Abstract

Polysaccharide pullulan acts as a base matrix for the fabrication of pullulan/collagen blend film with dopant ZnO nanoparticles. From the FTIR data, it could be confirmed that there was significant interaction among the pullulan/collagen/ZnO-NPs. The weak interactions like H-bonding was evident by shift absorption band of hydroxyl groups into the lower frequency region. The powder X-ray diffraction study revealed the amorphous nature of pullulan/collagen blended film which was modified into a crystalline structure after the addition of ZnO nanoparticles. The transformation of the films into crystallinity and the presence of the Zn element was confirmed by SEM-EDAX. Further, the results of TGA revealed that the addition of nanoparticles influenced the thermal stability of the pullulan/collagen blended films. The addition of ZnO nanoparticles lead to an increase of the stiffness and mechanical resistance of the nanocomposite films; which showed an increase in their tensile strength evidenced by an increase in Young’s modulus. The fabricated films exhibited antifungal activity against Aspergillus niger with a maximum zone of inhibition of 18 mm for pullulan/collagen/ZnO-NPs (0.5%). However, the nanocomposite films easily dissolved in an aqueous medium, indicating their possible use as edible packaging films in the food industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polysaccharides and proteins such as pullulan, chitosan, collagen, and gelatin, etc., were recognized as the magnificent materials for the fabrication of films due to their distinct properties. As there were adverse effects with plastic, the biopolymers became an attractive, alternative to synthetic polymers [1,2,3,4]. The characteristic features of biopolymers include biodegradability, nontoxic nature followed by eco-friendly, renewable, and available for a low cost. Biopolymers were used as edible film packaging or coating materials in the food industry as they increase sustainability while maintaining food product quality and further contribute to control the foodborne pathogens [5,6,7,8,9,10]. Hence, it is a challenge to prepare new polymer composite films for the production of packaging or coating material from biodegradable natural renewable resources and also to solve the waste disposal complications. Pullulan might be considered as the foremost matrix of such a film. The biopolymer’s performance could be further enhanced by fabricating with natural fiber or protein and were considered as composites.

Pullulan is a non-ionic polysaccharide produced extracellularly by the fungus Aureobasidium pullulans. It consists of maltotriose type units i.e. α-(1 → 6)-linked with (1 → 4)-α-d-triglucosides. Due to this unique linkage pattern, pullulan has high adhesion, tensile strength and is biodegradable. Pullulan was approved by the Food and Drug Administration (FDA) for a variety of applications. Pure pullulan films exhibit poor mechanical properties. Therefore pullulan could be blended with other natural polymers and reinforcement additives like nanoparticles which showed strong antimicrobial activity [3, 11,12,13,14]. The biopolymer, collagen which was a protein isolated from animal tissues used in numerous fields starting from tissue engineering to photonics. In the present study, collagen was isolated from the skin of Indian mackerel (Rastrelliger kanagurta) which was the main catch at the Arabian Sea [15,16,17,18].

The ZnO-NPs were extensively used in various applications including the food industry, paints, cosmetics, as drug carriers, fillings in medical materials [19,20,21]. The ZnO-NPs were commonly used as a food additive. The ZnO-NPs were listed by the FDA as generally recognized as safe (GRAS) materials and had been used in foodstuffs due to their ability to dissociate into Zn2+ ions in the human body and ZnO-NPs, with small particle size, made zinc more easily to be absorbed by the body. The ZnO-NPs were recognized with potential antimicrobial activities exhibited relatively less toxic property and were available commercially at low-cost [22,23,24]. The ZnO-NPs had also been used as a dietary supplement in humans and cattle because zinc could stimulate the immune system and act in an anti-inflammatory way [25,26,27]. The ZnO nanoparticles could absorb the moisture, making the food fresh for an extended period [4, 20, 28, 29]. Globally, substantial research was focused on ZnO nanoparticles and their composites on applications in the food industry. For instance, carboxymethyl cellulose/chitosan/ZnO nanocomposite film, ZnO-NPs incorporated into PLA film, agar film incorporated with ZnO-NPs, gelatin-based nanocomposite containing chitosan and ZnO-NPs. The Zno-NPs incorporated into the starch film, ethylene–vinyl alcohol copolymer (EVOH) nanocomposite film was prepared by adding nano zinc oxide, ZnO-NPs incorporated into semi-refined iota carrageenan, ZnO-NPs/chitosan nanocomposite film, ZnO-NPs were also added to the pectin/alginate films and extensively studied to increase the shelf life of fruits, vegetables, and fresh poultry meat to use them as packaging or coating materials [4, 5, 24, 30,31,32,33,34,35,36]. These research results had given confidence to the prospective application of zinc oxide nanoparticles in edible food packaging/coating material. The prepared films, when fabricated with nanoparticles, form the nanocomposites with enhanced mechanical and thermal properties and also contributed to the antimicrobial activities. The nanocomposites when used as the materials of packing conferred enormous applications such as ease in transportation, withstanding the thermal stress generated during food processing, and viability during storage etc. [37, 38].

The collagen and zinc oxide nanoparticles composite films were developed for biomedical applications [39]. However; there was no study on the incorporation of zinc oxide nanoparticles into pullulan/collagen blended film for food packaging or coating applications. Keeping this in view, in the present study it was contemplated to make composites consisting of pullulan, collagen, and further fabricated with ZnO nanoparticles and represented as [(pullulan/collagen) − (ZnO-NPs)]. This nanocomposite was used to test its application as an efficient antimicrobial agent against both bacteria and fungi.

Materials and methods

Materials

Indian mackerel were collected from a market in Mangalore. The skin portions of the fish were removed and washed with cold distilled water and stored at − 20 °C for further use. Chemicals used in the study including acetic acid (M.W. 60.05 g/mol, 0.5 M in water), butanol (M.W. 74.12, 10% w/v in water), EDTA (M.W. 372.24, 0.5 M in water), tris (hydroxymethyl) aminomethane (M.W. 121.14, 0.05 M) and ZnO nanoparticles with < 100 nm (20 wt% in H2O) were procured from Merck®, India. Pullulan (M.W. 100–200 kDa, 2% w/v in water) was purchased from TCI, Japan.

Experiments

The [(pullulan/Collagen) − (ZnO-NPs)] Nanocomposite Film

The acid-soluble collagen was isolated from the skin of Indian mackerel (Rastrelliger kanagurta) using a reported method with a slight modification [40]. Pullulan acted as a base matrix for the preparation of a pullulan/collagen blend film. Blends of the pullulan and collagen doped with ZnO-NPs had been prepared in the form of films by using the solution casting method. Different concentrations of ZnO-NPs suspension (0.25%, 0.5% and 1%) (w/v) were added to pullulan (2%)/collagen (2%) blend solution and it was stirred at 4 °C, 350 rpm for 12 h on a magnetic stirrer. After the completion of the reaction, the doped solution (30 mL) was sonicated for 10 min and it was uniformly poured onto the Petri plate as thin film and dried at 40 °C for 24 h. The films were cooled at room temperature, slowly peeled off from the Petri plate, and stored in a polythene bag.

Characterization

Structural confirmation of ZnO-NPs doped pullulan/collagen composite films was carried out by using Fourier Transform Infrared Spectroscopic analysis (between 4000 and 550 cm−1) using Shimadzu FTIR. RigaKu 600 Miniflex benchtop X-ray diffractometer was used to study the structural changes in blended films. The surface morphology of films was analyzed by Field Emission Scanning Electron Micrograph (Carl Zeiss Microscopy Ltd). Elemental analysis was carried out by using EDAX. Thermogravimetric analysis (TGA) was carried out to analyze the thermal decomposition of prepared films using TA instruments (Model; SDTQ600, TA Instruments, UK). The thermal scanning was carried out at a uniform scanning rate of 10 °C/min over the temperature range of 25–700 °C. Mechanical properties of the nanocomposite films were measured by using Zwick & Roell 2020 (Loadcell 100 N) testing machine with a test speed of 12.5 mm/min.

The Density of the Cross-Linked Nanocomposite Film

The density of all prepared cross-linked film samples were analyzed by using the liquid displacement method with ethanol as a liquid [41, 42]. At first, a known weight (W) of the sample (35 mg) was immersed in a graduated cylinder containing a known volume (V1) of ethanol for 15 min. The volume of ethanol with the sample was measured (V2). Then, the sample was removed from the cylinder, the volume of ethanol (V3) was recorded too. Each kind of sample was measured in triplicates. Density could be calculated by the following equations:

Antimicrobial Study

Antibacterial activity of fabricated films was tested against four different bacterial strains namely Bacillus subtilis (ATTCC 6051), Escherichia coli (ATTCC 25922), Pseudomonas aeruginosa (ATCC 27853), and Staphylococcus aureus (ATTCC 25923). Antifungal activity was tested against two fungal strains such as Aspergillus niger (ATCC 6275) and Candida albicans (ATCC 10231). The disk diffusion method was used to determine the antimicrobial activity of the films. The bacterial strains were inoculated in 100 mL of the flask containing nutrient broth and incubated at 37 °C for 24 h. After incubation, the test organisms were spread on the sterile Muller Hinton agar plates. Whereas for the antifungal activity, the Sabouraud agar medium was used and the plates were incubated for the 72 h. The stock solution weighing 10 mg of the film was dissolved in 1 mL of DMSO. Later different volumes of film solutions were injected into the 1 mm sized sterile discs and were impregnated onto the inoculated plates. For control plates, Ciprofloxacin (10 µg/mL) and Fluconazole (30 µg/mL) were used as standard antibacterial and antifungal agents respectively. These plates were incubated at 37–48 °C, according to an optimum temperature required. Antimicrobial activity was obtained by evaluating the zone of inhibition around the wells and the diameter of the inhibition zone was measured [43].

Results and Discussion

Nanocomposite Film Synthesis [(Pullulan/Collagen) − (ZnO-NPs)]

The addition of collagen into the pullulan was to increase the thermal stability and to strengthen the film upon which resulted in good quality films. The pullulan contains substantial amounts of hydroxyl groups and also hydroxyl proline component of collagen, this would lead to the formation of hydrogen bonds between the –N–H– and –O–H– of the collagen molecules and the –O–H– of the pullulan molecules [44, 45]. Upon the addition of ZnO-NPs, the stable nanocomposite films were formed. The changes in characteristics of the developed films with varying concentrations of NPs were determined. The films formed readily dissolved in aqueous medium. It was noteworthy that collagen usually dissolved in acetic acid (0.1 M), but the nanocomposite film [pullulan/collagen (50:50) blend] readily dissolved in water.

FTIR Analysis

The cross-linking reaction between pullulan/collagen blended films was investigated by using FTIR spectroscopy. The image of the FTIR spectra was represented in Fig. 1 with different fabricated materials from (a) to (e). Figure 1a represents the pure pullulan film with a broad –OH stretching vibrations band at 3332 cm−1 and 2924 cm−1 which could be attributed to the sp3 C–H bond. Besides, only a single absorption band appeared at 1636 cm−1 was assigned to the stretching vibration of –O–C–O– group in pullulan. Other features of pullulan were also observed in the spectrum including –C–O–H– bend (1354 cm−1) and –C–O–C– stretch (1148 cm−1). The typical absorption bands for the α configuration of α-d-glucopyranose units in pullulan were observed at 851 cm−1. Besides, the absorption bands due to the two main linkages of pullulan (i.e., α-(1,4) and α-(1,6)-d-glucosidic bonds) were observed at 734 cm−1 and 918 cm−1 [46,47,48].

Figure 1b represents the pullulan /collagen blend film, indicated the formation of hydrogen bonding between pullulan and collagen. A broad absorption band located at 3319 cm−1 arose from the –NH– stretching vibration of the amide A band and also due to the hydroxyl group (–O–H–) of the pullulan matrix. The shift of –OH– stretch to a lower position from 3332 cm−1 to 3319 cm−1 indicated the hydrogen bonds were formed between the –N–H– and –O–H– of the collagen molecules and the –O–H– of the pullulan molecules. At 2945 cm−1 an absorption band observed was due to the –C–H– stretching. However, the most characteristic amide bands for collagen were observed at 1646 cm−1 which corresponded to the –C=O– of amide I band, and at 1552 cm−1 was due to the –NH bend coupled with –CN stretch. A band seen at 1438 cm−1 could be due to –CH2 bending (scissors) vibration and a band appeared at 1371 cm−1 due to –CH2 wag of proline and glycine. The α- configuration of α-d-glucopyranose units of pullulan was observed at 860 cm−1. A sharp peak at 1026 cm−1 belonged to the stretching of the C6-OH bonds. Also besides, the two main linkages of pullulan, α-(1,4), and α-(1,6)-d-glucosidic bonds were observed in the 750 cm−1 and 910 cm−1. From the above discussion, favors that the blending of collagen with pullulan was successful.[44, 45, 49,50,51].

Pullulan/collagen blends doped with different concentrations of ZnO-NPs showed that the position of amide bands was almost at the same wavenumbers for all the blends as shown in Fig. 1c–e. There was a minor shift of the bands in the spectrum corresponding to hydroxyl, amino, and amide groups in the nanocomposite films towards lower spectral range which indicated the interaction between the pullulan, collagen, and ZnO nanoparticles. The addition of ZnO-NPs, decreased the content of α- helix conformation. As the concentration of ZnO was increased there were slight changes in the intensity of the absorption band indicating that ZnO-NPs slightly modified the triple helical structure of collagen. At around 462 cm−1 Zn–O stretching could be observed. The absorption band in the range of 1100–1600 cm−1 corresponded to the Zn–O bending mode [52, 53].

X-ray Diffraction (XRD)

The morphology of polymer/nanoparticle composite films was further established by XRD and the results are represented in Fig. 2. Pure pullulan film did not exhibit any sharp peak representing its amorphous nature. But the pullulan/collagen blend film showed a peak at 2θ = 16.1° resulted due to the presence of pullulan/collagen hydrogen bonding or interchain H-bonding of collagen. The formation of crystallites in the matrix was the reason for its crystallinity. It was observed in Fig. 2c–e an additional peak at 2θ = 24.4° was seen along with 16.1°. This clearly indicated the nanocomposite had been formed by doping ZnO nanoparticles into the pullulan/collagen matrix. It was observed that pure ZnO nanoparticle XRD spectrum exhibited at a sharp peak at 2θ = 31.75°, 34.52°, 36.33° etc., [54,55,56]. But this peak was not prominent in the composite film might be due to the –Zn–O– interaction with the functional groups of the polymers. The shifting of 2θ = 24.4° supported the interaction of nanoparticles with the matrix.

SEM Analysis

The microscopy of surface changes in the pullulan and pullulan/collagen blend film doped with different concentrations of ZnO-NPs as shown in Fig. 3a–e. The pullulan film was uniform in shape, size and the surface was flat and smooth. When collagen was mixed with pullulan it showed a dense fibrous form and rough surface which could be due to ultrasonication leading to aggregation of collagen fiber. The SEM analysis of ZnO-NPs doped blend films showed that there was a difference between pullulan film and doped blend films. The ZnO-NPs were dispersed and embedded in the matrix at lower concentrations. It was also observed that the nanoparticles strongly adhered to the matrix which exhibited modification in the physical and chemical characteristics of the films.

The chemical composition and distribution of the pullulan/collagen blend doped with ZnO-NPs composite film was studied by EDAX. In Fig. 4a–e the EDAX spectrum of all the films doped with different concentrations of ZnO-NPs is presented. In the pullulan film and blended films, only carbon and oxygen were detected, whereas oxygen and zinc were present in the nanocomposite films [36]. This result indicated the presence of the Zn element in the fabricated nanocomposite films.

Thermogravimetric Analysis (TGA)

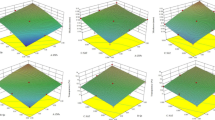

The TGA was used to determine the thermal stability of fabricated films. The TGA analysis was carried out in the range of 25–800°C in the air at a heating rate of 10 °C/min as shown in Fig. 5. The thermogram of the films revealed actual weight loss which was observed in two main decomposition stages. It could be inferred that below 100 °C, weight loss occurred in all the samples, due to the loss of water from the protein and polysaccharides. For the pullulan film the 30% weight loss at 150 °C, 40% weight loss at 295 °C, 95% weight loss at 350 °C and complete degradation occurred at 700 °C. While pullulan blended with collagen film showed 20% weight loss at 145 °C, 30% weight loss at 280 °C, 80% weight loss at 350 °C and complete degradation was observed at 700 °C. When different concentrations of ZnO-NPs were added to the pullulan/collagen blend, it showed 15% weight loss at 150 °C, 20% weight loss at 285 °C, major degradation 80% weight loss at 350 °C and complete degradation at 700 °C. The first decomposition around 150 °C resulted in a weight loss of 15–30% and reasoned for breaking down of macromolecules into smaller ones. The second decomposition of weight loss (30–40%) occurred at around 280–290 °C, indicating the production of gaseous elements. From the above result, it was confirmed that incorporating different concentrations of ZnO nanoparticles into a pullulan/collagen blend film, it improved its thermal stability compared to pure pullulan film and pullulan/collagen blend films.

Mechanical Properties

The variation in the mechanical properties of the nanocomposite films is shown in Table 1. The addition of ZnO-NPs increased Young’s modulus (1270–2420 MPa), tensile strength (27.7–35.4 MPa) gradually, and decreased its elongation @ break (2.2–1.8%). The crystallites formed by the interchain H-bonding between pullulan and collagen increased the crystallinity of the matrix which lead to internal friction in the matrix. The presence of ZnO-NPs increased the crystalline nature which was evident by the increase in Young’s modulus and a decrease in elongation at break. The high Young’s modulus could be related to the good dispersion of nanoparticles throughout the pullulan/collagen matrix as well as strong interaction between the matrix and nanoparticles [5, 22, 45, 57].

The Density of Cross-Linked Nanocomposite Film

The concentration of ZnO-NPs increased, the density of all cross-linked films were increased as shown in Table 2. An increase in density might be due to the increase in crystallinity by the addition of collagen as well as nanoparticles into the pullulan matrix due to interchain interactions resulting in rigid regions in the matrix. The analysis further confirmed that a higher crosslink density lead to a higher Young’s modulus [58, 59].

Antimicrobial Activity

The inhibitory activity of fabricated films were measured by disc diffusion. Both bacteria and fungi showed resistance to the polysaccharide matrix pullulan, pullulan/collagen blend film, and 0.25% ZnO-NPs. The fabricated films showed inhibitory effects on Gram-positive bacteria Bacillus subtilis with a zone of inhibition of 10 mm for pullulan/collagen/ZnO-NPs (0.5%) and The growth of Staphylococcus aureus, Pseudomonas aeruginosa, and Candida albicans was not inhibited by any of the fabricated composite films. The mechanism for antibacterial effect of ZnO-NPs had been reported as the ZnO-NPs cause oxidative stress in the bacterial cells by the generation of ROS which leads to weakening of mitochondria. The films were fabricated using pullulan as a matrix which is a natural antioxidant [60]. Even though the oxidative stress caused by the nanoparticles on bacteria might have been nullified by the antioxidant property of pullulan. It resulted in marginal antibacterial activity, where as the antifungal mechanism was different from ROS generation. The developed films showed good activity against Aspergillus niger with a maximum zone of inhibition of 18 mm for pullulan/collagen/ZnO-NPs (0.5%) as shown in Fig. 6 and Table 3. The antifungal activity was not exhibited by 0.25% dopant NPs whereas 0.5% dopant exhibited maximum activity. Henceforth, antifungal activity decreased as the concentration of nano ZnO increased to 1%. One of the reasons for this might be the size of nanoclusters formed in the polymer matrix. It was stated that ZnO-NPs might affect cell functions in a fungus by increasing nucleic acid content [61]. The increase in nucleic acid content might be due to the stress caused by the presence of nanoparticles in the fungal cells. On observing SEM Fig. 3d the nanoparticles were found to be arranged in a regular pattern in a 0.5% dopant film. Hence, effective penetration to the fungal cell walls might have taken place. It could be the reason for its high antifungal activity. The lowest nano ZnO concentration (0.25%) was not effective enough. But the concentration of nano ZnO, (1%) might have agglomerated and would have resulted in inefficient penetration to fungal cells. The antifungal activity results of pullulan/collagen/ZnO-NPs composite films were highly promising and might help in the development of antifungal biopolymer film with potential applications in the food industry.

Antifungal (Aspergillus niger) activity images of pullulan/collagen blend films doped with different concentrations of ZnO nanoparticles a pullulan (2%), b pullulan (2%)/collagen (2%), c standard (fluconazole), d pullulan/collagen/ZnO-NPs (0.25%), e pullulan/collagen/ZnO-NPs (0.5%), f pullulan/collagen/ZnO-NPs (1%)

Conclusions

Herein, the collagen was isolated from the skin of Indian mackerel and used to blend it with polysaccharide pullulan to make thin films. The developed film was further doped with different concentrations of ZnO-NPs. The approach is easy and eco-friendly. The FTIR study confirmed the strong intermolecular hydrogen bonding between pullulan and collagen chains by shifting of absorption bands to lower positions. The SEM and EDAX analysis confirmed the distribution and presence of the Zn element in the pullulan/collagen matrix. The TGA study revealed that the thermal stability of the composite was improved by incorporating collagen into the pullulan matrix and it was further strengthened by nanoparticle addition. The addition of ZnO nanoparticles led to an increase of the stiffness and mechanical resistance of the nanocomposite films were evidenced by an increase in Young’s modulus and a decrease in elongation at break. The nanocomposite films enhance antimicrobial activity particularly it arrested the growth of fungus A. niger. Among tested films, the nanocomposite film with 0.5% ZnO-NPs dopant emerged as the best one. The penetration of nanoparticles into fungal cells greatly affected by nanoclusters formed in the polymer matrix. The nanocomposite film with 0.5% ZnO-NPs could be used as edible food packaging material.

References

Diab T, Biliaderis CG, Gerasopoulos D, Sfakiotakis E (2001) J Sci Food Agric 81:988–1000

Cazon P, Velazquez G, Ramirez JA, Vazquez M (2017) Food Hydrocoll 68:136–148

Krasniewska K, Pobiega K, Gniewosz M (2019) Int J Food Eng 15:20190030

Souza VGL, Rodrigues C, Valente S, Pimenta C, Pires JRA, Alves MM, Fernando AL (2020) Coatings 10:110

Mirjalili F, Yassini Ardekani A (2017) J Food Process Eng 40:e12561

Popovic SZ, Lazic VL, Hromis NM, Suput DZ, Bulut SN (2018) Biopolymers for Food Design. Academic Press, New York, pp 223–277

Dhaka RK, Upadhyay A (2018) J Pharm Innov 7:331–333

Said NS, Sarbon NM (2019). Active Antimicrob Food Packag. https://doi.org/10.5772/intechopen.80774

Xing Y, Li W, Wang Q, Li X, Xu Q, Guo X, Yang H (2019) Molecules 24(9):1695

Mohamed SA, El-Sakhawy M, El-Sakhawy MAM (2020) Carbohydr Polym 20:116178

Gabor D, Tita O (2012) Food Technol 16:3–17

Farris S, Unalan IU, Introzzi L, Fuentes-Alventosa JM, Cozzolino CA (2014) J Appl Polym Sci 131:40539

Chen F, Yu S, Liu B, Ni Y, Yu C, Su Y, Yan D (2016) Sci Rep 6:20014

Zhang S, Wei F, Han X (2018) New J Chem 42:17756–17761

Popescu R, Moldoveanu M, Rau I (2009) Key Eng Mater 415:33–36

Parenteau-Bareil R, Gauvin R, Berthod F (2010) Materials 3:1863–1887

Silvipriya KS, Kumar KK, Bhat AR, Kumar BD, John A, Lakshmanan P (2015) J Appl Pharm Sci 5:123–127

Radhakrishnan S, Nagarajan S, Bechelany M, Kalkura SN (2020) Processes and phenomena on the boundary between biogenic and Abiogenic nature. Springer, Cham, pp 3–22

Martirosyan A, Schneider YJ (2014) Int J Environ Res Public Health 11:5720–5750

Khoirunnisa AR, Joni IM, Panatarani C, Rochima E, Praseptiangga D (2018) AIP Conf Proc 1927:030041

Jiang J, Pi J, Cai J (2018) Bioinorg Chem Appl 2018:1062562

Sadeghi K, Shahedi M (2016) J Food Nutr Res 4:709–712

Noshirvani N, Ghanbarzadeh B, Rezaei Mokarram R, Hashemi M (2017) Food Packag Shelf Life 11:106–114

Amjadi S, Emaminia S, Nazari M, Davudian SH, Roufegarinejad L, Hamishehkar H (2019) Food Bioprocess Technol 12:1205–1219

Rincker MJ, Hill GM, Link JE, Meyer AM, Rowntree JE (2005) Anim Sci J 83:2762–2774

Prasad AS (2008) Exp Gerontol 43:370–377

Sahu D, Kannan GM, Vijayaraghavan R, Anand T, Khanum F (2013) Int Sch Res Notices 2013:316075

Tayel AA, Sorour NM, El-Baz AF, Wael F (2017) Food preservation. Academic Press, London, pp 487–526

Abbas M, Buntinx M, Deferme W, Peeters R (2019) J Nanomater 9:1494

Zhang L, Jiang Y, Ding Y, Povey M, York D (2007) J Nanopart Res 9:479–489

Youssef AM, El-Sayed SM, El-Sayed HS, Salama HH, Dufresne A (2016) Carbohydr Polym 151:9–19

Liu Z, Lv M, Li F, Zeng M (2016) J Aquat Food Prod Technol 25:1056–1063

Li W, Li L, Cao Y, Lan T, Chen H, Qin Y (2017) Nanomaterials 7:207

Fadeyibi A, Osunde ZD, Egwim EC, Idah PA (2017) J Agric Eng 48:137–146

Ngo TMP, Dang TMQ, Tran TX, Rachtanapun P (2018). Int J Polym Sci. https://doi.org/10.1155/2018/5645797

Kumar S, Boro JC, Ray D, Mukherjee A, Dutta J (2019) Heliyon 5:e01867

Arora A, Padua GW (2010) J Food sci 75:R43–R49

Gautam RB, Kumar S (2015) Int Food Res J 3:43–61

Mihai MM, Dima MB, Dima B, Holban AM (2019) Materials 12:2176

Nagai T, Suzuki N (2000) Food Chem 68:277–328

Ki CS, Kim JW, Hyun JH, Lee KH, Hattori M, Rah DK, Park YH (2007) J Appl Polym Sci 106:3922–3928

Sionkowska A, Michalska M, Walczak M, Smiechowski K, Grabska S (2016) Mol Cryst Liq Cryst 640:180–190

Umamaheswari G, Sanuja S, John VA, Kanth SV, Umapathy MJ (2015) Polym Polym Compos 23:199–204

Sa I, Bhanukeerthi AV, Poornimavelswamya UT, Thirumalai P (2016) RSC Adv 6:57863–57871

Wang Y, Guo Z, Qian Y, Zhang Z, Lyu L, Wang Y, Ye F (2019) Polymers 11:1424

Cheng KC, Demirci A, Catchmark JM (2010) Appl Microbiol Biotechnol 86:853–861

Trovatti E, Fernandes SCM, Rubatat L, Freire CSR, Silvestre AJD, Neto CP (2012) Cellulose 19:729–737

Saber-Samandari S, Gulcan HO, Saber-Samandari S, Gazi M (2014) Water Air Soil Pollut 225:2177

Priya B, Gupta VK, Pathania D, Singha AS (2014) Carbohydr Polym 109:171–179

Soud SAS (2017) Al-Mustansiriyah J Sci 28:86–92

Cai L, Shi H, Cao A, Jia J (2019) Sci Rep 9:1–11

Djaja NF, Montja DA, Saleh R (2013) Adv Mater Phys Chem 3:33

Kumar S, Mudai A, Roy B, Basumatary IB, Mukherjee A, Dutta J (2020) Foods 9:1143

Talam S, Karumuri SR, Gunnam N (2012). ISRN Nanotechnol. https://doi.org/10.5402/2012/372505

Arefi MR, Rezaei-Zarchi S (2012) Int J Mol Sci 13:4340–4350

Mohan AC, Renjanadevi B (2016) Procedia Technol 24:761–766

Cyras VP, Manfredi LB, Ton That M, Vazquez A (2008) Carbohydr Polym 73:55–63

Fan Q, Xiao C (2008) Polym Compos 29:758–767

Zhao J, Yu P, Dong S (2016) Materials 9:234

Synowiec A, Gniewosz M, Krasniewska K, Przybyl JL, Baczek K, Weglarz Z (2014) Innov Food Sci Emerg Technol 23:171–181

He L, Liu Y, Mustapha A, Lin M (2011) Microbiol Res 166:207–215

Acknowledgements

The authors would like to acknowledge funding from an NFSC fellowship (Id No. RGNF-2017-18-SC-KAR-41024). They also acknowledge DST PURSE and University Science Instrumentation Centre (USIC), Mangalore University for providing the SEM, TGA, and FTIR facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bailore, N.N., Balladka, S.K., Doddapaneni, S.J.D.S. et al. Fabrication of Environmentally Compatible Biopolymer Films of Pullulan/Piscean Collagen/ZnO Nanocomposite and Their Antifungal Activity. J Polym Environ 29, 1192–1201 (2021). https://doi.org/10.1007/s10924-020-01953-y

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01953-y