Abstract

Besides excellent adsorption performance of adsorbents, the disposal of spent adsorbents should be considered for environmental concern. In this study, a new all-biomass double network Jute/sodium alginate (Jute/SA) gel is prepared via the simple dripping technique. 80 wt% water of Jute/SA hydrogel endows the adsorbent with high permeability for heavy metal ions diffusion onto internal adsorption sites. The Jute/SA gel adsorbent can efficiently remove heavy metals from melting wastewater, especially Pb2+ and Cd2+. The adsorbent shows high adsorption capacities of 291.3 mg g−1 for Pb2+ and 149.9 mg g−1 for Cd2+ at 298 K. The adsorption equilibrium reaches within 45 min for 45 mg L−1 Cd2+ and Pb2+ using 1 g L−1 adsorbent, showing 98% removal efficiency of Pb2+ and Cd2+. Moreover, the removal efficiencies in 45 min reach up to 99.1% for Pb2+ (7.539 mg L−1) and 89.9% for Cd2+ (4.743 mg L−1) in actual melting effluent containing Zn (43.95 mg L−1), Cu (16.50 mg L−1), Mn (19.24 mg L−1), Ni (4.90 mg L−1) and Fe (33.75 mg L−1) using 1 g L−1 adsorbent. The concentrations of Pb and Cd decrease below 0.001 mg L−1 using 4 g L−1 adsorbent. Furthermore, the adsorption efficiencies for Pb2+ and Cd2+ remain above 95% in the tenth cycle, and the desorption efficiency is up to 99%. In addition, the spent Jute/SA gel was a good organic fertilizer for plant growth. This work develops an efficient and eco-friendly biomass adsorbent for the removal of heavy metals in actual wastewater.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Heavy metal contaminants in water and disposal of spent heavy metal adsorbents have been an environmental concern. The excessive discharge of wastewater containing lead (Pb2+) and cadmium (Cd2+) into aquatic environment may lead to a potential risk [1]. Adsorption technique is widely used to eliminate heavy metals in wastewater [2, 3]. Various adsorbent materials such as ion-exchange resins, carbon nanotubes and activated carbon have been extensively developed [4,5,6]. The adsorption process of heavy metal cations commonly involves boundary layer and intraparticle diffusion, as well as surface adsorption [7]. However, traditional compact granular adsorbents show a limited ion diffusion through pores. For example, the adsorption equilibrium time for activated carbon requires at least several hours [8]. In addition, the adsorption capacities of granular adsorbents are reluctantly discounted due to the pore blocking and burial of surface adsorption sites with the proceeding of adsorption [9]. Although nano-sized adsorbents show off faster adsorption, it is cumbersome for fine adsorbents to separate, leading to extra operation cost and potential threat to environment [10]. Low-cost and high-performance (high adsorption capacity, fast adsorption, and good recyclability) adsorbents are highly demanded for practical applications.

Polymer hydrogels with an interpenetrating network structure possess a high water permeability for ion diffusion into polymer frameworks. Some hydrogel adsorbents have been used to remove heavy metals in water. These polymer hydrogels were synthesized by polymerization of olefin monomers containing hydrophilic functional groups [11]. However, the disposal of spent adsorbents is an environmental concern due to the non-biodegradation of polyolefin polymers. In contrast, biodegradable biomass materials are attractive [12]. Conventional biomass hydrogels, however, are generally too weak and viscous to recycle. Some measures have to be taken to enhance the mechanical strength of biomass hydrogels, such as chemical crosslinking, synthetic polymer introduction and inorganic hybridization [13,14,15,16]. However, these modified bulk biomass-based adsorbents suffer reduced biodegradability, decreased adsorption capacity and increased use cost. The utilization of spent adsorbents is generally ignored. All-biomass adsorbents with both good adsorption performance and post-utilization are highly desired.

In this study, a new all-biomass double network jute/sodium alginate (Jute/SA) gel was prepared via the simple dripping technique. Both jute and sodium alginate are readily available biomass materials. The chains of Jute and SA were cross-linked together into a stable bead structure through the electrostatic interaction and hydrogen bonds. The high water permeability (80 wt%) endowed Jute/SA hydrogel with accessible channels for heavy metal ions diffusion into the adsorbent, which would ensure the utilization of adsorption sites as much as possible. Thus, the Jute/SA gel adsorbent showed a highly efficient removal of heavy metals in wastewater with an excellent recyclability. Furthermore, the spent Jute/SA hydrogel adsorbent was a good organic fertilizer for plant growth.

Materials and Methods

Chemicals

Jute leaf powder (100 mesh) was provided by Institute of Bast Fiber Crops, Chinese Academy of Agricultural Sciences. Sodium alginate (SA) was purchased from Shanghai Aladdin Bio-Chem Technology Co., Ltd. Other chemicals were purchased from Sinopharm Chemical Reagent Co., Ltd. and used as received. The industrial melting effluent was taken from Hengyang Shuikoushan smelting plant. All aqueous solutions were prepared with deionized water unless otherwise stated.

Preparation of Jute/SA Hydrogel

The specific preparation process of Jute/SA gel is as follows: 1.0 g of jute powder was dissolved in 50 mL of 0.5 mol L−1 NaOH aqueous solution to get a ropy solution. 2.0 g of SA was dissolved in 100 mL deionized water to form a viscous solution. The two as-prepared solutions were mixed well under magnetic stirring. The mixed solution was dropped into a 200 mL of 6.0 wt% Ca(NO3)2 solution using a syringe (10 mL) to obtain spherical particles. The formed particles were further stabilized through domestication in the solution for 15 min. The collected particles were washed with deionized water several times to neutral to get Jute/SA hydrogel adsorbent. In addition, dried Jute/SA gel could be obtained through the freeze drying of Jute/SA hydrogel. The schematic diagram of Jute/SA hydrogel synthesis and network structure is shown in Scheme 1.

Characterization and Analysis Methods

The surface morphology and network structure of Jute/SA gel was observed using a scanning electron microscope (SEM, S-4800). Fourier transform infrared spectra (FTIR, Nicolet 5700) was used to determine the functional groups of Jute, SA and Jute/SA gel. The surface chemistry of Jute/SA gel before and after adsorbing heavy metals was determined by X-ray photoelectron spectroscope (XPS, K-Alpha 1063). The thermal stability of the Jute/SA gel was analyzed by thermogravimetric analysis (TGA, TG/DTA7300) under nitrogen atmosphere. The zero-charge point (pHPZC) determination of Jute/SA gel was measured by ΔpH drift method in 0.01 mol L−1 NaCl solution [17].

Batch Adsorption Experiments

The Pb2+ and Cd2+ solutions with preselected concentrations were prepared by dissolving lead nitrate and cadmium nitrate in deionized water. The pH of the solutions was adjusted using a 0.1 mol L−1 HCl or NaOH aqueous solution, where the pH valves of Pb2+ and Cd2+ solutions were adjusted to 5.0 and 6.0 for adsorption experiments, respectively. Nitrates (K+, Na+, Mg2+, Ca2+, Zn2+, Ni2+, Cu2+ or Mn2+) or humic acid (HA) was separately added as background substances with a preset concentration. Jute/SA aerogel (1.0 g L−1) was added to the heavy metal solution at predetermined concentration, and the reaction was carried out at room temperature (ca. 25 °C) with shaking at 160 r min−1 until adsorption equilibrium, and then the supernatant was collected. The concentration of heavy metal ions in the initial solution and the solution after the reaction was measured by atomic absorption spectrometer (AAS, Hitachi Z-2000). For the regeneration study, the metal-adsorbed hydrogel was eluted with 0.1 mol L−1 HCl solution, and then regenerated with 0.1 mol L−1 NaOH solution (pH 13) followed by washing with deionized water to neutral.

Data Analysis

The adsorption data were fitted by two kinetic models (pseudo-first-order and pseudo-second-order equations) and three types of isotherms (Langmuir, Freundlich and Dubinin–Radushkevich (D–R) models). The adsorption percentage (sorption % = (C0 − Ce)/C0 × 100) and partition coefficient (Kd = (C0 − Ce)/Ce × V/m) were calculated by dividing the initial concentration (C0) and the equilibrium concentration (Ce), where V represents the volume of the heavy metal solution and m represents the mass of Jute/SA. All experimental data are the average value after repeated measurement at least three times, and the relative errors were less than 5%.

Plant Cultivation Experiments

The seed of Solanum nigrum L. was purchased from Hebei Qingfeng Seed Industry, China. The spent Jute/SA hydrogel was washed to remove heavy metal ions for use as fertilizer. Roseite and spent Jute/SA hydrogel (wt% ratio of 60/40, total mass of 800 g for one basin) were mixed well and used as the cultivation medium. Five seeds were sowed into the medium in one cultivation basin. The temperature was ca. 28 °C for daytime and ca. 25 °C for night in a training room. Three 300 W Xe lamps were used as simulated sunlight. The focused intensity on the plant was 120 mW cm−2. They were watered using tap water every two days. After 2 weeks, only one yang tree in one basin was retained and others were removed. As a control, the growth of Solanum nigrum L. was only in roseite cultivation medium but watered using Hoagland’s nutrient solution (Hoagland’s nutrient solution: Ca(NO3)2·4H2O (0.005 mol L−1), KNO3 (0.005 mol L−1), MgSO4·7H2O (0.002 mol L−1), KH2PO4 (0.001 mol L−1) and H2O).

Results and Discussion

Characterizations

The Jute/SA hydrogel was prepared as shown in Scheme 1. The chains of Jute and SA were cross-linked into a stable bead structure through the electrostatic interaction (between Ca2+ cations and oxygen-containing anionic groups) and hydrogen bonds (–O–H⋯O(N)). During the swelling process in water, the gel reached a swelling equilibrium within about 8.0 h and the swelling ratio was about 3.1 (from about 1 mm for freeze-dried gel to approximately 3 mm for hydrogel) (Fig. 1a), which contained about 80 wt% water in hydrogel and kept a stable bead structure due to the cross-linking of the chains by electrostatic interaction and hydrogen bonds. Moreover, the freeze-dried Jute/SA gel was a porous aerogel (top left, Fig. 1a). The porous structure and high water permeability endowed Jute/SA hydrogel with accessible channels for heavy metal ions diffusion into the adsorbent, which would ensure the utilization of adsorption sites as much as possible. The FTIR spectra of the samples are shown in Fig. 1b. SA exhibited characteristic absorption peaks at around 1628 cm−1 and 1423 cm−1 ascribed to symmetric stretching vibration and antisymmetric stretching vibration for –COO− in SA, respectively [18]. After gelation of Jute and SA in the presence of Ca2+ cations, the absorption peaks of –COO− in Jute/SA gel became stronger and shift slightly compared to those in SA, possibly due to the introduction of more –COO− from Jute and the electrostatic interaction. In contrast, the absorption peak (1647 cm−1) of C=O in Jute/SA occurred blue shit compared with that (1726 cm−1) in Jute, which was due to the decrease in electron cloud density of C=O after the introduction of Ca2+ cations. Moreover, there was a broad absorption band in the range of 3200–3500 cm−1 in Jute and Jute/SA, due to the stretching vibration of –OH and –NH2 functional groups [19]. In addition, the strong absorption peak at around 1045 cm−1 for C–O stretching vibration in Jute/SA should be due to the formation of more hydrogen bonds of –O–H⋯O(N) after crosslinking [20]. The TGA result indicated that Jute/SA gel was highly stable below 150 °C (Fig. 1c), meeting the need of actual application. The zero-charge point (pHPZC) of Jute/SA was about 3.0 (Fig. 1d). The pHPZC plays an important role in determining the surface charge and adsorption capacity of adsorbents. The presence of H+ or OH− ions in the solution may alter the potential surface charge of the adsorbent. When changing the pH, there will appear ΔpH drift. If the pH of the solution is below its pHPZC, the negative charges (OH−) will deviate from the surface of adsorbent. Conversely, if the pH is above its pHPZC, the positive charges (H+) will deviate from the surface of adsorbent companying the adsorption of cations from electrolytes. Thus, when the pH value of the solution is above 3.0, the surface of Jute/SA will be available for the adsorption of heavy metal cations by electrostatic interactions.

Adsorption Selectivity of Jute/SA Gel

The adsorption selectivity is important to evaluate the adsorption capacity for targeted heavy metals. The adsorption experiment was conducted in a solution containing one kind of interfering metal ion (Pb2+, Cd2+, Zn2+, Mn2+, Ni2+ or Cu2+) which commonly exist in practical melting effluent. The initial concentration of each metal ion was 0.25 mmol L−1 (52, 28, 16.5, 14, 14.5, and 16 mg L−1 for Pb2+, Cd2+, Zn2+, Mn2+, Ni2+ and Cu2+, respectively). The initial pH of the solution was 5.0. As shown in Fig. 2, the removal efficiency of Pb2+ and Cd2+ reached 97.7% and 89.6% in 45 min, respectively, which was much higher than that for other interfering metal ions.

The adsorption selectivity can be expressed by selectivity coefficient (βPb2+/M2+) (Eq. 1):

where, D is the distribution coefficient which can be calculated by Eq. 2:

where, C0 and Ce are the concentrations of metal ions before and after adsorption (mol L−1), V is solution volume (L), and m is adsorbent mass (g).

The calculated results are listed in Table 1. The selectivity coefficients of the Jute/SA gel for Pb2+ and Cd2+ were 1 and 0.2, respectively, much higher than those for other ions. The removal efficiency priority was Pb2+ > Cd2+ > Cu2+ > Zn2+ > Mn2+ > Ni2+. The selectivity is related to ion valence, stability constants, hydration radii, mass-to-charge ratio, and coordination capacity [21]. Thereby, the adsorption of Pb2+ and Cd2+ on Jute/SA gel was further investigated.

Effect of Environmental Conditions

The factors of pH value, background ions and HA in solution usually affect the surface chemistry (surface charge and ion states) of adsorbents. In order to investigate the effect of pH value on the adsorption of Pb2+ and Cd2+ by Jute/SA gel, a series of pH values were selected to carry out adsorption experiments (Fig. 3a, b). Under strong acidic conditions, high-concentration H+ could compete with heavy metal ions for adsorption sites. Even so, the adsorption efficiency of Pb2+ and Cd2+ should be boasted in a pH range of 2–3 (pHPZC of 3.0). The results indicate that chemosorption dominantly contributed to the adsorption behavior. With the increase of pH above 3.0, the electrostatic adsorption force became stronger, resulting in higher adsorption efficiencies of Pb2+ and Cd2+. At pH 5.0 and 6.0, the adsorption efficiencies for Pb2+ and Cd2+ reached a maximum of 99.1% and 98.8%, respectively. When further increasing the pH to 6.2 for Pb2+ or 8.6 for Cd2+, precipitation would occur at the pH of bulk solution precipitation (pHBSP for 50 mg L−1). Therefore, the adsorption on Jute/SA could be well conducted in a wide pH range of 3–6 for Pb2+ or 3–8 for Cd2+ at a high concentration level of 50 mg L−1.

The common cations (K+, Na+, Ca2+, and Mg2+) and humic acid (HA, C9H9NO6) in aquatic system may compete with heavy metal ions at the adsorption sites of the adsorbents. The concentration of interfering substances was set at 0.01 mol L−1 (230, 391, 243, 400, and 2271 mg L−1 for Na+, K+, Mg2+, Ca2+, and HA, respectively) much higher the initial concentration of Pb2+ and Cd2+ (50 mg L−1). As shown in Fig. 3c, d, HA had a negligible effect on the adsorption of Pb2+ and Cd2+. K+, Na+ and Ca2+ had little effect on Pb2+ adsorption and a little effect on Cd2+ adsorption. In contrast, Mg2+ had an obvious effect on adsorption of both Pb2+ and Cd2+. The influence of ionic species followed the sequence: Mg2+ > Ca2+ > K+ ≈ Na+, probably due to the difference in electronegativity (0.82 for K+, 0.93 for Na+, 1.00 for Ca2+, 1.31 for Mg2+) and Hard Soft Acid Theory [22]. The declined adsorption efficiency could be due to the competition and electrostatic repulsion among metal ions as well as the lowered activity coefficient of Cd2+ and Pb2+ at a high ionic strength [23].

Adsorption Kinetics

Only 45 min was required to reach adsorption equilibrium with 98% removal efficiencies of Pb2+ and Cd2+ (C0 = 45 mg L−1, m/V = 1 g L−1) (Fig. 4). The fast adsorption should be attributed to plenty of adsorption sites and high permeability of Jute/SA gel, which accelerated the diffusion of heavy metal ions.

The pseudo-first-order (Eq. 3) and pseudo-second-order (Eq. 4) models were used to describe the adsorption of Pb2+ and Cd2+ on Jute/SA gel.

where, Qt (mg g−1) and Qe are the adsorption capacity at time t and equilibrium, respectively; k1 (L min−1) and k2 (g mg−1 min−1) are the adsorption rate constants of pseudo-first-order and pseudo-second-order kinetic model, respectively. The correlation coefficients (R2) of the pseudo-second-order kinetic model were a little larger than those of pseudo-first-order kinetic model (Table 2), indicating that both physical electrostatic adsorption and chemosorption was involved.

Adsorption Thermodynamics

In order to study the adsorption mechanism of Pb2+ and Cd2+ on Jute/SA gel, Langmuir and Freundlich isotherms were used to fit the adsorption data of Pb2+ and Cd2+ at 288, 298 or 308 K (Fig. 5).

Langmuir isotherms can describe a mono-layer adsorption behavior (Eq. 5).

where, Qe and Ce are the equilibrium adsorption capacity (mg g−1) and equilibrium concentration (mg L−1), respectively; Qm is the maximum adsorption capacity (mg g−1); KL is adsorption constant (L mg−1).

Freundlich isotherms can describe a heterogeneous adsorption process (Eq. 6).

where, KF is adsorption constant (mg1−n Ln/g) and nF is Freundlich index.

The adsorption isotherms parameters are listed in Table 3. The correlation coefficient of Langmuir isotherm model was higher than that of Freundlich isotherm model, indicating that monolayered heavy metal ions were uniformly adsorbed onto the active sites. The adsorption capacity increased with increasing temperature, indicative of an endothermic reaction process. The Langmuir model predicted that the maximum theoretical adsorption capacities (Qm) for Pb2+ and Cd2+ by Jute/SA gel at 298 K were 291.3 mg g−1 and 149.9 mg g−1, respectively. For a bulk full-biomass adsorbent, it shows a comparable adsorption capacities for Pb2+ and Cd2+ with adsorbents reported (Table 4).

The thermodynamic parameters, Gibbs free energy difference (ΔG), enthalpy change (ΔH) and entropy change (ΔS) were calculated according to the van’t Hoff equation. The thermodynamic parameters are listed in Table 5. The average free energy (E) was calculated by the Dubinin–Redushckevich (D–R) isotherm analysis (Fig. 5c, d). The E values for Pb2+ and Cd2+ adsorption were 13.4 and 12.7 kJ mol−1, respectively, indicating that the adsorption involved a chemical reaction (E value between 8 and 16 kJ mol−1) [24]. In addition, ΔG < 0 and ΔH > 0 indicated a spontaneous and endothermic adsorption process.

As a control, Langmuir and Freundlich isotherms were used to fit the adsorption data of Pb2+ by Jute and SA at 288, 298 or 308 K (Fig. 6). The Langmuir model predicted that the maximum theoretical adsorption capacities (Qm) for Pb2+ by Jute and SA at 298 K were 224.6 mg g−1 and 177.0 mg g−1, respectively, which were lower than that by Jute/SA gel. The possible reason may be ascribed to more available adsorption sites of porous double-network Jute/SA.

Adsorption Mechanism

According to Hard Soft Acid Base Theory, the acidity of Cd2+ is weaker than that of Pb2+ (acidity: K+, Na+ > Pb2+, Cu2+ > Cd2+, Cu+). However, Jute/SA showed lower adsorption capacity for Cd2+ than Pb2+. So the study on adsorption mechanism of Cd2+ on Jute/SA is important to design high-performance adsorbents for Cd2+ adsorption. The chemical groups and chemical environments of Jute/SA gel before and after the adsorption for Cd2+ were characterized by FTIR and XPS spectra. As shown in the FTIR spectra (Fig. 7a), after the adsorption for Cd2+ the absorption band in the range of 3200–3500 cm−1 for the stretching vibration of –OH/NH2 functional groups was red-shifted. This change may be caused by the coordination of Cd2+ with lone pair electrons of –OH/NH2, resulting in reduced electron cloud density around these functional groups. In addition, the –COOH absorption peak at 1647 cm−1 shift to 1609 cm−1, due to the ion exchange between H+ and Cd2+. Thereby, the main adsorption sites for Cd2+ were the carboxyl, hydroxyl and amino groups on Jute/SA gel. The XPS analysis of Jute/SA gel before and after adsorption of Cd2+ was further performed. After adsorption of Cd2+, two peaks of Cd 3d5/2 (405.0 eV) and Cd 3d3/2 (411.0 eV) were clearly observed (Fig. 7b) [36]. The high resolution XPS (HRXPS) spectra of O 1s were analyzed (Fig. 7c). The adsorption of Cd2+ resulted in an increased binding energy of O in both C=O and C–O, due to the reduction of electron cloud density on O. Because of the coordination of Cd2+ with lone pair electrons of O atoms, the polarization of C=O and C–O bonds was strengthened, resulting in higher binding energy of C atoms adjacent to O atoms [37]. In addition, there appeared a new peak of N 1s at 399.7 eV after adsorbing Cd2+ (Fig. 7d), meaning a coordination of Cd2+ with N atoms. Moreover, the XPS peaks of Na+ and Ca2+ became poor or disappeared. It is well known that (according to Hard Soft Acid Theory) heavy metal ions will be better complexed by carboxylic group than Na+ or K+. Therefore, the adsorption of heavy metal ions on Jute/SA gel was through the coordination between Cd2+ ions and –OH/NH2 as well as the ion exchange between Cd2+ ions and other cations (H+, Na+ as well as Ca2+). Taking into account the results of thermodynamics and pH effect together, chemosorption dominantly contributed to the adsorption behavior of Cd2+. Strong electron-donating ability of functional groups in adsorbents is desired for capturing Cd2+-like soft acid heavy metal ions.

Reusability of Jute/SA Gel and Utilization of Spent Adsorbent

Adsorbent reusability is critical to practical applications. The adsorption for Pb2+ and Cd2+ by Jute/SA gel was highly sensitive in the pH range from 1 to 3 (Fig. 3a, b). At low pH, Pb2+ and Cd2+ could be easily desorbed due to strong protonation and competitive effect with H+. The metal ion-adsorbing Jute/SA gel was eluted with 0.1 mol L−1 HCl solution (pH 1) and regenerated with 0.1 mol L−1 NaOH solution (pH 13) followed by washing with deionized water to neutral (Fig. 8). The adsorption efficiencies for Pb2+ and Cd2+ were 99.1% and 98.8% in the first cycle and remained 96.1% and 95.3% in the tenth cycle, respectively. The desorption efficiency was higher than 99% in each cycle. Moreover, after 10 recycling processes, Jute/SA gel remained porous network structure (Fig. 9a) and exhibited good mechanical properties reflected in typical consecutive loading-unloading curves with gradually increased strain (Fig. 9b). These results indicated that the Jute/SA gel adsorbent had a good reusability.

The disposal of spent adsorbents is an environmental concern. Considering the biodegradation of all-biomass Jute/SA, the spent Jute/SA adsorbent (after 10 cycles) was thoroughly washed with 0.1 mol L−1 HCl solution and water to remove residual heavy metals and used as fertilizer for plant growth in roseite cultivation medium. As shown in Fig. 10, the plant of Solanum nigrum L. grew well after being watered with tap water within 8 weeks (No. 3 and 4), which could rival those growing in roseite cultivation medium without Jute/SA residue but watered using Hoagland’s nutrient solution (No. 1 and 2). After harvesting these plant, there were no heavy metals detected in the soil and the plant. So, the spent adsorbent could be used as a fertilizer in infertile soil for the cultivation of plant.

Treatment of Actual Melting Effluent

In order to evaluate the applicability of Jute/SA gel adsorbent, the metal adsorption efficiency was tested in an actual melting effluent. The suspended solid in the effluent was removed by filtration before test. The main metals are Pb, Cd, Zn, Cu, Mn, Ni and Fe with initial concentration of 7.539, 4.743, 43.95, 16.500, 19.24, 4.900 and 33.75 mg L−1, respectively. Before adsorption, the initial pH was adjusted from 2.4 to 5.0. The adsorption efficiencies within 45 min are listed in Table 6. When using 1 g L−1 Jute/SA gel, the adsorption efficiencies of Pb, Cd, Zn, Cu, Mn, Ni and Fe ions were 99.1, 89.9, 54.7, 42.1, 28.5, 2.0 and 99.4%, respectively. In this process, Fe showed a relatively high removal efficiency, probably due to high average valence electron energy and the 3d64s2 subshell, which offer empty orbital and strongly coordinate with active site [38]. When increasing adsorbent dose to 2 g L−1, the adsorption efficiencies of Pb2+ and Cd2+ increased to 99.9% and 99.5%, respectively. When further increasing adsorbent dose to 4 g L−1, the removal efficiencies of Pb2+ and Cd2+ reached almost 100% (the residual concentration was below 0.001 mg L−1). Jute/SA gel shows a great potential in the treatment of industrial effluent containing heavy metals.

Conclusions

This work develops a highly practical all-biomass hydrogel adsorbent. The double network structure and high water content of Jute/SA gel is conducive to improving metal ions diffusion, exposure of adsorption sites, and reusability. Jute/SA gel can be efficiently conducted in pH range of 3–6 and the adsorption kinetic equilibrium is fast. The adsorbent shows comparable adsorption capacities of Pb2+ and Cd2+ with those for the best adsorbents reported so far. Jute/SA gel is effective in removing Pb2+ and Cd2+ in actual melting effluent containing various metals. Meanwhile, Jute/SA gel can be easily regenerated and highly reused with an excellent recyclability. In addition, the spent Jute/SA hydrogel adsorbent was a good organic fertilizer.

References

Liu Y, Xiao T, Baveye P, Zhu J, Ning Z, Li H (2015) Potential health risk in areas with high naturally-occurring cadmium background in southwestern China. Ecotoxicol Environ Saf 112:122–131

Uddin M (2017) A review on the adsorption of heavy metals by clay minerals, with special focus on the past decade. Chem Eng J 308:438–462

Shao P, Liang D, Yang L, Shi H, Xiong Z, Ding L, Yin X, Zhang K, Luo X (2020) Evaluating the adsorptivity of organo-functionalized silica nanoparticles towards heavy metals: quantitative comparison and mechanistic insight. J Hazard Mater 387:121676

Chitpong N, Husson S (2017) High-capacity, nanofiber-based ion-exchange membranes for the selective recovery of heavy metals from impaired waters. Sep Purif Technol 179:94–103

Ihsanullah A, Al-Amer A, Laoui T, Al-Marri M, Nasser M, Khraisheh M, Atieh M (2016) Heavy metal removal from aqueous solution by advanced carbon nanotubes: critical review of adsorption applications. Sep Purif Technol 157:141–161

Kyzas G, Bomis G, Kosheleva R, Efthimiadou E, Favvas E, Kostoglou M, Mitropoulos A (2019) Nanobubbles effect on heavy metal ions adsorption by activated carbon. Chem Eng J 356:91–97

Liu D, Li Z, Li W, Zhong Z, Xu J, Ren J, Ma Z (2013) Adsorption behavior of heavy metal ions from aqueous solution by soy protein hollow microspheres. Ind Eng Chem Res 52:11036–11044

Loganathan P, Shim W, Sounthararajah D, Kalaruban M, Nur T, Vigneswaran S (2018) Modelling equilibrium adsorption of single, binary, and ternary combinations of Cu, Pb, and Zn onto granular activated carbon. Environ Sci Pollut Res 25:16664–16675

Bumanis G, Novais R, Carvalheiras J, Bajare D, Labrincha J (2019) Metals removal from aqueous solutions by tailored porous waste-based granulated alkali-activated materials. Appl Clay Sci 179:105147

Shao P, Ding L, Luo J, Luo Y, You D, Zhang Q, Luo X (2019) Lattice-defect-enhanced adsorption of arsenic on zirconia nanospheres: A combined experimental and theoretical study. ACS Appl Mater Interfaces 11:29736–29745

Zhao G, Huang X, Tang Z, Huang Q, Niu F, Wang X (2018) Polymer-based nanocomposites for heavy metal ions removal from aqueous solution: a review. Polym Chem 9:3562–3582

Anastopoulos I, Robalds A, Nguyen Tran H, Mitrogiannis D, Giannakoudaki D, Hosseini-Bandegharaei A, Dotto G (2019) Removal of heavy metals by leaves-derived biosorbents. Environ Chem Lett 17:755–766

Lai Y, Chang Y, Chen M, Lo Y, Lai J, Lee D (2016) Poly(vinyl alcohol and alginate cross-linked matrix with immobilized Prussian blue and ion exchange resin for cesium removal from waters. Bioresour Technol 214:192–198

Zhou G, Luo J, Liu C, Chu L, Crittenden J (2018) Efficient heavy metal removal from industrial melting effluent using fixed-bed process based on porous hydrogel adsorbents. Water Res 131:246–254

Zhou G, Luo J, Liu C, Chu L, Ma J, Tang Y, Zeng Z, Luo S (2016) A highly efficient polyampholyte hydrogel sorbent based fixed-bed process for heavy metal removal in actual industrial effluent. Water Res 89:151–160

Rajamani M, Rajendrakumar K (2019) Chitosan-boehmite desiccant composite as a promising adsorbent towards heavy metal removal. J Environ Manag 244:257–264

Avetta P, Pensato A, Minella M, Malandrino M, Maurino V, Minero C, Hanna K, Vione D (2015) Activation of persulfate by irradiated magnetite: implications for the degradation of phenol under heterogeneous photo-fenton-like conditions. Environ Sci Technol 49:1043–1050

Mu B, Zhong W, Dong Y, Du P, Liu P (2012) Encapsulation of drug microparticles with self-assembled Fe3O4/alginate hybrid multilayers for targeted controlled release. J Biomed Mater Res B 100:825–831

Zhou G, Liu C, Chu L, Tang Y, Luo S (2016) Rapid and efficient treatment of wastewater with high-concentration heavy metals using a new type of hydrogel-based adsorption process. Bioresour Technol 219:451–457

Yang P, Zhao J, Zhang L, Li L, Zhu Z (2015) Intramolecular hydrogen bonds quench photoluminescence and enhance photocatalytic activity of carbon nanodots. Chem Eur J 21:8561–8568

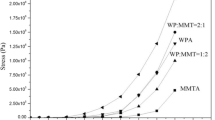

Chu L, Liu C, Zhou G, Xu R, Tang Y, Zeng Z, Luo S (2015) A double network gel as low cost and easy recycle adsorbent: highly efficient removal of Cd(II) and Pb(II) pollutants from wastewater. J Hazard Mater 300:153–160

Hadi P, Barford J, McKay G (2013) Toxic heavy metal capture using a novel electronic waste-based material—mechanism, modeling and comparison. Environ Sci Technol 47:8248–8255

Petrus R, Warcho J (2005) Heavy metal removal by clinoptilolite. An equilibrium study in multi-component systems. Water Res 39:819–830

Phetphaisit C, Yuanyang S, Chaiyasith W (2016) Polyacrylamido-2-methyl-1-propane sulfonic acid-grafted-natural rubber as bio-adsorbent for heavy metal removal from aqueous standard solution and industrial wastewater. J Hazard Mater 301:163–171

Xu R, Zhou G, Tang Y, Chu L, Liu C, Zeng Z, Luo S (2015) New double network hydrogel adsorbent: highly efficient removal of Cd(II) and Mn(II) ions in aqueous solution. Chem Eng J 275:179–188

Zhu Y, Hu J, Wang J (2012) Competitive adsorption of Pb(II), Cu(II) and Zn(II) onto xanthate-modified magnetic chitosan. J Hazard Mater 221:155–161

Sounthararajah D, Loganathan P, Kandasamy J, Vigneswaran S (2015) Adsorptive removal of heavy metals from water using sodium titanate nanofibers loaded onto GAC in fixed-bed columns. J Hazard Mater 287:306–316

El-Toni A, Habila M, Ibrahim M, Labis J, ALOthman Z (2014) Simple and facile synthesis of amino functionalized hollow core-mesoporous shell silica spheres using anionic surfactant for Pb(II), Cd(II), and Zn(II) adsorption and recovery. Chem Eng J 251:441–451

Deng S, Wang P, Zhang G, Dou Y (2016) Polyacrylonitrile-based fiber modified with thiosemicarbazide by microwave irradiation and its adsorption behavior for Cd(II) and Pb(II). J Hazard Mater 307:64–72

Liang X, Xu Y, Sun G, Wang L, Sun Y, Sun Y, Qin X (2011) Preparation and characterization of mercapto functionalized sepiolite and their application for sorption of lead and cadmium. Chem Eng J 174:436–444

Liu D, Li Z, Zhu Y, Li Z, Kumar R (2014) Recycled chitosan nanofibril as an effective Cu(II), Pb(II) and Cd(II) ionic chelating agent: adsorption and desorption performance. Carbohydr Polym 111:469–476

Ding Y, Liu Y, Liu S, Li Z, Tan X, Huang X, Zeng G, Zhou Y, Zheng B, Cai X (2016) Competitive removal of Cd(II) and Pb(II) by biochars produced from water hyacinths: performance and mechanism. RSC Adv 6:5223–5232

Cataldo S, Gianguzza A, Merli M, Muratore N, Piazzese D, Liveri M (2014) Experimental and robust modeling approach for Pb(II) uptake by alginate gel beads: Influence of the ionic strength and medium composition. J Colloid Interface Sci 434:77–88

He J, Lu Y, Luo G (2014) Ca(II) imprinted chitosan microspheres: an effective and green adsorbent for the removal of Cu(II), Cd(II) and Pb(II) from aqueous solutions. Chem Eng J 244:202–208

Sangi M, Shahmoradi A, Zolgharnein J, Azimi G, Ghorbandboost M (2008) Removal and recovery of heavy metals from aqueous solution using Ulmus carpinifolia and Fraxinus excelsior tree leaves. J Hazard Mater 155:513–522

Zhou G, Liu C, Tang Y, Luo S, Zeng Z, Liu Y, Xu R, Chu L (2015) Sponge-like polysiloxane-graphene oxide gel as a highly efficient and renewable adsorbent for lead and cadmium metals removal from wastewater. Chem Eng J 280:275–282

Wu N, Li Z (2013) Synthesis and characterization of poly(HEA/MALA) hydrogel and its application in removal of heavy metal ions from water. Chem Eng J 215–216:894–902

Srivastava S, Agrawal S, Mondal M (2015) A review on progress of heavy metal removal using adsorbents of microbial and plant origin. Environ Sci Pollut Res 22:15386–15415

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51778218), the Science and Technology Innovation Plan of Hunan Province (2019JJ10001, 2020JJ7036, 2017SK2420 and 2019RS3015) and Hunan Provincial Key Laboratory for Cost-effective Utilization of Fossil Fuel Aimed at Reducing Carbon-dioxide Emissions (HND2018005).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wen, L., Zhang, Y., Liu, C. et al. All-Biomass Double Network Gel: Highly Efficient Removal of Pb2+ and Cd2+ in Wastewater and Utilization of Spent Adsorbents. J Polym Environ 28, 2669–2680 (2020). https://doi.org/10.1007/s10924-020-01806-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01806-8