Abstract

The biodegradable polymer cholesteryl-(L-lactic acid)50, CLA50, was synthesized via ring-opening polymerization of L-lactide in the presence of cholesterol as an initiator and a catalytic amount of Sn(Oct)2. The resulting monohydroxyl-terminated CLA50 was subsequently converted to a bromine-ended macroinitiator (CLA50–Br) by esterification with 2-bromisobutyryl bromide. The amphiphilic diblock copolymer CLA50-b-PGMA was then synthesized via atom transfer radical polymerization of glycidyl methacrylate (GMA). The resulting polymers were characterized by FTIR, 1H NMR, GPC, and DSC. Polymeric micelles were prepared by the co-solvent evaporation method. The aqueous self-assembly of the copolymer CLA50-b-PGMA was investigated by TEM and DLS. Using naproxen as a hydrophobic model drug, drug-loaded micelles were prepared. TEM images of naproxen-loaded micelles of the copolymer (which exhibited a loading efficiency of 76.5 % and a loading capacity of 15.3 %) showed that the micelles were spherical and had diameters of 29–40 nm. An in vitro release study of naproxen was performed using the dialysis method in a phosphate-buffered solution at 37 °C. According to the results obtained in this work, these polymeric micelles could be tailored (by modifying the copolymer composition and molecular weight of blocks) to act as effective drug carriers that facilitate the release of various drugs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polymeric amphiphiles can form nanosized self-assemblies—spherical micelles—with an inner core of hydrophobic segments and an outer shell of hydrophilic segments in aqueous media, due to the intra- and/or intermolecular interactions of hydrophobic segments [1]. These polymeric micelles that form through the self-assembly of amphiphilic block copolymers exhibit many merits, such as nanoscale dimensions, core–shell structure, relatively high stability due to their low critical micelle concentration (CMC), and prolonged circulation because of their high water solubility [2]. In recent years, they have attracted wide scientific and technological interest due to their potential use as nanosized carriers of drugs that show poor solubility in water [3]. Controlled release of the loaded drug can be achieved through diffusion from the micelles or by the biodegradation of amphiphilic polymers. Many investigations [4–6] have reported that these self-assemblies, when used as drug-delivery systems, can reduce unwanted toxic side effects, increase the solubility of drugs that are poorly water soluble (by storing them within the hydrophobic core of the micelle), prolong the circulation time, reduce uptake by the reticuloendothelial system (RES), and enhance the therapeutic indices of drugs. Among the various polymeric amphiphiles that could potentially act as drug carriers, block copolymers of biodegradable poly-L-lactic acid (PLA) are the most attractive [7, 8]. Aliphatic polyesters such as PLA have high potential for use as biomaterials and environmentally friendly materials because of their hydrolytic and/or enzymatic degradation into products that are ultimately metabolized in most cases [9]. PLA is a biodegradable material with low toxicity and excellent biocompatibility; it has therefore been incorporated into the cores of micelles and used as a matrix for controlled drug release [1]. It has been reported that copolymers that include PLA can be synthesized through a combination of atom transfer radical polymerization (ATRP) and other polymerization methods such as chemical ring-opening polymerization (ROP) [10, 11]. In recent years, interest has grown in epoxy-based copolymers such as glycidyl methacrylate (GMA), which have been used in advanced biotechniques such as DNA separation, enzyme immobilization, and targeted drug delivery [12–14]. Controlled/“living” radical polymerization procedures can be used to prepare copolymers with predetermined molecular weights and narrow molecular weight distributions. Importantly, polymer chains prepared by atom transfer radical polymerization (ATRP) are highly end-functionalized and can therefore participate in various post-polymerization modifications and serve as macroinitiators in the synthesis of block copolymers [15, 16].

Amphiphilic acrylate- and lactone-based block copolymers find application in the fabrication of polymer systems for a variety of biomedical applications, ranging from controlled release systems used in drug delivery [17] to the fabrication of degradable surgical implants. The acrylate group allows the synthesis of systems that are nondegradable but readily tunable—in terms of hydrophilicity [18], pH- and temperature-induced phase behavior [19], and loading with therapeutic agents [20], for instance—through simple variation of the acrylate substituent. Further advantages of combining these blocks include the selective introduction of large numbers of functional groups via the polyacrylate block, the generation of amphiphilic block copolymers, and the creation of partially biodegradable structures. Nevertheless, only a few examples of the synthesis of polyester-block-polyacrylate copolymers via ROP of a lactone and ATRP of an acrylate have been described in the literature so far [10, 11, 17, 18, 21, 22]. Among the vast number of potential comonomer combinations, block copolymer systems based on lactide and glycidyl methacrylate (GMA) have not been reported so far, even though each of these polymers has been successfully and usefully employed in biomedical applications.

In our previous work, we synthesized and characterized liquid crystalline cholesteryl-(L-lactic acid) n , CLA n (n = 30), via an Sn(Oct)2-catalyzed bulk ROP method [23]. Although this method is not strictly a “living” process, the molecular weight of the copolymer can be adjusted by varying the L-lactic acid/cholesterol ratio [24]. The main purpose of the present study was to produce a new micellar vehicle to deliver the hydrophobic drug naproxen. This vehicle was prepared from the amphiphilic copolymer PCLA-b-PGMA. It is expected that PCLA-b-PGMA micelles possess a high loading capacity and good controlled-release properties in addition to their good biocompatibility due to the notable self-assembly capacity of the cholesteryl groups [25, 26]. In the work described in this paper, the synthesis and characterization of CLA50 and its block copolymer with glycidyl methacrylate via the ATRP method were achieved. In particular, we discuss initial studies on micellization and the in vitro release of naproxen as a hydrophobic model drug.

Experimental

Material

L-lactide, tin(II) bis(2-ethylhexanoate) (Sn(oct)2), and triethylamine (TEA) were obtained from Alfa Aesar (Ward Hill, MA, USA). 2-Bromisobutyryl bromide, copper(I) chloride (CuCl), 2,2′-bipyridine (bpy), glycidyl methacrylate (GMA), naproxen, and cholesterol were purchased from Merck (Darmstadt, Germany). Dialysis membrane (MWCO = 10,000) was purchased from Sigma–Aldrich (St. Louis, MO, USA). TEA was refluxed for 12 h in the presence of CaH2 and distilled in vacuo. GMA, dichloromethane, and DMF were distilled over calcium hydride (CaH2) in vacuo before use. CuCl was purified by precipitation from glacial acetic acid to remove Cu2+, filtered and washed with ethanol, and then dried. L-lactide, Sn(oct)2, 2-bromisobutyryl bromide, cholesterol, and bpy were used without further purification.

Cholesteryl-(L-lactic acid)50 (CLA50)

A mixture of L-lactide (1.5 g, 0.01 mol) and cholesterol (0.161 g, 0.4 mmol) was placed in a preheated oil bath at 150 °C and stirred until everything was molten. A solution of Sn(Oct)2 in toluene (1 mL, 0.0043 g Sn(Oct)2/mL) was then added, and the reaction mixture was stirred at 150 °C under an argon atmosphere. After 5 h, the reaction mixture was allowed to cool to room temperature, and the residual solid was triturated with MeOH (15 mL) and diethyl ether (15 mL). Solids were collected by filtration and finally vacuum dried at room temperature. The yield was 1.05 g (68 %).

Synthesis of the bromine-terminated macroinitiator (CLA50–Br)

The resulting CLA50 (0.3 g, 0.102 mmol) was dissolved in 5 mL of dry dichloromethane and then cooled in an ice bath (0 °C). To this solution, 0.094 mL (1.02 mmol) of TEA were added. After 5 min of stirring, 0.084 mL (1.02 mmol) of 2-bromisobutyryl bromide in 5 mL of dry dichloromethane were added dropwise to the solution over a period of 0.5 h. The reaction mixture was stirred at 0 °C for 2 h and then at room temperature for 22 h. The color of the solution changed from white to yellow. The precipitated by-product was removed by filtration and then the filtrate was evaporated to dryness. The crude product was dissolved in 30 mL of dichloromethane, and the organic phase was thoroughly washed successively with 5 % aqueous NaHCO3 and deionized water before being dried over MgSO4. The concentrated solution was poured into methanol to precipitate the product. The resulting white solid was dried for 24 h in vacuo. The yield was 0.23 g (76 %).

Synthesis of AB-type diblock copolymer

A dry flask equipped with a magnetic stirrer was charged with 0.024 g (0.08 mmol) of CuCl, 0.111 g (0.24 mmol) of bpy, and 0.2 g (0.015 mmol) of the macroinitiator CLA50–Br. The reaction mixture was immersed in an ice–water/NaCl mixture at about −10 °C and degassed using vacuum and argon three times, and then 18.3 mL (46.6 mmol) of the monomer GMA and 5.58 mL (30 % v/v of the monomer) of the solvent DMF were degassed using vacuum and argon three times. After the CLA50 macroinitiator had completely dissolved, polymerization was carried out under continuous stirring at 50 °C for 3 h. Finally, the reaction mixture was opened to the air and cooled to room temperature. The catalyst was removed by passing the polymer solution through a short aluminum oxide column. The crude polymer was purified by precipitation in methanol and then diethyl ether and dried in a vacuum oven overnight. The yield was 0.08 g (40 %).

Micelle formation and drug encapsulation

Polymeric micelles were prepared using a precipitation method. In brief, CLA50-b-PGMA (10 mg) and naproxen (2 mg) were dissolved in 5 mL of THF, and this solution was added to 10 mL of distilled water. After removing the THF, a dispersion of micelles in solution was prepared. Empty micelles (not loaded with the drug) were prepared using the same method as described above.

Unencapsulated naproxen was removed by centrifugation at 4,000 rpm for 10 min. The precipitate containing the unloaded drug was dissolved in a 50 % ethanol solution, and the amount of drug present was analyzed by UV-visible spectrophotometry at 330 nm. Standard solutions were prepared at concentrations ranging from 0.02 to 0.10 g L−1. The correlation coefficient (R 2) was at least 0.998.

It was found that ∼76.5 wt% of the free drug naproxen was loaded into the polymeric micelles (W total = 2 mg). The drug-loading efficiency (76.5 %) and drug-loading capacity (15.3 %) were calculated as follows:

where A is the total mass of naproxen used, B is the mass of unloaded naproxen in the precipitate after centrifugation, and C is the mass of the copolymer.

In vitro drug release test

The in vitro release of naproxen from the micelle was determined using the dialysis membrane diffusion technique. Three milliliters of the drug-loaded micelle solution were transferred into a dialysis tube (MWCO = 10,000) and immersed in 30 L of release media (pH 7.4 buffer solution) at 37 °C.

The mixed solution was monitored by UV-visible spectroscopy at 330 nm to determine the amount of drug released. At predetermined intervals, 3 mL of the medium were taken, and 3 mL of fresh PBS were added after each removal. The concentration of the drug released was determined using an UV-visible spectrophotometer at 330 nm, and all experiments were carried out in triplicate. Standard aqueous solutions were prepared at concentrations ranging from 0.003 to 0.02 g L−1. The correlation coefficient (R 2) was at least 0.996. The release percentage of naproxen was calculated from the following equation:

where W t is the mass of released naproxen at time t and W total is the total mass of absorbed naproxen in the polymeric micelle structure. W total was calculated as the mass of the free drug (i.e., the total mass of the drug used in this work, A, which was 4 mg) minus the mass of unloaded drug (B).

Methods

Melting points were recorded with a model 9100 melting point apparatus (Electrothermal, Rochford, UK). FT-IR spectra were recorded on a PS-15 spectrometer (Bruker Optics, Ettlingen, Germany). 1H NMR spectra were taken on a 400 MHz SP-400 Avance spectrometer (Bruker Biospin, Rheinstetten, Germany) using chloroform as solvent and tetramethylsilane as the internal standard. UV spectrometry was carried out using a T80 UV–vis spectrometer (PG Instruments, Lutterworth, UK). A model 822 differential scanning calorimeter from Mettler Toledo (Columbus, OH, USA) was used to determine phase transition temperatures at heating and cooling rates of 10 °C/min. The instrument was calibrated for temperature and enthalpy using indium. Thermogravimetric analysis (TGA) was carried out using a Mettler Toledo 822 instrument. The number-average and weight-average molecular weights were determined using gel permeation chromatography (GPC, 6A instrument, Shimadzu, Kyoto, Japan), with a Waters (Milford, MA, USA) Ultrastyragel 103 Å column, chloroform used as eluent at 40 °C, and a differential refractive index detector, performing calibration with polystyrene standards.

The polymeric micelles were analyzed by transmission electron microscopy (TEM). TEM observations were recorded with a Philips (Amsterdam, The Netherlands) SM10 TEM and Epson (Suwa) HP8300 photo flatbed scanner operated at an accelerating voltage of 150 keV. The TEM sample was prepared by placing a drop of the micellar dispersion on a copper grid coated with carbon film and staining with a 2 % (w/v) phosphotungstic acid aqueous solution. The average size and the size distribution of the polymeric micelles were determined by dynamic light scattering (DLS) using a light scattering spectrometer (SEM-633, SEMATech, Nice, France) at 25 °C.

Results and discussion

Synthesis and structural characterization

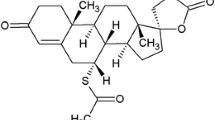

The synthetic paths to CLA50, the macroinitiator CLA50–Br, and the amphiphilic diblock copolymer CLA50-b-PGMA are presented in Scheme 1.

The synthesis of cholesteryl-(L-lactic acid) n with n = 10, 24, 37 in bulk using Sn(Oct)2 as a catalyst has been reported previously [27]. According to that report, in the absence of an alcohol used as a co-initiator, this ROP procedure does not permit accurate control over the molecular weight of the copolymer. However, in the presence of cholesterol and a catalytic amount of Sn(Oct)2, polymers with narrow molecular weight distributions can be prepared; in this case, the average molecular weight corresponds to the L-lactide/alcohol ratio. In our previous work, liquid-crystalline CLA30 was synthesized with accurate control over the molecular weight via the ROP method with a catalyst concentration of 100–1,000 ppm in 5 h [23]. The number-average degree of polymerization of CLA30 was evaluated by 1H NMR spectroscopy. Cholesteryl-terminated poly-L-lactic acid, CLA50, with a tightly controlled molecular weight was prepared according to our previously reported procedure [23], and was characterized by FT-IR and 1H NMR spectroscopy. The concentration of water in the reaction medium needs to be minimized because this determines the molecular weight distribution and the degree of incorporation of the initiator cholesterol into the CLA n chain terminus. The number-average degree of polymerization of CLA50 was evaluated by 1H NMR spectroscopy and GPC methods (Table 1).

The 1H NMR spectrum of CLA50 is shown in Fig. 1. In addition to the dominant PLA signals, the characteristic signal of the cholesterol moiety (a) is evident at 5.4 ppm, thus confirming the cholesterol-initiated ROP of L-lactide. Quartet signals at 5.2 ppm (b) derive from the main-chain methine protons of the PLA, while the doublet signals at 1.53 ppm (i) correspond to the methyl protons of the PLA main chain. Very small peaks from the protons of the methine and methyl groups closest to the cholesteryl moiety at around δ 5.1 and 1.45 ppm (Fig. 1), respectively, in the 1H NMR spectrum of CLA50 are also visible.

The number-average degree of polymerization of CLA50 was estimated from end-group analysis by 1H NMR spectroscopy. The intensity of the vinyl proton peak of the cholesterol moiety (at 5.4 ppm) was used for this purpose. Consequently, a number-average degree of polymerization of 54 was calculated.

The macroinitiator CLA50–Br for ATRP was obtained from the subsequent esterification reaction between the terminal hydroxyl group of the resulting CLA50 and 2-bromisobutyryl bromide. In the associated 1H NMR spectrum, new signals at 1.94 and 1.97 ppm were assigned to the diastereotopic methyl protons adjacent to the active bromide. In addition, the disappearance of the signal from the methine proton at the α position to the terminal –OH group of CLA50 (see Fig. 1, peak e) indicated the complete substitution of the end hydroxyl groups.

The prepared macroinitiator was subsequently used for bromoester-mediated GMA polymerization. ATRP of GMA from CLA50–Br was carried out at 50 °C in DMF (30 % v/v of the monomer) with CuCl/bpy as the catalytic system. The 1H NMR spectrum of copolymer CLA50-b-PGMA is shown in Fig. 2. It is apparent that besides the dominant CLA50 signals, there are new peaks (d) and (e) at 3.23 ppm and at 2.64 and 2.84 ppm, respectively, which were assigned to the methine proton and the methylene protons of the epoxy group. The signals at 4.33 and 3.79 ppm arise through the splitting of the signal due to methylene protons in the –CH2OCO– group of the GMA unit by the methyne proton of the epoxy group. In addition, the resonance signal from the α-CH3 splits into three well-resolved peaks at 0.94, 1.10, and 1.26 ppm, which are assigned to isotactic, heterotactic, and syndiotactic triads (stereochemical configuration of monomeric units along the PGMA chains), respectively. The composition of the copolymer was also obtained from the 1H NMR spectrum. For example, the intensities of the peaks at 0.94, 1.10, and 1.26 ppm and at 1.57 ppm for the copolymer CLA50-b-PGMA, due to the methyl protons of the PGMA block and the methyl protons of the PLA backbone, respectively, were used for this purpose (see Figs. 1 and 2). The molar masses, the average degree of polymerization (DP), and the copolymer composition are listed in Table 1.

Figure 2 shows the related FT-IR spectra of CLA50, CLA50–Br, and the CLA50-b-PGMA diblock copolymer. CLA50 contains an end hydroxyl group that yields a broad peak from 3,300 to 3,600 cm−1, which were assigned to O–H stretching vibrations (Fig. 3). As seen in the FT-IR spectrum of CLA50–Br, the attachment of 2-bromisobutyryl bromide to CLA50 resulted in a significant decrease in the OH-group absorbance peak at 3,510 cm−1 (Fig. 3).

For CLA50 and the CLA50–Br macroinitiator, a characteristic absorption band occurs at 1,759 cm−1, which was assigned to the ester carbonyl group of the PLA main chain. Comparison of the IR spectra of CLA50 and CLA50–Br with that of the CLA50-b-PGMA copolymer showed that the ester carbonyl absorption is shifted to 1,721 cm−1. This is probably due to the high content of PGMA in the copolymer (∼70 mol %), because the C=O stretching peak from the ester group of PGMA is observed at a lower wavenumber than it is for PLA [27, 28]. In addition, the spectrum of CLA50-b-PGMA shows new absorption bands at wavenumbers of approximately 848, 908, and 993 cm−1, which were ascribed to the epoxy group (Fig. 3). The characteristic bands at 2,851 and 2,930 cm−1 were assigned to the stretching of methyl groups in the α position with regard to the ester groups. Another variation associated with the GMA blocks in the copolymer was an increase in C–H stretching resonances from methyl groups, which resonate at 2,851 and 2,930 cm−1 (Fig. 3).

Thermal analysis

The second DSC heating curve of CLA50 (heating rate 10 °C min−1, Fig. 4) shows a glass transition at 50 °C, a cold crystallization at 93.8 °C (16.4 J g−1), and an endothermic transition peak at 133 °C with a total enthalpy of −47 J g−1. For CLA50-Br, the corresponding transitions were observed at 55 °C, 105 °C (36.6 J g−1), and 143 °C (−49 J g−1), respectively. The glass transition temperatures (T g) for these materials were still below the T g for PLA, which is known to be 57 °C. Thus, the results obtained for CLA50 and CLA50–Br clearly demonstrate the inability of the cholesterol segment to induce self-assembly in these polymers. The DSC curve for the block copolymer CLA50-b-GMA is also presented in Fig. 4. No melting or crystallization peaks were observed for the block copolymer. PGMA is an amorphous material without any crystallization temperature; the crystallinity of the block copolymer was attributed to the CLA50 block. However, its melting enthalpy reflects the amount of crystallinity in the sample. Due to the short CLA50 block in the copolymer, a melting transition was not observed for the CLA50 block, which could be due to a very small melting peak for the CLA50 block. The glass transition temperature of the PGMA block was 74 °C, similar to that of the homopolymer. There was no observable glass transition in the region between 50 and 74.8 °C, suggesting that the CLA50 segments and PGMA segments were immiscible.

Characterization of polymeric micelles

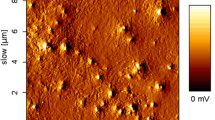

The amphiphilic block copolymer CLA50-b-PGMA, which consists of a potentially hydrophilic PGMA block and a biodegradable hydrophobic CLA50 block, provides the possibility of unique micellar formation in aqueous media. The precipitation method was therefore employed to prepare polymeric micelles [29]. The copolymer was first dissolved in THF and micellization was induced by the dropwise addition of water. The formation of nanoscale micelles in aqueous solution was judged based on the bluish tinge of such a solution. The aqueous self-assembly of the amphiphilic copolymer was monitored by DLS and TEM. The mean diameter of the copolymer in water was 239 ± 2.8 nm and the polydispersity index was 0.244 ± 0.03 (see Fig. 5a), as measured by the DLS method TEM can be used to probe the size and shape of the micelles in the solid state, which eliminates any perturbations caused by swelling in solvent. Figure 5b shows TEM images of micelles of the CLA50-b-PGMA diblock copolymer. A micrograph of the copolymer shows the presence of spherical micelles with diameters of 25–38 nm.

Drug-loaded copolymer micelles were prepared using naproxen as a hydrophobic model drug. A TEM image of naproxen-loaded copolymer micelles (loading efficiency 76.5 %) showed that the micelles were spherical with diameters of about 29–40 nm (Fig. 5c). However, compared with the blank nanoparticles (Fig. 5b), the drug-loaded polymeric micelles were slightly larger. This increase in the average diameter of the nanoparticles may suggest that naproxen molecules were physically entrapped in the nanoparticles.

In vitro drug release study

Naproxen, which shows poor solubility in water, was used as a model drug to investigate the drug loading and release properties of the polymer carrier. The naproxen was encapsulated in the hydrophobic micelle cores. The release behavior of naproxen from polymer micelles was studied in vitro by the dynamic dialysis method in PBS solution (0.1 M, pH 7.4) at 37 °C. Figure 6 presents the in vitro release profile of naproxen-loaded micelles in PBS. Naproxen was released at a relatively slow rate; only 40 % of the naproxen was released in 48 h. However, during the same time period, about 80 % of the naproxen permeated into the solution when the drug was added without being encapsulated in micelles. Thus, the drug was released more slowly from the micelles, which suggests that this polymer is an effective drug carrier for controlling the release of this drug.

Conclusions

In conclusion, an amphiphilic block copolymer consisting of cholesteryl-modified poly-L-lactide and poly(glycidyl methacrylate) was synthesized via ROP and ATRP. The number-average molecular weight of the mPLA and the copolymer composition were obtained using 1H NMR spectroscopy in accordance with the GPC results. DSC analyses showed that the high content of PGMA in the copolymer causes its amorphous structure. The amphiphilic, well-defined diblock structure self-associated in water to form core–shell micelles. Based on TEM observations, these micelles were found to be spherical with a mean diameter of 25–38 nm. Finally, the results of a study of the release of naproxen from these micelles indicated that this block copolymer could be used for controlled drug delivery.

References

Wang YS, Liu LR, Jiang Q, Zhang QQ (2007) Self-aggregated nanoparticles of cholesterol-modified chitosan conjugate as a novel carrier of epirubicin. Eur Polym J 43:43–51

Allen TM, Cullis PR (2004) Drug delivery systems: entering the mainstream. Science 303:1818–1822

Yan W, Li M, Gao H (2009) Polymeric micelle composed of PLA and chitosan as a drug carrier. J Polym Res 16:11–18

Jones MC, Leroux JC (1999) Polymeric micelles—a new generation of colloidal drug carriers. Eur J Pharm Biopharm 48:101–111

Kwon GS, Kataoka K (1995) Block copolymer micelles as long-circulating carriers for delivery of therapeutic and diagnostic agents. Adv Drug Deliv Rev 16:295–309

Torchilin VP (2001) Polymeric micelles for delivery of poorly soluble drugs: preparation and anticancer activity in vitro of paclitaxel incorporated into mixed micelles based on poly(ethylene glycol)–lipid conjugate and positively charged lipids. J Control Release 73:137–172

Sahoo R, Sahoo S, Nayak P, Sahoo S, Nayak P (2011) Controlled release of the drug cefadroxil from polycaprolactone–polylactic acid nanocomposites. Eur J Sci Res 53:154–162

Auras R, Lim LT, Selke SEM, Tsuji H (2010) Poly(lactic acid): synthesis, structures, properties, processing, and applications. Wiley, New York

Wu Y, Zheng Y, Yang W, Wang C, Hu J, Fu S (2005) Synthesis and characterization of a novel amphiphilic chitosan–polylactide graft copolymer. Carbohydr Polym 59:165–171

Hsiue GH, Lo CL, Cheng CH, Lin CP, Huang CK, Chen HH (2007) Preparation and characterization of poly(2-methacryloyloxyethyl phosphorylcholine)-block-poly(D,L-lactide) polymer nanoparticles. J Polym Sci Pt A Polym Chem 45:688–698

Wolf FF, Friedemann N, Frey H (2009) Poly(lactide)-block-poly(HEMA) block copolymers: an orthogonal one-pot combination of ROP and ATRP, using a bifunctional initiator. Macromolecules 42:5622–5628

Alagusundaram M, Madhu SCC, Umashankari K, Attuluri VB, Lavanya C, Ramkanth S (2009) Microspheres as a novel drug delivery system—a review. Int J ChemTech Res 1:526–534

Milosavić NB, Prodanović RM, Jovanović SM, Vujčić ZM (2004) Immobilization of glucoamyase on macroporous spheres. Acta Periodica Technologica (APTEFF) 35:207–214

Zhou WQ, Gu TY, Su ZG, Ma GH (2007) Synthesis of macroporous poly(glycidyl methacrylate) microspheres by surfactant reverse micelles swelling method. Eur Polym J 43:4493–4502

Matyjaszewski K (2012) Atom transfer radical polymerization (ATRP): current status and future perspectives. Macromolecules 45:4015–4039

Tsarevsky NV, Matyjaszewski K (2007) “Green” atom transfer radical polymerization: from process design to preparation of well-defined environmentally friendly polymeric materials. Chem Rev 107:2270–2299

Ma X, Wang H, Jin S, Wu Y, Liang X-J (2012) Construction of paclitaxel-loaded poly(2-hydroxyethyl methacrylate)-g-poly(lactide)-1,2-dipalmitoyl-sn-glycero-3-phosphoethanolamine copolymer nanoparticle delivery system and evaluation of its anticancer activity. Int J Nanomedicine 7:1313–1328

Wang Y, Yang J, Yang J (2011) Synthesis and self-assembly of novel amphiphilic copolymers poly(lactic acid)-block-poly(ascorbyl acrylate). J Polym Sci Pt A Polym Chem 49:3988–3996

Feil H, Bae YH, Feijen J, Kim SW (1993) Effect of comonomer hydrophilicity and ionization on the lower critical solution temperature of N-isopropylacrylamide copolymers. Macromolecules 26:2496–2500

Barz M, Tarantola M, Fischer K, Schmidt M, Luxenhofer R, Janshoff A, Theato P, Zentel R (2008) From defined reactive diblock copolymers to functional HPMA-based self-assembled nanoaggregates. Biomacromolecules 9:3114–3118

Jakubowski W, Matyjaszewski K (2006) New segmented copolymers by combination of atom transfer radical polymerization and ring opening polymerization. Macromol Symp 240:213–223

Wang W-W, Ren W-Y, Jiang L, Dan Y (2010) Synthesis and characterization of AB-type copolymers poly(L-lactide)-block-poly(methyl methacrylate) via a convenient route combining ROP and ATRP from a dual initiator. J Appl Polym Sci 118:2379–2388

Bagheri M, Hashempour M (2012) Preparation of thermoresponsive membrane using thermotropic liquid crystalline cholesteryl-(L-lactic acid) n . Iran J Polym Sci Technol 25(5):367–376

Klok HA, Hwang JJ, Iyer SN, Stupp SI (2002) Cholesteryl-(l-lactic acid) building blocks for self-assembling biomaterials. Macromolecules 35:746–759

Bagheri M, Shateri S (2012) Synthesis and characterization of novel liquid crystalline cholesteryl-modified hydroxypropyl cellulose derivatives. J Polym Res 19:9842–9854

Zhou Y, Briand VA, Sharma N, Ahn S, Kasi RM (2009) Polymers comprising cholesterol: synthesis, self-assembly, and applications. Materials 2:636–660

Hwang JJ, Iyer SN, Li LS, Claussen R, Harrington DA, Stupp SI (2002) Self-assembling biomaterials: liquid crystal phases of cholesteryl oligo(L-lactic acid) and their interactions with cells. Proc Natl Acad Sci USA 99:9662–9667

Hayek A, Xu Y, Okada T, Barlow S, Zhu X, Moon JH, Marder SR, Yang S (2008) Poly(glycidyl methacrylate)s with controlled molecular weights as low-shrinkage resins for 3D multibeam interference lithography. J Mater Chem 18:3316–3318

Bagheri M, Shateri S (2012) Thermosensitive nanosized micelles from cholesteryl-modified hydroxypropyl cellulose as a novel carrier of hydrophobic drugs. Iran Polym J 21:365–373

Acknowledgments

The authors would like to thank the Research Vice Chancellor of Azarbaijan Shahid Madani University for financial support of this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bagheri, M., Motirasoul, F. Synthesis, characterization, and micellization of cholesteryl-modified amphiphilic poly(L-lactide)-block-poly(glycidyl methacrylate) as a nanocarrier for hydrophobic drugs. J Polym Res 20, 59 (2013). https://doi.org/10.1007/s10965-012-0059-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-012-0059-3