Abstract

3,5-Dihydroxy-4-i-propylstilbene (DHPS) is a compound expected to be developed into effective drugs for many inflammatory and autoimmune diseases. In order to improve the stablity of DHPS, the cross-linked chitosan (CS) microspheres loading of DHPS were prepared and characterized. The optimal conditions for preparing CS-microspheres loading of DHPS were investigated. The results showed that the CS-microspheres loading of DHPS had spherical shape with diameters between 8 and 12 microns. The entrapment of DHPS in the CS-microspheres was more than 36%. The released percentage of CS-microspheres loading of DHPS in pH 3.6 buffer solution was up to 30.9% within 96 h. In transdermal in vitro release, DHPS kept release within 60 h through rat skin and the released percentage could arrive 76.2%. The CS-microspheres loading of DHPS had excellent stability and ability of sustained release.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Stilbene derivatives are noted compounds because they have exhibited miscellaneous pharmacological activities such as inoxidizability, anti-inflammation, antiestrogenic and cancer chemoprevention etc [1, 2]. 3,5-Dihydroxy-4-i-propylstilbene (DHPS) (also named as 2-isopropyl-5-(2-phenylethenyl)-benzene-1,3-diol) was first reported as metabolite of the antimicrobial compound from cultures of a Photorhabdus sp. [3]. And it is also isolated as an antibiotic production from a genus of bacteria symbionts which live in the parasitic nematodes guts [4, 5], from Photorhabdus luminescens, a bacterial symbiont of the entomopathogenic nematode Heterorhabditis megidis [6], and from larval Galleria mellonella which is infected by nematode bacterium [7]. Later researches illustrate that DHPS shows a lot of active pharmacological properties such as having effects on T lymphocytes, mast cells, neutrophils and weakly cytotoxic to mammalian cells [8]. So it has therapeutic potential and is intensely expected to be developed into the effective drugs for many diseases, such as inflammatory bowel disease, rheumatoid arthritis and autoimmune skin disorder. Welichem Biotech Inc. (Canada) developed that DHPS can use as a new drug for common skin disorders such as atopic dermatitis (a type of eczema) and psoriasis which is a chronic skin disease with silvery white scaling patches and can cause outbreaks of skin inflammation [8, 9]. Following further investigations report that the DHPS has shown in prior clinical trials to be effective and to have good safety profiles [2]. However, in the molecular structure there are two hydroxyl groups in the benzene ring, so DHPS is sensitive to the environment conditions such as air and light. Impurities such as quinone and polymers of DHPS, which are probably harmful to human and can interfere in the healing effect of drug, will arise from ordinary use or preservation. Therefore, it is necessary to establish a suitable method for DHPS to enhance its stability and achieve a steady efficacy for an extended period of time simultaneously.

One of the best ways for realizing the purpose is to encapsulate medicine into an absorbable coating, and this method has been applied by many investigators [10–12]. Chitosan (CS) is a biodegradable natural material with great potential for pharmaceutical applications because of its biocompatibility, high charge density and non-toxicity. It has shown that chitosan may not only improve the dissolution of poorly soluble drugs and promotion of fat metabolism in the body, but also has potential antifungal and antibacterial activities. For this reason, chitosan is currently widely used as coating film or drug carrier for many oral and parenteral drugs [13, 14]. However, non-crosslinked chitosan microspheres (CS-microspheres) can not keep stable in water because of swelling and dissolution. Then crosslinked CS-microspheres are investigated for favourable stable protecting coating materials and have been reported which can not only to provide biodegradable controlled release of many drugs, but also can promote hydrophilic molecules across biomembranes [14, 15]. The cross-linking agents, such as glutaraldehyde and formaldehyde, are generally used to solidify the CS-microspheres.

To the best of our knowledge, there is no precedent report on the preparation and release property of the CS-microspheres loading of DHPS. In this work, the model for cross-linked CS-microspheres loading of DHPS was designed to elevate the stability of DHPS and to realize the release controll. The optimal conditions for preparing CS-microspheres loading of DHPS were investigated. In vitro drug release simulating a physiological condition and the transdermal experiment through rat skin had been carried out. The results show that the CS-microspheres loading of DHPS has a satisfied stability. The released percentage of DHPS is up to 30.8% within 96 h in pH 3.6 buffer solution. Transdermal experiment through rat skin shows that the released percentage of DHPS from CS-microspheres can be achieved 76.2% over 72 h.

Experimental

Materials

Chitosan (CS) with at least 90% degree of deacetylation (MW = 50,000) was purchased from Heppe Biotechnology Ltd., Qingdao, China. DHPS was synthesized in our laboratory [16], which molecular structure shows in Scheme 1. Methanol was chromomatographically pure and purchased from Kangkede Company, Tianjin, China. Glutaraldehyde (GA) and other chemical reagents were all analytically pure grades and purchased from Shijiazhuang Modern Reagent Company, Shijiazhuang, China. Soy bean salad oil, olive oil and peanut oil were all of food grades and made in COFCO, Tianjin, China.

Preparation of CS-microspheres

1.5 g Chitosan was dispersed in 47 mL sterile distilled water, and 3 mL 36% acetic acid was added slowly with agitating into the above solution and then set it for 1 h to eliminate bubbles. 2 mL 3% chitosan solution was dropped into 15 mL 5% Span-80-soybean salad oil (W/V). After stirring for 30 min an emulsion was formed and then 1 mL 50% glutaraldehyde (GA) was dropped into the emulsion and the above emulsion was stirred for 6 h continuously. The CS-microspheres were separated by centrifugation at 1,000 r/min for 30 min. The oil and un-reacted GA were removed completely by fully washing with petroleum ether. Then CS-microspheres were filtered under vaccum and lyophilized.

0.02 g DHPS dissolving in a small quantity ethanol was put into a beaker which contained 2 mL 3% chitosan solution with continuous stirring. Then the uniform solution was dropped into 15 mL soybean salad oil which contained 5% (W/V) Span-80, then operated following above method, and the microspheres loading of DHPS were obtained.

Many factors will influence on the shape and grain diameter of CS-microspheres. Therefore, the factors like chitosan concentration, dispersive medium and emulsifier concentration were studied to optimize the preparing process. The concentration of chitosan was taken as 1%, 2%, 3% and soybean oil, petroleum ether, olive oil, paraffin oil and peanut oil were chosen as dispersive medium in microsphere preparation, respectively. The mass proportion of glutaraldehyde or DHPS to chitosan was changed to investigate the encapsulation efficiency and loading capacity of CS-microspheres.

Characterization analysis

IR spectra of chitosan and CS-microspheres with and without loading of DHPS were recorded with a FTIR spectrophotometer (FTS135, Bio-Rad, America). DSC analysis was performed by a DSC-TGA (SDT-2960, TA Co., America). The chitosan and DHPS were ground into particles diameter less than 0.127 mm. About 4 mg sample was placed into a platinum DSC sample cell and heated from 0 °C to 350 °C under nitrogen flow of 20 mL·min−1 at a heating rate of 10 °C/min. The test of drug release in vitro was conducted by an Intelligent Dissolution tester (RC2-8A, Tianjin University, China) and the style of dialysis tube used was MD34 (MW 3500, Beijing Solarbio Science & Technology Co., Ltd.). Transdermal experiment in vitro of CS-microspheres loading of DHPS was carried out through rat skin in a Franz diffusion cell (RYJ-12B, Huanghai, China). The amount of DHPS was determined by high performance liquid chromatography (HPLC, Agilent 8453, Agilent, Japan). The mobile phase was a mixture of methanol and distilled water (V/V = 80/20). The column of HPLC was Phenomenexluna-C18 (250 × 4.6 mm, 5 μm). The flow rate was 1.0 mL/min, the detection wavelength was 316 nm and injected volume of the sample was 10 μL. The morphology and size of CS-microsphere were observed under scanning electron microscopy (SEM, S-4800 HITACHI, Japan).

Stability of CS-microspheres loading of DHPS was determined according to the regulations of Chinese Pharmacopoeia (2010 Edition) [17]. CS-microspheres were stored at 60 °C (high temperature test), relative humidity 92.5% (high humidity test) and (4,500 ± 500 nm) lx (high light irradiating test) conditions for a period separately. Simultaneouly, the daylight and UV light irradiating test for samples was also done, and stability of CS-microspheres loading of DHPS was also compared with that of DHPS and physical mixture of DHPS and CS. Loading capacity (LC) and mass of the CS-microspheres loading of DHPS were detected by HPLC and electronic balance with sampling at 0, 5 and 10 days, respectively.

DHPS encapsulation efficiency (EE) and loading capacity (LC) of CS-microspheres were determined by HPLC. 0.01 g CS-microspheres loading of DHPS was put into a beaker and extracted with ethanol under ultrasonic wave. Volume of the suspension was maintained to 50 mL. The resulted suspension was centrifuged at 6,000 r/min and then the amount of DHPS in supernatant was determined by HPLC.

The EE and LC of CS-microspheres are calculated as follows:

Among the above formula, all data are averaged from thrice or quintic experiments.

The dynamic dialysis method was used in vitro release test of CS-microspheres loading of DHPS. A certain amount of microspheres was suspended in the buffer solution (pH 3.6 or pH 7.4) in a MD34 dialysis tube which was placed in a shaking basket. The basket was immersed in the release medium acetic acid-sodium acetate buffer solution (ABS, pH 3.6) or phosphate buffered saline (PBS, pH 7.4) at 37 °C with continuous agitation. In accordance with the selected time interval, a small amount of the release medium was taken out and extracted by ethyl acetate. Then the ethyl acetate phase was concentrated to remove the solvent, the amount of DHPS was measured by HPLC and the accumulating release degree was calculated. While an equal volume of buffer solution (ABS or PBS) was added into the release system for maintaining the constant volume. In vitro drug dialysis behavior was compared with that of DHPS in pH 3.6 ABS or pH 7.4 PBS buffer solution.

Membrane, which was abdomen skins taken from mice (♂, 25 ± 2 g, Kunming, China) depilated by 8% sodium sulfide and cleaned up the fat, was fixed to the Franz diffusion cell and horny layer was faced to the supply chamber. 4 mg microspheres and 5 μL dimethyl sulphoxide were put into the supply chamber to contact closely with membrane. 7 mL 70% sodium chloride—alcohol solution (V/V) was used as receipting medium. Temperature of receipting medium was kept at 37 °C and rotating speed was constant at 120 r/min. 2 mL receipting medium was taken out from the supply chamber at certain time intervals to measure the amount of DHPS, and simultaneously, the equal volume of fresh receipting medium was added to maintain the total volume unchanged. DHPS released was quantified by HPLC after treatment and the release behavior was compared with that of drug DHPS (1.2 mg). The experiments were repeated in thrice.

Results and disccussion

The FTIR spectra of chitosan, CS-microspheres with and without loading of DHPS are shown in Fig. 1. The characteristic absorption band of 3,420 cm−1 (b) is attributed to stretching vibration of hydroxy groups in chitosan. The 1,636 cm−1 band is characteristic peak of imine formed by crosslinking of chitosan with glutaraldehyde (a) [18]. In FTIR spectrum of CS-microsphere containing DHPS, the strong peak at 1,572 cm−1 is attributed to conjugating aromatic skeleton vibration in stilbene and there is an out-of-plane bending vibration peak of trans-arylolefin at 951 cm−1. The peaks from 2,950 cm−1 to 2,800 cm−1 observed increasing substantially, and superadding the peak at 1,376 cm−1 indicate that i-propyl group of DHPS is existed in the CS-microspheres (c).

The SEM images of CS-microspheres loading of DHPS are shown in Fig. 2. These microspheres are about 8–12 microns in size and spherical in shape. Fig. 2b is the amplified surface of microsphere, which shows that the microsphere is porous.

Figure 3 exhibits the DSC curves of DHPS, DHPS/CS-microspheres physical mixture and CS-microspheres loading of DHPS. As seen from Fig. 3(a), the DHPS has melting endothermic peak at 142.5 °C, for the mixture, the melting peak increases to 147.0 °C (b), which is attributed to the molecular interaction between DHPS and CS (as hydrogen bonds). The endothermic peak below 100 °C is attributed to solvent or water slopping over from the sample. For the CS-microspheres loading of DHPS (c), there is not obvious endothermic peak, which illuminates that the DHPS has been enwraped in the CS-microspheres.

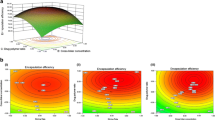

When mass ratio of CS/DHPS is changed, the results of HPLC analysis for EE and LC are listed in Table 1. As seen from Table 1, the EE and LC values are all increased with decreasing mass ratio of CS/DHPS. When mass ratio is 3.0:1.0 (n = 3), the EE and LC have a maximum values, which is 36.7 ± 1.5% and 1.59 ± 0.5%, respectively. Then the EE and LC decreased gradually as the reduction mass radio of CS/DHPS. The result shows that the mass ratio of DHPS to chitosan is the principally factor which influence significantly on the EE and LC. This is because the amount of CS decreased, the relative amount of DHPS is actually increased, so the increase in EE and LC. But when the mass ratio of CS with DHPS decreases to a certain extent, the DHPS molecules will agglomerate and precipitate from the system owing to its lower solubility in water, thus causing decreased EE and LC.

The results of CS-microspheres obtained from different concentrations of chitosan show that the concentration of chitosan solution influences obviously on dispersion and diameter of microspheres. The microsphere granularity reduces gradually along with decreasing concentration of chitosan, but conglutination arises. The microsphere has a favorable sphericity and dispersion when concentration of chitosan is 3% (as shown in Fig. 2).

The concentration of emulsifier (Span-80) in soybean salad oil on the size and shape of microspheres have a serious influence. The lower concentration of Span-80 can only obtain large, uneven size and poor sphericity of CS-microspheres. If concentration of Span-80 is below 5%, aggregation of microspheres will appears, especially, when the concentration of Span-80 is lower than 3%, the CS-microspheres tend to agglomerate. When the concentration of Span-80 is equal to or greater than 5%, the CS-microspheres with favourable sphericity and diameter can be obtained.

Organic dispersive medium also has important influences on the shape and diameter of microspheres. Petroleum ether, olive oil, paraffin oil and peanut oil were used as dispersive medium respectively under the same amount of emulsifier, and the results are shown in Fig. 4. As seen from Fig. 4, when petroleum ether, peanut oil and olive oil are used as dispersive mediums, the serious aggregation arises (a, b and c); when paraffin oil is used as a dispersive medium, the size distribution of microspheres is broad (d). In fact, when soybean oil is used as a dispersive medium, the microspheres’ shape becomes rounder and smoother, at the same time, they have favorable dispersivity, and the diameter of the CS-microspheres loading of DHPS is usually between 8 and 12 microns (as shown in Fig. 2a).

The CS crosslinking was performed by carbonyl of glutaraldehyde condensing with the free amino group of CS. Therefore, the crosslinking degree of CS is prominently influenced by the dosage of glutaraldehyde. The experiment results show that the crosslinking degree and the total mass of CS-microspheres increases with increasing the mass proportion of glutaraldehyde to chitosan, and simultaneity, the EE increases also, but the loading capacity of CS-microspheres will decreases. When the mass proportion of glutaraldehyde to chitosan is equal to 1:6, the EE of CS-microspheres is 36.7% and LC is 4.5%.

To investigate the stability of CS-microspheres loading of DHPS, the test of stability was carried out according to the regulations of Chinese Pharmacopoeia (2010 Edition) [17]. Tables 2 and 3 show determined data for CS-microspheres loading of DHPS and pure DHPS under the different experimental conditions, respectively. As seen from Table 2, the CS-microspheres loading of DHPS are stable to temperature, light and humidity and there is no obvious change in spheric form, encapsulation efficiency (EE) and weight of CS-microspheres. Compared with Table 2, in Tables 3 and 4, the pure DHPS and DHPS in physical mixture of DHPS with CS have obvious content loss under light radiation, especially the content loss rate under UV irradiation is over 3% within 10 days, but in CS-microspheres loading of DHPS, the EE is only loss 0.21%. These results show that the CS-microspheres loading of DHPS has good stability and the stability of DHPS is well improved by the method of encapsulating it into CS-microspheres.

Drug molecule may be released through passageways existed in the microspheres. In this work, the release of DHPS from the CS-microspheres was investigated in pH 3.6 ABS and pH 7.4 PBS buffer solution. In comparison, the dynamic dialysis of DHPS in pH 3.6 or pH 7.4 buffer solutions was carried out. As seen from Fig. 5, it is clear that the DHPS drug has a burst release effect within 24 h in pH 3.6 buffer solution, but DHPS release from CS-microspheres increases gently in initial and almost keeps release uniformly in subsequential periods, and it has a like linear releasing relationship. The released percentage of DHPS from CS-microspheres is up to 30.9% within 96 h. The lower release percentage within 96 h, it may be caused by lower solubility and part of the degradation of DHPS in this solution, because of the release rate is related with solubility. The experimental results show that solubility of DHPS in water and buffer solutions of pH 3.6 and pH 7.4 are 0.059, 5.039 and 0.123 μg/mL, respectively. The solubility of DHPS in buffer solution of pH 3.6 is only 5.039 μg/mL, so the release rate is only 30.9% within 96 h, and in this solution and so long time that some degradation of DHPS is also a factor in lower release rate. But compared with pure DHPS, the result shows that the CS-microspheres loading of DHPS prepared by this method still have a relatively good ability of controlled release. However, there is almost no release in pH 7.4 buffer solution within 96 h, because DHPS is almost insoluble in pH 7.4 PBS buffer solution, some porous passageways of microspheres in this condition may be blocked by released drug molecules.

Release of medicines from carriers is affected by supporting material, diameter of microspheres and properties of loading drug. Transdermal ability of CS-microspheres loading of DHPS was investigated through rat skin under simulated physiological condition in Franz diffusion cell. For comparison, the permeation of drug DHPS under the same condition was also carried out and shows in Fig. 6. As seen from Fig. 6, it is worth noting that permeation of DHPS is very fast at the initial stage and exhibits a burst release effect. The released percentage can be up to 93% within 12 h. Then the accumulating release degree decreases after 16 h due to degradation of DHPS. In comparison, the releasing speed of the CS-microspheres loading of DHPS is very slow in the initial several hours and the release can be kept in the successive 72 h. After 24 h, the release of DHPS becomes gradual increase and the released percentage can be up to 76.2% within 60 h. The results show that the CS-microsphere has very good controlled release ability for DHPS. The decrease of released percentage after 72 h is related with the degradation of DHPS.

Conclusion

The crosslinked CS-microspheres loading of DHPS were successfully prepared. The optimal conditions for preparing CS-microspheres loading of DHPS were discussed. When soybean oil is used as a dispersive medium and the concentration of chitosan solution is taken as 3%, the CS-microspheres loading of DHPS prepared have a round shape with the diameter between 8 and 12 microns. The encapsulation efficiency (EE) and loading capacity (LC) of DHPS in CS-microspheres could be up to 36.0% and 4.5%, respectively. This CS-microsphere loading of DHPS has a satisfied stability. In vitro release test, the released percentage of DHPS from CS-microspheres was up to 30.9% within 96 h in pH 3.6 buffer solution, but there was almost no release in pH 7.4 buffer solution. Transdermal experiment through rat skin illustrated that the released percentage of DHPS from CS-microsphere could arrive 76.2% over 60 h and has a property of significant sustained release action.

References

Akbuga J, Durmaz G (1994) Inter J Pharm 111:217

Chen GH, Webster JM (2008) US Patent Office 0255245

Paul VJ, Frautschy S, Fenical W, Nealson KH (1981) J Chem Ecol 7:589

Krow GR, Miles WH, Smiley PM (1992) J Org Chem 57:4040

Richardson WH, Schmidt TM, Nealson KH (1988) Appl Environ Microb 54:1602

Hu K, Li J, Webster JM (1996) Can J Plant Pathol 18:104

Hu K, Webster JM (2000) FEMS Microbiol Let 189:219

Tang LR, Chen GH, Li B (2007) Clin Immunol 123.

Hu KJ, Li JX, Li B (2006) Bioorgan Med Chem 14:4677

Babazadeh M, Edjlali L, Rashidian L (2007) J Polym Res 14:207

Wang TW, Jing M, Wu Y (2010) J Polym Res 17:335

Liu CC, Chang KY, Wang YJ (2010) J Polym Res 17:459

Wu Y, Li MG, Gao HG (2009) J Polym Res 16:11

Zhang C, Cheng Y, Qu GW, Wu XL, Ding Y, Cheng ZH, Yu LL, Ping QN (2008) Carbohyd Polym 72:390

Gupta KC, Jabrail FH (2006) Carbohyd Polym 66:43

Zhang Y (2009) CN Patent Office, 101 648 851

Chinese Pharmacopoeia, 2010: The guiding principles for stability test of drugs and drug preparations

Wang ZX (1989) Infrared spectroscopy and characterization of polymer. Sichuan Univ Bub Co, Chengdu, pp 179–183

Acknowledgment

The authors would like to thank Dr Yanyan Zhao and her collegues for the HPLC measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, Jg., Zhang, Y., Yu, Yf. et al. Preparation of chitosan microspheres loading of 3,5-dihydroxy-4-i-propylstilbene and in vitro release. J Polym Res 18, 1501–1508 (2011). https://doi.org/10.1007/s10965-010-9555-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-010-9555-5