Abstract

Chitosan (CTS) gel was successfully prepared by organic titanium (OT) ionic crosslinking agent. The viscoelastic properties of CTS gel was investigated through rheological measurement. The sol-gel transition point (t cr ) of gel prepared with CTS (22.5 g•L−1) and OT (1.5 %) was determined at 339 s, with the increases of either CTS or OT concentration, the gelation became faster and the sol-gel transition time became shorter. The optimal chitosan gel beads were prepared with 35 g•L−1 chitosan and 7 % organic titanium (OT) at room temperature for 1 h reaction. The SEM data indicated that the gel beads had special shape with rough and poriferous surface. The effective grain size range was 1.0–1.2 mm. It was confirmed by TG data that the gel beads performed better in thermal stability than original chitosan. Swelling experiments showed that the swelling ability of gel beads strongly depended on the pH value of buffer solution. On the whole, the modified CTS/OT gel beads showed high adsorption capacity, good mechanical properties, strong acidic and alkali resistances, it could serve as potential drug deliver and the absorbent for heavy metal ions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

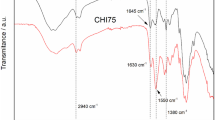

Chitosan (CTS), an abundant natural polysaccharide sourced from chitin with favorable biodegradability, antibiotic property, water holding capacity, nontoxicity as well as biocompatibility, has attracted worldwide focus and been applied in many fields of social production and living [1]. CTS, consisting of (1,4) linked 2-amino-2-deoxy-β-D-glucan, is linear cationic polymers, as it is shown in Fig. 1, there are plentiful amino and hydroxyl groups on the molecules of CTS, which makes it available in gelation with different crosslinkers via formation of hydrogen bond, ionic bond and covalent bond [2–4].

The most common crosslinker used in CTS gelation is dialdehyde, such as glutaraldehyde and glyoxal, could form hydrogel with chitosan via schiff reaction between amino and aldehyde groups, there are a lot of researches on the modification of CTS with dialdehyde [5–9], however, the toxic reagent would possibly remain in the hydrogel through covalent bonds and result in pollution [5].

Ionic crosslinkers is used for CTS gel because it’s low toxicity and mild gelation conditions [10–13]. CTS beads with core-shell structure was prepared under simple and mild condition with trisodium citrate as ionic crosslinker and further coated with poly (methacrylic acid) (PMAA) could serve as suitable candidate for drug site-specific carrier in stomach, and the rapid drug release was restrained by PMAA coating [14]. CTS/gelatin beads were successfully prepared at low temperature using anions (sulfate, citrate and tripolyphosphate) as crosslinker and the influence of anion structure on the beads’ properties was studied. CTS beads, crosslinked by a combination of tripolyphosphate and citrate (or sulfate) together, not only form a good shape, but also became more sensitive to the pH of medium. Furthermore, crosslinked chitosan beads may be useful in stomach specific drug deliver [15, 16].

Chitosan (CTS) performs good absorption ability and there are a lot of studies about using chitosan as direct absorbent on the disposal of sewage containing heavy metal ions [17–19]. However, static absorption experiment indicated that it is difficult to extract the absorbent from solution for the small size of powdery chitosan which disperses easily in the solution; it’s also observed in the dynamic absorption experiments that powdery chitosan easily swelled and agglomerated resulting in blockage in absorption column which made the absorption hard to proceed. This defect has greatly limited the application of chitosan as absorbent.

In this paper, a series of CTS/OT complex gels were prepared and the gelation process was investigated with rheological measurements. Additionally, the optimal condition for preparation of CTS/OT gel beads was investigated, considering the concentration of CTS, Organic titanium, acetum and crosslinking time. The prepared gel beads have good shape and enough mechanical strength, the swelling ability in different buffer solutions was also investigated, the results shows that the gel beads were stable in both acid and alkaline solutions. This CTS/OT gel beads could serve as potential drug delivers and absorbent for heavy metal ions.

Materials and experimental

Materials

Chitosan (CTS) was purchased from Zhejiang Yuhuan Biochemistry Co. Ltd (China), the degree of deacetylation and molecular weight (Mv) is 92 % and 480,000. Coupling agent of organic titanate TA9-2 was purchased from Anhui Taichang chemical Co. Ltd (China). All other reagents are analytical pure.

Preparation of CTS/OT gel

Chitosan is cationic polyelectrolytes, it can reaction with anion or polyanionic compounds and form the network structure [14]. When chitosan solution pH value is greater than 6.2, it can form a white gel precipitation [20].

In order to obtain a series of CTS solutions (17.5 g•L−1, 20 g•L−1, 22.5 g•L−1, 25 g•L−1 mass concentration), a certain amount of powdery CTS were dissolved in acetum (1 % volume concentration) under magnetical stir for several hours. The organic titanium crosslinker is Titanium bis(triethanolamine) diisopropoxide [21–23], as it is shown in Fig. 2. The achieved solid OT were dissolved in distilled water to obtain OT solutions with weight fraction of 20.5, 41, 61.5 and 82 % respectively. The CTS and OT solutions with desired concentrations were chose for preparing CTS/OT gel and the obtained gels were immediately tested for the rheological studies.

Rheological measurements

Rheological measurements were performed with an AR 2000 rheometer (TA Instruments, USA). CTS/OT solutions were placed between parallel-plate of 40 mm diameter with a gap of 1.5 mm for investigation. A small deformation of 1 % within which all the samples performed linear viscoelasticity according to our preliminary work was used in the following tests. For time sweeping tests, storage moduli (G′) and loss moduli (G″) were monitored as a function of time at a frequency of 2.15 rad/s under a constant temperature (25 °C).

Preparation of CTS/OT gel beads

Chitosan gel beads were prepared with the chitosan and organic titanium through the outside resource technique.

In order to obtain chitosan solutions with different concentration (respectively 20 g•L−1, 25 g•L−1, 30 g•L−1, 35 g•L−1, 40 g•L−1), desired quantities of chitosan was dissolved in acetum and these solutions were placed until to be defoamed after magnetically stirred for 1 h at room temperature.

The original cross-linking agent was diluted by distilled water to obtain a series of samples with different weight fraction. The prepared homogeneous chitosan solutions were injected into slowly stirred organic titanium solutions with a syringe at the rate of 1 ml•min−1. In the course of time, cross-linked organic titanium-chitosan gel beads were obtained by filtration, then these gel beads were washed by distilled water for several times and dried to constant weight at 40 °C.

Measurement of gel beads size

Twenty well-shaped dried gel beads were picked out randomly. Their diameters were measured by vernier caliper and the mean value of obtained diameters was taken as the size of gel beads.

SEM study

The morphology of the gel beads were investigated by SEM (JSM5610-LV) with 20kv electron intensity and magnification varying from 80 to 5000.

Thermal stability analysis (TG-DSC)

The thermal stability of original powdery chitosan and gel beads were investigated with STA 449(NETZSCH, Germany) under the protection of nitrogen flowing at the rate of 10 ml · min−1. Both the samples weighed 15 mg, temperature rose from 30 to 500 °C at heating rate of 10 °C · min−1.

Swelling ability study

SD refers as the swelling degree of gel beads. A certain amount of dried gel beads were immersed in prepared buffer solutions of different pH and periodically picked out. After absorption of water on the surface, the swelled gel beads were weighed. Swelling process proceeded until the weight of swelled gel beads was constant (when swelling equilibrium was established). The swelling degree was determined as follows [24]:

Where W is the mean weight of swelled gel beads and Wd is the mean weight of initial dried beads. Two parallel samples were chose from each swelled gel beads solution, the mean SD of these two samples was taken as the final swelling degree.

Results and discussion

Sol-gel transition points

Viscoelastic properties of concentrated and semidilute polymer solutions are well described by two parameters: the dynamic storage modulus, representing the elasticity of the network, and the loss modulus, which accounts for the local friction between polymer chains [25, 26].

Figure 3 showed the time dependence of storage modulus (G′), loss modulus (G″) and tanδ for CTS (22.5 g•L−1)/OT (1.5 wt%) solution at frequency of 2.15 rad/s under 25 °C, where tanδ represents for loss tangent.

In the starting stage when G″ > G′, both the two moduli increased sharply and an obvious decrease of tanδwas observed, viscosity was dominant over elasticity. This indicated the entanglement of Ti4+ crosslinked CTS molecular chains and the gel network was forming in local area. After the intersection time, the growth rate of G′ was higher than the G″ and the two moduli achieved steadily increased plateau after 1500s, as a result, the loss tangent decreased to approximately stable value with time, showing the elasticity of the complex gel. It can be concluded that an integral three-dimensional network has formed, and after which the crosslinking density would not increase with time.

According to Winter-Chambon theory based on dynamic mechanical experiment, the critical gelation point corresponded to the point at which G′(ω)~G″(ω)~ωn, 0<n<1 and tanδ=G″/G′=tan(nπ/2) both hold, where n represents the relaxation exponent [27, 28]. A system is defined as purely viscous gel when n = 1, and purely elastic gel with n = 0. This criterion has been successfully applied to synthetic and natural physical gels [29, 30].

Figure 4 showed the time dependence of loss tangent (tanδ) of CTS (22.5 g•L−1)/OT (1.5 %) solutions at different frequencies under 25 °C. The sol-gel transition of the solution was monitored by the change of tanδ with time. The critical gelation time tcr was determined to be 339 s and the relaxation exponent n was calculated to be 0.367, where tanδ was independent of frequency.

Effects of CTS mass concentration and organic titanium volume concentration on sol-gel transition

Figure 5 has shown the sol-gel transition time (t cr ) as a function of c(CTS) while w(OT) was fixed to 0.5, 0.9, 1.2, 1.6 wt%, respectively. The t cr declined sharply as c(CTS) ranged from 18 to 22 g•L−1. It was also clear that the t cr decreased with an increase in w(OT) at the same value of c(CTS). The effects of CTS and organic titanium concentration on n were shown in Fig. 6. The relaxation kept decreasing as a result of increase in c(CTS) at same w(OT), showing the gel became more and more elastic. Generally, with the increase in CTS concentration, there were more hydroxyls and aminos available to combine with the free titanate ions. Similarly, when increasing the OT concentration, more freedom titanate ions enhanced the chance of combination. In a word, an increase in either c(CTS) or w(OT) would increase the probability of the crosslinking reaction and the sol-gel transition time became shorter in response. The change of sol-gel transition time was shown in Table 1.

CTS/OT gel beads forming mechanism

At the moment that a drop of chitosan-acetic acid solution contacted with organic titanium solution, precipitated linear molecules of chitosan at the boundary crosslinked with organic titanium, sequentially, a solidified membrane forms. This membrane is semi-permeable as it deters outside radical from spreading in and prevents internal chitosan molecules from spreading out; however, Ti4+ is allowed to spread in and H2O can spread out. As there is an existence of pressure due to different solute concentrations at the two sides of the membrane, when outside pressure is greater than the inside, the membrane would not spontaneously crack. When the crosslinkage between chitosan molecules which form the membrane is strong enough, outside chitosan molecules would not loose in the crosslinking agent solution. Due to intermolecular forces, internal chitosan molecules are attached by the solidified membrane, they firstly crosslink with Ti4+ coming from the outside, sequentially, precipitate on the internal surface of the membrane. With internal H2O spreading out, the droplet shrinks. The membrane becomes thicker during such a process, internal chitosan molecules continuously precipitate on the inner surface of solidified membrane, finally the chitosan-organic titanium gel beads forms.

Gel beads prepared with this method have core/shell structure with the core consisting of macromolecules and shell consisting of crosslinking agent, thus the control of gel bead structure can be realized through changing the concentrations of chitosan and organic titanium crosslinking agent, finally improves the feasibility of chitosan’s application in absorption agent.

Effects of preparing conditions on gel beads

Different preparing conditions have certain effects on the appearance of chitosan/organic titanium gel beads. In our experiments, preparing conditions including concentrations of chitosan solution and acetum, crosslinking agent dosage, crosslinking time were investigated through orthogonal experiment method.

Effects of chitosan mass concentration on gel beads formation

HAc volume concentration and organic titanium mass concentration were fixed at 1 and 10 %, chitosan mass concentration increased progressively from 25 to 40 g•L−1, the appearances of gel beads were shown in Table 2.

It is indicated in Table 1 that gel beads appearance had greatly changed as the chitosan concentration increased. Droplet could not shape up at the chitosan concentration of 20 g•L−1; as the concentration increased to 25 g•L−1, it forms into uniform spheres with obvious dent on the surface, and then it became an irregular piece with certain strength after dried for dehydration. When the concentration increased to 30 g•L−1, droplets formed into relatively regular gel beads; as the concentration came to 40 g•L−1, it was quiet hard to squeeze out chitosan solution due to its high viscosity, tailing was observed at the tine of needletube, making the operation hard to proceed with.

Effects of organic titanium concentration on gel beads formation

HAc volume concentration and chitosan mass concentration were fixed at 1 % and 35 g•L−1, with organic titanium concentration increasing from 3 to 20 %. The effects of organic titanium concentration on gel beads formation were shown in Table 3.

It is indicated that when organic titanium concentration was lower than 5 %, formed gel beads were tailed and adhesive, the formation proceeded slowly; however, as the concentration rose up to 20 %, gel beads shrank into round; thus, the proper range of organic titanium concentration varied from 7 to 20 %.

Effects of acetum concentration on gel beads formation

Concentrations of chitosan and organic titanium were fixed at 35 g•L−1 and 10 %, respectively. Effects of different volume concentration of acetum (1 %,2 %,3 %) on gel beads formation were investigated. Gel beads prepared from chitosan/1 % acetum showed the most regular appearance and uniform size, the formation took shortest time; beads suspended firstly, and then sank down without adhesion.

Effects of crosslinking time on gel beads formation

HAc volume concentration was fixed at 1 %, the concentrations of chitosan and organic titanium were 35 and 10 %, respectively, the effects of crosslinking time on gel beads sizes were investigated. It’s shown in Table 4 that as the crosslinking time increased, the shrinkage of gel beads were more salient and the mean size of dried beads became smaller. Additionally, the color went darker and eventually became brown when crosslinking lasted longer than 3 h.

Considering all the factors involved in chitosan gel beads formation and operational convenience, we prepared three kinds of gel beads from chitosan solution (35 g•L−1, mass concentration) and organic titanium solution (8 %, 10 %, 15 %, weight fraction), diameter of syringe needle was 0.8 mm. Appearances of wet and dry gel beads prepared with organic titanium concentration at 10 % were shown in Fig. 7 in which (a) showed wet beads and (b) showed dry beads. It is obvious that wet crosslinked chitosan gel beads were semitransparent and uniform, their diameters varied from 3.2 to 3.6 mm, however, the beads became brown yellow transparent spheres after shrinkage due to dehydration, and the diameters varied from 1.0 to 1.2 mm.

Chitosan/organic titanium gel beads characterization

SEM study

According to the optimal conditions included in last segment, we prepared three kinds of gel beads with chitosan solution (35 g•L−1, mass concentration) and organic titanium solution (8 %, 10 %, 15 %, weight fraction). The crosslinking lasted for 1 h, obtained beads were dried in vacuum dryer at 40 °C and the micro morphology was investigated with SEM.

As shown in Fig. 8a, there was obvious dent in the surface of gel bead prepared with 8 % organic titanium solution due to the evaporation of internal water, meanwhile, the special core/shell structure of gel bead was clear. Appearances of the gel beads were more regular and hollow area in the surface decreased gradually with increase of concentration of crosslinking agent. Additionally, micrographs b, d, f showed clearly microporous structures, the surface structure of became compact with fewer pores with higher concentration of crosslinking agent.

Thermal stability (TG-DSC)

Thermal stabilities of original chitosan and crosslinked chitosan gel beads were shown in Fig. 9 where (a) represented thermogravimetric analysis (TG), (b) represented differential scanning calorimetry (DSC). There were two prominent weight loss zones of both the original chitosan and crosslinked gel beads in testing temperature region concluded from upper analysis, the first zone (0~200 °C) was caused by loss of water and the second was resulted from decomposition of chitosan. For the relatively high content of water in gel beads, there was no obvious terrace in weight loss zone of TG curve. As chitosan was hypocrystalline, its decomposition included decompositions of amorphous backbones, crystalline backbones and complete decomposition, thus the range of weight loss zone was very wide.

Additionally, that the temperature at which gel beads performed largest decomposition rate was lower than that of original chitosan by 8 °C may result from the followed two aspects [31]: (1) The strong interaction between chitosan and organic titanium brought down the crystallinity of chitosan, the heat resistance of amorphous chitosan was weaker compared to crystalline chitosan. (2) Residual HAc in the composite also had an influence on the decomposition temperature. However, the comparison of weight loss ratio of chitosan and gel beads at final testing temperature(500 °C) indicated that the final thermal stability was improved as the weight loss ratio of gel beads was smaller than that of original chitosan. In summary, the thermal stability of chitosan was improved after crosslinked with organic titanium.

Swelling ability of chitosan/organic titanium gel beads

Alkalescent -NH+ on unmodified chitosan molecules would combine with H+ in dilute acid when directly used as absorption agent, sequentially became polyelectrolyte with positive charge, the inter/intro molecule hydrogen bonds were destroyed which made chitosan unstable and easily swell in acid medium even dissolve when acidity was strong. This defect greatly limited the application of chtiosan for disposal of water. In order to find out whether chitosan is stable enough to be used as drug carrier or absorbent, it’s important to study the swelling ability of gel bead in solutions with different pH.

The effects of static placing time, pH of swelling medium and concentration of crosslinking agent on swelling ability of gel beads were investigated through orthogonal experiments.

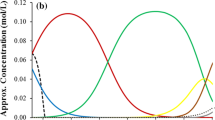

Effect of static placing time on SD

Six groups of accurately weighed gel beads were immersed in buffer solution with pH 4.00, 6.86, 9.18 and picked out at set interval, after an elimination of surface water, the mass of swelled gel beads was weighed with electronic balance, and the swelling degrees were calculated according to the formula mentioned in 2.6, results were shown in Fig. 10. As is shown in the graph, all the swelling degrees increased sharply to 35 % during the first 1 h, and then swelling rates gradually decreased with the increase of swelling time. Gel beads in solution with pH 6.86 reached swelling equilibrium after immersed for 3 h, however, it took quite longer for gel beads in solution with 4.00 and 9.18 to reach swelling equilibrium, 7 and 5 h respectively.

Effects of pH solution on swelling degree

According to Fig. 10, the pH of medium played an important role in the swelling degree, the gel beads performed largest swelling degree in acid medium within same swelling time. Because the protonation of amino groups on chitosan chains is much easier in acid medium and there were abundant H+ for combination with free amino groups, consequently, the electrostatic repulsion among the internal parts and chains of macromolecules were enforced which made the macromolecular network loose. Meanwhile, protonation could weaken the intensity and density of crosslinkage. On the contrary, protonation in neutral and alkaline medium was less effective and ion content of gel beads was higher which made the swelling degree smaller.

Effects of crosslingking agent concentration on swelling ability

Six groups of gel beads prepared from organic titanium with concentration at 8 %,10 %,15 % were immersed in buffer solution with pH 6.86, swelling degrees at different time were measured, it was shown in Fig. 11 that the swelling degree of gel beads prepared from organic titanium with concentration 8 % was largest, however, all the three kinds of SDs were smaller than 50 % due to the low crosslinking density of shell structure when the organic titanium concentration was relatively low, the surface structure was looser and in favor of absorbing water.

Conclusions

A series of complex gels was successfully prepared through the crosslinking reaction between hydroxyls on the CTS molecular chains and free titanate ions from organic titanium aqueous solution. The gelation processes of the gels was clearly shown in the time dependence of rheological properties and the sol-gel transition point can be determined through Winter-Chambon theory based on mechanical experiments. An increase in either CTS or OT concentration could contribute to the gelation rates, resulting in shorter gelation time. Beads based on this complex gel with obvious core/shell structure were prepared through outside resource technique, uncrosslinked chitosan consisted of the core, and the shell was a gel layer formed with chitosan and organic titanium. SEM indicated that the gel beads had regular appearance and surface with wrinkles and pores. With the increase of organic titanium concentration, the spherical structure became more compact and the surface was smoother. Thermal analysis shows the gel beads has higher thermal stability compared to original chitosan.

The effects of preparing conditions on CTS/OT gel beads formation were investigated, which indicated that chitosan concentration was the key factor in gel beads formation. Gel beads prepared with 35 g•L−1 chitosan had regular and uniform appearance. Organic titanium concentration also had an influence on gel beads formation, only when the concentration of organic titanium was higher than 7 % could the gel beads shape up, gel beads shrank and became darker with the increase of concentration about crosslinking agent. The gel beads would seriously deform when the organic titanium concentration was higher than 20 %.

The swelling study shows that CTS/OS gel beads have high mechanical strength in medium of different pH, generally, the SD was weak and reached only 81 % even in acid medium, dissolution was not observed. Swelling abilities of gel beads largely depends on pH value of the medium; protonation of amino group was obvious when gel beads were immersed in acid medium, making the macromolecular network loose, thus, the swelling degree increased. Gel beads prepared with 8 % organic titanium solution performed the best swelling ability due to its loosest surface structure.

References

Boucard N, Viton C, Domard A (2005) New aspects of the formation of physical hydrogels of chitosan in a hydroalcoholic medium. Biomacromolecules 6(6):3227–3237

Kurita K (2006) Chitin and chitosan: functional biopolymers from marine crustaceans. Mar Biotechnol (N Y) 8(3):203–226

Xu Y, Zhan C, Fan L, Wang L, Zheng H (2007) Preparation of dual crosslinked alginate-chitosan blend gel beads and in vitro controlled release in oral site-specific drug delivery system. Int J Pharm 336(2):329–337

Liang S, Liu L, Huang Q, Yam KL (2009) Preparation of single or double-network chitosan/poly(vinyl alcohol) gel films through selectively cross-linking method. Carbohydr Polym 77(4):718–724

Barreiro-Iglesias R, Coronilla R, Concheiro A, Alvarez-Lorenzo C (2005) Preparation of chitosan beads by simultaneous cross-linking/insolubilisation in basic pH: rheological optimisation and drug loading/release behaviour. Eur J Pharm Sci 24(1):77–84

Liang ZP, Feng YQ, Meng SX, Liang ZY (2005) Preparation and properties of urease immobilized onto glutaraldehyde cross-linked chitosan beads. Chin Chem Lett 16(1):135–138

Gupta NV, Shivakumar HG (2010) Development of a gastroretentive drug delivery system based on superporous hydrogel. Trop J Pharm Res 9(3):257–264

Umadevi SK, Thiruganesh R, Suresh S, Reddy KB (2010) Formulation and evaluation of chitosan microspheres of aceclofenac for colon-targeted drug delivery. Biopharm Drug Dispos 31(7):407–427

Rinaudo M (2010) New way to crosslink chitosan in aqueous solution. Eur Polym J 46(7):1537–1544

Chenite A, Wang D, Chaput C, Kandani N (2001) Rheological characterisation of thermogelling chitosan/glycerol-phosphate solutions. Carbohydr Polym 46(1):39–47

Cho J, Heuzey MC, Bégin A, Carreau PJ (2005) Physical gelation of chitosan in the presence of beta-glycerophosphate: the effect of temperature. Biomacromolecules 6(6):3267–3275

Gupta KC, Jabrail FH (2006) Effects of degree of deacetylation and cross-linking on physical characteristics, swelling and release behavior of chitosan microspheres. Carbohydr Polym 66(1):43–45

Wu J, Su Z-G, Ma G-H (2006) A thermo- and pH-sensitive hydrogel composed of quaternized chitosan/glycerophosphate. Int J Pharm 315(1–2):1–11

Chen S, Liu M, Jin S, Wang B (2008) Preparation of ionic-crosslinked chitosan-based gel beads and effect of reaction conditions on drug release behaviors. Int J Pharm 349(1–2):180–187

Shu XZ, Zhu KJ (2002) Controlled drug release properties of ionically cross-linked chitosan beads: the influence of anion structure. Int J Pharm 233(1):217–225

Wu Z, Li S, Wan J, Wang Y (2012) Cr(VI) adsorption on an improved synthesized cross-linked chitosan resin. J Mol Liq 170:25–29

Schmuhl R, Krieg HM, Keizer K (2001) Adsorption of Cu(II) and Cr(VI) ions by chitosan: kinetics and equilibrium studies. Water SA 27(1):1–7

Webster A, Halling MD, Grant DM (2007) Metal complexation of chitosan and its glutaraldehyde cross-linked derivative. Carbohydr Res 342(9):1189–1201

Deleanu C, Simonescu CM, Constantinescu I (2008) Adsorption behaviour of Cu(II) ions from aqueous solution on chitosan. Revista Chimie 59(6):639–642

Chenite A, Gori S, Shive M, Desrosiers E, Buschmann MD (2006) Monolithic gelation of chitosan solutions via enzymatic hydrolysis of urea. Carbohydr Polym 64(3):419–424

Köpf H, Köpf-Maier P (1979) Titanocene dichloride -the first metallocene with cancerostatic activity. Journal Article 18(6):477–478

Shibata Y, Suzuki D, Omori S, Tanaka R, Murakami A, Kataoka Y, Baba K, Kamijo R, Miyazaki T (2010) The characteristics of in vitro biological activity of titanium surfaces anodically oxidized in chloride solutions. Biomaterials 31(33):8546–8555

Fang J, Zhao J, Sun Y, Ma H, Yu X, Ma Y, Ni Y, Zheng L, Zhou Y (2014) Biocompatibility and antibacterial properties of zinc-ion implantation on titanium. J Hard Tissue Biol 23(1):35–43

Felinto MCFC, Parra DF, da Silva CC, Angerami J, Oliveira MJA, Lugão AB (2007) The swelling behavior of chitosan hydrogels membranes obtained by UV- and γ-radiation. Nucl Instrum Methods Phys Res Sect B: Beam Interactions with Materials and Atoms 265(1):418–424

Doi M (1980) Molecular rheology of concentrated polymer systems. J Polym Sci B Polym Phys 18(5):1005–1020

Yu L, Wang D, Li H, Liu B, Wang X, Xu Y (2010) Preparation and characterization of magnetic resin made from chitosan and cerium. J Ocean Univ China (English Edition) 9(2):185–192

Chambon F, Henning Winter H (1985) Stopping of crosslinking reaction in a PDMS polymer at the gel point. Polym Bull 13(6):499–503

Winter HH, Mours M (1997) Rheology of polymers near liquid–solid transitions. Adv Polym Sci 134:165–234

Te Nijenhuis K, Winter HH (1989) Mechanical properties at the gel point of a crystallizing poly(vinyl chloride) solution. Macromolecules 22(1):411–414

Andrew B, Rodd DED, Ross-Murphy SB, Boger DV (2001) Dependence of linear viscoelastic critical strain and stress values on extent of gelation for a thermally activated gelling system. Rheol Acta 40(1):23–29

Meena A, Parikh T, Gupta SS, Serajuddin ATM (2014) Investigation of thermal and viscoelastic properties of polymers relevant to hot melt extrusion - II: cellulosic polymers. J Excipients Food Chem 5(1):46–55

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, Y., Shen, C. & Gao, S. Preparation and characterization of chitosan gel beads crosslinked by organic titanium. J Polym Res 22, 53 (2015). https://doi.org/10.1007/s10965-015-0693-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-015-0693-7