Abstract

YBa2Cu3O7−δ (YBCO)-coated conductors have wide-ranging potential in large-scale applications such as superconducting magnets and superconducting electric cables, but low current carrying capability restrains the practical application of YBCO-coated conductors at high temperatures and high magnetic fields. It is crucial to develop YBCO-coated conductors with high flux pinning capabilities. In this paper, YBa2Cu3−x Fe x O7−δ (x = 0, 0.0005, 0.001, 0.002, 0.005) and YDy x Ba2Cu3O7−δ (x = 0∼0.5) films were prepared on a LaAlO3 (LAO) single crystal substrate via a fluorine-free polymer-assisted metal organic deposition (PA-MOD) method. The effects of elements doping on the properties of YBCO in different positions of the lattice were investigated. The superconducting critical temperature (T c) decreases, and the superconducting transition width broadens with the Fe and Dy doping. However, the critical current densities (J c) improve at 77 K with Fe doping quantities of xless than 0.005 and Dy doping quantities of xless than 0.5. It means that the current carrying capability of a YBCO film can be improved by doping with appropriate amounts of Fe and Dy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recently, worldwide attention has been paid to the preparation of YBa2Cu3O7−δ (YBCO)-based coated conductors, i.e., the second-generation tapes, because of their wide-ranging potential in large-scale application such as superconducting magnets and superconducting electric cables [1–7]. Major approaches for fabricating YBCOcoated conductors include physical methods and chemical methods. Compared to the physical methods, chemical methods [8–12] are low cost and suitable for commercial application in the future. In this paper, YBCO films were prepared using a non-fluorine chemical solution deposition method which was devised in our laboratory [13–15] However, the large-scale application of YBCOcoated conductors in superconducting magnets, generators, motors etc. is prevented because of relatively low current carrying capability with increasing magnetic field and temperature. Therefore, enhancing the J c is crucial for the practical applications of the YBCO-coated conductors at high temperatures and high magnetic fields. Chemical doping is a promising fabrication technique to create specific pinning landscapes in YBCO-coated conductors [16–19]. Studies have confirmed that rare earth elements dope to the A-O layer of the YBCO lattice and they replace each other between the rare earth ions. Because of the different ionic radius of rare earth, some micro structural defects such as dislocations, stacking faults, and twins are produced in the superconductor. These defects can serve as effective flux pinning centers and improve the critical current density of the superconductor [20]. Also, incorporation of impurities such as Co, Fe, Ga, Zn, Ni etc. to the Cu sites of YBCO can significantly increase the critical current density vs magnetic field (J c−H) characteristics of hightemperature superconductor bulks [21–23]. The impurity doping to the CuO chain enhances flux pinning by lattice deformation but also results in a decrease of superconducting critical temperature [21]. There are few reports about the doping effects in YBCO films [24, 25], especially those prepared with fluorine-free metal organic deposition.

In this paper, the YBCO films were prepared on a LaAlO3 (LAO) single crystal substrate by a fluorine-free polymer-assisted metal organic deposition method [13]. Superconducting properties of Dy and dilute Fe-doped YBCO films were investigated. And the J c of YBCO films were improved by this different elements doping method.

2 Experiments

Dy-doped Y1−x Dy x Ba2Cu3O7−δ (x = 0, 0.3, 0.5) and Fe-doped YBa2Cu3−x Fe x O7−δ (x = 0, 0.0005, 0.001, 0.002, 0.005) films were deposited on a LaAlO3 (LAO) single crystal substrate using a fluorine-free method [13]. The precursor solutions were synthesized by dissolving acetates of dysprosium, in addition to acetates of yttrium, barium, and copper, in propionic acid with x = 0, 0.3, 0.5. Other precursor solutions were synthesized by dissolving acetates of iron, in addition to acetates of yttrium, barium, and copper, in propionic acid with x = 0, 0.0005, 0.001, 0.002, 0.005. Then, polyvinyl butyral was added into the solutions, which were subjected to continuous stirring to adjust the viscosity in order to obtain the final coating solutions. The final cation concentrations of the solutions both are 0.6 M. The solutions were coated to LAO using a spin coater with a rotation speed of 6000 r/min and dried at 150–200 ∘C for 5–10 min. The coated samples were fabricated in humid Ar/O2 mixture gas at 160–500 ∘C for 11 h and then fired at 770–800 ∘C in dry Ar/O2 mixture gas for 1 h. Finally, the samples were annealed in dry O2 gas at 400–450 ∘C for 1 h. The obtained Y1−x Dy x Ba2Cu3O7−δ and YBa2Cu3−x Fe x O7−δ -coated films were about 500 nm in thickness.

A Philips X’Pert MRD diffractometer with Cu-K α radiation was used to record the 𝜃–2 𝜃 X-ray diffraction (XRD) patterns. Superconducting transition and magnetic hysteretic loop were measured by Quantum-Design SQUID XL. The J c value of the YBCO film was determined using the Bean critical state model formula.

3 Results and Discussion

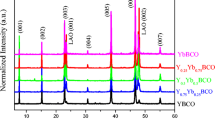

Figure 1 shows the typical 𝜃–2 𝜃 X-ray diffraction patterns of YBa2Cu3−x Fe x O7−δ (x = 0, 0.0005, 0.001, 0.002, 0.005) films and Y1−x Dy x Ba2Cu3O7−δ (x = 0, 0.3, 0.5) films. As can be seen, only (0 0 l) YBCO reflection peaks were detected, excluding the peaks of the LAO single crystal substrate. This indicates a strong c-axis orientation for all films.

Figure 2 shows the normalized magnetic susceptibility vs the temperature for YBa2Cu3−x Fe x O7−δ (x = 0, 0.0005, 0.001, 0.002, 0.005) films and Y1−x Dy x Ba2Cu3O7−δ (x = 0, 0.3, 0.5) films. The insert shows the superconductivity critical temperature as a function of doping level x. It is found that the superconductivity critical temperatures of YBa2Cu3−x Fe x O7−δ and Y1−x Dy x Ba2Cu3O7−δ films decrease with Fe doping and Dy doping. When the value of x = 0.005 for YBa2Cu3−x Fe x O7−δ , the T c value is 1.2 K smaller than that of pure YBCO film. For Y1−x Dy x Ba2Cu3O7−δ , the decrease of the T c value is no more than 0.3 K even if x = 0.5. It can be seen that a small amount of Fe doping can cause a great decrease of T c; however, the large amount of Dy doping hardly affects the T c of YBCO. The significant decline of T c by doping of the Fe may be due to the direct iron substitution for copper in the Cu-O chain of the YBCO lattice. The substitution affects the oxygen vacancies which play an important role in determining the transport properties of YBCO [21]. These weakly superconducting phases are embedded in the high superconducting YBCO matrix, and thus show a large broadening on the R-T curve. The superconducting transition width reached the maximum for the YBa2Cu2.998Fe0.002O7−δ . With the increase of Fe doping, the T c of the whole YBCO matrix decreases and the broadening of superconducting transition is reduced. However, when Dy is doping into the A-O layer of the YBCO lattice, the rare earth ions can be replaced by each other. Because it is the substitution of equal valence ions, the effects on T c are very small [20]. At the same time, the superconducting transition width broadens for all the doped samples and the superconducting transition width reached the maximum of Y0.7Dy0.3Ba2Cu3O7−δ samples compared with the Y0.5Dy0.5Ba2Cu3O7−δ samples. It has been found that RE-doped YBCO can produce a small number of weakly superconducting Y24 phases [26, 27] which broadens the superconducting transition width. As mentioned above, the superconductivity of the doped YBCO films exhibits different degrees of decline because of the Fe and Dy doping to the different position of the YBCO lattice.

Figure 3 shows the magnetic field dependence of critical current densities J c for YBa2Cu3−x Fe x O7−δ (x = 0, 0.0005, 0.001, 0.002, 0.005) films and Y1−x Dy x Ba2Cu3O7−δ (x = 0, 0.3, 0.5) films with the magnetic field parallel to the c-axis. The J c values of Fe-doped YBCO films possess higher values than those of pure YBCO films at 77 K, except for the sample with x = 0.005. In particular, The J c values of the sample with x = 0.002 reached the maximum. Fe doping to the Cu-O chain of the YBCO lattice come into being lattice deformations, such incorporation of weak superconducting impurities can be flux pinning centers and enhance the critical current density vs magnetic field (J c−−H) characteristics [21]. The optimal critical current density value can be achieved by the appropriate quantity and density of pinning centers in the YBCO. However, excess incorporation of impurities greatly disrupted the superconductivity of the YBCO and the current transport properties declined. For the Dy-doped YBCO films, the J c values of the sample with x = 0.3 possess higher values than those of pure YBCO films. However, the J c values of the sample with x = 0.5 decrease compared with the pure YBCO films. Dy doped to the A-O layer of the YBCO lattice and produced some micro structural defects such as dislocations, stacking faults, and twins in the superconductor. These defects can serve as effective flux pinning centers and improve the critical current density of the superconductor [20]. The excess of such defects greatly disrupted the superconductivity of the YBCO and the current transport properties declined. Also as mentioned in the previous, Y0.7Dy0.3Ba2Cu3O7−δ samples have the maximum superconducting transition width and J c is also the maximum. It is perhaps due to the presence of a second phase such as Y24 phases causing some extra pinnings and further research and confirmation of the experimental evidence are also required.

From the results of the above, it means that Fe doping level x = 0.002 and Dy doping level x = 0.3 are the optimal doping levels for the YBa2Cu3−x Fe x O7−δ (x = 0, 0.0005, 0.001, 0.002, 0.005) films and Y1−x Dy x Ba2Cu3O7−δ (x = 0, 0.3, 0.5) films. As 77 K is a feasible temperature for application of YBCO superconductors by using liquid nitrogen, these improved J c values are significant. It means that the current carrying capability of YBCO film can be improved by doping with appropriate amounts of Fe and Dy.

4 Conclusions

In this paper, from the investigation of the Fe and Dy doping effects on the properties of YBCO films, it can be seen that the T c decreases and the superconducting transition width broadens with the Fe and Dy doping. J c improves at 77 K with an Fe doping level of xless than 0.005 and Dy doping level of xless than 0.5.

References

Yao, X., Oka, A., Izumi, T., Shiohara, Y.: Physica C 339, 99–105 (2000)

Espinosa-Arronte, B., Djupmyr, M., Andersson, M.: Physica C 423, 69–73 (2005)

Liu, L.H., Dong, C., Zhang, J.C., Chen, H., Chen, L.: Physica C 383, 17–22 (2002)

Qiao, Y., Li, Y., Sathiraju, S., Reeves, J., Lenseth, K., Selvamanickam, V.: Physica C 382, 48–51 (2002)

Obradors, X., Puig, T., Pomar, A., Sandiumenge, F., Mestres, N., Coll, M., Cavallaro, A., Rom, N., Gazquez, J., Gonzalez, J.C., Castano, O., Gutierrez, J., Palau, A., Zalamova, K., Morlens, S., Hassini, A., Gibert, M., Ricart, S., Moreto, J.M., Pinol, S., Isfort, D., Bock, J.: Supercond. Sci. Tech 19, s13–s15 (2006)

Izumi, T., Yamada, Y., Shiohara, Y.: Physica C 392–396, 9–16 (2003)

Motowidlo, L.R., Selvamanickam, V., Galinski, G., Haldar, P., Sokolowski, R.S.: Physica C 335, 44–50 (2000)

Parans Paranthaman, M., andIzumi, T.: Editors. MRS Bull. 29, 533–536 (2004)

Parans Paranthaman, M.: Superconductor wires, McGraw-Hill 2006 Year book of science and technology, pp. 319–322. McGraw-Hill Publishers (2006)

Goyal, A., Norton, D.P., Budai, J.D., Paranthaman, M., Specht, E.D., Kroeger, D.M., Christen, D.K., He, Q., Saffian, B., List, F.A., Lee, D.F., Martin, P.M., Klabunde, C.E., Hatfield, E., Sikka, V.K.: Appl. Phys. Lett. 69, 1795–1797 (1996)

Goyal, A., Paranthaman, M., Schoop, U.: MRS Bull. 29, 552–561 (2004)

Rupich, M.W., Verebelyi, D.T., Zhang, W., Kodenkandath, T, Li, X.: MRS Bull. 29, 572–578 (2004)

Wang, W.T., Pu, M.H., Yang, Y., Zhang, H., Cheng, C.H., Zhao, Y.: Physica C 470, 1261–1265 (2010)

Wang, W.T., Li, G., Pu, M.H., Sun, R.P., Zhou, H.M., Zhang, Y., Zhang, H., Yang, Y., Cheng, C.H., Zhao, Y.: Physica C 468, 1563–1566 (2008)

Zhao, Y., Pu, M.H., Li, G., Du, X.H., Zhou, H.M., Zhang, Y.B., Yang, X.S., Wang, Y., Sun, R.P., Cheng, C.H.: Physica C 463-465, 574–579 (2007)

Feng, Y., Pradhan, A.K., Zhao, Y., Wu, Y., Koshizuka, N., Zhou, L.: Supercond. Sci. Technol. 14, 224–228 (2001)

Babu, N.H., Shi, Y.H., Iida, K., Cardwell, D.A.: Nature Mater. 4, 476–480 (2005)

Werner, M., Sauerzopf, F.M., Weber, H.W., Wisniewski, A.: Phys. Rev. B 61, 14795–14803 (2000)

Sauerzopf, F.M.: Phys. Rev. B 57, 10959–10971 (1998)

Zhou, Y.X., Ghalsasi, S., Rusakova, I., Salama, K.: Supercond. Sci. Technol. 20, s147–154 (2007)

Ishii, Y., Shimoyama, J.I., Tazaki, Y., Nakashima, T., Horii, S., Kishio, K.: Appl. Phys. Lett. 89, 202514–1–4 (2006)

Zhou, Y.X., Scruggs, S., Salama, K.: Supercond. Sci. Technol. 19, S556–558 (2006)

Pan, S.H., Hudson, E.W., Lang, K.M., Eisaki, H., Uchida, S., Davis, J.C.: 403, 746–750 (2000)

Ohazama, T., Mukaida, M., Horii, S., Saito, A., Kita, R., Ichinose, A., Yoshida, Y., Matsumoto, K., Ohshima, S.: Physica C 426-431, 1611–1615 (2005)

Horii, S., Ichino, Y., Yoshida, Y., Matsumoto, K., Mukaida, M., Ichinose, A., Shimoyama, J., Kishio, K.: Physica C 445-448, 837–840 (2006)

Holesinger, T.G., Jia, Q.X., Maiorov, B., Civale, L., Dowden, P.C., Gibbons, B.J.: Adv. Mater. 19, 1917 (2007)

Specht, E.D., Goyal, A., Li, J., Martin, P.M., Li, X., Rupich, M.W.: Appl. Phys. Lett. 3, 89 (2006)

Acknowledgments

In this paper, the authors wish to thank the fund for the project support, including the Fundamental Research Funds for the Central Universities (A0920502051411-5), the National Natural Science Foundation of China (51377138 and 51271155), and the National Science and Technology Projects Foundation (2013DFA51050, 2013GB114003-1, 2014AA032701).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, H., Zhao, Y., Wang, W.T. et al. The Effects of Elements Doping on the Properties of YBCO Epitaxial Films Prepared by Chemical Solution Deposition. J Supercond Nov Magn 28, 3281–3284 (2015). https://doi.org/10.1007/s10948-015-3201-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-015-3201-8