Abstract

A novel concept of cloaking, concentration and transferring of the static magnetic fields by the combination effect of the superconductor (SC) and ferromagnet (FM) has been recently presented. The performance of these hybrid structures strongly depends on the properties of the involved materials as well as its geometrical parameters. In this work, we have practically demonstrated a magnetic hose, which is developed by a FM core wrapped by a SC layer. Meanwhile, a finite-element simulation with experimentally derived permeability of both SC and FM constituents was also established. Based on the verified simulation, further investigations were carried out to systematically examine the dependence of the transfer efficiency of the magnetic hose on its dimension and magnetic properties of the involved materials, both of which are difficult to be varied in practical case, especially for the magnetic properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The combination of the superconductor (SC) and ferromagnet (FM), which can be expected to achieve novel magnetic applications such as the cloaking [1–13], concentration [6, 14, 15], and transferring [15–17] of the magnetic field, by using the opposite response to the exotic magnetic stimulation of the two materials, has received intensive attention in recent years. In a given magnetic environment, the FM tends to attract magnetic flux, whereas the SC excludes the magnetic flux from its interior acting as a diamagnet [18].

Sanchez et al. have numerically realized a magnetic cloak and concentration by a SC-FM hybrid [8, 14]. Later, Narayana et al. devised a grated material composed of artificially patterned SC and soft FM elements that firstly cloaks the DC magnetic fields by experiment [4]. Subsequently, Gömöry et al. have experimentally realized a perfect magnetic cloak which was made by a SC-FM bilayer with an interior SC layer coated by a FM layer, in which the relative permeability was tuned according to the dimensions of layers [2]. More recently, Prat-Camps et al. experimentally demonstrated a magnetostatic wormhole [19] and proposed a realistic version of magnetic device to concentrate and transfer the static magnetic fields by the SC-FM bilayer [15], and Zhu et al. proposed a single-crystal YBCO bulk-based magnetic cloak that has been shown to work from DC to 250 KHz [20].

Navua et al theoretically proposed and experimentally demonstrated a magnetic hose, made by the combination of SC and FM to transfer the static magnetic field of a given source to distant positions along a chosen path with much higher efficiency in comparison to the conventional method [17] However, the performance of the magnetic hose as a function of the geometrical parameters and the magnetic properties of the involved materials has not been well examined. In this paper, we constructed a set of magnetic hoses with different dimensions and experimentally analyze its performance as a function of the dimension of the system. Meanwhile, for well understanding how to design a more effective magnetic hose, we established the finite-element model, in which the permeability of the SC and FM constituent were derived from measured results, to further investigate how the number of the superconducting layer and the magnetic properties of the materials affect the transfer effect of the magnetic hose.

2 Description of the Experimental Scenario and Simulation

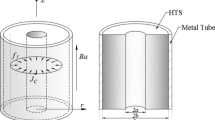

The magnetic hose in this paper was made by a ferromagnetic cylinder wrapped by superconducting layers. The ferromagnetic core was made of commercial soft iron with different diameters and lengths, the superconducting integument adopted in this case was fabricated by coated SC from SuperPower (http://www.superpower-inc.com) SCS4050 with a width of 4 mm and a thickness of 0.1 mm. Being different from [17], we constructed a polygon instead of a circle while winding the SC constituent by placing the superconducting tapes along the axis of the cylinder to protect the coated SC from excess bending, which can well prevent the SC constituent from damaging in superconductivity. Figure 1 shows the naked ferromagnetic cylinder and the magnetic hoses with different lengths.

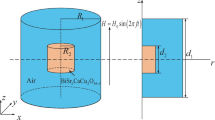

The static magnetic field was created by a hollow permanent magnet (PM) with an interior radius of 3 mm and an exterior radius of 5 mm. The transferred magnetic field is measured by a cryogenic Hall probe (Lakeshore HGCT-3020) connected with a gaussmeter (Lakeshore 3-Channel Gauss Meter). The experimental setup is sketched in Fig. 2, the PM deployed at a distance d from one side of the magnetic hose, and the Hall probe was placed at the opposite end with a same distance (see Fig. 2b). In the experiments, the length of the magnetic hose L was varied from 40 to 80 mm with 20-mm interval for three different diameters: 16, 20, and 25 mm.

The magnetic hose has been suffered a zero-field-cooling condition in liquid nitrogen in all experiments, as this study mainly exploits the diamagnetic response of the SC Furthermore, measurements for the naked ferromagnetic core structure were carried out at the RT for comparison. To ensure the superconductivity of the samples, a four-probe method was utilized to test the properties of the SC samples before being cut into pieces with a length L. The samples were cooled in liquid nitrogen, the obtained critical current of each sample is around 103 A with a criterion of electric field E c = 10-4 V/m, which is consistent with the nominal value (100 A) that the provider states.

In this study, we follow the definition of transfer efficiency in [17], which uses an index ? to estimate the transfer efficiency as follows:

where B 0 is the initial magnetic flux density at a distance of 2 d = 20 mm from the surface of the PM, B 1 is the transfer magnetic field at a distance of 2 d + L.

We have established a 3-D finite-element model of the PM and ferromagnetic core with an actual geometry by using the AC/DC module of COMSOL Multiphysics software. As the provider states, the valid SC constituent in the coated SC tape is merely 1 µm, of which the thickness is extremely thin comparing to the geometry of the whole structure. Actually, it is practically impossible to numerically calculate such a complex model within an acceptable time. To speed up the calculation, the SC layer was simplified from a polygon to a circle with a thickness of 0.25 mm. Meanwhile, because the SC constituent could be regarded as a diamagnet without losses in static magnetic environment, thereby the SC was assigned a constant relative permeability, which is less than 1 in the simulation. We consider that, as the magnitude of the magnetic field unchanged in this study, a constant relative permeability, which is determined by matching the simulated magnetic field with its measured data, has been assigned to the FM constituent. Additionally, the magnetization of the hollow PM was derived from measurements as well.

3 Results and Discussion

We firstly verified the simulation by the measurements of different dimensions of magnetic hose. Figure 3 portrays the dependence of the transfer efficiency on the diameter of the naked FM cylinder and magnetic hose with the same length: (a) 40, (b) 60, and (c) 80 mm. The dash lines in Fig. 3 represent the simulated results, whereas the solid lines represent the measured data. We find from this figure that the measured transfer efficiency could be well reproduced by the finite-element simulations with the respective permeability to the FM and SC constituents being 200 and 0.025.

From Fig. 3, it can be seen that the transfer efficiency of the magnetic hose was increased by a factor of around 1.4 with respect to the naked FM cylinder. The results imply that the magnetic hose we fabricated in this study can upgrade the transfer efficiency by adding the SC layers to prevent the magnetic flux from leaking outside. Moreover, we observe that the transfer efficiency decreases with the increase of the diameter of the ferromagnetic core, which can be understood that (i) although more magnetic flux are allowed to enter the ferromagnetic core, a portion of which cannot turn back by the exterior of the cylinder due to the large diameter and have to return through the central ferromagnetic core, which results in a weaker magnetic field at the opposite side of the magnetic hose; (ii) larger diameters provide more space for the magnetic lines to turn around to the bottom of the cylinder without reaching the measuring point, which also decreases the transfer efficiency.

For energy transfer applications, except transfer efficiency, transfer distance is another key factor. Thus, we compared the transfer efficiency of the magnetic hose with different lengths. Figure 4 demonstrates the measured (solid line) and simulated (dash line) dependence of the transfer efficiency on the length L of the magnetic hose and ferromagnetic core, respectively. As Fig. 4 shows, with the increase of the length L at a fixed diameter R, the transfer efficiency dependence approximates to a linear decrease, a considerable degradation around 20 % has been found with the length increased from 40 to 60 then to 80 mm. This phenomenon reveals that by whichever choice of the method, the transfer efficiency cannot maintain with longer transfer distance. It can be easily understood that (i) unlike the time-varying electromagnetic waves, which can be routed and transmitted with waveguides or optical fibers to a long distance, static magnetic fields rapidly decay with distance; (ii) the imperfect sealing of the superconducting layer. The results hint that, by utilizing the SC and FM composite, one can upgrade the transfer efficiency comparing to the conventional way, but extending the transfer distance without decaying the transfer efficiency needs however a more elaborated treatment.

The excellent agreement between simulation and experiment validates the established finite-element model, which makes the systematic study of the relation between the transfer efficiency of the system and its geometry possible, as the geometrical and material parameter of the magnetic hose could be tuned arbitrarily in the simulation model Secondly, in the simulations, we varied the diameter of the ferromagnetic core from 3 to 15 mm for three different lengths: 40, 60, and 80 mm. Figure 5 plots the transfer efficiency as a function of the diameter of the magnetic hose, in which the curves illustrate a nonlinear dependence of the transfer efficiency on the diameter of the ferromagnetic core. As Fig. 5 shows, for a small diameter of the ferromagnetic core, the transfer efficiency continuously increases with the diameter, and if we keep increasing the diameter, the transfer efficiency will have a maximum at 16 mm then tend to decrease as the experimental results display. Therefore, for a certain magnetic source, there is an optimum value of the diameter of the ferromagnetic core, which suggests that the transfer efficiency of the magnetic hose could be further enhanced by using an appropriate size of the central ferromagnetic cylinder. Moreover, we varied the length of the magnetic hose from 40 to 150 mm with a fixed diameter of 40 mm. Figure 6 shows the influence of the length of the magnetic hose on the transfer efficiency of the system; it can be seen that the transfer efficiency decreases as the length increases.

Thirdly, it is of practical interest to study how the magnetic properties of the ferromagnetic material affect the transfer efficiency of the system; we have varied the relative permeability of the ferromagnetic material from 10 to 8000. As Fig. 7 presents, the transfer efficiency increases rapidly with the relative permeability when the relative permeability is lower than 100 and reaches a plateau for high values of relative permeability, which is implying that the transfer efficiency of the magnetic hose is weekly dependent on the permeability of the central ferromagnetic core.

Lastly, to further find out the methods to improve the transfer efficiency, we consider making a difference in the SC constituent. The investigations were performed by finite-element simulation to study the transfer efficiency as a function of the number of SC layers, and the results are presented in Fig. 8 This figure tells that, keeping the diameter of the central FM core invariant, the transfer efficiency increases as the number of the SC layers. It can be seen that a transfer efficiency as high as 56 % was achieved by the FM core wrapped by ten SC layers, being significantly higher than the single-layered structure, which can be easily understood that more SC layers can prevent more magnetic flux from leaking outside of the FM core, which in return causes a higher transfer effectiveness. This phenomenon suggests that we can well tune the transfer efficiency by changing the portion of SC constituent. Meanwhile, Fig. 9 illustrates the transfer efficiency as a function of the relative permeability of the SC for magnetic hose with the outer SC constituent constructed by a single layer (rectangle symbol) and ten layers (circle symbol). It can be seen that the transfer efficiency can achieve 57 % by the single-layered structure and 70 % by the ten-layered structure with the relative permeability of the superconducting material decreased to 10 -4, which means that as the outer SC layer approaches the ideal diamagnet, the transfer efficiency would be significantly improved.

It is worth noting that the improvement of the transfer efficiency by the combination in the experiments is lower than the transfer efficiency of the ideal magnetic hose with the relative permeability of the superconducting material downward to 10 -4. It can be explained by that the SC constituent in this study is not a perfect diamagnet owing to the imperfect sealing of the SC layer. Specifically speaking, axially placing the superconducting tape, although being able to protect it from being damaged in the superconductivity, it will certainly cause much air gap between each tape and between the SC layer and the FM core, which results in magnetic flux escaping easier than that demonstrated in [17]. Further optimization of the magnetic hose presented in this work to achieve a higher transfer capability could be taken by decreasing the width of the SC constituent to approach a circle in a higher degree to reduce the air gap and coupling the SC constituent and FM constituent tightly by a compatible adhesive.

Worth of mention is that, in this study, the magnetic source created by the hollow PM utilized in this work was about 4.5 mT at a distance 2 mm from the surface, which is a moderate magnetic field, and we have not varied that in this study. However, in actual, being subjected to different magnetic fields, especially intensity magnetic environment, both of the two materials are nonlinear. Therefore, further work can investigate the performance of the magnetic hose as a function of the magnetic fields, including the magnitude and the magnetic source. Meanwhile, to match the further work, the simulation in this work should be accommodated due to the following: (i) the polygonal SC layer in this study which is constructed by discrete SC tapes has been simplified to a circle structure; (ii) due to the invariant magnetic source, we assigned a constant permeability to the FM and SC material, respectively. In further work, for the purpose of building a more reliable and reasonable simulation, the FEM model of the SC layers could be established in actual geometry, and the SC material would better be treated according to the critical state model. Regarding the FM constituent, it is possible to incorporate the nonlinear magnetic permeability by an analytical approximation or an interpolation of the experimental data.

4 Conclusions

In conclusion, we have demonstrated a realistic magnetic hose by a FM core wrapped by SC constituent and studied its transfer effect by experiments and simulations using a hollow PM to create the source magnetic field. We find that the finite-element simulations used in this work precisely reproduce the measured results and thus can be used to obtain optimized designs. Moreover, grounding on the verified simulations, we varied the geometrical parameters of the whole structure and the magnetic properties of the involved materials; on the basis of which, we find that there is an optimum size of the central FM core to achieve the best transfer effect, and the transfer efficiency is weekly dependent on the magnetic intensity of the FM constituent, which means the central FM core can be made of the commercial material. In addition, changing the relative permeability of the SC material will have a significant impact on the transfer effect, which implies that the SC material should maintain its excellent properties in the actual application by developing a more perfect construction. The attained results of magnetic hose provide a promising paradigm for the design of its applications. It should be noted that this study has examined only the SC-FM heterostructure in the static and unvaried magnetic environment; it is worth investigating the performance of the magnetic hose as a function of different magnetic fields, meanwhile, the finite-element model would be combined with more complex parameters, including e.g. field-dependent properties of SC and the nonlinear permeability of the FM and the related investigation will be summarized in our further study.

References

Souc, J., Solovyov, M., Gömöry, F., Prat-Camps, J., Navau, C., Sanchez, A.: New J. Phys. 15, 053019 (2013)

Gömöry, F., Solovyov, M., Souc, J., Navau, C., Prat-Camps, J., Sanchez, A.: Science 335, 1466 (2012)

Anlage, S.M.: J. Opt. 13, 024001 (2011)

Narayana, S., Sato, Y.: Adv. Mat. 24, 71 (2012)

Mawatari, Y., Navau, C., Sanchez, A.: Phys. Rev. B. 85, 134524 (2012)

Prat-Camps, J., Sanchez, A., Navau, C.: Supercond. Sci. Technol. 26, 074001 (2013)

Wang, R-F., Mei, Z-L., Cui, T-J.: Appl. Phys. Lett. 102, 213501 (2013)

Sanchez, A., Navau, C., Prat-Camps, J., Chen, D-X.: New. J. Phys. 13, 093034 (2011)

Yampolskii, S.V., Genenko, Y.A.: Appl. Phys. Lett. 104, 033501 (2014)

Yampolskii, S.V, Genenko, Y.A.: Appl. Phys. Lett. 104, 143504 (2014)

Gömöry, F., Solovyov, M., Šouc, J.: Supercond. Sci. Technol. 28, 044001 (2015)

Gömöry, F., Solovyov, M., Šouc, J., Vojeciak, M., Švec, P.: J. Supercond. Nov. Magn. 28, 725 (2015)

Solovyov, M., Šouc, J., Gömöry, F.: IEEE Trans. Appl. Supercond. 25, 8800705 (2015)

Navau, C., Prat-Camps, J., Sanchez, A.: Phys. Rev. Lett. 109, 263903 (2012)

Prat-Camps, J., Navau, C., Sanchez, A.: Appl. Phys. Lett. 105, 234101 (2014)

Zhou, P-B., Ma, G-T., Liu, H., Li, X-T., Zhang, H., Yang, C., Ye, C-Q.: IEEE Magn. Lett. 7, 1300304 (2016)

Navau, C., Prat-Camps, J., Romero-Isart, O., Cirac, J.I., Sanchez, A.: Phys. Rev. Lett. 112, 253901 (2014)

Araujo-Moreira, F.M., Navau, C., Sanchez, A.: Phys. Rev. B 61, 634 (2000)

Prat-Camps, J., Navau, C., Sanchez, A.: . Sci. Rep 5, 12488 (2015)

Zhu, J., Jiang, W., Liu, Y., Yin, G., Yuan, J., He, S., Ma, Y.: Nat. Commun. 6, 8931 (2015)

Acknowledgments

This work was supported in part by the National Natural Science Foundation of China under Grant 51475389 by the Fundamental Research Funds for the Central Universities under Grant 2682014CX039, and by the Self-determined Projects of the State Key Laboratory of Traction Power under Grants 2013TPL_T05 and 2015TPL_T05.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, PB., Ma, GT., Liu, H. et al. Experimental and Numerical Studies of the Magnetic Field Transfer of a Magnetic Cylinder Coated with Superconductor. J Supercond Nov Magn 29, 1747–1753 (2016). https://doi.org/10.1007/s10948-016-3477-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-016-3477-3