Abstract

A novel hybrid-nanocomposite of polyacrylamide-TiO2 (PAM/TiO2) with nano-anatase particles was synthesized in two steps. Firstly, the surface of nano-anatase particles was modified by 3-methacryloxy-propyl-trimethoxysilane (TMSM) as coupling agent by sol–gel method. Secondly, the surface modified nano-anatase particles were grafted onto the acrylamide monomer (AM) as an organic phase by free radical polymerization. The spectral (Fourier transform Infrared spectroscopy) and thermal (TGA) methods, verified the participation of coupling agent, polymer and titanium dioxide (anatase) into the hybrid structure. The results also showed that the degradation temperatures and residual content were obviously higher in nanocomposite than those of pure polyacrylamide (PAM). Scanning electron microscopy (SEM), transmission electron microscopy (TEM) and atomic force microscopy (AFM) studies proved that the nano-anatase particles have been uniformly encapsulated inside the nanocomposite sample containing 5wt% TiO2. However, the agglomeration of nano-particles in the nanocomposite with 20wt% of TiO2 was detected by atomic force microscopy (AFM) and dynamic mechanical thermal analysis (DMTA) studies. Thermo-mechanical properties of acrylamide homopolymer (PAM) and their nanocomposites were investigated by DMTA. The shifts in storage modulus and tanδ peaks were attributed to morphological changes in the nanocomposites with increasing the amount of inorganic nano-particles and their distribution in polymer matrix. Flocculation behavior of PAM and PAM/TiO2 in two different level of titanates (i.e. 5 and 20wt% TiO2) for 0.25wt% nano-clay suspension was evaluated using batch method. The adsorption results showed that PAM/TiO2 have ability for interaction with clay particles by means of adsorption through electrostatic interaction, Vander Waals forces and hydrogen bonding. However, it was found that the flocculation efficiency of the pure polymer (PAM) and the hybrid-nanocomposite (5wt% TiO2) is much better than that of its high concentration (20wt% TiO2) in the hybrid. This flocculation behavior can be attributed to uniform distribution of nano-particles and agglomeration possibility in the case of low and high concentration level of titanate in hybrid nanocomposite, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polyacrylamide (PAM), derivatives and its composites have been extensively used in wide range of industrial and environmental applications such as flocculants, fine solids retention in papermaking processes, mineral separation, water treatment, and soil remediation [1–4]. In recent years, the application of novel polymeric nanocomposite flocculants has been particularly attractive by incorporation of nano-particles [3]. In this regard, the various polyacrylamide nanocomposites have been prepared to improve its performance in different field of applications [5].

One of the most attractive nano-particles is titanium dioxide with three different crystal structures i.e. rutile, anatase and brookite. Nano titanates have gained much attention for their industrial application in different fields as well as catalysis, photocatalysis, electrocatalysis, lithium batteries, hydrogen storage, solar-cell technologies [6], pigment in paints, coating materials in optical thin films due to its transparency and high refractive index and also chemical durability in the visible and near IR region [7]. Among various nano-titanates, rutile and anatase are usually used in photo-catalysis, especially the anatase crystal structure [8].

Anatase nano-particle is inorganic filler, relatively inexpensive, nontoxic, biocompatible and photoactive with anti-bacterial properties and high thermal resistant. Anatase exhibits outstanding decomposition ability for many organic compounds and a fairly good anti-bacterial effect. It also shows strong photo-catalytic reaction induced by illumination with UV light [9, 10]. Further investigation is required to improve the compatibility of the inorganic nano-particles with polymer matrix for formation of novel functional composite materials [11].

The high hydrophilicity of nano-structured titanate surface can be induced the nano-particles to be easily agglomerated and hardly dispersible in polymer matrix. Surface modification of inorganic fillers from hydrophilic to hydrophobic entities can be provided by a wide range of organic modifiers [12]. Among the surface modifiers, silane coupling agents are by far the most frequently used to functionalize with different moieties on the surface. In treatment of nano-silica with silane coupling agent, 3-trimethoxysilyl-propyl-methacrylate (TMSM), the results showed that the grafting ratio of TMSM on the surface of nano-silica increased with the TMSM content [13].

Jang et al. [14] have investigated the effect of three different coupling agents (i.e. amine, epoxy and acrylate functional group) on the modification of SiO2 particles and on the emulsion polymerization of methyl methacrylate (MMA) and hydroxyl ethyl methacrylate. According to their results, a decreased particle size with a narrow size distribution was reported. However, the resultant composite has the most homogenous particle size distribution when modified by coupling agent containing acrylate functional group.

Modification of titanium dioxide surface was also conducted by organic coupling agents containing vinyl, amine and methacryloxy functional groups in order to alter its physico-chemical properties [12]. The results also indicated that surface modification of particles with silane coupling agents has not deteriorated morphological and micro-structural character of titanium dioxide; however, it has promoted some changes in polydispersity and in the range of particle diameters.

Titanium dioxide particles modified with 3-methacryloxy-propyl-trimethoxysilane have been found to be the best modifier which have demonstrated a lower range of diameters and the most pronounced time-related increase in weight of the sediment as compared to the unmodified and modified with the two other silane coupling agents. Nevertheless, all employed alkoxysilane modification promotes particle agglomeration which represents an undesirable phenomenon [12].

The characteristic composites containing micro-particle would give better flocculation and dewatering performance than conventional polymer flocculation systems [15, 16]. However, the flocculation was worse in several cases because of micro-particle agglomeration in the composites [17].

Hybrids of polyacrylamide/inorganic particles such as H3PW12O40, Al2O3 and silica have been prepared [18, 19]. Flocculation properties of Al (OH)3–polyacrylamide hybrids and polyacrylamide on kaolin suspensions were compared [20]. Organic—inorganic hybrid nanocomposites have been used as attractive materials to improve the compatibility of the inorganic nano-particles with polymer matrix for creating high performance or high function, due to synergism of two components. In this paper, a commercial nano-titanate with anatase nano-structure is modified with 3-methacryloxy-propyl-trimethoxysilane as coupling agent prior to solution polymerization with acrylamide monomer (AM). In this study, the physical properties of nanocomposite and the effect of nano-particle feed molar ratio on the properties of resultant nanocomposite was evaluate and studied.

Experimental

Materials

Anatase nano-sized was supplied by Degussa Ag (Dusseldorf, Germany) with an average diameter of 12nm, ignition loss less than 1% and a specific surface area of 200m2/g. Acrylamide (AM) synthesis grade was purchased from Merck. Silane coupling agent, 3-methacryloxy-propyl-trimethoxysilane (TMSM) was purchased from Fluka. Methanol, Ethanol, potassium per-sulfate (KPS), hydrochloric acid and acetone were supplied from Merck as analytical grade. Deionized water (DW) was utilized in all the experiments. The materials were used as received.

Preparation of PAM/TiO2 nanocomposite

One gram of nano-titanate (aerosil 200), 1ml of coupling agent TMSM (i.e. molar ratio of the coupling agent to TiO2 was 1:3) and 20ml of deionized water (by adjusting pH of the solution to 2 with hydrochloric acid) were added into 40ml of ethanol while stirring. After 15min intensive stirring, the mixture was subjected to an ultrasound bath for 5 min, followed by heating and refluxing at 50 °C for 5 days in oil bath. Then, the modified particles were washed and filtered several times with a mixture of ethanol/water and in the last time, washing and filtration were done only with water. Finally, 10ml deionized water was added to the resulting modified nano-particles prior to use, resulting in the formation of the surface-modified anatase particles (TMSM–TiO2).

The graft polymerization was carried out in a 500ml glass reactor fitted with a reflux condenser, glass stirrer, nitrogen gas inlet, and thermometer. The TMSM–TiO2 to monomer molar ratio was designed at 5 and 20wt%. Initially, acrylamide was dissolved in water to obtain a 10wt% aqueous solution and purged with nitrogen gas for 30 min. The modified TiO2 suspension and potassium per-sulfate as water soluble initiator (The initiator-to-monomer ratio was 1000 ppm) were purged with nitrogen gas for 5min., then added to the reactor. In order to complete polymerization, the content of reactor was stirred and heated to 75 ± 5 °C. The graft polymerization reaction was performed under nitrogen atmosphere for 4h [12–14, 19].

At the end, the white viscous solution was stopped by cooling the emulsion below 30 °C. The product was extracted with methanol to remove the unreacted monomer. The PAM/TiO2 nanocomposite was purified with repeating dissolving and extracting in water and ethanol, and then dried under vacuum, and finally the grafted particles PAM/TiO2 were gained. Scheme 1 indicates the different steps of preparation processes of PAM/TiO2 nanocomposite.

Characterization

The chemical structure of the samples was characterized with spectroscopy technique (FTIR). FTIR Spectra were recorded on a Bruker IFS 48, spectrometer in the region of 400–4000 cm−1. The samples were prepared in the form of pellets with KBr and measured in the absorption mode.

Thermal gravimetric analysis (TGA) was performed for detecting degradation mechanisms of the samples. TGA tests were conducted under nitrogen flow from room temperature up to 700 °C. The heating rate was 10 °C/min.

The morphology of polymers was observed by using scanning electron microscopy (SEM) on a Cambridge S360 microscope using a back scattered or a secondary electron image detector at 20KV and 2.85A probe current. The samples were coated with gold in order to be conductive and subjected to scanning electron microscope analysis. The XPS analyses were performed by SEM-EDX mapping (LEO 440) for investigation of Ti atoms on the hybrid samples.

According to ASTM E1640, the constant frequency (1 Hz) and the temperature range from −100 to 200 °C, with a heating rate of 5 °C/min under nitrogen atmosphere, were used in DMTA measurements, using DMTA-PL instrument in single cantilever bending mode. AFM (NT-MDT) operated at ambient atmosphere was used to study the surface topography of the hybrid coatings. The integral Si3N4 tips and rectangular cantilevers, with gold reflecting coating on the back side used for the AFM measurements, had a spring constant of 0.1Nm−1, and the contact force used for imaging between tip and surface was typically1.5nN. The AFM topographic images were acquired in the constant force mode. The TEM image was obtained by Philips EM 208, H-7100. In order to prepare samples for the TEM experiment, the grid was placed on a glass substrate and then the coating solution was put on this substrate. After curing in the appropriate temperature, the coated grid was used for the TEM experiment.

The flocculants solutions were prepared by dissolving 5 and 20wt% of TiO2 hybrid nanocomposite samples as well as polyacrylamide homopolymer (PAM) as flocculent agents in 50 ml distillated water with concentration of 0.0001 g/ml. The flocculating ability was evaluated using batch method. The 0.25wt% of nano-clay sample is dispersed in 50 ml distillated water in a 100 ml beaker and vigorously stirred with magnetic stirrer for 15 min at room temperature. Then, the flocculent solution was added to the nano clay suspension and stirred again for 5 min at ambient conditions. After mixing, sedimentation rate and the settled volume was qualitatively investigated with respect to time intervals.

Results and discussion

FTIR studies: formation and interaction of nanocomposites

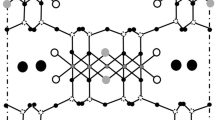

Scheme 2 shows the proposed modification of nano-anatase with 3-methacryloxy-propyl-trimethoxy silane coupling agent (TMSM) as well as the resultant hybrid nanocomposite.

The structure modification of anatase and their polymeric composites with acrylamide were studied by FTIR spectroscopy. FTIR spectra of unmodified TiO2 nano-particles, 3-methacryloxy-propyl-trimethoxy silane coupling agent (TMSM) and anatase modified with coupling agent are presented in Fig. 1. It is expected that 3-methacryloxy-propyl-trimethoxy silane was grafted onto the surface of TiO2 nano-particles by reaction of surface hydroxyl groups of TiO2 with the hydrolyzed functionalities of silane. FTIR spectroscopy confirmed the formation of covalent bonds due to condensation reaction between the surface hydroxyl groups of TiO2 and hydrolyzed TMSM(Fig. 1).

FTIR spectra of unmodified TiO2 nano-particles shows the broad band at around 3300 cm−1 and sharp band at around 1625 cm−1 can be attributed to the adsorbed water on the TiO2 [21, 22]. FTIR spectrum of the anatase modified with silane exhibits some new characteristic absorption peaks of TMSM, suggesting that the coupling agent molecules have been grafted onto TiO2 nano particles. The peak at 1703 cm−1 is assigned to the stretching vibration of the C = O groups. The vinyl bond at 1635 cm−1 could not be detected separately probably due to the overlapping with the strong peak of adsorbed water on the TiO2 in the same frequency region. The peak at 1452 cm−1 is attributed to the methylene C–H bending vibration whereas the peak at 1407 cm−1 may be due to the vinyl C–H in plane bending vibration of TMSM. The two well resolved peaks appeared at around 1322 and 1300 cm−1 and the peak at 1170 cm−1 assigned as –C–CO–O– skeletal vibration originating from the methacryloxy group [23]. Another set of peak appeared at 1014 cm−1 and 980 cm−1 has been assigned to CH3 rocking vibration [23].

An additional peak is present at 2950 cm−1 which is due to the C–H asymmetric stretching vibration of the methyl group of the organic compound. The sharp peak near 2840 cm−1 is characteristic peak of methoxy group which is disappeared after modification reaction, providing the occurrence of the hydrolysis reaction [24]. The findings of FT-IR indicate the formation of bonds between TMSM and the surface of TiO2 particles via the disappearance of OH groups on TiO2.

There are absorption peaks at 3423 cm−1, 1090 cm−1, 800 cm−1 and 467 cm−1 in the IR spectra curves which are ascribed to the vibrations of −OH and Si-O-Si groups in the SiO2. In the IR spectrum of TMSM, three new absorption peaks are found at 1697 cm1, 1454, and 1395 cm−1. These are attributed to the vibrations of C = O, C = C, and C-H groups of the TMSM molecules. These results indicate that the silane coupling agents have been incorporated on the surface of TiO2 particles [25].

FTIR spectra of homopolymer (PAM) and copolymer of 80% PAM and 20% modified TiO2 samples are depicted in Fig. 2. The peaks at around 1220 and 1085 cm−1, which are associated with Si-O-Si asymmetric bond stretching vibration, were observed in the copolymer PAM with modified TiO2 particles (20%TiO2:80%PAM). The peaks at 796 and 460 cm−1 are related to a Si-O-Si symmetric bond stretching vibration and a Si-O-Si bending vibration, respectively [14].

A vinyl group had also remained. At 1350 cm−1 the band was due to the methacrylate group. An intense, merged band of siloxane layer, polymerized silane layer could be seen at ca.1055 cm−1. A weak signal of the Si-O-Ti stretching vibration was seen at ca. 920 cm−1 [26]. The presence of silanols groups on the anatase is evidenced by the appearance of the hydroxyl peaks at 3100–3600 cm−1. In PAM–TiO2 hybrid nanocomposite, the shift of the carbonyl stretching peak to a low wave number is indicative of hydrogen bonding formation between the TiO2 surface hydroxyls and/or coupling agent and carbonyl groups of PAM. Moreover, in PAM–TiO2 hybrid, hydrogen bonding between the two phases could also be present. Scheme 3 shows the proposed Schematic presentation for hydrogen bonding between the OH groups of the modified TiO2 as well as the amide groups of the acrylamide in the nanocomposite [14].

The organic modification by silane coupling agents increases the affinity of the TiO2 particles towards AM monomers, owing to the covalent bond formation between the hydroxyl groups on the surface of the TiO2 particles and silane coupling agents. In addition, the organic chain originated from the coupling agent has good compatibility with monomer, which leads to more monomer absorption on the surface of TiO2 particles and thus enhances higher monomer conversion.

TEM analysis

A typical TEM image of the samples with 5 and 20 wt% of TiO2 were shown in Fig. 3. According to the micrograph Fig. 3a, TiO2 particles were irregularly spherical and homogeneously dispersed throughout the sample with diameter less than 60nm. This is indicative of lack of agglomeration of inorganic nano-particles in the bulk of polymer composite. It is believed that the polymerization of acrylamide monomer in the presence of 5wt% of modified TiO2 particles has produced an organic–inorganic hybrid nanocomposite.

However, the TiO2 particles are agglomerated to each other in some zones as seen in the Fig. 3b. It can be induced the zones of high and low dispersion of anatase in the PAM matrix which can be effected on the thermal and mechanical behavior of the composite as seen in the following sections.

AFM analysis

AFM technique was used to monitor the size and distribution of nano-particles in different places of sample surfaces at two levels of concentration of TiO2 particles in the nanocomposite. Figures 4 and 5 shows the AFM micrograph and particle size of the samples with 5 and 20wt% TiO2 in a two-dimensional level. The diameter of the nano-particles is in the range of 40–75nm and 40–175nm in low and high TiO2 content, respectively. In hybrid nanocomposite containing 5wt% TiO2, the nano-particles are uniformly distributed in the surface of matrix which is in good agreement with TEM results. The results confirm the well dispersed particles without aggregation and any particle growth in the matrix at nano-scale during solution polymerization, precipitation, purification and drying. This may be due to the formation of covalent bonds between vinyl groups of monomer and TMSM grafted on TiO2 nano-particles, which can reduce macroscopic phase separation and stabilize the nano-particles in the PAM matrix.

However, the TiO2 particles are somewhat agglomerated in the matrix with increasing the concentration of TiO2 particle in the nanocomposite (up to 20wt% TiO2). The agglomeration of particles in the composite containing 20wt% TiO2 can be attributed to association of inorganic particles to the covalent bond formation with each other due to condensation reactions of hydroxyl groups, induced macroscopic phase separation, and hence agglomeration of the nano-particles in the matrix.

SEM and EDX analysis

The morphology of hybrid nanocomposite containing 5wt% TiO2 was investigated by means of SEM technique (Fig. 6). SEM micrograph clearly evidences that there is not any agglomeration and phase separation in the nanocomposite. Moreover, the inorganic particle-size distributions were investigated in the hybrid by Ti mapping and SEM techniques. The Ti-map image of the same nanocomposite was shown by bright spots on the SEM morphological image (Fig. 7).

It is seen that Ti particle distribution in the hybrid is uniform and particle dimensions are small, without leading to the formation of large clusters. It can be attributed to good miscibility of organic and inorganic phases in the hybrid, which leads to the uniform distribution of organic and inorganic parts in the nanocomposite. In addition, the presence of TMSM grafted TiO2 nano-particles in the nanocomposite were also confirmed by means of XPS analysis. The EDX elemental analysis for 5wt% TiO2 grafted nanocomposite confirmed the presence of titanium, oxygen, silicon and carbon atoms (Fig. 8).

Furthermore, the SEM image of hybrid PAM-20 wt% TiO2 was shown in Fig. 9. As seen in this figure, with increasing of inorganic particles, the two phases morphology can be distinguished in the SEM micrograph by dark and bright zones. The bright zones can be attributed to TiO2 particles agglomeration zones in the PAM matrix.

TGA analysis

The thermal stability of PAM homopolymer and samples containing 5 and 20wt% of TiO2 (i.e. 5 % TiO2:95 %PAM and 20 %TiO2:80 %PAM) were compared and evaluated by thermal analysis data (Fig. 10). PAM showed four steps of weight loss [5]. The weight loss at 100 °C is attributable to loss of moisture, while those coincided with the weak drop of the TGA curve at 215 °C can be related to thermal processes involving both melting of the PAM chains and onset of degradation. In PAM polymer, the second step of weight loss started at about 215 °C and attained 26 % and 44 % at 300 and 350 °C, respectively. The first stage decomposition may be attributed to the thermo-oxidative cleavage of the weak and unstable linkages, i.e. methylene groups, leading to thermal degradation of PAM producing low molecular weight gases such as H2O, CO2, NH3, resulting also from the breakdown of side chain groups of amino acid residues. The sharp drop at above 300 °C is indicative of the occurrence of more extensive thermal degradation processes and being due to the cleavage of the imides linkages. There is a weight loss from 500 °C onwards, which is attributed to the oxidation of residual carbon.

The TGA curve of homopolymer showed about 98 % weight loss till 700 °C, while at the same temperature the hybrid nanocomposites showed about 92 and 75 % weight loss, respectively. Char yield at 700 °C also increases by increasing the nano-particle content. In the hybrid 20wt% TiO2, 5 % of weight is lost up to 182 °C due to the removal of ethanol and water trapped into the gel network of the nanocomposite. There is sharp weight loss which begins at 380 °C due to loss of the organics. After that, the nanocomposite exhibits slow and partial loss of the organics up to 700 °C.

The variation of the instantaneous rate (dw/dt) of hybrid nanocomposites and PAM is illustrated in Fig. 11. The differential TGA curves showed that the hybrid 20wt% TiO2 composite has higher temperatures (293 and 405 °C) at maximum pyrolysis rates (Tp), whereas the pure PAM had temperatures of 268 and 366 °C, respectively. The onset decomposition temperature (TD) increased by grafting of nano-particles onto the PAM. Although, the differential TGA curve of 5wt% TiO2 exhibited slightly lower temperature peaks than pure PAM homopolymer and 20 wt% TiO2, however, a broad and wide peak is seen in the following of this nanocomposite curve at higher temperature (i.e. above 400 °C). The better thermal stability of 5wt% TiO2 in compared with PAM and PAM-20wt% TiO2 can be attributed to better dispersion of anatase nanoparticles in the matrix.

DMTA analysis

Thermo-mechanical properties of homopolymer (PAM) as well as their nanocomposites with 5 and 20wt% of TiO2 content were characterized by dynamic mechanical thermal analysis (DMTA). The DMTA tests were performed on the samples namely PAM, PAM-5wt% TiO2 and PAM-20wt% TiO2, to investigate the morphology, glass transition temperature (Tg) and storage modulus (E’) in the temperature range of −50 to 200 °C. Typical storage modulus (E’) and tanδ curves of PAM and nanocomposites are presented in Figs. 12 and 13, respectively. The storage modulus of the nanocomposite with 5wt% of TiO2 is higher than that of the homopolymer as well as the sample containing 20wt% of TiO2. This could be explained by better dispersion and the existence of the strong interaction between the modified nano-particles and polymer chain leading to limitation of polymer chain movement [27]. The decrease in storage modulus of nanocomposite at higher value of nano-particle is due to agglomeration of grafted nano-particles. The temperature dependence of storage modulus of PAM-20wt% TiO2 shows almost similar pattern to PAM-5wt% TiO2 and is higher than the pure polymer at the temperature interval of −50 to 100 °C. It was found that the storage modulus of homopolymer is situated between their nanocomposites (i.e. more than 5wt% TiO2 and less than 20wt% TiO2 nanocomposite) at the temperature range of 100–150 °C and above 150 °C; it has decreased less than the nanocomposites. Beyond the Tg, the E’ curve exhibited a sharp fall, accompanied by the appearance of a prominent relaxation peak in tanδ, in response to strong motional transitions exhibited by the polymer chains at this temperature.

The tanδ behavior of polyacrylamide and their nanocomposites in two anatase loadings are presented in Fig. 13. The overall relaxation behavior is fairly similar for the three polymeric materials. The main relaxation peaks gave roughly similar curves with a sharp peak at about 180 °C. However, in nanocomposites the peak position was shifted slightly to higher temperatures while the amplitude was decreased by increasing the amount of grafted-TiO2.

The glass-transition temperatures of the polymer and their nanocomposites, as measured in tanδ curves, are in the range of 170–200 °C. These are comparable to the value of 165 °C reported in the polymer handbook [28]. The presence of grafted-TiO2 in the samples probably accounts for their higher glass-transition values. The presence of nano-particles is responsible for higher modulus with respect to that of pure polymer. Therefore, this may account for the higher storage modulus values below the glass-transition temperatures. The incorporation of a small amount of anatase nano-particle in polymer increased the storage modulus of nanocomposite below its glass transition temperature.

The polyacrylamide and their nanocomposites also present other small peaks in the region of 50 to about 100 °C. The peak position was changed with increasing the amount of grafted anatase in homopolymer matrix. The presence of these peaks may reflect the incipient distribution of molecular weights in polymerization process and/or segmental motion of acrylate grafted molecules to TiO2 attributed to an incipient glass transition. Tg value increases from 179 °C for homopolymer to 184 °C for nanocomposite with 5 wt% TiO2. This can be attributed to restriction of the segmental motions of polyacrylamide chains due to copolymerization with modified nano-particles [29].

Flocculation study

The application and the settling rate of the nano-clay suspension with the PAM and their nanocomposites were studied. On dosage of 1% flocculent, the settling rate was the highest for the PAM-5wt% TiO2 nanocomposite and the lowest for the PAM-20wt% TiO2 nanocomposite. In comparison of flocculation behavior between the samples, the hybrid nanocomposite (5wt% TiO2) is more beneficial from application point of view. This behavior can be attributed to the positive core of the TiO2 nano-particles in nanocomposite, which is responsible for attraction of the negatively clay particles by electrostatic interaction as well as hydrogen bonding. Therefore, the suitable flocculation efficiency in the hybrid nanocomposite is due to the synergism effect of polyacrylamide and nano-particles.

Conclusion

The infrared spectroscopy confirms the incorporation of organic modifier (TMSM) and PAM onto the surface of TiO2 particles. The composite properties could be well tailored by varying the TiO2 molar ratio in nanocomposites.

SEM and EDX images showed uniform distribution of Ti particles in 5wt% TiO2 grafted nanocomposite. At higher TiO2 contents (20wt %), agglomeration occurred. The thermal stability and dynamic-mechanical properties of nanocomposites were also studied by TGA and DMTA. The glass transition temperature of pure polymer increased from 179 °C to about 184 °C for PAM-5wt% TiO2, indicating an effective interaction between the PAM matrix and TiO2 particles. The decrease of storage modulus and presence of two relaxation peaks in Tanδ for the PAM-20wt% may be due to the agglomeration of grafted TiO2 particles within the PAM matrix that reduces the polymer/TiO2 interaction and may also reflect the distribution of molecular weight in polymerization process and/or segmental motion of acrylate grafted molecules to TiO2 attributed to an incipient glass transition.

Flocculation efficiency of PAM-5wt% nanocomposite is better than that of the pure PAM and PAM-20wt% TiO2 composite used for clay suspensions. The synergism effect between TiO2 and PAM in the PAM-5wt% nanocomposite exists in the clay flocculating process. It can be related to electrostatic interaction between the positive TiO2 core and the negative particle of clay as well as the adsorption-bridging effect of polyacrylamide chains in the nanocomposite.

In PAM-5wt% nanocomposite, the homogeneous and uniform dispersion morphology of TiO2 particles was observed with average particle size of 60nm. According to TGA data, the nanocomposite revealed a higher thermal stability and more residual ash than that of pure homopolymer.

The observed morphology of the hybrid nanocomposite can be attributed to the particle–matrix morphology. At low TiO2 values, the particles are well dispersed. These particles tend to aggregate and clusters formation with increasing TiO2 contents. According to AFM studies it was concluded that by increasing the TiO2 contents, the roughness of the fracture surface and the aggregation of nano-particles was increased.

References

Noppakundilograt S, Nanakorn P, Sonjaipanich K, Seetapan N, Kiatkamjornwong S (2009) Synthesis and characterization of acrylamide-based aluminum flocculent for turbidity reduction in wastewater. J Appl Polym Sci 114:2564–2575. doi:10.1000/app.30817

Wong SS, Teng TT, Ahmad AL, Zuhairi A, Najafpour G (2006) Treatment of pulp and paper mill wastewater by polyacrylamide (PAM) in polymer induced flocculation. J Hazard Mater 135:378–388. doi:10.1016/jjhazmat.2005.11.076

Sojka RE, Bjorneberg DL, Entry JA, Lentz RD, Orts WJ (2007) Polyacrylamide in agriculture and environmental land management. Adv Agron 92:75–162. doi:10.1016/S0065-2113(04)92002-0

Sharma BR, Dhuldhoya NC, Merchant UC (2006) Flocculants—an Esuriently Approach. J Environ Polym Degr 14:195–202. doi:10.1007/S10924-006-001x

Yang WY, Qian JW, Shen ZQ (2004) A novel flocculant of Al (OH) 3–polyacrylamide ionic hybrid. J Colloid Interface Sci 273:400–405. doi:10.1016/j.jcis.2004.02.002

Bavykin DV, Friedrich JM, Walsh FC (2006) Protonated titanates and TiO2 nano-structured materials: synthesis, properties, and applications. Adv Mater 18:2807–2824. doi:10.1002/adma.200502696

Gülşen G, Naci Inci M (2002) Thermal optical properties of TiO2 films. Opt Mater 18:373–381

Bach H, Krause D (1997) Thin films on glass. Springer, Berlin

Wang R, Hashimoto K, Fujishima A, Chikuni M, Kojima R, Kitamura A (1997) Light-induced amphiphilic surfaces. Nature 388:431–432. doi:10.1038/41233

Luo Z, Cai H, Liu J, Hong WL, Tang S (2005) Preparation of TiO2 coating on the glass and hydrophilicity under sunlight irradiation. Key Eng Mater 280–283:827–830. doi:10.4028/www.scientificnet/kem.280-283.827

Tianbin W, Ke Y (2006) Preparation of silica–PS composite particles and their application in PET. Eur Polym J 42:274–285. doi:10.1016/jeurpolymj.2005.08.002

Siwińska-Stefańska K, Krysztafkiewicz A, Jesionowski T (2007) Modification of hydrophilic/hydrophobic character of TiO2 surface using selected silane coupling agents. Physicochem Probl Miner Process 41:205–214

An F, Feng X, Gao B (2009) Adsorption of aniline from aqueous solution using novel adsorbent PAM/SiO2. Chem Eng J 151:183–187. doi:10.10.16/j.cej.2009.011

Jang J, Park H (2002) Formation and structure of polyacrylamide–silica nanocomposites by sol–gel process. J Appl Polym Sci 83:1817–1823. doi:10.1002/app.10116

Swerin A, Odberg L, Wagberg L (1996) An extended model for the estimation of flocculation efficiency factors in multicomponent flocculant systems. Colloids Surf, A Physicochem Eng Asp 113:25–38. doi:10.1016/0927-7757(95)03506-0

Yan ZG, Deng YL (2000) Bäcklund transformation, non-local symmetry and exact solutions for (2 + 1)-dimensional variable coefficient generalized KP equations. Chem Eng J 80:31–35

Ovenden C, Xiao HN (2002) Flocculation behavior and mechanisms of cationic inorganic microparticle/polymer systems. Colloids Surf, A Physicochem Eng Asp 197:225–234. doi:10.1016/S0927-7757(01)00903-7

Feng W, Zhang TR, Wei L (2002) Photochromic behavior and mechanism of thin films in H3PW12O40/polyacrylamide system. Mat Lett 54:309–313. doi:10.1016/S0167-577X901)00583-3

Matsuura Y, Matsukawa K, Kawabata R, Higashi N, Niwa M, Inoue H (2002) Synthesis of polysilane-acrylamide copolymers by photopolymerization and their application to polysilane-silica hybrid thin films. Polymer 43:1549–1553. doi:10.1016/S0032-386(01)00693-3

Yang WY, Qian JW, Shen ZQ (2004) A novel flocculant of Al (OH) 3-polyacrylamide ionic hybrid. J Colloid Interface Sci 273:400–405. doi:10.1016/J.JCIS.2004.02.002

Deng C, James PF, Wright PV (1998) Poly (tetraethylene glycol malonate)–titanium oxide hybrid materials by sol–gel methods. J Mater Chem 8:153. doi:10.1039/A703624H

Park HK, Kim DK, Hee C (1997) Effect of solvent on titania particle formation and morphology in thermal hydrolysis of TiCl4. J Am Ceram Soc 80:743. doi:10.1111/j.1151-2916.1997.tb02891.x

Katritzky AR, Lagowski JM, Beard JAT (1960) The Infrared spectra of esters. 2. Acetates, propionates, n-Butyrates, beta-aryl propionates, acrylates, methacrylates, crotonates, beta-aryl acrylates, formates, chloroformates, and carbonates. Spectrochim Acta 60:964–980

Chen R, Boerio FJ (1990) Infrared and X-ray photoelectron spectroscopy of aminophenyltrimethoxysilane films on metals. J Adhes Sci Technol 4(6):453–463. doi:10.1163/156856190X00423

Kang JS, Yu CL, Zhang FA (2009) Effect of silane modified SiO particles on poly (MMA-HEMA) soap-free emulsion polymerization. Iran Polym J 18:927–935. doi:10.1002/app.10116

Matinlinna JP, Ozcan M, Lassila LVJ, Vallittu PK (2004) The effect of a 3-methacryloxypropyltrimethoxysilane and vinyltriisopropoxysilane blend and tris (3- trimethoxysilylpropyl) isocyanurate on the shear bond strength of composite resin to titanium metal. Dent Mater 20:804–813. doi:10.1016/j.dental.2003.10.009

Mansoori Y, Atghia SV, Zamanloo MR, Imanzadeh G, Sirousazar M (2010) Polymer–clay nanocomposites: free-radical grafting of polyacrylamide onto organophilic montmorillonite. Eur Polym J 46:1844–1853. doi:10.1016/j.eurpolymj.2010.07.006

Gilman JW, Jackson CL, Morgan AB, Harris RJR, Manias E, Giannelis EP (2000) Flammability properties of polymer-layered-silicate nanocomposites. Polypropylene and polystyrene nanocomposites. Chem Mater 12:1866–1873. doi:10.1021/cm0001760

Yeh JM, Liou SJ, Chang YW (2004) Polyacrylamide–clay nanocomposite materials prepared by photopolymerization with acrylamide as an intercalating agent. J Appl Polym Sci 91:3489–3496. doi:10.1002/app.13555

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ershad-Langroudi, A., Rabiee, A. A novel acrylamide-anatase hybrid nanocomposite. J Polym Res 19, 9970 (2012). https://doi.org/10.1007/s10965-012-9970-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-012-9970-x