Abstract

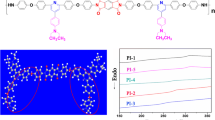

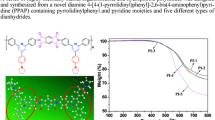

New soluble polyimides were synthesized from different 4,4′-diaminodiphenylmethane monomers with different alkyl substituents [4′4′-diamino-3,3′-dimethyl-diphenyl-methane, DDMDPM; 4,4′-methylene -bis(2-ethyl-6-methylaniline), MBEMA; and 4,4′-methylene-bis(2,6-diethylaniline), MBDEA] in one-step with the poly(amic acid)s prepared from the polyaddition of 4,4′-oxydiphthalic anhydride (ODPA). The structures of the synthesized polyimides were confirmed by Fourier transform infrared (FTIR) and nuclear magnetic resonance (NMR) spectroscopy measurements. The sizes and numbers of alkyl substituents affected the thermal properties, dielectric constants, and solubilities of the polyimides. The obtained polyimides were soluble in various solvents, such as N-methyl-2-pyrrolidone (NMP), N,N-dimethylacetamide (DMAc), N,N-dimethylformamide (DMF), tetrahydrofuran (THF), dichloromethane (DCM), and chloroform (CClH3). These polyimides exhibited excellent thermal stability with a decomposition temperature (Td) greater than 500 °C and relatively low coefficients of thermal expansion and dielectric constants. The resulting properties make these new polyimides attractive for practical applications.

Typical mechanism for the synthesis of polyimides from 4,4′-diamino-diphenyl-methane monomers and 4,4′-Oxydiphthalic anhydride

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polyimides (PIs) are step or condensation polymers derived from either aliphatic or aromatic dianhydrides and diamines or their derivatives, and they contain a heterocyclic imide linkage in their repeat unit [1–4]. Polyimides have various applications in the printed circuit, automobile, aerospace, and memory industries due to their thermal stability, high chemical resistance, high mechanical strength, and lower dielectric properties [1–5]. Polyimides or their composites and related compounds have also emerged as promising materials for pervaporation dehydration of solvents due to their excellent thermal, chemical, and mechanical stabilities [6–9]. However, polyimides are classified as insoluble and intractable due to their rigid backbone structure, which limits their use. Recently, a considerable amount of synthetic effort has been focused on improving the processability and solubility of polyimides through the synthesis of new diamine or dianhydride monomers [10–15]. The solubilities of polyimides using a two-step thermo-imidization synthesis are very poor and form a crosslinked structure easily [16]. However, various authors have reported that a one-step method may be the most effective for the preparation of processable polyimides with large molecular weights and linear structures [17, 18]. Some methods to overcome the aforementioned disadvantages include adding pendant groups and reducing chain crystallinity and electronic polarization interactions [10–15]. These polyimide properties can be dramatically altered by minor variations in their structures.

Previous investigations have shown that bulky groups enhance interchain spacing, prevent coplanarity of aromatic rings, and reduce the packing efficiency, which can result in an unsymmetrical and bulky pendant effect that enhances the solubility of the prepared polyimides [10–15]. In addition, these studies did not systematically discuss the effects of different pendant alkyl groups on the properties of polyimides. Therefore, the synthesis and characterization of new polyimides derived from 4,4′-oxydiphthalic anhydride (ODPA) and three types of diamine monomers were investigated using the one-step imidization approach. In addition, we investigated the effects of different pendant alkyl groups on the properties of polyimides. The resulting materials may be used as a low dielectric constant material in future applications, such as flexible printed circuits or in membrane-based separation.

Experimental

Materials

4,4′-Oxydiphthalic anhydride (ODPA) [Tokyo Chemical Industry (TCI) Co., Ltd., Japan] was recrystallized from acetic anhydride prior to use. 4′4′-Diamino-3,3′-dimethyldiphenylmethane (DDMDPM) (TCI Co., Ltd., Japan), 4,4′-methylene-bis(2-ethyl-6-methylaniline) (MBEMA) (TCI Co., Ltd., Japan), and 4,4′-methylene-bis(2,6-diethylaniline) (MBDEA) (TCI Co., Ltd., Japan) were purified by recrystallization from a hexane and toluene solvent mixture (volume ratio of 3:1) prior to use [1]. N-isopropyl-2-pyrrolidone (NIP) and isoquinoline (TCI Co., Ltd., Japan) were used. The diamines and dianhydride are shown in Scheme 1. Alkaline cleaning solutions and deionized water were used to rinse all of the glassware prior to use. All of the other solvents were purchased from Sigma Aldrich Corp., St. Louis, MO, USA.

Preparation of polyimides

The difference between the one-step imidization in Scheme 2a and the two-step thermal imidization in Scheme 2b is the use of a catalyst. Thermal imidization uses heat to perform the imidization without the need for any further catalyst. However, the one-step imidization requires a catalyst, such as isoquinoline, to increase the reaction rate [4]. Our syntheses were performed using the one-step method [19, 20]. The diamine monomer of DDMDPM (2.263 g, 10 mmol) or MBEMA (2.824 g, 10 mmol) or MBDEA (3.104 g, 10 mmol) dissolved in NIP (25 mL) was added under N2to a dry, 100-mL round-bottom flask equipped with a magnetic stir bar. Then, the dianhydride monomer of ODPA (3.102 g, 10 mmol) was added to this solution and vigorously stirred. The reaction mixture was stirred at ambient temperature under N2 for 6 h to afford a yellow solution. Then, isoquinoline (2.351 mL) was added to the homogeneous solution and stirred for 1 h. After stirring, a Dean-Stark trap was filled with toluene, and the temperature was increased to 180 °C for 15 h. This process is shown in Scheme 2a for the one-step polycondensation. Then, the polymers were precipitated in white fiber-like forms when the resulting polymer solutions were slowly poured into methanol with stirring.

Measurements

Fourier transform infrared (FTIR) spectra were recorded on a Nicolet 750 spectrometer. The spectra were obtained by averaging 64 scans at a resolution of 2 cm−1 over a range of 400–4,000 cm−1. The 1H NMR spectra were recorded on a Bruker 400 MHz instrument. Thermogravimetric analysis (TGA) data were obtained using a Perkin-Elmer Pyris 1 TGA thermogravimetric analyzer at a heating rate of 10 °C/min from 100 to 800 °C under a N2 atmosphere. The coefficient of thermal expansion (CTE) and softening point (Ts) of the fibers were measured using a TA Instruments 2940 thermomechanical analyzer (TMA) at a heating rate of 10 °C/min using the slope of the expansion temperature plots over a range of 100–250 °C. A schematic diagram of the testing procedure is shown in Fig. 1. To examine the solubility of these polyimides, seven solvents were used to dissolve the polyimides at ambient temperature including dichloromethane (DCM), chloroform (CHCl3), tetrahydrofuran (THF), dimethylformamide (DMF), N-methyl-2-pyrrolidinone (NMP), dimethyl sulfoxide (DMSO), and dimethylacetamide (DMAc). One gram of polyimides was considered to be soluble in 1 mL of solvent. In addition, the viscosities were measured at a concentration of 0.5 g/dL in DMAc at 30° using an AR-2000ex rheometer (TA Instrument, New Castle, DE, USA), and the results indicated that their molecular weights were sufficiently high to be useful. One-milliliter samples were run in a parallel-plate configuration using a 40-mm stainless steel plate with a gap distance of 103 μm. In a typical viscosity experiment, a constant frequency of 1 Hz and a strain of 10 % were used. The dielectric constant (ε) of the polyimide films was measured using the parallel-plate capacitor method at 1 MHz and room temperature. The dielectric constant was calculated from the capacitance (C, in Farad) using k = 4 Ct/πd2, where t is the thickness and d is the diameter of the sample.

Results and discussion

Characterization of polyimides

The structures of the synthesized polyimides (DDMDPM-ODPA, MBEMA-ODPA, MBDEA-ODPA) were confirmed by FTIR and NMR spectroscopy measurements. The FTIR spectra of the one-step synthesized polyimides from DDMDPM-ODPA, MBEMA-ODPA, MBDEA-ODPA, and PAA of DDMDPM-ODPA are shown in Fig. 2. The absorption bands of PAA from DDMDPM-ODPA at 2900–3250 cm−1 correspond to the N-H bond. The bands near 1,719 cm−1 were assigned to the vibrational modes of the acid groups. The bands near 1,660 and 1,537–1,542 cm−1 were assigned to the vibrational modes of the amide groups. However, the IR characteristic absorption bands of the imide ring appeared at 1,770 cm−1 and 1,720 cm−1 in the polyimides, which correspond to asymmetric C = O and symmetric C = O stretching, respectively [21, 22]. The absorption band at 1,395 cm−1 is attributed to C–N stretching of the imide ring. Stretching of the hydroxyl (O-H) group was observed near 3,470 cm−1. In addition, the peak at 725 cm−1 corresponds to the bending vibration of the C = O group. The bands at 2,850–3,300 cm−1 are due to the CH3, CH2, and CH groups, respectively [21, 22].

The NMR spectra were also obtained by dissolving the polyimides in CDCl3-d. The 1H-NMR spectra of the different diamine polyimides are shown in Figs. 3, 4, and 5. The NMR spectrum of the DDMDPM-ODPA polyimide has six protons corresponding to CH3 as a singlet at 2.18 δ ppm and two protons corresponding to CH2 as a singlet at 4.46 δ ppm. The aromatic proton appeared at 7.11–7.99 δ ppm for the DDMDPM-ODPA polyimide. The solvent was CDCl3-d, which corresponds to the peak observed at 7.24 δ ppm. The MBEMA-ODPA polyimide has 6 protons corresponding to CH2 as a triplet at 1.12–1.16 δ ppm, six protons corresponding to CH3 as a singlet at 2.14 δ ppm, four protons corresponding to CH2 as a quadruplet at 2.44–2.49 δ ppm, and two protons corresponding to CH2 as a singlet at 3.97 δ ppm. The aromatic proton appeared at 7.03–8.01 δ ppm for the MBEMA-ODPA polyimide. The MBDEA-ODPA polyimide has 12 protons corresponding to CH3 as a triplet at 1.11–1.15 δ ppm, eight protons corresponding to CH2 as a quadruplet at 2.42–2.47 δ ppm, and two protons corresponding to CH2 as a singlet at 4.03 δ ppm. The aromatic proton also appeared at 7.08–8.01 δ ppm for the MBDEA-ODPA polyimide. As expected, the NMR spectra did not display any amide or acid protons or the corresponding carbons, indicating that the polyimides were completely imidized.

Thermal properties of the polyimides

Figure 6 shows the degradation temperatures of the different polyimides. Some thermal differences in the polyimides produced by one-step imidization can be explained by the different alkyl pendant groups in the polyimide backbones. Table 1 lists the temperatures of the initial softening (Ts), 5 % (Td5), and 10 % (Td10) gravimetric losses in nitrogen. DDMDPM-ODPA exhibited a slightly higher Ts and Td10 compared to that for MBEMA-ODPA and MBDEA-ODPA. None of the investigated polymers exhibited any significant weight loss up to a temperature of 490 °C under a nitrogen atmosphere. In general, the thermal decomposition of polyimides started above 400 °C, which demonstrates their excellent thermal stability [23]. Research has shown that polyimides containing side chains exhibit distinct two-stage weight loss behaviors [23]. The weight loss percentage during the first degradation was equivalent to the weight fraction of the side chain, indicating that the values of Td5 have a close relationship with the structure of side chains. Higher values of Td5 demonstrated that DDMDPM-ODPA was more thermally stable compared to MBDEA-ODPA. The second degradation corresponded to the thermal degradation of the polymer main chain. Therefore, the larger alkyl pendant groups in the polyimide backbone exhibit lower thermal properties due to their less efficient packing. However, the three types of PIs obtained from the three functional diamines had similar structures, but different alkyl pendant groups in their polyimide backbones resulting in effective packing of the structure, higher Td10 values and residual weight. All of the polymers exhibited excellent thermal properties, and their decomposition temperatures at a weight loss of 10 % were greater than 500 °C under N2. One reason is that the polyimide structure contains many benzene rings, which results in easier packing leading to a coplanar structure. Therefore, the higher packing of the structure cannot be easily destroyed, which favors improved thermal properties. In addition, higher molecular weights lead to higher intrinsic viscosities [24], which improves the thermal properties. For example, Yoo et al. reported that the number average molecular weight and intrinsic viscosity of polyimides prepared were approximately 19,600 g/gmol and 0.24 dL/g, respectively [25]. The higher inherent viscosity indicates a relatively higher molecular weight. The studied polymers have a higher inherent viscosity of more than 0.7 dL/g. Therefore, the molecular weight of these polyimides cannot be low and will enhance the thermal properties. In addition, the effects of the pendent groups on the softening temperature (Ts) data were studied. For example, Fig. 7 and Table 1 show the softening point temperatures of these polymers. The Ts decreased when the number of pendent groups increased, and the reason for this behavior is similar to that for the behavior of Td.

In addition, the TMA results indicate that the three polyimides possess very low coefficients of thermal expansion (<50 ppm/°C) than a typical polymer, in which the slope of expansion change percentage on the temperature ranges from 100 to 250 °C. Some polymeric materials experience very large thermal expansions upon heating as indicated by the coefficients, which ranged from approximately 50 to 400 ppm/°C [26]. There are no obvious differences for CTEs among these three polyimides, as shown in Table 1. Therefore, these results indicate that these polyimides can be employed in high temperature applications.

Electrical and solubility properties

The dielectric constants (ε) of the three polyimides films are summarized in Table 1. According to the Maxwell-Garnett model [16], the porous structures in polyimide films can substantially reduce the dielectric constants because the dielectric constant of air is unity. The incorporation of alkyl pendant groups into the polyimide backbones can effectively decrease the dielectric constants of the materials, and the value of k decreases as the size of the pendant group increases, which may lead to less packing of the structure and a decrease in ε. This phenomenon indicates that interactions between polymer chains are effectively reduced by the presence of pendant groups along the linear backbone.

Table 2 lists the solubilities of the three polyimides. In this study, we synthesized three polyimides using the one-step method, and the results indicated that these polyimides are soluble in some organic solvents, such as N-methyl-2-pyrrolidone (NMP), N,N-dimethylacetamide (DMAc), N,N-dimethylformamide (DMF), tetrahydrofuran (THF), dichloromethane (DCM), and chloroform (CClH3). Based on the results of previous studies, this one-step method may be the most effective for preparation of processable polyimides with linear structures and large molecular weights [17, 18]. The solubilities of the polyimides prepared by the traditional two-step method using thermo-imidization easily forms crosslinked structures. These polyimides cannot be dissolved in any solvent other than sulfuric acid [16, 27]. When placed in the sulfuric acid, these polyimides may directly carbonize instead dissolving.

Conclusion

We synthesized new soluble polyimides in which aromatic polyimides with alkyl side chains of various sizes decreased the rigidity of the polymer chain and affected the thermal properties and dielectric constants. These new polyimides were synthesized from different 4,4′-diaminodiphenylmethane monomers with different alkyl polyimide substituents using a one-step method with the poly(amic acid)s prepared from the polyaddition of 4,4′-oxydiphthalic anhydride (ODPA). These polyimides exhibited excellent thermal stability with decomposition temperatures (Td) greater than 500 °C. In addition, the results also indicated that the decomposition temperature (Td) and softening temperature (Ts) decreased as the size or number of pendant groups increased due to polymer packing and coplanarity. The resulting polyimides also possessed relatively low coefficients of thermal expansion and dielectric constants. The dielectric constant (k) also decreased as the size or number of pendant groups increased. These new polyimides were soluble in various solvents and exhibited an amorphous nature. In addition, these polyimides are thermally stable and form strong, flexible films that can be cast from solution. These properties make these polyimides attractive for practical applications, such as in processable high-performance engineering plastics.

References

Wang L, Chang P, Cheng CL (2006) Structural effects of pendant groups on thermal and electrical properties of polyimides. J Appl Polym Sci 100:4672–4678

Jiang LY, Wang Y, Chung TS, Qiao XY, Lai JY (2009) Polyimides membranes for pervaporation and biofuels separation. Prog Polym Sci 34:1135–1160

Li Y, Wang Z, Li GJ, Ding MX, Yan JL (2012) Synthesis and properties of polyimides based on isomeric (4, 4′-methylenediphenoxyl) bis (phthalic anhydride)s (BPFDAs). J Polym Res 19:9772–9778

Ghosh MK (1996) In: Ghosh MK, Mittal KL (eds) Polyimides: fundamentals and applications. Marcel Dekker, Inc, New York

Myung BY, Kim JJ, Yoon TH (2002) Synthesis and characterization of novel 3,6-di[3′,5′-bis(trifluoromethyl)phenyl] pyromellitic dianhydride for polyimide synthesis. J Polym Sci A Polym Chem 40:4217–4227

Jiang LY, Chung TS (2010) Homogeneous polyimide/cyclodextrin compositemembranes for pervaporation dehydration of isopropanol. J Membr Sci 346:45–58

Wang Y, Jiang L, Matsuura T, Chung TS, Goh SH (2008) Investigation of the fundamental differences between polyamide-imide (PAI) and polyetherimide (PEI) membranes for isopropanol dehydration via pervaporation. J Membr Sci 318:217–226

Kung G, Jiang LY, Wang Y, Chung TS (2010) Asymmetric hollow fibers by polyimide and polybenzimidazole blends for toluene/iso-octane separation. J Membr Sci 360:303–314

Song ZW, Zhu JM, Jiang LY (2014) Novel polysiloxaneimide/polyetherimide/non-woven fabric composite membranes for organophilic pervaporation. J Membr Sci 472:77–90

Zheng Y, Zhai Y, Li G, Guo B, Zeng X, Wang L, Yu H, Guo J (2011) Synthesis and properties of a high-molecular-weight poly(amic acid) and polyimide based on 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane. J Appl Polym Sci 121:702–706

Akhter T, Siddiqi HM, Akhter Z, Butt MS (2011) Synthesis and characterization of some polyimide-epoxy composites. E-Polymers 022:1–13

Yang CP, Chen WT (1993) Synthesis and properties of novel aromatic polyimides of 2,3-bis(4-aminophenoxy)naphthalene. Macromolecules 26:4865–4871

Li F, Fang S, Ge JJ, Honigfort PS, Chen JC, Harris FW, Cheng SZD (1999) Diamine architecture effects on glass transitions, relaxation processes and other material properties in organo-soluble aromatic polyimide films. Polymer 40:4571–4583

Hsao SH, Chen YJ (2002) Structure–property study of polyimides derived from PMDA and BPDA dianhydrides with structurally different diamines. Eur Polym J 38:815–828

Liaw DJ, Wang KL, Huang YC, Lee KR, Lai JY, Ha CS (2012) Advanced polyimide materials: syntheses, physical properties and applications. Prog Polym Sci 37:907–974

Garnett JCM (1904) Colours in metal glasses and in metallic films. Philos Trans R Soc London Ser A203:385–420

Giesa R, Keller U, Eiselt P, Schmidt HW (1993) Synthesis and thermal properties of aryl-substituted rod-like polyimides. J Polym Sci A Polym Chem 31:141–151

Kuznetsov AA, Yablokova MY, Buzin PV, Tsegelskaya AY, Kaminskii VA (2004) New alternating copolyimides by high temperature synthesis in benzoic acid medium. High Perform Polym 16:89–100

Kim SD, Lee S, Heo J, Kim SY, Chung LS (2013) Soluble polyimides with trifluoromethyl pendent groups. Polymer 54:5648–5654

Dong J, Yin C, Luo W, Zhang Q (2013) Synthesis of organ-soluble copolyimides by one-step polymerization and fabrication of high performance fibers. J Mater Sci 48:7594–7602

Chung IS, Park CE, Ree M, Kim SY (2001) Soluble polyimides containing benzimidazole rings for interlevel dielectrics. Chem Mater 13:2801–2806

Liaw DJ, Liaw BY (1998) Synthesis and characterization of new soluble polyimides from 3,3′,4,4′-benzhydrol tetracarboxylic dianhydride and various diamines. Chem Mater 10:734–739

Kim SI, Ree M, Shin TJ, Jung JC (1999) Synthesis of new aromatic polyimides with various side chains containing a biphenyl mesogen unit and their abilities to control liquid-crystal alignments on the rubbed surface. J Polym Sci A Polym Chem 37:2909–2921

Chen SH, Tsao CT, Chang CH, Wu YM, Liu ZW, Lin CP, Wang CK, Hsieh KH (2012) Synthesis and characterization of thermal-responsive chitin-based polyurethane copolymer as a smart material. Carbohydr Polym 88:1483–1487

Yoo DK, Lim SK, Yoon TH, Kim D (2003) Physical properties and stress analysis of low dielectric polyimide films containing adamantine pendant group. Polym J 35:697–703

Kakani SL (2006) In: Kakani SL (ed) Material science: chapter 13. Thermal and optical properties of materials. New Age International, Ltd, New Delhi

Aguilar-Lugo C, Perez-Martinez AL, Guzman-Lucero D, Likhatchev D, Alexandrova L (2012) In: Marc Jean Médard A (ed) High Performance Polymers–Polyimides Based –from Chemistry to Applications: Chapter 1. Polyimides Based on 4-4′-Diaminotriphenylmethane (DA-TPM). InTech, Rijeka

Acknowledgments

The authors gratefully acknowledge the support for this research by the Ministry of Economic Affairs in Taiwan under the grant numbers 101-EC-17-A-08-S1-205 and Kaohsiung Medical University in Taiwan under the grant numbers KMU-TP103B03, respectively.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Wei-Yao Chang and Szu-Hsien Chen contributed equally to this work.

Rights and permissions

About this article

Cite this article

Chang, WY., Chen, SH., Yang, CH. et al. Preparation and characterization of aromatic polyimides derived from 4,4′-oxydiphthalic anhydride and 4,4′-diaminodiphenylmethane with different alkyl substituents. J Polym Res 22, 38 (2015). https://doi.org/10.1007/s10965-015-0679-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-015-0679-5