Abstract

To further verify the forming mechanism of multi-core structure during the direct melt copolycondensation of lactic acid (LA) with the compounds containing multifunctional groups, the biodegradable material poly(lactic acid-co-glycerol) [P(LA-co-GL)] was synthesized as designed using L-lactic acid (L-LA) and glycerol (GL) as the starting materials. For the molar feed ratio n(LA)/n(GL) of 60/1, the optimal synthetic conditions were discussed. Using 0.3 wt% stannous oxide (SnO) as the catalyst, after the prepolymerization was carried out at 140 °C for 8 h, the melt copolymerization for 8 h at 160 °C gave the polymer with the biggest intrinsic viscosity ([η]) 0.76 dL•g−1. The copolymers P(LA-co-GL)s at different molar feed ratios were characterized by Fourier transform infrared spectroscopy (FT-IR), proton nuclear magnetic resonance (1H-NMR), gel permeation chromatography (GPC), differential scanning calorimetry (DSC) and X-ray diffraction (XRD). Increasing the molar feed ratio n(LA)/n(GL), the weight-average molecular weight (Mw) didn’t increase all the time, but a peak of Mw was formed, which indeed validated the above special phenomenon during the direct melt copolycondensation of LA with the monomers containing multifunctional groups. However, the forming mechanism of multi-core copolymer was different when multihydroxyl alcohol (e.g. GL) was used as the monomer containing multifunctional groups. Because the multi-core structure was linked by the ether bonds with less reversibility in the reaction, the biggest Mw of copolymers was relatively lower. For GL with three terminal hydroxyls as the core, only when n(LA)/n(GL) was more than 100/1, the star-shaped polylactic acid (SPLA) containing one core could be obtained.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

As a kind of important biodegradable aliphatic polyester, polylactic acid (PLA) is wholly environment-friendly. Its excellent biocompatibility and biological resorbability afford it extensive applications in bioplastic, biomedical polymer and other fields [1, 2]. In most cases, PLA was synthesized via traditional ring-opening polymerization (ROP) of lactide, and the resulted PLA usually has bigger weight-average molecular weight (Mw) and smaller polydispersity index (PDI). The other method is direct melt polycondensation of lactic acid (LA). It is simpler for shorter synthetic steps, less solvent consumption and lower cost. Unfortunately, the Mw of PLA from the direct method is relatively smaller although some papers reported Mw could reach the same level of ROP method [2–4].

Even so, recently more and more attentions have been attracted to the direct melt copolycondensation of LA with other monomers to improve the properties of PLA, such as the poorer hydrophilicity, the worse cell affinity and unsatisfactory degradation rate [1, 5–37]. Therefore, in these cases, how to get a copolymer with the higher Mw has been becoming an important challenge for the simpler synthetic method. Furthermore, it is strange that during the direct melt copolymerization of LA with the monomers containing multifunctional groups, the Mw didn’t increase with the increase of LA feed amount [35–37]. And interestingly, the peak phenomena of Mw and multi-core structure of the copolymer were found when increasing the molar feed amount of LA [35, 36].

According to the previous results [35, 36], it could be believed that, in order to get the higher Mw of the copolymer during direct melt copolycondensation of LA with the compounds containing multifunctional groups, only the investigations on the optimal synthetic conditions are not enough, the deeper researches on the reaction mechanism of direct melt copolycondensation should be carried out. Thus, in order to further verify the forming mechanism of multi-core structure during the direct melt copolycondensation of LA with the compounds containing multifunctional groups, the biodegradable material poly(lactic acid-co-glycerol) [P(LA-co-GL)] was synthesized as designed using L-lactic acid (L-LA) and glycerol (GL) as the starting materials (Scheme 1).

Why using the simple and inexpensive GL with three hydroxyls as the multihydroxyl compound, the reason is due to not only the convenience, but also the extensive applications of PLA modified by GL in biomedical fields. For example, Arvanitoyannis synthesized three-arm star-shaped polylactic acid (SPLA) via ROP using GL as the core, and the product had many special properties, such as good biodegradability, low crystallinity, low melt viscosity and high molecular weight [38]. These advantages made SPLA with GL core and its derivatives used as good drug delivery carriers, tissue engineering scaffolds and medical device materials [39–45]. Therefore, it is well worth to investigate the direct synthesis of P(LA-co-GL) via melt copolymerization, and the results showed that the formation of SPLA with GL core was related to the feed ratio of reactants (Scheme 1).

Experimental

Materials

L-Lactic acid (L-LA) was purchased from Wako Pure Chemical Industries, Ltd. (Japan), and Glycerol (GL) was purchased from Damao Chemical Reagent Factory (Tianjin, China). All other chemicals, including p-toluenesulfonic acid (TSA), stannous oxide (SnO), stannous chloride (SnCl2), zinc chloride (ZnCl2) and zinc oxide (ZnO), were commercially available in analytical grade. All these materials were used without further purification.

Instrumental analysis and measurements

Proton nuclear magnetic resonance (1H-NMR) spectra were recorded with a DRX-400 NMR spectrometer (Bruker instruments, Billerica, MA) with deuterated chloroform (CDCl3) as solvent and tetramethylsilane (TMS) as internal standard. Infrared spectra were obtained from a Fourier transform infrared (FT-IR) spectrometer (Bruker Vector 33, Ettlingen, Germany) by the dichloromethane (CH2Cl2) liquid film method.

The intrinsic viscosity ([η]) of PLA modified by GL was determined with Ubbelohde viscometer (Cannon-Ubbelohde, State College, PA) using chloroform (CHCl3) as solvent at 25 °C. According to literatures [38, 46, 47], the relative molecular weight and molecular weight distribution of the modified PLA were determined by gel permeation chromatography (GPC) (Waters 1,515 pump, Torrance, CA) with tetrahydrofuran (THF) as solvent and with polystyrene (PS) as reference at 40 °C and a flow velocity 1 mL•min−1.

Differential scanning calorimetry (DSC) was performed with Perkin-Elmer DSC7 thermal analyzer (Perkin-Elmer, Cetus Instruments, Norwalk, CT) at a heating rate of 10 °C•min−1 under a nitrogen atmosphere (flow velocity 20 mL•min−1). The crystallinity of PLA modified by GL was investigated by X-ray diffraction (XRD) on a PANalytical X’pert PRO X-ray diffractometer (PANalytical Co., Holland) using CuKα radiation with a wavelength of 1.5418 × 10−10 m, and scanning range 2θ = 5–50° at a scanning speed of 0.03 deg•min−1.

Prepolymerization

According to the previous works on melt homo-/co- polymerization of LA [15, 34–36, 48], LA and GL should be prepolymerized before copolymerization. After LA and GL were uniformly mixed as preplanned molar feed ratio, the mixture was directly dehydrated for 8 h at 140 °C under 4,000 Pa in a flask equipped with mechanical stirring and thermometer.

Melt copolymerization

After prepolymerization, the selected catalyst was added in according to the weight percent (wt%) of dehydrated reactants. The melt copolymerization was carried out at a certain temperature (140–180 °C) and an absolute pressure of 70 Pa for 4–12 h. When the reaction finished, the purification via the dissolution in CHCl3 and the subsequent precipitation by the mixed solvent of methanol and distilled water (CH3OH/H2O) ordinarily produced a white powder after drying in vacuo.

Results and discussion

Using L-LA and GL as starting materials, the copolymers P(LA-co-GL)s with different molar feed ratios [n(LA)/n(GL) = 20/1, 40/1, 60/1, 80/1, 100/1, 120/1, 140/1] were directly synthesized via melt copolycondensation after the synthetic conditions were discussed. The structure and properties of these P(LA-co-GL)s were characterized by FT-IR, 1H-NMR, GPC, DSC, XRD and viscosity [η] measurements.

Optimal synthetic conditions for P(LA-co-GL)

The optimal synthetic conditions for P(LA-co-GL), including the influences of catalyst kinds and dosage, melt copolycondensation time and temperature on the synthesis of P(LA-co-GL), were first investigated. Catalyst played an important role in the direct melt polycondensation of LA, and usually tin catalysts gave the best effect for their good dispersibility in the reaction system [49–51]. The influences of different catalysts on reaction are shown as Table 1. Among the catalysts, including SnO, SnCl2, ZnCl2, TSA and ZnO, although the reaction catalyzed by TSA gave the biggest yield (52%, run 4), the [η] was smaller than that using SnO as the catalyst (run 5). Thus, SnO was selected as the catalyst for the following experiments because it was most likely to generate the bigger molecular weight.

The influences of different SnO catalyst quantities are shown as Table 2. Usually, the metallic catalysts, including SnO, have double-side effects. They could accelerate the polymerization, but also make the thermal decomposition of the product catalyzed [15, 19]. With the increase of catalyst quantity, the effect of much dosage was exhibited from the color change of product appearance (run 4 and run 5). Therefore, neither too much nor too little is suitable for the catalyst concentration. And for this reaction, the best quantity of SnO was 0.3 wt% (run 2).

The influences of different melt copolymerization temperatures on reaction are shown as Table 3. When the temperature was 140 °C, the lower temperature was disadvantageous for polycondensation to remove the produced water from the reaction system, and the reaction gave a white product with the smallest [η] (0.55 dL•g−1, run 1). Increasing the temperature to 160 °C yielded the biggest [η] (0.76 dL•g−1, run 3). But at the higher temperature, the [η] decreased, even the color of the product began to become yellow due to the side-reactions, such as the thermal decomposition and oxidation (run 4 and run 5). Thus, the suitable temperature should be 160 °C.

The influences of melt copolymerization time on reaction are shown as Table 4. Obviously, the suitable time should be 8 h. The reason is similar to the above discussion, but mainly due to the influence of the balance between polycondensation and thermal decomposition. Therefore, when the molar feed ratio of n(LA)/n(GL) was the same as 60/1, the optimal synthetic conditions were as follows: catalyst 0.3 wt% SnO, melt copolymerization temperature at 160 °C, and polycondensation time 8 h. Under these conditions, the biggest [η] was 0.76 dL•g−1, and GPC determination showed that the corresponding Mw was 6,400 Da.

Under the above optimal synthetic conditions, serial P(LA-co-GL)s at different molar feed ratios were synthesized with the yield of 23% ~ 44% (Table 5).

Structure characterization of P(LA-co-GL)

The structural characterization of P(LA-co-GL) synthesized with a molar feed ratio n(LA)/n(GL) of 60/1 under the above optimal synthetic conditions was compared with poly(L-lactic acid) (PLLA), the product of the direct melt homopolymerization of LA [15]. It was elucidated that these compounds show similar absorptions in their FT-IR spectra, especially the strong absorption of ester carbonyl near 1,755 cm−1 (Fig. 1). The absorption at 2,945 cm−1 from the -CH2- group [52, 53], appeared in the FT-IR spectrum of P(LA-co-GL) while it became stronger and broader than that observed in the PLLA spectrum, indicating that GL segment has been introduced into the copolymer. Similarly, the HO stretch vibration absorption near 3,530 cm−1 in copolymer also became stronger and broader than that in homopolymer. From another side, this also indicated that the core GL was existed in the copolymer.

The structural studies on P(LA-co-GL) copolymers with different molar feed ratios by FT-IR (Fig. 2) showed similar features. However, there were some differences in the strength of HO stretch vibration absorption between different molar feed ratios. Obviously, the less LA content in the feed ratio, the more the relative amount of terminal HO in the copolymer, which indicated that not only three terminal HO groups per a polymer molecule were existed in the copolymer for all n(LA)/n(GL) molar feed ratios, and the number of the terminal HO group per a copolymer molecule may be more than 3 in some cases, especially for the lower n(LA)/n(GL) molar feed ratios.

1H-NMR data of P(LA-co-GL) with a molar feed ratio n(LA)/n(GL) of 60/1, δ, ppm (CDCl3 as solvent and TMS as internal standard, Fig. 3): 1.502 (Ha′, CH3 in terminal PLA segment), 1.592 (Ha, CH3 in PLA chain), 2.710 (He, terminal OH), 4.260 (Hb′, CH in terminal PLA segment), 4.351 (Hd, CH2 in GL segment), 5.136 (Hc, CH in GL segment), 5.171 (Hb, CH in PLA chain). Compared with the PLAs modified by GL via ROP (CH3 in PLA: 1.56 [40], or 1.55 [54], or 1.55–1.58 [55]; He: 2.8 [38] or 2.85 [40]; Hb′: 4.20 [54]; Hd: 4.35 [40, 54]; Hb and Hc: 5.16 [40, 54]), the structure of the copolymer P(LA-co-GL) was basically demonstrated by 1H-NMR as anticipated.

Therefore, the examination of FT-IR and 1H-NMR indicated that the obtained products were copolymers and lactate moieties were incorporated into the polyester backbones. However, the analysis of FT-IR for different molar feed ratios and the following more serial analyses, especially 1H-NMR calculation results of P(LA-co-GL)s at different molar feed ratios, showed that in some cases the structure of P(LA-co-GL) was not a simple star-shaped polymer only embedding a GL core as Scheme 1 -(1).

Influences of different molar feed ratios on [η] and Mw

The influences of different molar feed ratios on [η] and GPC results are shown in Table 5. Obviously, with the increase of the molar feed ratio of LA, Mw didn’t increase all the time, and a peak of Mw was found as reported before [35, 36] (herein, the biggest Mw was 8,800 Da, run 5). Therefore, this indeed validated the special peak phenomena of Mw during the direct melt copolycondensation of LA with the monomers containing multifunctional groups. Of course, for n(LA)/n(GL) 100/1, the PDI (Mw/Mn) was 1.87, the biggest of all, but it was still less than 2. Combined with the single peak shapes in all GPC curves, these PDI data showed that the product of direct melt copolycondensation from two monomers was indeed a copolymer P(LA-co-GL) and not a mixture containing any homopolymer PLLA.

When n(LA)/n(GL) was 80/1, run 4 had the same Mw as run 6 (4,900 Da), though its corresponding [η] was lower than that of run 6. These indicated that the multi-core structure of the copolymer may be existed in this case, but for run 6 it may be not existed. The explanation is similar to the reported before [35, 36], and could be further confirmed by the following investigations. The Mw peak phenomena and the multi-core structure in the copolymer also should be related to the copolymerization mechanism as reported before [35, 36].

At the same time, it could be seen that, when n(LA)/n(GL) was 20/1, the smallest Mw was 3,100 Da (Table 5, run 1). In the literature [40], when n(lactide)/n(GL) was 9/1, the copolymer P(LA-co-GL) synthesized via ROP was waxy, and its molecular weight by GPC was 1,513 Da; when n(lactide)/n(GL) was 15/1, the GPC molecular weight of the solid copolymer synthesized via ROP was 2,674 Da; for n(lactide)/n(GL) 27/1, the molecular weight was 4,860 Da. Thus, when the feed molar ratio is close, it is possible for the direct method to give the Mw that reached or surpassed the level of ROP method.

Usually, when the PLA biodegradable polymers were used as drug-delivery materials, the Mw was no more than 30,000 Da [7, 48, 56]. As reported in the literature, the PLA material with a molecular weight of 1,800 Da could be applied in drug delivery, even PLA copolymers with Mw of only 900 Da could be used as drug-delivery device [57, 58]. The Mw of P(LA-co-GL) synthesized in these experiments was overwhelmingly higher than 900 Da (Table 5). Therefore, the Mw could meet the requirement for drug delivery application at the least.

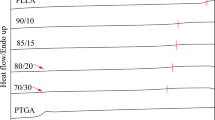

Influences of different molar feed ratios on thermal properties

The thermal properties of P(LA-co-GL) copolymers were characterized by DSC, and the data were shown in Table 6. Obviously, increasing LA content in the feed, the glass transition temperature (Tg) increased gradually (runs 1–7). On the one hand, compared with the linear PLLA synthesized via the direct melt copolycondensation [15] (run 8), the Tg and the melting temperature (Tm) of the copolymers were lower in all cases. This indicated that the introduction of the core GL made the structure changed and Tg decreased indeed as the literature reported that SPLA usually had a lower Tg than the linear PLA [59].

What’s more, compared with the star-shaped P(LA-co-GL) synthesized via ROP [38] (in Table 6, the data of Tg and Tm were cited in the parentheses), Tg and Tm were also lower in all corresponding cases. These further indicated that the introduction of GL made the structure the copolymers changed, and the regularity of the copolymers was also decreased. The latter should be related to the fact that the copolymer P(LA-co-GL) maybe have more PLA arms, rather than the normal three arms. In other words, these phenomena indicated that the multi-core structure may be formed during the direct melt copolymerization of LA with GL.

The data of Tg and Tm in Table 6 also showed that, the bigger LA content in the feed, the smaller difference between two PLA modified by GL using different methods. This revealed that increasing n(LA)/n(GL) could reduce the core number in the multi-core copolymer, which was further demonstrated in the following analyses of XRD characterization and 1H-NMR calculation.

Influences of different molar feed ratios on crystallinity

The crystallinity of polymers has an important effect on their physical and biological properties, especially their degradability which is crucial for biomaterials. However, no data of XRD characterization was reported before when the star-shaped P(LA-co-GL) synthesized via ROP. Even so, compared with the homopolymer PLLA (its XRD absorption peaks appeared at the 2θ of 16.7° and 19.1°) [15], the position of the XRD absorption peaks of all powder solid P(LA-co-GL)s was basically similar (Fig. 4).

Further compared with PLLA synthesized via the direct melt copolycondensation [15] (Table 6, run 8), the XRD data of the copolymers showed that the crystallinity (X,%) was obviously lowered due to the introduction of the core GL. Especially, the more GL content in the feed, the smaller X datum. Even when n(LA)/n(GL) was no more than 40/1, the multi-core structure of the copolymers was more complicated, which made the copolymer a yellow viscous solid, and no XRD data could be obtained.

Though all X data were lower than that of PLLA, to some degree, increasing n(LA)/n(GL) could increase the crystallinity, and this may be related to the reduction of the core number in the multi-core copolymer. At the same time, though the whole regularity of the copolymers was decreased due to the introduction of GL as the core, the crystallite dimension contrarily became bigger than that of PLLA also for the same reason. In a word, the XRD characterization also showed that the multi-core structure was formed when PLA was modified by GL via the direct melt copolymerization.

1H-NMR calculation results of P(LA-co-GL)s

According to the principle that the integral of proton peak area ratio reflects the amount of substance containing hydrogen group ratio, we calculated the composition of the copolymer molar ratio of each unit using S Ha+Ha′/S Hb′+Hd as the standard (here, S is the integration area). Supposed that only one GL core was contained in the copolymer, and x is the degree of polymerization (DP) for LA repeating unit, its calculation method could be shown as Formula 1-A.

Furthermore, according to the integral of the proton peak area ratio, the number-average molecular weight (Mn) of the copolymer also could be roughly estimated. And the calculation method is shown as Formula 2-A (where 92 is the molecular weight of GL, 72 is the molecular weight of LA repeating unit, x is the DP of LA repeating unit).

According to the above two formulae, when the copolymers were synthesized at the different molar feed ratios, the results of 1H-NMR calculation were shown as Table 7 (All Mn values are based on 100 Da as the unit). It could be seen that, Mn of the copolymers tested by 1H-NMR is usually smaller than the corresponding theoretic value for the escape of LA out of the reaction systems as lactide during the direct melt copolycondensation.

On the other hand, when the n(LA)/n(GL) molar feed ratio is no more than 100/1, the Mn tested by 1H-NMR is also correspondingly smaller than that tested by GPC (Table 7, runs 1–5). This suggested that the copolymers with multi-cores should be formed via the ether bond between the terminal hydroxyl of the copolymer. In our previous work, the forming of ether bond has been found during the copolymerization of LA with diethanolamine [60].

According to the similar approach [35], the numbers of GL core in the copolymers could be estimated from the ratio of the Mn tested by GPC to the corresponding Mn tested by 1H-NMR. It could be found that, when the n(LA)/n(GL) molar feed ratio was less than or equal to 100/1, all ratios were bigger than 1.00, even above 2.00 (Table 7, runs 1–5). These further indicated that two-core or three-core copolymers may be formed during the melt copolycondensation. But when n(LA)/n(GL) was more than 100/1, the corresponding Mn tested by 1H-NMR was gradually bigger than that tested by GPC (runs 6 and 7). These indicated that P(LA-co-GL) mainly was the copolymer with one GL core in these cases, which was shown as Scheme 1-(1).

If P(LA-co-GL) mainly was the copolymer with two GL cores, the calculation formulae should be changed from Formula 1-A and Formula 2-A to the following Formula 1-B and Formula 2-B. And the corresponding calculation results of 1H-NMR data were listed as Table 8.

From Table 8, it could be seen that, for runs 2 and 3, the Mn data of tested by 1H-NMR were close to those tested by GPC, and the corresponding ratios were very close to 1.00. Namely, when the molar feed ratio n(LA)/n(GL) was 40/1 or 60/1, the resulted P(LA-co-GL) was more tended to be the two-core copolymer, which was shown as Scheme 1 -(2).

For n(LA)/n(GL) 80/1, the Mn tested by GPC (3,300 Da) was between the Mn tested by 1H-NMR according two cores (4,700 Da, Table 8, run 4) and that according to one GL core (2,700 Da, Table 7, run 4), which implied that the copolymers’ structure was more complex for the products simultaneously contained one-core and two-core copolymers. For n(LA)/n(GL) 100/1, the similar conclusion could be drawn from the corresponding data (Table 8, run 5; Table 7, run 5).

When the molar feed ratio n(LA)/n(GL) was 20/1 (Table 8, run 1-B), it could be seen that, the Mn data of tested by 1H-NMR (1,900 Da) was still smaller than that tested by GPC (2,600 Da). Therefore, we supposed that P(LA-co-GL) mainly was the copolymer with three GL cores, and the calculation formulae were shown as Formula 1-C and Formula 2-C.

The corresponding calculation results in Table 8 (run 1-C) showed that the Mn tested by 1H-NMR was very consistent with that tested by GPC. Namely, in this case, the resulted P(LA-co-GL) was very tended to be three-core copolymer, which was shown as Scheme 1 -(3). Thus, when the molar feed ratio n(LA)/n(GL) was different, the copolymer with different main structure was formed, which was related to the reaction mechanism of the direct melt copolymerization.

Possible mechanism of direct melt copolycondensation of LA with GL

Based on the above analyses and our previous works [35, 36, 60], the possible mechanism of direct melt copolycondensation of LA with GL was proposed as Scheme 2. It could be believed that, in the first stage of the direct melt copolycondensation, the main reaction was the forming of SPLA using GL as the core shown as Scheme 2 -(1), and the increment of Mw was dependent on the length of PLA arms.

In the late stage of the copolycondensation, especially increasing the molar feed of GL, the terminal hydroxyl of PLA arms was likely to form ether bond by dehydration, and the two-core or three-core copolymer was produced, which was the reaction shown as Scheme 2-(2). Hence, the product was not the simple three-arm PLA. And the structure of the copolymers was dependent on the molar feed ratio n(LA)/n(GL) during direct melt copolycondensation.

When the molar feed ratio n(LA)/n(GL) was less than or equal to 100/1, the SPLA with smaller Mw was combined with ether bond, and the copolymer with multi-core structure was obtained. The less the molar feed of LA was, the easier the forming of multi-core structure was. Only when the molar feed ratio n(LA)/n(GL) was more than 100/1, the SPLA with bigger Mw could be synthesized as anticipated, which was shown as Scheme 2 -(3).

During the forming of multi-core copolymers, the Mw of copolymers also could be increased. Hence, two factors had influence on the value of Mw. One was the length of PLA arm, and the other was the number of GL core. Increasing the molar feed of LA was advantageous to make the PLA arm longer. Contrarily, it was disadvantageous to make the forming of multi-core structure harder because the forming of ester bond was easier than that of ether bond. Thus, only the simultaneous existence of both suitable arm length and core number could make the copolymer with the biggest Mw, namely make the Mw peak value formed.

These phenomena of multi-core structure and Mw peak value also explained why Mw was not increased constantly with the increase of LA molar feed when LA and pentaerythritol (also a multihydroxyl core) were directly copolymerized [61]. These conclusions were indeed similar to the reported before [35, 36]. However, for different multi-core structure, the connection bond was different. During the direct melt copolycondensation of LA with cholic acid (CA), multi-core structure was combined with ester bond [35]. For the copolymerization of LA with trimesic acid (TMA), the connection bond was anhydride bond [36]. In this study, it was ether bond.

The forming reversibility of ester bond or anhydride bond, and the further transesterification [35] or esterification [36] could make Mw increased. However, once the ether bond in the reaction system was formed, it was difficult to convert the ether bond into alcohol hydroxyl. Therefore, the biggest Mw (8,800 Da) in this reaction system was relatively smaller than that in other cases (for the copolymerization of LA and CA, the biggest Mw was 12,800 Da [35]; for the copolymerization of LA and TMA, the biggest Mw was 23,100 Da [36]).

Conclusions

To further verify the forming mechanism of multi-core structure during the direct melt copolycondensation of LA with the compounds containing multifunctional groups, the biodegradable material P(LA-co-GL) was synthesized as designed using L-LA and GL as the starting materials. For the molar feed ratio n(LA)/n(GL) of 60/1, after the prepolymerization was carried out at 140 °C for 8 h, the melt copolymerization catalyzed by 0.3 wt% SnO for 8 h at 160 °C gave the polymer with the biggest [η] 0.76 dL•g−1.

The systematical characterization of the copolymers P(LA-co-GL)s at different molar feed ratios by FT-IR, 1H-NMR, GPC, DSC and XRD showed that, the forming of the multi-core structure and the Mw peak phenomenon was found indeed as expected. And only when n(LA)/n(GL) was more than 100/1, SPLA containing one GL core could be obtained. The further confirmed mechanism of the direct melt copolycondensation of LA and other monomers is favorable for the modification of PLA by more monomers containing multifunctional groups via direct melt copolycondensation.

References

Rasal RM, Janorkar AV, Hirt DE (2010) Prog Polym Sci 35:338

Maharana T, Mohanty B, Negi YS (2009) Prog Polym Sci 34:99

Konishi S, Yokoi T, Ochiai B, Endo T (2010) Polym Bull 64:435

Sedlarik V, Kucharczyk P, Kasparkova V, Drbohlav J, Salakova A, Saha P (2010) J Appl Polym Sci 116:1597

Gao QW, Lan P, Shao HL, Hu XC (2002) Polym J 34:786

Qian ZY, Li S, Zhang HL, Liu XB (2003) Colloid Polym Sci 281:869

Zhou SB, Deng XM, Li XH (2004) J Appl Polym Sci 91:1848

Moon SI, Deguchi K, Miyamoto M, Kimura Y (2004) Polym Int 53:254

Slivniak R, Langer R, Domb AJ (2005) Macromol 38:5634

Lee CM, Kim HS, Yoon JS (2005) J Appl Polym Sci 95:1116

Matsudo K, Mihara T, Koide N (2005) Polym Prep Jpn 54:1266

Abe H, Tetsuka H, Doi Y (2005) Polym Prep Jpn 54:5243

Deng LD, Li AG, Yao CM, Sun DX, Dong AJ (2005) J Appl Polym Sci 98:2116

Gong QX, Wang LQ, Tu KH (2006) Carbohydr Polym 64:501

Wang ZY, Zhao YM, Wang F, Wang J (2006) J Appl Polym Sci 99:244

Kim HS, Hwang MO, Kim MN, Yoon JS (2006) J Appl Polym Sci 100:466

Du J, Fang YY, Zheng YB (2007) Polymer 48:5541

Duan JF, Du J, Zheng YB (2007) J Appl Polym Sci 103:2654

Duan JF, Du J, Zheng YB (2007) J Appl Polym Sci 103:3585

Sokolsky-Papkov M, Domb AJ (2008) Polym Adv Technol 19:671

Cohen-Arazi N, Katzhendler J, Kolitz M, Domb AJ (2008) Macromol 41:7259

Tsuji H, Matsuoka H, Itsuno S (2008) J Appl Polym Sci 110:3954

Sun ZJ, Wu L, Lu XL, Meng ZX, Zheng YF, Dong DL (2008) Appl Surf Sci 255:350

Sun ZJ, Wu L, Huang W, Zhang XL, Lu XL, Zheng YF, Yang BF, Dong DL (2009) Mat Sci Eng C 29:178

Li WD, Zeng JB, Li YD, Wang XL, Wang YZ (2009) J Polym Sci Part A Polym Chem 47:5898

Zhai YL, Deng LD, Xing JF, Liu Y, Zhang Q, Dong AJ (2009) J Biomat Sci Polym Ed 20:923

Zhang Y, Wang XL, Wang YZ, Qu MH (2009) J Macromol Sci Part A Pure Appl Chem 46:631

Ding J, Chen SC, Wang XL, Wang YZ (2009) Ind Eng Chem Res 48:788

Inkinen S, Stolt M, Södergård A (2010) Biomacromol 11:1196

Akesson D, Skrifvars M, Seppala J, Turunen M, Martinelli A, Matic A (2010) J Appl Polym Sci 115:480

Namkajorn M, Petchsuk A, Opaprakasit M, Opaprakasit P (2010) Express Polym Lett 4:415

Michinobu T, Bito M, Tanimura M, Katayama Y, Masai E, Nakamura M, Otsuka Y, Ohara S, Shigehara K (2010) J Macromol Sci Part A Pure Appl Chem 47:564

Miao PK, Wu DM, Zhao CE, Xu GL, Zeng K, Wang YP, Fu Q, Yang G (2010) E-polym No. 006

Ye RR, Wang ZY, Yang K, Luo SH (2010) Des Monomers Polym 13:415

Wang ZY, Zhao HJ, Wang QF, Ye RR, David EF (2010) J Appl Polym Sci 117:1405

Wang ZY, Luo YF, Ye RR, Song XM (2011) J Polym Res (doi: 10.1007/s10965-010-9442-0)

Xu YP, Li JH, Chen MQ, Ren JJ, Ni ZB, Liu XY (2010) Acta Polym Sin: 300

Arvanitoyannis L, Nakayama A, Kawasaki N, Yamamoto N (1995) Polymer 36:2947

Han DK, Hubbell JA (1996) Macromol 29:5233

Han DK, Hubbell JA (1997) Macromol 30:6077

Han DK, Park KD, Hubbell JA, Kim YH (1998) J Biomater Sci Polym Ed 9:667

Ju YM, Ahn KD, Kim JM, Hubbell JA, Han DK (2003) Polym Bull 50:107

Lee SH, Kim SH, Han YK, Kim YH (2001) J Polym Sci Part A Polym Chem 39:973

Tsuji H, Miyase T, Tezuka Y, Saha SK (2005) Biomacromol 6:244

Grijpma DW, Melchels FPW, Hou Q, Feijen J (2006) Mater Res Innovat 10:321

Zhang WA, Zheng SX (2007) Polym Bull 58:767

Gou PF, Zhu WP, Shen ZQ (2008) J Polym Sci Part A Polym Chem 46:2108

Zhao YM, Wang ZY, Yang F (2005) J Appl Polym Sci 97:195

Moon SI, Lee CW, Miyamoto M, Kimura Y (2000) J Polym Sci Part A Polym Chem 38:1673

Moon SI, Lee CW, Taniguchi I, Miyamoto M, Kimura Y (2001) Polymer 42:5059

Moon SI, Kimura Y (2003) Polym Int 52:299

Sayed FN, Grover V, Dubey KA, Sudarsan V, Tyagi AK (2011) J Colloid Interf Sci 353:445

Ma YD, Huang LQ, Song CX, Zeng XW, Liu G, Mei L (2010) Polymer 51:5952

Park SY, Han BR, Na KM, Han DK, Kim SC (2003) Macromol 36:4115

Ray WC, Grinstaff MW (2003) Macromol 36:3557

Yang F, Song FL, Pan YF, Wang ZY, Yang YQ, Zhao YM, Liang SZ, Zhang YM (2010) J Microencapsul 27:133

Wang N, Wu XS, Lujan-Upton H, Donahue E, Siddiqui A (1997) J Biomater Sci Polym Ed 8:905

Wang N, Wu XS (1998) J Biomater Sci Polym Ed 9:75

Kim ES, Kim BC, Kim SH (2004) J Polym Sci Part B Polym Phys 42:939

Ye RR, Wang ZY, Yang K, Li JX (2009) Chem 72:637

Luo YF, Wang ZY, Song XM, Mao ZZ, Zhao HJ (2008) Chin J Synth Chem 16:166

Acknowledgements

We are grateful to the financial support by Guangdong Provincial Natural Science Foundation of China (No. 5300082) and National Natural Science Foundation of China (No. 20772035).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Luo, SH., Wang, ZY., Mao, CX. et al. Synthesis of biodegradable material poly(lactic acid-co-glycerol) via direct melt polycondensation and its reaction mechanism. J Polym Res 18, 2093–2102 (2011). https://doi.org/10.1007/s10965-011-9619-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-011-9619-1