Abstract

Nickel ferrite nanoparticles were synthesized by co-precipitation/hydrothermal synthesis. The synthesis temperature of the co-precipitation of the precursor was studied. At this stage, proper reaction temperature to synthesize superparamagnetic nickel ferrite nanoparticles with zero coercivity (H c) was found to be 80 ∘C. More importantly, the effects of temperature and time of the hydrothermal process on the structural and magnetic properties of the nanoparticles were also investigated. X-ray diffraction (XRD) and Fourier transform infrared spectroscopy were used for the structural analysis. Particle sizes and shapes were determined by transmission electron microscopy (TEM). Magnetic measurements were done by using a vibrating sample magnetometer (VSM). The particle sizes d XRD, d TEM and d VSM of nickel ferrite nanoparticles were calculated from XRD patterns, TEM images and magnetic data, respectively. By hydrothermal process, the reaction time is seen to be effective on the properties of NiFe 2O4 nanoparticles since the size of the nanoparticles and saturation magnetization (M s) increase with the increase of the time. The effect of reaction temperature on the properties of nickel ferrite nanoparticles is also slightly observed. It is seen that the synthesized nanoparticles at 125 ∘C for 40 h exhibit a superparamagnetic behaviour (zero H c). And M s is found to be 50.8 emu/g which is a substantially high value. Also, the limit of superparamagnetic particle size for our study is ∼12 nm since NiFe 2O4 nanoparticles bigger than 12 nm show H c.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Ferrite nanoparticles (MFe2O4, M = Fe, Ni, Co, Mn, etc.) have various applications in magnetic films [1], magnetic fluids [2], catalysis [3], magnetic resonance imaging (MRI) [4, 5], magnetic hyperthermia [2, 5] and drug delivery [6, 7]. Also, nickel ferrite (NiFe2O4) nanoparticles have promising electrical and magnetic properties and are frequently used in electronic devices [8], high frequency applications [9], MRI contrast agents [10], etc. Magnetic nanoparticles can be synthesized by various techniques including co-precipitation, hydrothermal synthesis, thermal decomposition, microemulsion and sol-gel [11, 12]. The co-precipitation is a simple and efficient way to synthesize high-yield magnetic nanoparticles [13]. However, a co-precipitation method cannot solely be used to prepare NiFe2O4 nanoparticles without further processes, such as hydrothermal process [14], annealing [15] and calcination [16].

In the study [16], nickel ferrite nanoparticles are synthesized by a co-precipitation/calcination process. In the first step, FeOOH and Ni(OH)2 are obtained as a precursor and the precursor is calcinated at high temperatures (650 and 800 ∘C) for 2 h in air environment. The NiFe2O4 nanoparticles obtained in this study show coercivity (H c), and their saturation magnetization (M s) values are 33 and 49 emu/g. In another study [15], NiFe2O4 nanoparticles are co-precipitated in the first step and annealed afterwards. The obtained nanoparticles are 17 nm in size. The M s of the sample is 44 emu/g and its H c is 51 Oe. Wang et al. [14] obtained a colloidal suspension by co-precipitation in the first step, and this suspension is hydrothermally processed at 180 ∘C for 6–48 h. NiFe2O4 nanoparticles obtained in the co-precipitation/hydrothermal synthesis show H c. Superparamagnetic NiFe2O4 nanoparticles are also obtained in [17]; however, the M s values are highly low. Barreto et al. [17] obtained superparamagnetic NiFe2O4 nanoparticles by the co-precipitation/calcination process. The M s values of the nanoparticles are as low as 13 and 15 emu/g. In [18], NiFe2O4 nanoparticles are synthesized hydrothermally with and without using surfactants. The M s values of the sample with zero H c is around 35 emu/g, and the sample with higher M s (∼40 emu/g) shows H c (∼17 Oe).

In the synthesis of NiFe2O4 nanoparticles, Albuquerque et al. [8] and Shi et al. [19] proposed that co-precipitation only produces the amorphous precursor for the synthesis of NiFe2O4 in the second step. Furthermore, Shi et al. [19] regarded the precursor phase as hydroxide. It is known that hydrothermal synthesis allows controlling the particle size and crystallinity through the reaction time and temperature [20]. Thus, hydrothermal synthesis as a second step provides NiFe2O4 formation with controlling the particle size and crystallinity through the reaction time and temperature. In this study, NiFe2O4 nanoparticles are synthesized in a two-step co-precipitation/hydrothermal process. The effect of the temperature on the co-precipitation is investigated to determine the proper temperature. In the second step, the effects of the temperature and time are studied. The structural and magnetic properties of the final product are investigated. Superparamagnetic NiFe2O4 nanoparticles with a quite high M s value of 50.8 emu/g, which is close to the M s value of bulk NiFe2O4, are obtained.

2 Experimental

NiCl2⋅6H2O (Riedel-de Haën, > 97 %), FeCl3⋅6H2O (Sigma-Aldrich, > 99 %) and NH4OH (Merck, 25 % of ammonia) were used in this work. All reagents were of analytical grade and used without further purification. For the first step, the co-precipitation process, the precursor was synthesized under air atmosphere. Ni 2+ and Fe 3+ were dissolved with a 1:2 molar ratio in 25 ml deionized water. Then, 25 ml NH4OH was added into solution under vigorous stirring. The solution was stirred at 1000 rpm for 45 min. For the second step, the hydrothermal process, 15 ml of the precursor was transferred into a Teflon-lined stainless steel autoclave. The sealed autoclave was put into an oven, and the reaction temperature was changed between 125 and 200 ∘C for 40 h to reveal the temperature effect. And the reaction was performed at 150 ∘C for 10–80 h in order to investigate the effect of the reaction time on the properties of the nanoparticles. When the reaction was completed, the autoclave cooled down to room temperature naturally and the resulting black precipitate was washed with deionized water several times and dried in oven at 60 ∘C.

The crystal structure of the samples was characterized by the X-ray diffraction (XRD) technique, using a PANalytical’s X’Pert Pro X-ray diffractometer. Scan was performed between 20 ∘ and 80 ∘ by using CuKα radiation (λ = 1.54056 Å). Fourier transform infrared spectroscopy (FT-IR, PerkinElmer) was used to obtain the transmittance spectrum of the samples at a 370–4000 cm−1 range using KBr pellets. Transmission electron microscopy (TEM) images were taken by using a FEI Tecnai G2 F30 model high-resolution microscope. The samples were prepared by placing a drop of the diluted suspension of the samples on a carbon-coated copper grid. ImageJ programme was used to calculate the particle sizes after taking the TEM pictures of nanoparticles. The magnetic properties were investigated using a ADE EV9 model vibrating sample magnetometer (VSM) at room temperature between −20 and + 20 kOe by 1-Oe intervals.

3 Results and Discussion

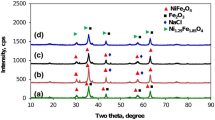

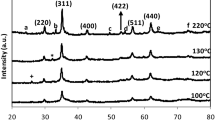

In order to obtain the precursor of the hydrothermal process, the first-step reactions were performed at different temperatures (20, 40, 60 and 80 ∘C) and the effect of the temperature on the properties of the final product was investigated. Synthesis conditions and structural and magnetic properties of the samples are given in Table 1. The precursor of sample A1 was obtained at 20 ∘C, and the sample was hydrothermally synthesized at 150 ∘C for 40 h afterwards. For the other samples (A2, A3 and A4), the precursors were obtained at 40, 60 and 80 ∘C, respectively, and the samples were synthesized at the same conditions as A1 in the hydrothermal step. The XRD pattern of sample A1 includes the peaks of crystal planes (012), (104), (110), (113), (024), (116), (214), (300), (1010) and (220) at 2𝜃 = 24.2∘, 32.7∘, 36.7∘, 40.9∘, 49.4∘, 54.0∘, 62.4∘, 64.0∘, 71.8∘ and 75.4∘, respectively (Fig. 1). These peaks correspond to hematite (JCPDS no. 33-0664). The peak (labelled with asterisk) observed at 33.2 ∘, near the (104) peak of hematite, may correspond to ferrihydrite (JCPDS no. 46-1315). The intense peaks were only labelled, and the rest seems to belong to hematite and/or iron oxide hydroxide phases according to the JCPDS card nos. 33-0664, 46-1315, 76-2301 and 89-6096. All these peaks imply that the sample is mainly hematite. It is known that iron oxide hydroxide converts to hematite by thermal transformation [21]. In our case, sample A1 is mainly hematite according to the structural analysis and magnetic measurements showing a low magnetization value (see Table 1). Black precipitate of NiFe2O4 was obtained at 40, 60 and 80 ∘C. In the XRD pattern of sample A2 in Fig. 1, (220), (311), (400), (422), (511), (440) and (533) peaks are observed at 2 𝜃 = 30.7 ∘, 36.1 ∘, 43.7 ∘, 54.2 ∘, 57.7 ∘, 63.4 ∘ and 74.9 ∘, respectively. The same peaks are seen in the XRD patterns of samples A3 and A4. The observed peaks are the characteristic peaks of NiFe2O4 according to the JCPDS card no. 86-2267. The mean crystal sizes, d XRD, were calculated from the most intense peaks of the main phase in the patterns using the Scherrer equation [22], and the results are given in Table 1. The d XRD of sample A1 is 52.6 nm. The d XRD of samples A2, A3 and A4 is 16.3, 19.3 and 10.6 nm, respectively.

For further information about the structure of the samples, FT-IR analysis was done and the spectra of all samples are shown in the 1300–370 cm−1 region in Fig. 2. Two main metal-oxygen bands are seen in the FT-IR spectra. The highest band, observed at ν 1 = 600–550 cm−1, corresponds to intrinsic stretching vibrations of the metal at the tetrahedral site (Mtetr-O), whereas the lowest band at ν 2 = 450–385 cm−1 is assigned to octahedral metal stretching vibration (Moct-O) [18, 23]. In the spectrum of A1, the bands observed at 480 and 562 cm−1 imply that the sample is hematite [24]. The transmittance bands of samples A2, A3 and A4 are observed at about 404 and 600 cm−1, indicating that the samples are NiFe2O4 [18, 25].

TEM images of the samples (A1–A3) are given in Fig. 3. As can be seen from Fig. 3a, sample A1 has cubic particles with high particle size. In the images of samples A2 and A3, nanoparticles are roundish and particle size distribution is wider. The physical particle sizes, d TEM, of samples A1, A2, A3 and A4 are 134 ± 35, 12.3 ± 5.0, 15.5 ± 5.8 and 10.1 ± 3.6 nm, respectively, and are given in Table 1. It is observed that the calculated d TEM value of A1 is bigger than the d XRD value. This difference can be explained by considering that the particles are polycrystalline and the particle size is not equal to crystallite size. The d TEM of the other samples shows the same trend with d XRD as the temperature changes.

The magnetization curves of the nanoparticles (A1–A4) are presented in Fig. 4. Insets show the curves at ± 100 Oe. As seen from Fig. 4a, sample A1 is almost paramagnetic with a little ferromagnetic contribution. The maximum magnetization value (maximum magnetization measured at the highest applied magnetic field) of the sample is 1.1 emu/g and coercivity (H c) is 36 Oe. Samples A2 and A3 are superparamagnetic with 4 and 2 Oe H c, respectively. And their saturation magnetizations (M s) are 54.4 and 54.3 emu/g, respectively. Sample A4 is superparamagnetic with zero H c, and the M s is 48.7 emu/g. The mean magnetic size, d MAG, of the sample with zero H c was calculated according to the equation in [26] and found to be 6.9 ± 0.6 nm (see Table 1).

In order to investigate the effect of reaction temperature and time of the hydrothermal process on the structural and magnetic properties of the samples, the temperature was changed from 125 to 200 ∘C and the time was increased from 10 to 80 h, separately. The precursors of all these samples were obtained at 80 ∘C. Samples B1–B4 were synthesized at different temperatures, and samples B5–B9 were synthesized at different times by using the same precursor. The samples and synthesis conditions are given in Table 2. XRD patterns of samples B1, B2 and B4 synthesized at different temperatures (125, 150 and 200 ∘C, respectively) are given in Fig. 5. Peaks (220), (311), (400), (422), (511), (440) and (533) peaks of the NiFe2O4 are observed in the patterns at 2𝜃 = 30.5∘, 35.9∘, 43.7∘, 54.1∘, 57.6∘, 63.4∘ and 74.7∘, respectively. The d XRD was calculated from the (311) peak in the patterns, and the results are given in Table 2 as 12.5, 10.6 and 12.5 nm for B1, B2 and B4, respectively. The particle sizes obtained from XRD patterns slightly fluctuate with the change of reaction temperature. According to the FT-IR spectrum in Fig. 6, the samples (B1, B2, B4) are NiFe2O4. All samples in the spectrum show the characteristic bands at around 397 and 601 cm−1. TEM images of sample B4 in 20- and 5-nm scales are given in Fig. 7a, b, respectively. The d TEM of the samples calculated from the images is 10.1 ± 3.6 and 11.4 ± 3.8 nm for B2 and B4, respectively. Magnetization curves of the nanoparticles synthesized at different temperatures are presented in Fig. 8. All samples are superparamagnetic with zero H c. M s values of samples B1–B4 are 50.8, 48.7, 49.5 and 48.5 emu/g, respectively. M s slightly changes according to the reaction temperature. In [16], NiFe2O4 nanoparticles synthesized by the co-precipitation/calcination process are ferrimagnetic, showing 33 and 49 emu/g M s. In another study [15], NiFe2O4 nanoparticles are obtained by co-precipitation/annealing and the nanoparticles (17 nm) are ferrimagnetic with M s = 44 emu/g and H c = 51 Oe. NiFe2O4 nanoparticles synthesized solvothermally in the study of Wang et al. [14] show high M s values between 37.7 and 53.3 emu/g; however, they show H c from 41.8 to 58.2 Oe. Superparamagnetic NiFe2O4 nanoparticles are also obtained in [17] by the co-precipitation/calcination process; however, the M s values are highly low as 13 and 15 emu/g. In another study [18], hydrothermally synthesized NiFe2O4 nanoparticles show two kinds of magnetic properties. One of the nanoparticles with zero H c have M s ≈35 emu/g, and the others show H c ≈17 Oe and M s ≈40 emu/g. The M s of sample B1 (50.8 emu/g) is higher than the values of the superparamagnetic NiFe2O4 nanoparticles in the studies mentioned above. d VSM is calculated as 8.0 ± 0.4, 6.9 ± 0.6, 7.3 ± 0.5 and 7.4 ± 0.5 nm for B1, B2, B3 and B4, respectively. It can be concluded that the reaction temperature of the hydrothermal process is slightly effective on the properties of the NiFe2O4 nanoparticles.

The reaction time of the hydrothermal process was changed from 10 to 80 h, and the effect of the time on the properties of the nanoparticles was investigated. Figure 9 shows the XRD patterns of the selected samples from B5 to B9 series. The patterns include (220), (311), (400), (422), (511), (440) and (533) peaks at 2 𝜃 = 30.7∘, 36.0∘, 43.7∘, 54.2∘, 57.5∘, 63.2∘ and 75.3∘, respectively. Samples were crystallized in an inverse spinel structure of NiFe2O4. Crystal sizes, d XRD, were calculated and are given in Table 2. d XRD of samples B5, B7 and B9 is 7.9, 10.6 and 11.8 nm, respectively. It can be seen from the patterns in Fig. 9 that the width of the (311) peak slightly decreases and hence the crystal size increases as the reaction time increases. The FT-IR spectrum in Fig. 10 also confirms the NiFe2O4 nanoparticles by showing the bands around 397 and 598 cm−1 for all samples. TEM images of samples B5, B7 and B9 are given in Fig. 11, and d TEM values of these samples are 6.6 ± 2.9, 10.1 ± 3.6 and 11.9 ± 3.9 nm, respectively. The increase in the physical particle sizes of the samples is consistent with the increase of crystal sizes. M s of the samples increase from 45.6 to 51.7 emu/g as the reaction time increases from 10 to 80 h (Fig. 12). All samples except for B9 are superparamagnetic with zero H c. Sample B9 has 2 Oe H c. The d VSM was also calculated for samples B5–B8 and is given in Table 2. Magnetic particle sizes of the samples are found to be around 7 nm. The d VSM is also smaller than d TEM and d XRD for all samples since there might be a magnetically dead surface layer on the nanoparticles as reported in [27]. However, the similar trend of change is observed in the d XRD, d TEM and d VSM. It is observed that the particle sizes of the samples having H c are larger than those of the samples with zero H c, indicating the limit of superparamagnetic size for NiFe2O4 nanoparticles. According to the d TEM and d XRD values of the samples (Tables 1 and 2), it can be concluded that the limit of superparamagnetic particle size for our study is about 12 nm since NiFe2O4 nanoparticles show H c.

4 Conclusions

Co-precipitation/hydrothermal synthesis was used to obtain NiFe2O4 nanoparticles. X-ray diffraction technique, Fourier transform infrared spectroscopy, transmission electron microscopy and vibrating sample magnetometer were used to characterize the nanoparticles. It was observed that the superparamagnetic NiFe2O4 nanoparticles can be synthesized by using the precursor synthesized at 80 ∘C. The effects of temperature and the time of the hydrothermal process on the structural and magnetic properties of the nanoparticles were investigated. The reaction temperature is slightly effective on the properties of the nanoparticles. However, the saturation magnetization (M s) increases with the increase of the reaction time. Superparamagnetic NiFe2O4 nanoparticles with high M s were obtained. NiFe2O4 nanoparticles with zero H c show high M s of 50.8 emu/g which is close to the value of bulk nickel ferrite. d VSM of the NiFe2O4 nanoparticles was also calculated to be 8.0 ± 0.4 nm.

References

Sohn, B.H., Cohen, R.E.: Processible optically transparent block copolymer films containing superparamagnetic iron oxide nanoclusters. Chem. Mater 9, 264–269 (1997)

Hiergeist, R., Andrä, W., Buske, N., Hergt, R., Hilger, I., Richter, U., Keiser, W.: Application of magnetite ferrofluids for hyperthermia. J. Magn. Magn. Mater. 201, 420–422 (1999)

Rossi, L.M., Costa, N.J.S., Silvia, F.P., Wojcieszak, R.: Magnetic nanomaterials in catalysis: advanced catalysts for magnetic separation and beyond. Green Chem. 16, 2906–2933 (2014)

Lee, H., Shao, H.P., Huang, Y.Q., Kwak, B.: Synthesis of MRI contrast agent by coating superparamagnetic iron oxide with chitosan. IEEE Trans. Magn. 41(10), 4102–4104 (2005)

Mornet, S., Vasseur, S., Grasset, F., Veverka, P., Goglio, G., Demourgues, A., Portier, J., Pollert, E., Duguet, E.: Magnetic nanoparticle design for medical applications. Progress Solid State Chem. 34, 237–247 (2006)

Jain, T.K., Morales, M.A., Sahoo, S.K., Leslie-Pelecky, D.L., Labhasetwar, V.: Iron oxide nanoparticles for sustained delivery of anticancer agents. Mol. Pharm. 2(3), 194–205 (2005)

Mc Gill, S.L., Cuylear, C.L., Adolphi, N.L., Osińki, M., Symth, H.D.C.: Magnetically responsive nanoparticles for drug delivery applications using low magnetic field strengths. IEEE Trans. Magn. 8(1), 33–42 (2009)

Albuquerque, A.S., Ardisson, J.D., Macedo, W.A.A., Lopez, J.L., Paniago, R., Persiano, A.I.C.: Structure and magnetic properties of nanostructured Ni-ferrite. J. Magn. Magn. Mater. 226-230, 1379–1381 (2001)

Goldman, A.: Modern Ferrite Technology. Springer, New York (2006)

Ahmad, T., Bae, H., Iqbal, Y., Rhee, I., Hong, S., Chang, Y., Lee, J., Sohn, D.: Chitosan-coated nickel-ferrite nanoparticles as contrast agents in magnetic resonance imaging. J. Magn. Magn. Mater. 381, 151–157 (2015)

Lu, A-H., Salabas, E.L., Schüth, F.: Magnetic nanoparticles: Synthesis, protection, functionalization, and application. Angew. Chem. Int. Ed. 46, 1222–1244 (2007)

Mohapatra, M., Anand, S.: Synthesis and applications of nano-structured iron oxides/hydroxides—a review. Int. J. Eng. Sci. Technol. 2(8), 127–146 (2010)

Harivardhan, R.L., Arias, J.L., Nicolas, J., Couvreur, P.: Magnetic nanoparticles: Design and characterization, toxicity and biocompatibility. Pharma. Biomed. Appl. Chem. Rev. 112, 5818–5878 (2012)

Wang, J., Ren, F., Yi, R., Yan, A., Qiua, G., Liu, X.: Solvothermal synthesis and magnetic properties of size-controlled nickel ferrite nanoparticles. J. Alloys Compounds 479, 791–796 (2009)

Ati, A.A., Othaman, Z., Samavati, A.: Influence of cobalt on structural and magnetic properties of nickel ferrite nanoparticles. J. Molecul. Struct. 1052, 177–182 (2013)

Li, J., Lin, Y., Liu, X., Zhang, Q., Miao, H., Zhang, T., Wen, B.: The study of transition on NiFe2O4 nanoparticles prepared by co-precipitation/calcination. Phase Trans. 84, 49–57 (2011)

Barreto, A.C.H., Santiago, V.R., Freire, R.M., Mazzetto, S.E., Sasaki, J.M., Vasconcelos, I.F., Denardin, J.C., Mele, G., Carbone, L., Fechine, P.B.A.: Grain size control of the magnetic nanoparticles by solid state route modification. J. Mater. Eng. Perform. 22(7), 2073–2079 (2013)

Nejati, K., Zabihi, R.: Preparation and magnetic properties of nano size nickel ferrite particles using hydrothermal method. Chem. Central J. 6, 23 (2012)

Shi, Y., Ding, J., Liu, X., Wang, J.: NiFe2O4 ultrafine particles prepared by co-precipitation/mechanical alloying. J. Magn. Magn. Mater. 205, 249–254 (1999)

Laurent, S., Forge, D., Port, M., Roch, A., Robic, C., Vander Elst, L., Muller, R. N.: Magnetic iron oxide nanoparticles: Synthesis, stabilization, vectorization, physicochemical characterizations, and biological applications. Chem. Rev. 108, 2064–2110 (2008)

Kahani, S.A., Jafari, M.: A new method for preparation of magnetite from iron oxyhydroxide or iron oxide and ferrous salt in aqueous solution. J. Magn. Magn. Mater. 321, 1951–1954 (2009)

Cullity, B.D.: Elements of X-ray Diffraction. Addison-Wesley, USA (1978)

Lumina, S.M.M., Blessi, S., Pauline, S.: Effect of copper substitution on the structural, morphological and magnetic properties of nickel ferrites. Int. J. Res. (IJR) 1(8), 1051–1054 (2014)

Sarkar, S., Mondal, A., Deyb, K., Ray, R.: Magnetic memory in nanocrystalline a-Fe2O3 embedded in reduced graphene oxide. RSC Adv. 5, 81260–81265 (2015)

Maensiri, S., Masingboon, C., Boonchomb, B., Seraphin, S.: A simple route to synthesize nickel ferrite (NiFe2O4) nanoparticles using egg white. Scripta Materialia 56, 797–800 (2007)

Morales, M. P., Veintemillas-Verdaguer, S., Montero, M. I., Serna, C.J., Roig, A., Casas, Ll., Martinez, B., Sandiumenge, F.: Surface and internal spin canting in γ-Fe2O3 nanoparticles. Chem. Mater. 11, 3058–3064 (1999)

Liebermann, L., Clinton, J., Edwards, D.M., Mathon, J.: Dead layers in ferromagnetic transition metals. Phys. Rev. Lett. 25, 232–235 (1970)

Acknowledgments

This work was supported by the Balikesir University Research Grant no. BAP 2016/147. The authors would like to thank the State Planning Organization, Turkey, under Grant no 2005K120170, for the VSM system. The authors also thank the Chemistry Department, Balikesir University, Turkey, for the FT-IR measurements and the National Nanotechnology Research Center (UNAM), Bilkent University, Turkey, for the XRD and TEM analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Karaagac, O., Atmaca, S. & Kockar, H. A Facile Method to Synthesize Nickel Ferrite Nanoparticles: Parameter Effect. J Supercond Nov Magn 30, 2359–2369 (2017). https://doi.org/10.1007/s10948-016-3796-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-016-3796-4