Abstract

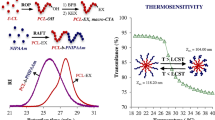

The formation of micelle self-assembled from hydrophobically end-capped poly(ethylene oxide) (PEO) and its application for drug delivery have been investigated. As an important ABA-type associative triblock copolymer, a series of hydrophobically end-capped poly(ethylene oxide) [H(CH2)nO(CH2CH2O)m(CH2)nH], consisting of PEO (B) as hydrophilic segment and alkyl groups as hydrophobic block, are synthesized successfully according to 1H NMR, Fourier transform infrared (FTIR), and differential scanning calorimetry (DSC) measurements. The triblock polymer is easy to form aggregates (micelles) under the appropriate conditions. The morphologies of micelles are found to be spherical confirmed by atomic force microscopy (AFM) measurement. Then, the polymeric micelles self-assembled from the triblock copolymer are used as a nanocarrier to solubilize poorly water-soluble drug spironolactone (a typical hydrophobicity drug). In vitro release behavior of spironolactone from triblock copolymer micelle is investigated carefully. It indicates interestingly that the drug can be released from triblock copolymer micelle stably and the release rate can be modulated by the variation of copolymer composition.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Over the last decades, shape-defined and functional supramolecular structures of polymer system attracted widespread interest for many applications, such as material science, nanotechnology, biology, medicine, and so on. The self-assembly of polymers induced by noncovalent forces, including π-π interactions, electrostatic interactions, hydrogen bonding, and hydrophobic and hydrophilic effects, plays an important role in the formation of supramolecular structures [1–12]. As is known to all, micelle is a typical core/shell structure and can be induced to form in the aqueous solvent of amphiphilic polymers. Furthermore, many researchers have focused on the function investigation of micelle extensively as drug delivery carriers, because polymeric micelles as novel drug vehicles possess huge advantages significantly, such as nanoscale size, solubility of hydrophobic drugs, drug targeting, stable storage, and feeble side effect of anticancer drugs [12–20].

Hydrophobically end-capped poly(ethylene oxide) belongs to amphiphilic polymer family and is easy to form polymer micelle particularly. Hydrophobically end-capped poly(ethylene oxide) is a triblock copolymer and consists of CnEmCn composition, in which poly(ethylene oxide) (PEO) chains are functionalized with alkyl groups at both ends. Here, it is used the mark E = oxyethylene, OCH2CH2, C = methylene, CH2, and subscripts m and n to denote the number-average block lengths of repeat units. As an important member of associative polymers, the properties of hydrophobically end-capped poly(ethylene oxide) in aqueous solution had been investigated extensively [21–31]. It indicated that the alkyl groups of polymer in aqueous solution associated to form the core of flower-like micelle above a critical concentration. The liquid–solid transition phenomenon can be observed at high volume fraction solution of flower-like micelle [32]. The micellization of hydrophobically end-capped poly(ethylene oxide) is mainly determined by many factors, such as molecular weight, the length of hydrophobic end chain, or the length of hydrophilic main chain. In particular, hydrophobically end-capped poly(ethylene oxide) has been widely taken as an ideal model system to study fundamental rheology property of associating polymers, due to its distinct and adjustable architecture [27, 33–36].

Hydrophobically end-capped poly(ethylene oxide) is able to form flower-like micelles with hydrophobic core surrounded by hydrophilic poly(ethylene oxide) shells. Alkyl group aggregates to come into being an inner core which has the ability of encapsulating and transporting the hydrophobic drugs; however, the hydrophilic PEO segments of copolymer constitute the hydrated outer shell which is able to stabilize the micelles in its aqueous solution. Furthermore, the hydrophobically end-capped poly(ethylene oxide) is a degraded polymer, and its degraded products, PEO and fatty alcohol, are considered to be nontoxic to our body. Therefore, the hydrophobically end-capped poly(ethylene oxide) bears substantial potential as vehicle for the encapsulation and controlled drug release.

In this paper, we want to continue developing the drug release function research of hydrophobically end-capped poly(ethylene oxide) deeply. Spironolactone is selected as model drug which is insoluble in water, and Fig. 1 shows the structure of spironolactone. A series of hydrophobically end-capped poly(ethylene oxide) consisting of PEO as hydrophilic segment and alkyl groups as hydrophobic block, will be synthesized, aiming to emphasize the effect of main chain and end chain on the in vitro release behavior of spironolactone from polymeric flower-like micelles. The formation of micelle self-assembled from hydrophobically end-capped PEO is also investigated in details.

Experimental section

Materials

A series of poly(ethylene oxide) (M w = 1500, 4000, 6000, respectively) were purchased from Acros Organics company and were dried by toluene azeotropic distillation to eliminate the moisture before using. A series of alkyl bromide (1-bromododecane 98 %, 1-bromotetradecane 98 %, 1-bromohexadecane 98 %, and 1-bromooctadecane 98 %) were purchased from J&K Scientific Ltd. Sodium hydride was obtained from Aladdin Reagent Corporation. Spironolactone was used as received from Sigma Company. Tetrahydrofuran (THF) was refluxed with sodium to remove water. All other chemicals used in this paper were reagent grade and used without further purification as purchased.

Synthesis of hydrophobically end-capped poly(ethylene oxide)

Hydrophobically end-capped poly(ethylene oxide) in this work were synthesized as the literature method described by Nicol et al. [37]. Hydrophobically end-capped poly(ethylene oxide) were obtained by reacting the corresponding PEO-sodium alcoholate with alkyl bromide in THF solvent (Williamson reaction). The details for the synthesis of hydrophobically end-capped poly(ethylene oxide) could be found elsewhere [38].

Preparation of blank micelle and drug-loaded micelle

Micelles of the hydrophobically end-capped poly(ethylene oxide) were obtained in aqueous solution with a procedure of rotary evaporation method. The triblock copolymer C18E136C18 (50 mg) was dissolved in chloroform solvent (CHCl3, 5 ml) in a 50-ml flask. Hydrophobic spironolactone was used as an objective drug. To prepare drug-loaded micelle, the triblock copolymer C18E136C18 (50 mg) and spironolactone (5 mg) were dissolved in 5 ml CHCl3 solvent in another 50-ml flask.

Deionized water (10 ml) was added into each flask at a rate of one drop every 10 s under vigorous stirring. Then, CHCl3 in the aqueous solution was removed with a rotary evaporator under vacuum for 2 h to form triblock polymer micelles. The remained solution was collected and centrifuged at 3000 rpm for 5 min to eliminate aggregated particles and unloaded spironolactone. Then, freeze-dried micelle products were obtained in power.

The critical micelle concentration was determined by measuring surface tension change with triblock copolymer concentration at 37 °C. The copolymer concentrations were prepared from 10−4 to 101 mg/ml within liquid solution. The surface tensions were measured by drop volume method using surface tension instrument (Germany, Kruss Gmbh, DSA10-MK2). The critical association concentration is estimated from the plot change of surface tension vs. concentration and is much less than 0.1 mg/ml. Here, the micelle concentration with 5 mg/ml above the critical micelle concentration is chosen to prepare for the investigation, and it also will ensure the formation of polymer micelle.

Characterization

1H NMR was used to determine the composition of hydrophobically end-capped poly(ethylene oxide). 1H NMR spectra were measured with a Bruker 400 MHz Advance NMR spectrometer in CDCl3 at 400 MHz. Tetramethylsilane was taken as an internal standard.

Fourier transform infrared (FTIR) spectroscopy measurements were carried out to confirm the end groups of hydrophobically end-capped poly(ethylene oxide). FTIR spectroscopy was recorded on spectrometer (Nicolet Nexus 470), where 16 scans were collected with a spectral resolution of 4 cm−1 wave number. The spectra were measured after the spectrum scan of the pure KBr pellet.

Differential scanning calorimetry (DSC) (NETZSCH 204F1) was used to decide melting point (T m). The samples were first annealed at 100 °C for 5 min to eliminate any thermal history and then quickly quenched with a cooling rate of 80 °C/min. DSC curves were recorded by a heating rate of 10 °C/min in the second scan.

Drug loading efficiency and entrapment efficiency

Drug loading efficiency was calculated by the weight ratio of spironolactone in drug-loaded micelles to pre-weighed freeze-dried micelles. Entrapment efficiency was defined as the weight ratio of the drug incorporated in micelles to initial value used in the preparation. Drug loading efficiency and entrapment efficiency of drug-loaded micelles were investigated by using a UV-visible spectrophotometer (UV-3600). UV-visible detection at 238 nm was used for the analysis of spironolactone. Block polymer and spironolactone (mass ratio 10:1) were dissolved in chloroform solvent and stirred for 15 h at room temperature. Then, the deionized water was dripped into the mixed solution to form micelles at 10-s interval. The drug loading micelles were obtained after the solution was centrifuged at 3000 rpm for 300 s to eliminate the free spironolactone. The concentration of spironolactone was calculated according to a standard curve. The standard curve was mainly obtained from the chloroform and spironolactone solution. The LE of the micelles was then calculated based on the following formula:

The encapsulation efficiency (EE) of the micelles was calculated based on the following formula:

Micelle size measurement

The diluted micelle solution was passed through filter (0.22 μm pore size) to remove impurity before size measurement. It is noted that we also have measured the micelle size measurement using atomic force microscopy (AFM) before passing through filter with 0.22 μm pore size, and the micelle size are less than 130 nm. Therefore, the micelle size measurement is not affected by the filtering process with 0.22 μm pore size filter. The micelle size and distribution are close to reality. The filtering process is performed only to remove solution impurity in this paper. The average particle size of micelles was determined by Malvern Zetasizer equipment (Nano ZS 90) at room temperature.

The micelle morphology in solid state was collected with a multimode AFM (Bruker Digital Instrumental Nanoscope VII). Tapping mode was chosen to obtain height and phase images. The samples were prepared by drop-casting solution contained micelle onto the silicon wafer. Then, the samples were dried at room temperature and treated in vacuum for 12 h.

In vitro release of spironolactone from hydrophobically end-capped poly(ethylene oxide) micelle

The release behaviors of spironolactone from drug-loaded micelles were investigated in vitro. Freeze-dried micelles (5 mg) and phosphate-buffered saline (PBS) (0.1 M, pH 7.4, 2 ml) was put into a dialysis bag which was immersed into PBS solution (25 ml). The system was kept at 37 °C. At the specified intervals, 2 ml PBS solution was taken out and accumulative release weight of spironolactone was calculated according to a standard curve. The standard curve was gained from the mixed solution of chloroform (little content) and PBS solution with pH 7.4, due to the insolubility of spironolactone.

Results and discussion

Synthesis and characterization

Hydrophobically end-capped poly(ethylene oxide) consisting of hydrophobic alkyl and hydrophilic PEO segment has been synthesized by Williamson reaction, as shown in Fig. 2. Hydrophobically end-capped poly(ethylene oxide) are obtained by reacting the corresponding PEO-sodium alcoholate with alkyl bromide in THF solvent. The successful synthesis of hydrophobically end-capped poly(ethylene oxide) by this method can also be found elsewhere [37, 38]. In this article, six kinds of triblock copolymers are obtained by adjusting the relative length of alkyl and PEO segment block. The different composition of copolymer is used to design the polymer molecule, aiming to emphasize the effect of main chain and end chain on the micelle formation and in vitro release behavior of drug from polymeric micelles. The triblock copolymers gained are denoted as CnEmCn, including C18E35C18, C18E90C18, C12E136C12, C14E136C14, C16E136C16, and C18E136C18, where m and n represent the carbon atom number of PEO segment and alkyl group, respectively. To confirm the synthesized product, the samples are characterized by 1H NMR, FTIR, and DSC measurements. Figure 3 shows 1H NMR spectrum of triblock copolymer C18E136C18 in CDCl3 solvent. The peaks at 3.652 and 1.257 ppm positions correspond to methylene units in PEO segment and in alkyl block, respectively, and the signal at 0.883 ppm is assigned to methyl unit in alkyl block. The results are in accordance with the literature report [37, 38], and it is suggested that the sample is gained with designed composition successfully.

The FTIR spectra of samples are also investigated to confirm the stretching interaction of end groups of hydrophobically end-capped poly(ethylene oxide). Figure 4 shows the FTIR spectra of PEO136, C18E136C18, and 1-bromooctadecane at room temperature. The absorbance peak from 3300 to 3600 cm−1 is present due to the stretching vibration of –OH group. Compared with the FTIR spectrum of PEO polymer, the broad absorbance characteristic of –OH groups (from 3300 to 3600 cm−1) is disappeared within the triblock polymer C18E136C18 completely. This is mainly due to the molecule chain terminal of polymer PEO are replaced by alkyl blocks within the triblock polymer C18E136C18. In addition, it indicates that the same absorption peak at 2920 cm−1 due to methyl unit interaction of alkyl group is formed for the triblock copolymer and 1-bromooctadecane. Therefore, we can infer that the alkyl groups are connected to the main chain of PEO block steadily.

Thermal properties of hydrophobically end-capped poly(ethylene oxide) are investigated by DSC measurement. The DSC curves of PEO and triblock copolymers with different molecule length of alkyl group are shown in Fig. 5. It can be found that only one melting peak or melting point is present in all samples, due to the crystallization of PEO block segment within triblock copolymers. Furthermore, all melting point temperatures of PEO segment within copolymers are lower than that of pure PEO polymer, and the corresponding melting point deviation increase gradually along with the length addition of alkyl group block. It indicates that the presence of alkyl group block within triblock copolymer may confine the molecule movement to crystallize and the influence is enhanced with the length increase of alkyl molecule chain. Therefore, the melting point of copolymer is reduced correspondingly.

In all, hydrophobically end-capped poly(ethylene oxide) consisting of hydrophobic alkyl and hydrophilic PEO segment is synthesized successfully, and it is able to ensure the investigation of micelle formation in the following discussion.

Micelle size investigation

It is well known that the hydrophobically end-capped poly(ethylene oxide) is able to aggregate in aqueous solution to form spherical micelle above a critical association concentration. Furthermore, it is suggested that this aggregation number of typical triblock copolymer depends on the relative segment length of hydrophobic and hydrophilic block within copolymer. For a fixed segment length of hydrophilic block, the triblock polymer aggregation number increases with segment length addition of hydrophobic block. For example, Pham et al. [39] indicated that the triblock copolymer aggregation number was 66 for PEO block (with M w = 35 kg/mol) end-capped with C18 on both ends via a urethane link; however, the copolymer aggregation number was 40 for PEO block end-capped with C16. Consequently, the micelle size was bound to increase along with segment length addition of hydrophobic block.

We also want to investigate the micelle formation of triblock copolymer and the effect of PEO block length and alkyl group segment length of triblock copolymer on micelle size. Drug-free and drug-loaded micelles of amphiphilic triblock polymers are prepared by rotary evaporation method. The average micelle size was measured by a Malvern Zetasizer in aqueous solutions at a concentration of 5.0 g/l, as shown in Table 1 and Table 2. It is suggested that all the micelle size (in diameter) are nanoscopic and mainly depend on both triblock copolymer composition (PEO block and alkyl group) and drug loading degree. The micelle size formed by copolymer becomes much larger along with the segment length addition of alkyl group block, but the micelle size decreases gradually with the PEO block length addition within triblock copolymer. This is because the micelle core is usually formed by hydrophobic alkyl group and the superior segment length of hydrophobic block within copolymer is inclined to result in larger core, contributing to increased micelle size. In addition, the drug-loaded micelle sizes are significantly larger than that of drug-free micelles, which is suggested that drug has been incorporated into micelles. The drug-loaded micelle size also becomes larger along with the relative increasing of alkyl group segment composition within copolymer. This is due to enlarged hydrophobic group block resulting in the larger core within polymer micelles, which accommodates more drugs to incorporate into.

Drug loading efficiency and entrapment efficiency are usually used to estimate the drug loading capacity within the polymer micelle. Although the values of DLE and EE in this paper are low, the formation of drug loading within copolymer micelle makes sense as drug release carrier. In this paper, we aim to investigate the micelle formation of triblock copolymer and the effect of PEO block length and alkyl group segment length of triblock copolymer on micelle size and the drug release behavior in vitro. As we know, the drug loading efficiency and entrapment efficiency depend on many factors, such as the type and size of copolymer micelle, loaded drug factor, and loading process. Here, the formation of micelle self-assembles from hydrophobically end-capped poly(ethylene oxide) (PEO), and spironolactone is chosen as a hydrophobicity drug. Therefore, the low drug loading efficiency and entrapment efficiency might be affected by the present loading process condition. Spironolactone has been reported as poorly water-soluble drug in many existing studies [40, 41], but there is not comparable work between existing studies and this paper due to the differences of research process condition in details. Of course, as an important and continuous work, we will try our best to gain the higher drug loading efficiency and entrapment efficiency in the next to highlight the connection among the triblock copolymer, micelles, and drug loading. Thus, here, a series of hydrophobically end-capped poly(ethylene oxide) consisting of different hydrophilic segments and hydrophobic blocks have been synthesized to emphasize the effect of main chain and end chain within copolymer on the micelle formation, drug loading, and in vitro drug release behavior.

Figure 6 shows the AFM phase images of drug-free and drug-loaded micelles formed by triblock copolymer C16E136C16. The polymer micelle concentration is about 5.0 mg/ml in the deionized water solution. It indicates that the micelles show similar sphere morphology. The average micelle sizes calculated from the AFM phase images are close to the size results discussed above. Furthermore, the AFM phase images also are used to confirm that drug entrapment leads to the increasing of micelle size correspondingly. It is suggested further that the small drug molecule might take part in the self-assembly process of triblock copolymer and change the micelle dimension.

In vitro release investigation of spironolactone from the triblock copolymer micelles

The hydrophobically end-capped poly(ethylene oxide) has substantial potential as vehicle for the encapsulation and controlled drug release. We anticipate to investigate the drug release function of hydrophobically end-capped poly(ethylene oxide) micelle deeply and spironolactone is selected as model drug. In vitro release behaviors of spironolactone entrapped micelles are evaluated in PBS (pH 7.4) at 37 °C. According to above discussion, the micelle formation of triblock copolymer mainly depends on the relative segment length of hydrophobic and hydrophilic block within copolymer. Thus, we have studied the effect of main chain and end chain within copolymer on the in vitro release behavior of spironolactone from polymeric micelles, as shown in Fig. 7. It indicates that when the segment length of PEO block is fixed, the cumulative release degree of spironolactone at the same time (release rate) is different and the release rate becomes smaller with the segment length addition of alkyl group within triblock copolymer, as shown in Fig. 7a. It is suggested that the release rate can be affected by the block composition of triblock polymer. As a matter of fact, the release rate depends on the micelle size and the molecule interaction between poorly water-soluble drug and hydrophobic alkyl group. Alkyl group aggregates to come into being an inner core and the hydrophilic PEO segments of copolymer constitute the hydrated outer shell during the micelle formation. With the segment length increase of alkyl group within copolymer, triblock polymer is inclined to form micelles with larger size, where the micelles are able to accommodate more spironolactone molecules to insert into and then the interaction between drugs and short hydrophobic alkyl block within the micelle core is enhanced effectively. Therefore, the final release rate of spironolactone from the triblock copolymer micelles is decreased with the longer alkyl segment within copolymer correspondingly.

Then, we also have investigated the effect of PEO block on the spironolactone release from its micelles, as shown in Fig. 7b. For a given alkyl block, release rates of spironolactone-entrapped from its micelles are also variant but release rates are weakened gradually as the block length decrease of PEO segment within triblock polymer. As discussion above, alkyl group aggregates to come into being an inner core and the hydrophilic PEO segments constitute the hydrated outer shell. The hydrophilic PEO segments will contact with the water molecule on the shell surface, and it has to interact with each other. The longer PEO segments are within triblock polymers; the stronger interactions are between water and PEO segment. Then, the triblock copolymer with short PEO segment could form compact micelles, which finally restrains from spironolactone release from polymer micelles. In the end, the release rates are reduced gradually as the block length decrease of PEO segment within triblock polymer.

At the same time, as shown in Fig. 7, it indicates that the spironolactone release from micelles starts with an initial burst, followed by a slow release phase. The same release action trends are present in the all micelles formed by different block composition of copolymer. This release behavior is mainly due to the geometry of spironolactone location within micelles. The drug located in the hydrophilic corona of micelles leads to the initial release burst within the first several hours, and this action could proceed for a certain time via their passive diffusion. Then, the slower release mainly results from the drug localized in the inner core of micelles. The drug release process from the block copolymer micelle is usually a complicated process and depends on several factors, such as the nature of drug, micelle, or process technology. Thus, drug release process might be mainly controlled by different mechanism. According to previous Ritger–Peppas regression model [42, 43], n is acted as an exponent characteristic of the release mechanism. If the value of n is between 0.5 and 1, an anomalous diffusion from the micelle is present in the drug release process. In this paper, we also estimate the value of the exponent characteristic n, and it indicates that the values of n are more than 0.7 for all the examples within the drug release process. Therefore, it shows that the drug release from the micelle deviates from the Fickian diffusion control mechanism, and the in vitro release behavior of spironolactone from polymeric micelles is mainly affected by the main chain and end chain within copolymer.

In addition, it is well known that there is a dynamic equilibrium process between aggregated polymers and unimer. If polymer micelle is able to form glassy core under a certain condition, the equilibrium can be curbed completely and the frozen micelles are induced to form. Glassy core has been proposed to slow release rate of pyrene from a micelle carrier in aqueous solution [44]. It was reported that the hydrophobically end-capped poly(ethylene oxide) (with PEO molar mass 4.3 kg/mol and end capped with C18 group) was able to form frozen micelles in dilute aqueous solutions and be independent of temperature [33]. Therefore, in this paper, the frozen micelles may be present in the hydrophobically end-capped poly(ethylene oxide) aqueous solution with the segment length addition of alkyl group within triblock copolymer from C12 to C18, leading to slow down the spironolactone release rate and cut down the cumulative release. In the end, the release rate of spironolactone from the triblock copolymer micelles is decreased for the longer alkyl segment within copolymer correspondingly.

Conclusion

A series of hydrophobically end-capped poly(ethylene oxide) with different segment length of PEO block and alkyl group are synthesized successfully. The properties of triblock polymers are affected significantly by the relative length of PEO segment and alkyl group. The hydrophobically end-capped poly(ethylene oxide) is able to aggregate in aqueous solution to form spherical micelle above a critical association concentration. The spherical micelle size becomes larger along with the decrease of PEO segment length or the addition of alkyl group length within copolymer. The sizes of free-loaded micelle and drug-loaded micelle formed by triblock polymers are almost less than 130 nm, which indicates that the micelles are nanoscale. It is suggested that the drug-loaded micelle size is larger than the free-loaded micelle size, demonstrating that spironolactone drug is able to entrap into the micelle core. The drug release profiles indicate that hydrophobically end-capped poly(ethylene oxide) micelle could be employed as a promising vehicle for the delivery of poorly water-soluble drug. In addition, the final release rate of spironolactone from the triblock copolymer micelles is decreased gradually with the length addition of alkyl group or the length reduce of PEO block within triblock polymer.

References

Quemener D, Bonniol G, Phan TNT, Gigmes G, Bertin G, Deratani A (2010) Free-standing nanomaterials from block copolymer self-assembly. Macromolecules 43:5060–5065

Sun G, Cui HG, Lin LY, Lee NS, Yang C, Neumann WL, Freskos JN, Shieh JJ, Dorshow RB, Wooley KL (2011) Multicompartment polymer nanostructures with ratiometric dual-emission pH-sensitivity. J Am Chem Soc 133:8534–8543

Smith AE, Xu XW, Abell TU, Kirkland SE, Hensarling RM, McCormick CL (2009) Tuning nanostructure morphology and gold nanoparticle “locking” of multi-responsive amphiphilic diblock copolymers. Macromolecules 42:2958–2964

Zhao WF, He C, Wang HY, Su BH, Sun SD, Zhao CS (2011) Improved antifouling property of polyethersulfone hollow fiber membranes using additive of poly(ethylene glycol) methyl ether-b-poly(styrene) copolymers. Ind Eng Chem Res 50:3295–3303

Liu X, Basu A (2009) Core functionalization of hollow polymer nanocapsules. J Am Chem Soc 131:5718–5719

Stewart S, Liu GJ (1999) Hollow nanospheres from polyisoprene-block-poly(2-cinnamoylethyl methacrylate)-block-poly(tert-butyl acrylate). Chem Mater 11:1048–1054

Kellum MG, Smith AE, York SK, McCormick CL (2010) Reversible interpolyelectrolyte shell cross-linked micelles from pH/salt-responsive diblock copolymers synthesized via RAFT in aqueous solution. Macromolecules 43:7033–7040

Bertrand A, Chen S, Souharce G, Ladaviere C, Fleury E, Bernard J (2011) Straightforward preparation of telechelic H-bonding polymers from difunctional trithiocarbonates and supramolecular block copolymers thereof. Macromolecules 44:3694–3704

Opsteen JA, Cornelissen JJLM, Hest JCMV (2004) Pure block copolymer vesicles. Pure Appl Chem 76:1309–1319

Cerritelli S, Neil CPO, Velluto D, Fontana A, Adrian M, Dubochet J, Hubbell JA (2009) Aggregation behavior of poly(ethylene glycol-bl-propylene sulfide) di- and triblock copolymers in aqueous solution. Langmuir 25:11328–11335

Taribagil RR, Hillmyer MA, Lodge TP (2010) Hydrogels from ABA and ABC triblock polymers. Macromolecules 43:5396–5404

Yang YQ, Zheng LS, Guo XD, Qian Y, Zhang LJ (2011) pH-sensitive micelles self-assembled from amphiphilic copolymer brush for delivery of poorly water-soluble drugs. Biomacromolecules 12:116–122

Lavasanifar A, Samuel J, Kwon GS (2002) Nano and microparticle drug delivery systems comprising polyesters containing aliphatic dicarboxylate residues and residues of aliphatic polyols. Adv Drug Deliv Rev 54:169–190

Francis MF, Cristea M, Winnik FM (2005) Exploiting the vitamin b12 pathway to enhance oral drug delivery via polymeric micelles. Biomacromolecules 6:2462–2467

Yang Y, Hua C, Dong CM (2009) Synthesis, self-assembly, and in vitro doxorubicin release behavior of dendron-like/linear/dendron-like poly(ε-caprolactone)-b-poly(ethylene glycol)-b-poly(ε-caprolactone) triblock copolymers. Biomacromolecules 10:2310–2318

Su XF, Fricke J, Kavanagh DG, Irvine DJ (2011) In vitro and in vivo mrna delivery using lipid-enveloped ph-responsive polymer nanoparticles. Mol Pharmaceutics 8:774–787

Yuan H, Lu LJ, Du YZ, Hu FQ (2011) Stearic acid-g-chitosan polymeric micelle for oral drug delivery: in vitro transport and in vivo absorption. Mol Pharmaceutics 8:225–238

Wang F, Bronich TK, Kabanov AV, Rauh RD, Roovers J (2008) Synthesis and characterization of star poly(ε-caprolactone)-b-poly(ethylene glycol) and poly(l-lactide)-b-poly(ethylene glycol) copolymers: evaluation as drug delivery carriers. Bioconjugate Chem 19:1423–1429

Yang L, Qi X, Liu P, Ghzaouia AE, Li S (2010) Aggregation behavior of self-assembling polylactide/poly(ethylene glycol) micelles for sustained drug delivery. Int J Pharm 394:43–49

Li C, Madsen J, Armes SP, Lewis AL (2006) A new class of biochemically degradable, stimulus-responsive triblock copolymer gelators. Angew Chem Int Ed 45:3510–3513

Gourier C, Beaudoin E, Duval M, Sarazin D, Maıtre S, Francois J (2000) A light scattering study of the association of hydrophobically α- and α, ω-end-capped poly(ethylene oxide) in water. J Colloid Interf Sci 230:41–52

Chassenieux C, Nicolai T, Durand D (1997) Association of hydrophobically end-capped poly(ethylene oxide). Macromolecules 30:4952–4958

Lafleche F, Durand D, Nicolai T (2003) Association of adhesive spheres formed by hydrophobically end-capped PEO. 1. influence of the presence of single end-capped PEO. Macromolecules 36:1331–1340

Lafleche F, Nicolai T, Durand D (2003) Association of adhesive spheres formed by hydrophobically end-capped PEO. 2. influence of the alkyl end-group length and the chain backbone architecture. Macromolecules 36:1341–1348

Nicolai T, Lafleche F (2004) Jamming and crystallization of polymeric micelles. Macromolecules 37:8066–8071

Choi YW, Park J, Park Y, Kim K, Lee Y, Sohn D (2007) Structure formation of hydrophobically end-capped poly(ethylene oxide) in the solid state. J Phys Chem B 111:12959–12963

Renou F, Benyahia L, Nicolai T (2008) Structure and rheology of mixed polymeric micelles formed by hydrophobically end-capped poly(ethylene oxide). Macromolecules 41:6523–6530

Alami E, Almgren M, Brown W (1996) Aggregation of hydrophobically end-capped poly(ethylene oxide) in aqueous solutions. fluorescence and light-scattering studies. Macromolecules 29:2229–2243

Vorobyova O, Lau W, Winnik MA (2001) Aggregation number determination in aqueous solutions of a hydrophobically modified poly(ethylene oxide) by fluorescence probe techniques. Langmuir 17:1357–1366

Beaudoin E, Hiorns RC, Borisov O, Francüois J (2003) Association of hydrophobically end-capped poly(ethylene oxide). 1. preparation of polymers and characterization of critical association concentrations. Langmuir 19:2058–2066

Francüois J, Beaudoin E, Borisov O (2003) Association of hydrophobically end-capped poly(ethylene oxide). 2. phase diagrams. Langmuir 19:10011–10018

Graaf AJD, Boere KWM, Kemmink J, Fokkink RG, Nostrum CF, Rijkers DTS, Gucht J, Wienk H, Baldus M, Mastrobattista E, Vermonden T, Hennink WE (2011) Looped structure of flowerlike micelles revealed by 1H NMR relaxometry and light scattering. Langmuir 27:9843–9848

Renou F, Benyahia L, Nicolai T (2007) Influence of adding unfunctionalized PEO on the viscoelasticity and the structure of dense polymeric micelle solutions formed by hydrophobically end-capped PEO. Macromolecules 40:4626–4634

Liao DS, Dai S, Tam KC (2007) Rheological properties of a telechelic associative polymer in the presence of α- and methylated β-cyclodextrins. J Phys Chem B 111:371–378

Yoshida T, Taribagil R, Hillmyer MA, Lodge TP (2007) Viscoelastic synergy in aqueous mixtures of wormlike micelles and model amphiphilic triblock copolymers. Macromolecules 40:1615–1623

Rufier C, Collet A, Viguier M, Oberdisse J, Mora S (2008) Asymmetric end-capped poly(ethylene oxide): synthesis and rheological behavior in aqueous solution. Macromolecules 41:5854–5862

Nicol E, Niepceron F, Plaisance CB, Durand D (2005) Nanostructures from photo-cross-linked amphiphilic poly(ethylene oxide)-b-alkyl diblock copolymers. Polymer 46:2020–2028

Renou F, Nicolai T, Nicol E, Benyahia L (2009) Structure and viscoelasticity of mixed micelles formed by poly(ethylene oxide) end capped with alkyl groups of different length. Langmuir 25:515–521

Pham QT, Russel WB, Thibeault JC, Lau W (1999) Micellar solutions of associative triblock copolymers: entropic attraction and gas–liquid transition. Macromolecules 32:2996–3005

Jeong B, Bae YH, Kim SW (2000) Drug release from biodegradable injectable thermosensitive hydrogel of PEG-PLGA-PEG triblock copolymers. J Control Release 63:155–163

Lehto P, Kortejarvi H, Liimatainen A, Ojala K, Kangas H, Hirvonen J, Tanninen VP, Peltonen L (2011) Use of conventional surfactant media as surrogates for FaSSIF in simulating in vivo dissolution of BCS class II drugs. Eur J Pharm Biopharm 78:531–538

Luo YL, Zhang LL, Xu F (2012) Synthesis, micellization and caffeine drug release kinetics of novel PBMA-b-PNIPAAm block polymer brushes. Chem Eng J 189–190:431–442

Yang XL, Luo YL, Xu F, Chen YS (2014) Thermosensitivem PEG-b-PA-g-PNIPAM comb block copolymer micelles: effect of hydrophilic chain length and camptothecin release behavior. Pharm Res 31:291–304

Teng Y, Morrison ME, Munk P, Webber SE, Hunter R, Strickland F, Immunol FKJ (1998) Release kinetics studies of aromatic molecules into water from block polymer micelles. Macromolecules 31:3578–3587

Acknowledgments

This work was financially supported by National Natural Science Foundation of China (No. 51073064).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ding, G., Liu, H., Jin, Q. et al. Micelle formation from hydrophobically end-capped poly(ethylene oxide) and its application for delivery of poorly water-soluble drug. Colloid Polym Sci 294, 77–85 (2016). https://doi.org/10.1007/s00396-015-3726-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-015-3726-1