Abstract

YBa2Cu3 O 7−δ (YBCO) films with BaTiO3 (BTO) nanostructures were prepared by using the precursor solutions with different cationic molar ratios of Y:Ba:Cu = 1.0:1.6–2.0:3.0 in the TFA-MOD process. These YBCO films were deposited on (00 l)-oriented LaAlO3 single-crystal substrates using a spin coater. The high superconducting critical current density (J C) (77 K, self-filed) of more than 10 MA/cm2 for the final BTO-doped YBCO film was obtained. Moreover, the effect of different Ba/Y molar ratios in the precursor solution on superconducting properties of BTO-doped YBCO films was investigated. Compared with the BTO-doped YBCO film deposited by using the precursor solutions with Ba/Y molar ratio of 2.0, an enhancement of J C in a magnetic field for the film from the solution with Ba/Y molar ratio of 1.9 was achieved. For Ba/Y molar ratios of 1.6 and 1.7, a reduction of J C in a magnetic field occurred. The J C enhancement may be mainly ascribed to the enhanced flux pinning by the Y2Cu2 O 5 nanostructures with the optimal number dispersing in YBCO matrix.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Over the past two decades, the remarkable progress has been made in the production of YBa2Cu3 O 7−δ (YBCO)-coated conductors with enhanced critical current densities (J C) required for various practical applications such as low-loss cable, generator, motor, and magnet [1]. J C values of YBCO films have been greatly increased by overcoming the grain boundaries (GBs) problem based on the epitaxial growth techniques containing ion beam-assisted deposition (IBAD) [2, 3] and rolling-assisted biaxial textured substrate (RABiTS) process [4, 5]. Recently, these epitaxial growth techniques have produced YBCO films with a grain misorientation in the range of 3∘–5∘ [6, 7], where the GBs problem can be ignored. However, J C values of YBCO films decay rapidly in a magnetic field, which is an obstacle for practical applications. The solutions to the problem have been extensively studied by research groups worldwide [8–12]. These works have shown that the J C improvement in magnetic field can be achieved by introducing many types of artificial defects as pinning centers into the YBCO matrix, preventing vortices from moving by the Lorentz force.

There are several approaches for tailoring defects into the matrix, including decoration of substrate by nanoparticles [13, 14], addition of oxide nanoparticles [15, 16], mixed rare-earth elements doping [17, 18], and an intentional deviation from the 123 stoichiometry [19, 20]. Among these approaches, the introduction of oxide nanoparticles, such as BaZrO3 [21], BaSnO3 [22], BaTiO3 [23], BaIrO3 [24], and BaHfO3 [25], is the most promising candidate for the improvement of J C. Furthermore, Nakaoka et al. [20] reported the effect of the deviation from the 123 stoichiometry in the precursor solution on superconducting properties of YBCO films which were prepared based on the TFA-MOD method. They found that the Ba/Y molar ratios of 1.4–1.6 in the precursor solution could enhance the J C values of YBCO films over 3 MA/cm2. However, the combination of different approaches to enhance flux pinning in YBCO films was rarely studied.

In this work, we prepared BaTiO3 (BTO)-doped YBCO films based on the TFA-MOD process by simultaneously adding titanium ion into the precursor solution and reducing the Ba/Y molar ratio. The effect of different Ba/Y molar ratios in the precursor solution on superconducting properties of the BTO-doped YBCO films was discussed. The high J C BTO-doped YBCO films were obtained by using the precursor solution with the optimized Ba/Y molar ratio.

2 Experimental

Five kinds of precursor solutions with different Ba/Y molar ratios for YBCO films were prepared by mixing yttrium, barium, and copper acetates with molar ratios of Y:Ba:Cu = 1.0:1.6–2.0:3.0, trifluoroacetic acid (CF3COOH), deionized water, and propionic acid (C2 H 5COOH). The additional barium acetate and Ti acetylacetonate with a cationic ratio of 1:1 were also introduced into these solutions. The Ti content and the total Ba/CF3 COO − molar ratio of the solution were 6 mol% and 0.5, respectively. The obtained solutions were evaporated in a rotary evaporator under decompression to remove most of the solvents. Then, the residue was dissolved in methanol. After repeating the evaporation under decompression, the blue gel was re-dissolved in methanol to obtain the final solutions. The total metal concentration of all the solutions was 1.5 mol/L. The precursor solutions were spin coated on 10 mm × 10 mm (00l)-oriented LaAlO3 single-crystal substrates at a rotation speed of 3000 rpm for 30 s. Following this, the gel films were subjected to a thermal treatment in a quartz tube within a horizontal furnace. At the pyrolysis step, the samples were heated up to the temperature of 650∘C at a heating rate of the 2∘C/min and held for 30 min in a humid O2 gas atmosphere. Then, the samples were treated up to 820∘C at a heating rate of the 3∘C/min in a 200 ppm O2/Ar atmosphere. Finally, the films were oxygenated at 500∘C for 90 min in a dry oxygen atmosphere. For convenience, the final films which were prepared by using the precursor with Ba/Y molar ratios of 1.6, 1.7, 1.8, 1.9, and 2.0 are denoted as Ba/Y-1.6, 1.7, 1.8, 1.9, and 2.0 films, respectively. The thicknesses of all the films are about 200 nm.

The phase and texture of the as-grown film were characterized by X-ray diffraction (XRD) using Cu-Kα radiation in a Bruker D8 four-circle diffractometer. The surface morphologies of the films were observed by a scanning electron microscope (SEM). Magnetization hysteresis loops of the films were determined by a vibrating sample magnetometer in magnetic fields along the c-axis of YBCO films. The critical current density (J C) was calculated based on the extended Bean model [26]. Moreover, J C was also measured by a J C-scan Leipzig system [23].

3 Results and Discussion

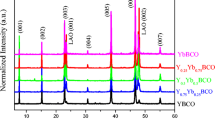

Figure 1 shows XRD 𝜃–2 𝜃 patterns of the final YBCO films prepared by using the precursor solutions with different Ba/Y molar ratios. All the major diffraction peaks are corresponding to the YBCO (00 l) reflections, which indicate that all samples are highly c-axis oriented. In addition, small BTO (101) and BTO (200) peaks can be observed at 2𝜃 = 31.49∘ and 45.38∘, respectively, in all the films. In our previous work, we prepared BTO-doped YBCO films by the conventional TFA-MOD process [23]. The BTO nanostructures dispersed randomly within the YBCO matrix, with some of them nucleating in the bulk of YBCO film and others nucleating at the surface of the YBCO film. The BTO nanocolumns and the YBCO matrix were not coherent. Therefore, BTO nanostructures act as random pinning centers. The sizes of BTO nanostructures are about 20 ∼100 nm. Moreover, Y2Cu2 O 5 can be obviously detected in the Ba/Y-1.6, 1.7, 1.8, and 1.9 films, as shown in Fig. 1a–d. Y2Cu2 O 5 (013) and Y2Cu2 O 5 (031) peaks appear at 2 𝜃 = 33.45∘ and 43.48∘, respectively. The intensity of Y2Cu2 O 5 peak enhances with decreasing Ba/Y molar ratio from 1.9 to 1.7. However, the intensity of Y2Cu2 O 5 peak becomes weak in the Ba/Y-1.6 film, and CuO (202) is apparently detectable. Y2Cu2 O 5 peak does not appear in the Ba/Y-2.0 film. As revealed in several works [20, 27], Y2Cu2 O 5 grains with submicron size are dispersed evenly in Ba/Y-1.6, 1.7, 1.8, and 1.9 films, supporting the appearance of Y2Cu2 O 5 peaks in XRD curves. It was believed that besides BTO, Y2Cu2 O 5 grains might also act as pinning centers to improve the superconducting properties of the YBCO films [20, 23].

The surface morphologies of the BTO-doped YBCO films are represented in Fig. 2. For all the films, the surfaces mainly consisted of c-axis orientated YBCO grains, which is in accord with the XRD patterns in Fig. 1. No obvious difference can be found between SEM images of Ba/Y-1.8, 1.9, and 2.0 films. The size of pores is small, and the number of pores is low in these films. However, it can be seen that some needle-shaped grains exist on the surface of the Ba/Y-1.6 and 1.7 films. This indicates that smaller Ba/Y molar ratios in the precursor solution induce the texture deterioration which is due to a larger number of Y2Cu2 O 5 or CuO nanostructures forming in YBCO composite films.

Figure 3 shows J C mappings at 77 K for the BTO-doped YBCO films fabricated from the precursor solutions with different Ba/Y molar ratios. One can see that the maximum J C value of 13 MA/cm2 was obtained for the Ba/Y-1.9 YBCO composite film, which is superior to that of the Ba/Y-2.0 YBCO composite film. It means that the Y2Cu2 O 5 nanostructures may act as pinning centers to enhance J C value. However, though Y2Cu2 O 5 nanostructures also exist in the Ba/Y-1.6, 1.7, and 1.8 YBCO composite films, J C values of these films are inferior to that of the Ba/Y-1.9 YBCO composite film. Combining with the XRD patterns of the final YBCO films in Fig. 1, the enhancement of J C in the Ba/Y-1.9 film is possibly connected with the appropriate number of the Y2Cu2 O 5 grains. The relative low J C values of Ba/Y-1.6 and 1.7 films are related to the greater quantities of CuO or Y2Cu2 O 5 nanostructures causing the texture deterioration as shown in Fig. 3. The optimal Ba/Y ratios of 1.4–1.6 in the work of Nakaoka et al. [20] are displaced by the Ba/Y ratio of 1.9 in the present work, and the reason is that the BTO phase is introduced into YBCO matrix, which changes the optimal Ba/Y ratio.

The J C-B curves of the BTO-doped YBCO films are shown in Fig. 4. It can be seen that the J C value of the Ba/Y-1.9 YBCO composite film is higher than those of other films in self-filed at 77 K, which is consistent with the result measured by the J C-scan Leipzig system represented in Fig. 3. The J C value of the Ba/Y-1.9 YBCO composite film drops very slowly with increase of magnetic field as compared to those of other films. At 77 K in 1-T field, the J C value of the Ba/Y-1.9 YBCO composite film is enhanced by a factor of 2 in comparison with that of the Ba/Y-2.0 YBCO film. These results strongly suggest that for a high magnetic field, the enhanced flux pinning by Y2Cu2 O 5 nanostructures with the appropriate number in the Ba/Y-1.9 YBCO composite film has occurred.

The superconducting transition temperatures (T C) of the BTO-doped YBCO films were measured using the standard four-probe method, as shown in Fig. 5. It can be seen that T C,R=0 values of the films are almost consistent with increasing the Ba/Y molar ratio and are around 89.5 K. Moreover, the superconducting transition width (ΔT) is less than 1 K, indicating the high homogeneity within the films.

4 Conclusion

In this work, the BTO-doped YBCO films were fabricated using the different precursor solutions (Y:Ba:Cu = 1.0:1.6–2.0:3.0) by the TFA-MOD approach. The high J C value (77 K, self-filed) of more than 10 MA/cm2 for BTO-doped YBCO films from the precursor solution with Ba/Y molar ratio of 1.9 was obtained, which was higher than those of films from the solutions with Ba/Y molar ratios of 1.6, 1.7, 1.8, and 2.0. Moreover, the J C enhancement in a high magnetic field for films from the solution with Ba/Y molar ratio of 1.9 was also achieved. The result may be mainly ascribed to the enhanced flux pinning by Y2Cu2 O 5 nanostructures with the optimal number dispersing in YBCO matrix.

References

Sharma, R.G.: Superconductivity: Basics and Applications to Magnets. Springer, Switzerland (2015)

Iijima, Y., Tanabe, N., Kohno, O., Ikeno, Y.: Appl. Phys. Lett. 60, 769 (1992)

Arendt, P.N., Foltyn, S.R.: MRS Bull. 29, 543 (2004)

Norton, D.P., Goyal, A., Budai, J.D., Christen, D.K., Kroeger, D.M., Specht, E.D., He, Q., Saffian, B., Paranthaman, M., Klabunde, C.E., Lee, D.F., Sales, B.C., List, F.A.: Science 274, 755 (1996)

Goyal, A., Paranthaman, M.P., Schoop, U.: MRS Bull. 29, 552 (2004)

Shiohara, Y., Taneda, T., Yoshizumi, M.: Jpn. J. Appl. Phys. 51, 010007 (2012)

Yamada, Y., Miyata, S., Yoshizumi, M.: IEEE Trans. Appl. Supercond. 19, 3236 (2009)

Macmanus-Driscoll, J.L., Foltyn, S.R., Jia, Q.X., Wang, H., Serquis, A., Civale, L., Maiorov, B., Hawley, M.E., Maley, M.P., Peterson, D.E.: Nat. Mater. 3, 439 (2004)

Gutiérrez, J., Llordés, A., Gazquez, J., Gibert, M., Roma, N., Ricart, S., Pomar, A., Sandiumenge, F., Mestres, N., Puig, T., Obradors, X.: Nat. Mater. 6, 367 (2007)

Miu, L., Ivan, I., Miu, D., Mele, P., Matsumoto, K., Mikheenko, P., Dang, V.S., Crisan, A.: J. Supercond. Nov. Magn. 26, 1167 (2013)

Maiorov, B., Baily, S.A., Zhou, H., Ugurlu, O., Kennison, J.A., Dowden, P.C., Holesinger, T.G., Foltyn, S.R., Civale, L.: Nat. Mater. 8, 398 (2009)

Llordés, A., Palau, A., Gazquez, J., Coll, M., Vlad, R., Pomar, A., Arbiol, J., Guzman, R., Ye, S., Rouco, V., Sandiumenge, F., Ricart, S., Puig, T., Varela, M., Chateigner, D., Vanacken, J., Gutierrez, J., Moshchalkov, V., Deutscher, G., Magen, C., Obrador, X.: Nat. Mater. 11, 329 (2012)

Crisan, A., Fujiwara, S., Nie, J.C., Sundaresan, A., Ihara, H.: Appl. Phys. Lett. 79, 4547 (2001)

Vanpoucke, D., Cottenier, S., Speybroeckc, V.V., Bultinck, P., Driessche, I.V.: Appl. Surf. Sci. 32, 260 (2012)

Samoilenkov, S.V., Boytsova, O.V., Amelichev, V.A., Kaul, A.R.: Supercond. Sci. Technol. 24, 055003 (2011)

Ding, F.Z., Gu, H.W., Zhang, T., Wang, H.Y., Qu, F., Dai, S.T., Peng, X.Y., Cao, J.L.: J. Alloys Compd. 513, 277 (2012)

Ishii, Y., Shimoyama, J., Tazaki, Y., Nakashima, T., Horii, S., Kishio, K.: Appl. Phys. Lett. 89, 202514 (2006)

Develos-Bagarinao, K., Yamasaki, H.: Supercond. Sci. Technol. 24, 065017 (2011)

Lee, S.Y., Song, S., Kim, B.J.: Phys. C 578, 445 (2006)

Nakaoka, K., Matsuda, J., Kitoh, Y., Goto, T., Yamada, Y., Lzumi, T., Shiohara, Y.: Phys. C 463–465, 519 (2007)

Rouco, V., Bartolome, E., Maiorov, B., Palau, A., Civale, L., Obradors, X., Puig, T.: Supercond. Sci. Technol. 27, 115008 (2014)

Horide, T., Kawamura, T., Matsumoto, K., Ichinose, A., Yoshizumi, M., Izumi, T., Shiohara, Y.: Supercond. Sci. Technol. 26, 075019 (2013)

Ding, F.Z., Gu, H.W., Zhang, T., Wang, H.Y., Qu, F., Qiu, Q.Q., Dai, S.T., Peng, X.Y., Cao, J.L.: App. Surf. Sci. 314, 622 (2014)

Hanisch, J., Cai, C., Huhne, R., Schultz, L., Holzapfel, B.: Appl. Phys. Lett. 86, 122508 (2005)

Engel, S., Thersleff, T., Hühne, R., Schultz, L., Holzapfel, B.: Appl. Phys. Lett. 90, 102505 (2007)

Chen, Y.Q., Wu, C.B., Zhao, G.Y., You, C.Y.: Supercond. Sci. Technol. 25, 062001 (2012)

Gàzquez, J., Sandiumenge, F., Coll, M., Pomar, A., Mestres, N., Puig, T., Obradors, X., Kihn, Y., Casanove, M.J., Ballesteros, C.: Chem. Mater. 18, 6211 (2006)

Acknowledgments

This work was supported by the National Natural Science Foundation of China under Contract No. 51577180 and 51272250, the Beijing Natural Science Foundation under Contract No. 2152035, the National Basic Research Program of China (973 Program) under Contract No. 2011CBA00105, and the National High Technology Research and Development Program of China (863 Program) under Contract No. 2014AA032702.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, H.L., Ding, F.Z., Gu, H.W. et al. Effect of Ba/Y Molar Ratio on Superconducting Properties of BaTiO3-Doped YBa2Cu3 O 7−δ Films. J Supercond Nov Magn 29, 1227–1232 (2016). https://doi.org/10.1007/s10948-016-3437-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-016-3437-y