isotherm constant related to the heat of adsorption.

Adsorption isotherms were obtained in a wide range of initial Cs(I) concentrations from 10 to 60 mM at constant temperature. Figure 5 show the Langmuir plots of C eq/Q eq and C eq. A linearity with R 2 of 0.9955 obtained from the isotherm suggested Cs(I) adsorption fit with Langmuir isotherm. This may be due to the homogenous distribution of active sites (Calix[4]arene-R14) on the (Calix[4] + Dodecanol)/SiO2–P surface. The monolayer adsorption Q max value for (Calix[4] + Dodecanol)/SiO2–P was calculated from the slope of the linear plots as 0.19 mmol g−1. The Langmuir constant of 0.25 dm3 mmol−1 was estimated from the intercept (1/K L Q max). In addition, an important parameter, R L, called equilibrium parameter related to the adsorption is favorable or unfavorable.

The R L value between 0 and 1 indicate favorable adsorption. The R L value for Cs(I) was calculated to be 0.29 at the initial concentration of 10 mM, indicating the adsorption of Cs(I) on (Calix[4] + Dodecanol)/SiO2–P was favorable. On the other hand, the fitted Freundlich plots show a low R 2 value of 0.8156 (Fig. 6), indicating the inapplicability of Freundlich isotherm.

Column operation

The column adsorption property should be clarified for the practical use in the separation process. A breakthrough of Cs(I) was tested at feed solution of 10 mM Cs(I) and at a high flow rate of 1 cm3 min−1. Figure 7 illustrate the breakthrough curve of Cs(I), which is a S-shaped profile having steep slope, suggesting no dislodgement of solvents (Calix[4]arene-R14 or Dodecanol) from the matrix of SiO2–P. The break point of 5 % breakthrough was estimated to be 80 cm3 (bed volume (BV) = 7.3), and column took approximately 144 cm3 (13.1 BV) before being completely exhausted with Cs(I). The breakthrough capacity (B. T. Cap.) and total capacity (T. Cap.) were calculated to be 0.15 and 0.18 mmol g−1, respectively, resulting in relatively high column utilization (B. T. Cap./T. Cap.) of 83.3 %. The column packed with (Calix[4] + Dodecanol)/SiO2–P was thus effective for removal of Cs(I).

On the other hand, the adsorbed Cs(I) on the column can be eluted by flowing the H2O. A relatively sharp and symmetric profile is observed, suggesting that Cs(I) is readily eluted with H2O. The elution of Cs(I) was performed with 90.5 % recovery of the adsorbed Cs(I) up to first 9 BV (100 cm3) of effluent (Fig. 8). Here, the elution of Cs(I) is due to the dissociation of ion-pair in such low concentrated NO3 − solution, resulting in reversing the extraction of Cs(I) (Eq. 3). In addition, the regeneration of (Calix[4] + Dodecanol)/SiO2–P can be carried out by washing with distilled water.

Repetitive experiments of adsorption and elution were further carried out using the packed column of (Calix[4] + Dodecanol)/SiO2–P. The feed containing Cs(I) (10 mM–3 M HNO3) was passed through the column and then eluted with H2O. After washing with H2O, the above run was repeated twice. The breakthrough and elution curves for a repeated run are illustrated in Figs. 9 and 10. The results show that (Calix[4] + Dodecanol)/SiO2–P can be used repeatedly without significant loosing the adsorption capacity for Cs(I). The T. Cap. only slightly decrease (5.6 %) after third adsorption/elution cycles. Thus, the use of distilled water as an eluent had the advantage of simultaneous elution and regeneration, meaning the (Calix[4] + Dodecanol)/SiO2–P proved effective for separation and recovery of Cs(I).

EPMA analysis

The specimen adsorbing Cs(I) was embedded in the acrylic resin and the cross section was analyzed by SEM and EPMA. Figure 11 show the SEM image and EPMA color map of the cross section of (Calix[4] + Dodecanol)/SiO2–P. The particle size roughly estimated from SEM image was about 50 μm. In the color map, Cs(I) is distributed uniformly in the matrix of SiO2–P, indicating the successful loading Calix[4]arene-R14 onto the pores of SiO2–P and the Calix[4]arene-R14 has high affinity for Cs(I).

Conclusions

The selective separation and recovery of Cs-137 from HLLW is of great interest in recent years for its application to volume reduction of radioactive wastes and partitioning of nuclides. (Calix[4] + Dodecanol)/SiO2–P with high selectivity towards Cs(I) can act as promising adsorbents for this purpose. The (Calix[4] + Dodecanol)/SiO2–P was prepared by successive loading of Calix[4]arene-R14 and Dodecanol into the macroporous silica-based support.

The thermal stability of (Calix[4] + Dodecanol)/SiO2–P indicated the adsorption ability of (Calix[4] + Dodecanol)/SiO2–P can be maintained up to 180 °C. The (Calix[4] + Dodecanol)/SiO2–P showed excellent absorbability toward Cs(I) compared to other test metal ions. The separation factors of Cs(I) and other metal ions were increased with increasing HNO3 concentration and had a maximum at around 4 M HNO3. The Cs(I) adsorption fitted well with Langmuir model, suggesting only one kind of binding site exhibited on the surface of (Calix[4] + Dodecanol)/SiO2–P. The breakthrough curve of Cs(I) had S-shaped profile, and the absorbed Cs(I) was effectively eluted by using the H2O. After three times adsorption/elution cycles, the (Calix[4] + Dodecanol)/SiO2–P only loosed the 5.6 % of adsorption capacity. The distribution profile of Cs(I) in (Calix[4] + Dodecanol)/SiO2–P was further examined by EPMA. The EPMA color map showed that Cs(I) ions were incorporated into the cross section of (Calix[4] + Dodecanol)/SiO2–P. Thus the (Calix[4] + Dodecanol)/SiO2–P proved to be effective for the selective adsorption and recovery of Cs(I) from the HLLW.

References

Kubota M, Okata K, Yamaguchi I, Morita Y (1986) Radioact Waste Manag Nucl Fuel Cycle 7:303

IAEA (1993) IAEA Technical Report Series No. 356

Atomic Energy Society of Japan (AESJ) (2006) J At Energy Soc Jpn 48:327

Ando Y, Takano H (1999) JAEA JAERI-Research 99-004

Loewenschuss H (1982) Radioact Waste Manag 24:327

Lehto J, Harjula R (1987) Solvent Extr Ion Exch 5:343

Lehto J, Harjula R, Wallace J (1987) J Radioanal Nucl Chem 111:297

Beheir ShG, Benyamin K, Mekhail FM (1998) J Radioanal Nucl Chem 232:147

Mimura H, Kobayashi T, Akiba K (1995) J Nucl Sci Technol 32:60

Chiarizia R, Horwitz EP, Bauvais RA, Alexandratos SD (1998) Solvent Extr Ion Exch 16:875

Mimura H, Saito M, Akiba K, Onodera Y (2000) Solvent Extr Ion Exch 18:1015

Reguillon AF, Dunjic B, Lemaiue M, Chomel R (2001) Solvent Extr Ion Exch 19:181

Schulz WW, Bray LA (1985) Sep Sci Technol 22:191

Dozol JF, Simon N, Lamare V, Roquette H, Eymard S, Tournois B, DeMarc D, Macias RM (1999) Sep Sci Technol 34(6&7):877

Sachleben RA, Bonnesen PV, Descazeaud T, Haverlock TJ, Urvoas A, Moyer BA (1999) Solvent Extr Ion Exch 17:1445

Sachleben RA, Urvoas A, Bryan JC, Haverlock TJ, Hay BP, Moyer BA (1999) Chem Commun 17:1751

Delmau LH, Bonnesen PV, Moyer BA (2004) Hydrometallurgy 72:9

Ji H-F, Dabestani R, Brown GM, Hettich RL (2001) J Chem Soc Perkin Trans 2:585

Engle NL, Bonnesen PV, Tomkins BA, Haverlock TJ, Moyer BA (2004) Solvent Extr Ion Exch 22:611

Delmau LH, Lefranc TJ, Bonnesen PV, Bryan JC, Presley DJ, Moyer BA (2005) Solvent Extr Ion Exch 23:23

Riddle CL, Baker JD, Law JD, McGrath CA, Meikrantz DH, Mincher BJ, Peterman DR, Todd TA (2005) Solvent Extr Ion Exch 23:449

Asfari Z, Wenger S, Vicens J (1994) J Incl Phenom Mol Recognit Chem 19:137

Wei Y-Z, Kumagai M, Takashima Y, Modolo G, Odoj R (2000) Nucl Technol 132:413

Wei Y-Z, Zhang A, Kumagai M, Watanabe M, Hayashi N (2004) J Nucl Sci Technol 41:315

Zhang AY, Hui QH, Chai Z (2010) Chem Eng J 159:58

Zhang AY, Hui QH, Chai Z (2010) Ind Eng Chem Res 49:2047

Zhang AY, Xiao CL, Xue WJ, Chai ZF (2009) Sep Purif Technol 66:541

Zhang AY, Kuraoka E, Kumagai M (2007) J Chromatogr A 1157:85

Acknowledgment

Present study is the result of “Breaking New Ground in the Research of Atomic Energy Application” entrusted to Tohoku University by the Ministry of Education, Culture, Sports, Science and Technology of Japan (MEXT).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, Y., Kim, SY., Tozawa, D. et al. Study on selective separation of cesium from high level liquid waste using a macroporous silica-based supramolecular recognition absorbent. J Radioanal Nucl Chem 293, 13–20 (2012). https://doi.org/10.1007/s10967-012-1738-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-012-1738-6