Abstract

Microbial polyhydroxyalkonate such as homopolyester of poly(3-hydroxybutyrate) (PHB) was produced from cheese whey by Bacillus megaterium NCIM 5472. Due to their numerous potential industrial applications, the focus was given to competently enhance the amount of PHB produced. The amount of PHB produced from whole cheese whey, and ultrafiltered cheese whey was first compared, and after observing a rise in PHB production by using ultrafiltered cheese whey, cheese whey permeate was chosen for further analysis. The presence of PHB was then confirmed by GCMS. Since the main aim of the study was to increase the amount of PHB produced through batch fermentation, various process parameters like time, pH, C/N ratio, etc. were optimized. After optimization, it was found that B. megaterium NCIM 5472 was capable of accumulating 75.5% of PHB of its dry weight and a PHB yield of 8.29 g/L. The chemical structure of the polymer was further analyzed by using FTIR and NMR spectroscopy methods. Also, the physical and thermal properties were studied by using Differential scanning calorimetry and Thermogravimetric analysis. It was found that the polymer produced had excellent thermal stability, thus allowing the possibility to exploit its properties for industrial purposes such as adhesives, packaging materials, etc.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Waste management constitutes one of the chief challenges that humanity is facing if it hopes to achieve a sustainable world. In 2016, according to The European Association of Plastic Recycling and Recovery Organizations (EPRO) 335 million tons per year of plastic was produced worldwide that mainly comes from a non-renewable source, which is both a pollutant and non-biodegradable. The increasing non-degradable waste on the planet and replenishing reserves of non-renewable fossil fuels is a major concern for us during the recent times [1,2,3]. The principle environmental concerns behind extensive synthetic plastic usage are its degradability and production of toxins during its degradation. Poly(3-hydroxybutyrate) (PHB) is a class of polyhydroxyalkanoates (PHA), which closely resemble synthetic plastics in various physical and chemical properties such as toughness and flexibility. Thus, making it a desirable alternative to petrochemical based plastics but with an added benefit of biodegradability without any ecological effect of solid waste disposal and incineration adopted in case of synthetic plastics [4, 5].

The use of waste-derived materials as feedstock for production of biomaterials is a highly desirable goal which is because utilizing waste materials will reduce the cost of carbon substrate substantially. As a prime example of this, a significant obstacle to the introduction of the biologically derived polymer PHA as a replacement of petroleum-based plastics is the high cost associated with its production, where the cost of carbon substrate contributes to about 40% towards the total production cost [6]. Cheese whey is the major by-product of the dairy industry, which comprises 80–90% of the total volume of milk. Although, Cheese whey constitute a major part of dietary nutrients for humans and animal feed but considerable amount of whey is disposed as waste. Since most whey constituent molecules are of small molecular weight and soluble such as lactose, minerals, bovine serum albumin, β-lactoglobulin etc, they can quickly decrease oxygen levels in natural water bodies [7, 8]. Whey permeate is a by-product obtained when cheese whey is passed through an ultrafiltration membrane to concentrate whey protein. Whey proteins get retained by the membrane, whereas smaller molecules such as lactose and salts pass through the membrane making up the whey permeate. While the whey retentate can be used in food products and as food supplements, the whey permeate has so far been of little value [9, 10]. This permeate portion can be utilized as a cheap carbon source for the production of PHAs due to higher proportion on lactose present in permeate. Azohydromonas lata, Bacillus megaterium, Cupriavidus necator and Pseudomonas oleovorans, are microorganisms capable of using various carbon sources to produce PHAs [11]. B. megaterium is a rod-like, Gram positive, aerobic spore forming bacteria found widely in diverse habitats. Recently, its popularity has escalated in the field of biotechnology for its recombinant protein production capacity [12]. It has also been previously reported for the production of intracellular PHAs by some studies [13,14,15]. In general, PHA accumulation is favored by a surplus availability of carbon source [16]. Along with this a restricted supply or deficiency of macro-components (nitrogen, phosphate or dissolved oxygen) or any micro-components (magnesium, sulfate, and other metals) [17,18,19] also favors PHA accumulation. PHB, is a homopolymer of 3-hydroxybutyrate and is the most used and best-characterized member of the polyhydroxyalkanoate family [3]. The biosynthesis of PHB (a class of PHAs) starts with the condensation of two molecules of acetyl-CoA, which gives acetoacetyl-CoA. This subsequently reduces to hydroxybutyryl-CoA. This compound is then used as a monomer to polymerize PHB [20].

The versatile nature of PHAs has emerged them into being potential candidates for a broad range of applications such as biomedical and medical fields, food and packaging industry, textiles, pharmaceuticals as well as for household products. However, the major drawback for the large-scale utilization of these polymers is due to its high cost of production [21]. This study aimed to utilize dairy industry cheese whey, which is the wastewater region, as an inexpensive carbon substrate to make the production of PHB economically feasible. Although cheese whey has been previously reported as a substrate for PHB production [7, 8] and B. megaterium is also a well-known PHB producing organism [13,14,15], only a few papers have focused on the optimization of process parameters and also have reported a lower yield of PHB [3, 22,23,24]. However, the yield so far produced was found to be negligible in comparison to PHB from Haloferax mediterranei, i.e., 12 g/L [25]. Thus, the PHB yield obtained in our study after the process optimization is so far the highest yield ever attained from the eubacterial origin. After the optimization of process parameters, even the thermoplastic properties were observed to have been enhanced.

Materials and Methods

Identification of PHB Inclusion Bodies in B. megaterium NCIM 5472

The B. megaterium NCIM 5472 strain was purchased from NCIM, Pune, India and was analyzed for the presence of intracellular PHB granules using Sudan black B and Nile blue A staining method [26]. The strain was propagated in nutrient agar media for 24 h at 37 °C. 0.3% Sudan black B stain was used to stain the heat fixed smear, and the same was observed under a light microscope at ×40 magnification [27]. Further, the presence of PHB was confirmed using Nile blue A fluorescent staining and was observed under a fluorescence microscope (Olympus CKX41) at ×40 magnification with acetone as solvent at absorbance wavelength 499 nm and emission wavelength 596 nm [3].

Substrate Characterization

Whole cheese whey was obtained from Institute of Food and Dairy Technology, Chennai, India. The cheese whey was pre-processed using centrifugation (for 4 °C at 10,000 rpm for 20 min), filtration (Whatman no. 1 filter) and ultrafiltration [10]. The protein, lactose, fat, ash, carbohydrate, total solids, moisture and the B.O.D content of the substrate were analyzed. The protein content was estimated by Lowry’s method [28], lactose content was by Anthrone test [8], fat content by phosphovanillin assay [29], B.O.D by standard methods for the examination of water and waste water [30], and moisture content was analyzed by oven drying method.

Culture Conditions

Minimal salts media (MSM) was prepared in shaking flask [7] and supplemented with trace element solution along with cheese whey permeate as the carbon source. The composition of PHB accumulating production medium is as follows (g/L) Na2HPO4-6.8; KH2PO4-3; NaCl-0.5; NH4Cl-1.05; Citric acid-1.66; MgSO4·7H2O-1.20; K2HPO4-1.5; NH4Fe(III)citrate-0.05; Yeast extract-0.1; Trace element solution-2 mL; in 1 L of cheese whey permeate. The trace element solution contained (g/L) FeCl3·6H2O-27; ZnCl2·4H2O-2; CoCl2·6H2O-2; Na2MoO4·2H2O-2; CaCl2·6H2O-1; CuCl2·6H2O-1.3; H3BO3-0.5; concentrated HCl-100 mL, made up to 1 L with distilled water. Media was inoculated with 5 mL of pre-grown B. megaterium NCIM 5472 in nutrient broth growth media for 24 h. The pH was attuned to 7 ± 0.2, and the media was incubated at 37 °C at 150 rpm, for 48 h.

Optimization of Process Parameters

The processing parameters (time, pH, substrate concentration, substrate nature, inoculum percentage, C/N ratio) were optimized for better yield of PHB [31]. The samples were incubated at different time intervals (24–72 h). The MSM media were prepared at different pH (5–7.5) and incubated for 48 h. The substrate dilution ratio of whey and water varying from 10–100 mL was used in MSM media to optimize the dilution ratio. The whole cheese whey was ultrafiltered (membrane pore size 10 kDa) to remove the protein part as whey retentate, and the lactose rich whey permeate was obtained. Whole whey cheese and ultrafiltered whey permeate were used as the substrate in MSM media to compare the PHB concentration produced by each of the substrates. The samples were inoculated with 24th hour inoculum with varying percentage from 2.5 to 12.5% (v/v) for 48 h. The carbon content was measured by standard total organic carbon method whereas nitrogen was measured by the Kjeldahl method [32]. Media with optimized parameters was prepared, and concentration profiling of lactose uptake, dry cell weight, PHB concentration, PHB mass fraction in biomass was estimated.

Extraction and Estimation of PHB

Samples were removed from shake flasks after 48 h of incubation at 37 °C and were extracted using sodium hypochlorite method. The wet biomass obtained after centrifugation was treated with chilled 6% sodium hypochlorite (v/v) and chloroform to extract PHB granules [3, 33]. The mixture was vortexed in 50 mL centrifuge tubes and incubated at 37 °C for 1 h. After 1 h of incubation three distinct phases were observed, top phase (aqueous hypochlorite solution), intermediate phase (cell debris and other biological matter) and bottom phase (PHB rich organic layer). The PHB rich chloroform phase was obtained using separating funnel, and other two phases were discarded. After extraction, the uncapped centrifuge tubes with PHB rich chloroform aliquots were left in the fume hood for 48 h to evaporate any excess solvent [34, 35]. The final PHB film obtained was weighed and estimated. PHB concentration was estimated using crotonic acid assay [36]. Concentrated sulfuric acid was added to known PHB concentration (10–50 mg), and absorbance was measured at 235 nm. The standard graph was plotted using PHB standard (Sigma Aldrich) and used as a reference to estimate the amount PHB produced.

Analytical Methods

GC–MS Analysis

The extracted sample was derivatized using acid transesterification [37] in reflux for 6 h, at 100 °C, filtered using 0.45 µ syringe filter and tested for GC–MS (Agilent Technologies, GC-7890B and MS-5977A) analysis. The column used for detection in GC–MS was HP5MS (5%-Phenyl–methyl siloxane, 30 m × 250 µm × 0.25 µm) where the inlet temperature was 250 °C, detector temperature 290 °C and splitless mode [3, 38].

FTIR Analysis

The extracted PHB was analyzed by FTIR spectroscopy (Agilent Cary 660 FTIR). 5 mg sample was mixed with 100 mg of KBr pellet and pelletized. Spectrum was recorded at 400–4000 cm−1 [37, 39, 40].

Characterization of PHB

1H Nuclear Magnetic Resonance (NMR) Spectroscopy

The extracted PHB was dissolved in 600 µl of CDCl3 and then analyzed by 1H NMR (Agilent Technologies NMR 500 MHz) spectroscopy. Spectral range was maintained between 0 and 15 ppm [13, 41].

Differential Scanning Calorimetry (DSC)

The thermo-mechanical properties like melting endotherm (Tm) and glass transition temperature (Tg) were examined for the extracted PHB film by DSC (Q20). 5 mg samples were encapsulated in aluminium pans and heated from − 30 to 300 °C, at the rate of 10 °C min−1 [42,43,44].

Thermogravimetric Analysis (TGA)

The thermostability of extracted PHB film was studied using Thermogravimetric Analyzer (SEIKO model TG/DTA 6200). The analysis was carried out on a 10 mg sample in a nitrogen atmosphere, where the nitrogen gas flow rate was 200 mL min−1 [42, 43, 45].

Results and Discussion

Identification of PHB Inclusion Bodies in B. megaterium NCIM 5472

The cell culture was subjected to preliminary screening via Sudan black B staining [46]. The stained cells, when viewed under a light microscope (Fig. 1a), revealed the presence of dark black to purple granules. The diazo dye is known to stain neutral triglycerides, lipids, and some lipoproteins. The presence of the dark blue granules led to the assumption that the strain had PHB accumulation capabilities and that the observed granules were lipophilic inclusion bodies [27]. To confirm, Nile blue A staining was performed. Nile blue A is a fluorescent dye [43] containing an oxazine group which makes the dye basic in nature. This stains PHB but the other cell components do not take up the dye and thus are not able to fluoresce. After staining the bacterial smear with it, granules were observed, which fluoresced as bright orange to red, when viewed at ×40 magnification (Fig. 1b). These granules represented the PHB accumulated in the cells, in the form of inclusion bodies [3].

Substrate Characterization

The composition of whole cheese whey was analyzed (shown in Table 1), and the result was similar to that obtained in the study conducted by Obruca et al. [47]. Whole cheese whey consisted of salts along with total solids. The presence of salts and total solids demanded a need to remove these, to allow bacterial growth. Since the lactose concentration was lesser than that of protein, it was imperative that the protein is removed to increase the lactose concentration. The whole whey was subjected to be centrifugation; filtration and then ultrafiltration to minimize the presence of unwanted substances and to generate lactose rich whey permeate. The increase in lactose concentration facilitates the utilization and storage of PHB granules in the inclusion body. When excess lactose enters the PHB production pathway, 3HB monomers [in the case of PHB or poly(3-hydroxybutyrate)] are formed due to the condensation of two acetyl-CoA molecules. These molecules form 3-hydroxy-butyryl-CoA, which undergoes polymerization via esterification to generate poly-3-hydroxybutyrate [48]. The lactose concentration in the permeate section was observed to increase after five passes of ultrafiltration.

Growth Profile of B. megaterium NCIM 5472

Samples were periodically removed from the fermentation broth, and their optical density was measured at 600 nm. The growth curve (Fig. 2) depicts the lag, log and stationary phase which was similar to that observed in work done by Pandian et al. [34]. The log or exponential phase began at the 5th hour itself. Since the exponential phase is characterized by cell doubling; the mid-log phase was chosen for inoculum transfer. This was found to be at the 18th hour. The log phase lasted till the 24th hour, and by the 25th hour, the bacteria had achieved its stationary phase. This phase is often attained due to growth-limiting factors like exhaustion of essential nutrients and due to the effect of inhibition due to metabolites. The number of new cells generated is limited, and rate of cell growth matches that of cell death.

Optimization of Various Process Parameters

PHB accumulation was affected by various parameters like time, pH, and inoculum volume. The type and concentration of carbon source played an important role too. It was vital to optimize carbon/nitrogen ratio, as theoretically, PHB production becomes high when carbon is excess when compared to nitrogen, as mentioned in the introduction. These optimizations are carried out manually and are conducted one parameter at a time.

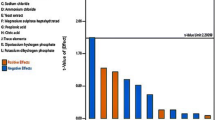

Comparison of PHB Production by Whole Whey and Ultrafiltered Whey

Whole whey generated a PHB yield of 2.31 g/L, which is lower than that by ultrafiltered whey, which generated a PHB yield of 7.34 g/L. The yield observed was comparable to the values previously reported by Yellore and Desai for PHB production for various whey medium using Methylobacterium sp. [8]. The observed increase in PHB concentration (Fig. 3a.), after ultrafiltration, could probably be due to the removal of some proteins which reduced the inherent nitrogen concentration in media, which in turn facilitated PHB accumulation. This statement is supported by the study conducted by Baldasso et al. [9] who reported that after ultrafiltration, the lactose concentration reduced drastically in the retentate part, thus implying that the permeate was rich in lactose. The total lactose present in permeate was found to be 11 ± 0.5 g/L along with 1.34 ± 0.06 g/L of protein after five passes of ultrafiltration. Hence, ultrafiltered whey was chosen for further optimizations.

Effect of Time on PHB Production

The effect of time was assessed by growing the bacteria in the MSM medium for different lengths of time (24–72 h). PHB accumulation started after the 12th hour [22]. It was observed that the amount of PHB produced increased till the 48th hour, after which there was a decline in PHB production. Thus, time was optimized at 48 h. The decline in PHB production (Fig. 3b.) could be due to lack of micronutrients or decrease in available carbon source in the media, which might have had an adverse effect on PHB production. A similar profile is observed in previously reported works of literature [23, 27, 49, 50].

Effect of pH on PHB Production

The effect of pH of media, on PHB production, was evaluated by maintaining media’s with varying pH (5–8) and incubated for 48 h. It was observed that PHB production gradually increased till pH 7 and then reduced drastically when the pH was further increased. As observed in Fig. 3c, when comparing pH 6.5 and 7.5, the yield at 7.5 is lower, unlike the results reported previously [26, 50]. A similar pattern was observed by Masood et al. [49]. The pH was optimized at 7. From the graph (Fig. 3c.), it can be inferred that the reduction in polymer production could be due to the effect of degradative enzymes on the polymer.

Effect of Inoculum Size on PHB Production

Inoculum size was varied from 2.5 to 12.5% (v/v). Highest PHB production was obtained at 5% inoculum beyond which it decreased. This decrease in PHB production (Fig. 3d) could be due to the increased competition between the organisms. Thus, 5% (v/v) inoculum size was set to be optimum.

Effect of Substrate Dilution Ratio on PHB Production

The dilutions were varied from 10:90 (whey: water) to a full 100% substrate concentration. The PHB extracted was highest at 100% substrate concentration (8.10 g/L) but the PHB extracted at 90% substrate concentration was similar to that of 100% (7.75 g/L). To further choose which dilution was the best, lactose concentration before inoculation and the residual lactose was determined. It was observed that the lactose utilization (as shown in Table 2) gradually increases but, at 100% substrate concentration the lactose utilization reduces. So, substrate dilution of 90:10 was found to be optimum. From Fig. 3e., and Table 2, it can be inferred that even though the PHB concentration was higher at a 100% substrate concentration, lactose utilization was higher for 90% substrate concentration. A similar increase in PHB concentration was observed when whey was diluted in the study conducted by Obruca et al. [47].

Effect of C/N Ratio PHB Production

The nitrogen concentration was varied relating to the carbon concentration (which was optimized previously), and its effect on PHB production was studied. It was observed that the PHB concentration increases till C/N ratio of 9 and then subsequently decreases. The initial increase (Fig. 3f) could probably be due to the uptake of available carbon in the presence of limited nitrogen source, which enters the PHB production pathway, but further increasing the nitrogen concentration results in a decrease in PHB production. The observed decrease after increasing the C/N beyond 9 could be due to the rapid uptake of carbon in the presence of excess nitrogen concentration, thus changing the physiological status of the cell which mimicked the log phase instead of stationary phase, which is unfavorable for PHB production. Thus, C/N ratio of 9 was found to be optimum. The result obtained is supported by available literature [39, 50].

Batch Kinetics Study

Batch kinetics study was conducted by using media with optimized process parameters and the concentration profile of cell growth, PHB production, PHB mass fraction in biomass and lactose utilization was studied. The rapid uptake of lactose was observed during the exponential phase of microbial cell growth, after which it gradually decreases. PHB production and accumulation slowly increase till the 36th hour and beyond which there is a steep increase. This is the approximate hour where the stationary phase of microbial cell cycle takes place and where the cells start accumulating PHB [50]. At 48th hour the maximum concentration of PHB is obtained along with the highest accumulation percentage. Beyond this, the PHB production and accumulation decreases (Fig. 4). This could probably be due to the reduction in available carbon sources. The PHB concentration of 8.29 g/L and an accumulation of 75.5% obtained by cheese whey permeate, is so far the highest reported result compared to those obtained by sugar beet juice-4.01 g/L [3]; red algae-2.8 g/L [22]; sewage samples (fruit peels and sugar industry waste)-0.23 g/L and 0.22 g/L [23]; and glycerol waste-1.82 g/L [24] from eubacterial sources. The PHB extracted at the 48th hour was analyzed for its physical and chemical properties.

Analytical Techniques

GC–MS Analysis of PHB

The derivative, butyric acid, 3-hydroxy-methyl ester, was identified for both the standard and the extracted sample. The chromatograms were obtained for transesterified PHB standard and extracted PHB (Fig. 5a, b). The peak at 4.888 ± 0.011 min represents butyric acid, 3-hydroxy-methyl esters in both the sample with a molecular weight of 118.06 kDa. The common peaks observed at 4.888 ± 0.011 min Fig. 5a, b represents butyric acid, 3-hydroxy-methyl esters. This confirms the presence of PHB, which is a type of PHB in our sample.

FTIR Spectroscopy of PHB Extracted from the Fermentation Broth

The functional groups present in the polymer were identified (Fig. 6.). The broad absorption band at 3429.073 cm−1 represented –OH stretching groups, 2924.854 cm−1 [44] and 2853.927 cm−1 corresponded to C–H stretching groups. The absorption band at 1745.031 cm−1 corresponded to C=O ester bond stretching. The absorption band at 1573.598 cm−1 corresponded to C=C stretching, 1462.943 cm−1 corresponded to C–H bending of a methylene group, 1382.321 cm−1 corresponded to C–H bending of alkane group, 1309.398 cm−1 corresponded to C–O stretching and 1084.462 cm−1 corresponded to C–O stretching of the aliphatic group. The band which is within 1740–1748 cm−1, has been reported to be a PHB marker band to carbonyl (C=O) ester bond stretching vibrations according to [51]. The bands observed (Fig. 6) are similar to those reported by several researchers [13, 45, 46, 49].

Characterization of PHB

H1 NMR Characterization

Proton NMR spectrum (Fig. 7.) showed characteristic signals for PHB. The peak at 0.851 ppm is a single peak or a singlet, which corresponds to the terminal methyl protons of the side chains. The peak at 1.269 ppm is also a singlet, which corresponds to the methylene protons of the side chain. The peak at 1.807 ppm is also a singlet, which corresponds to the methylene protons adjacent to β-carbon of side chains. The peak at around 2.594 ppm is a multiplet, which corresponds to the methylene protons of α-carbon. Peaks at 5.268 and 5.288 ppm are a doublet, which corresponds to the methine protons of β-carbon. The peaks are identical to the ones as by Gumel et al. [39] and similar to many researchers [24, 45, 46, 49, 52].

TGA of extracted PHB

This thermogram (Fig. 8.) was used to identify the thermal properties of the polymer. In the thermogram, three decomposition temperatures are available. At 163.8 °C, the residual mass is 63.5%. At 300.9 °C, highest decomposition occurs and after 456.2 °C, only 29.9% residual mass was left. Thus, the decomposition temperature was found to be 300.9 °C. At 300.9 °C, highest decomposition occurs. This was a result of ester cleavage occurs by β-elimination [43]. Due to this elimination, the polymer breaks and this breaking of the polymer is called as degradation or decomposition. Since, the decomposition temperature was higher than previously reported temperatures [44, 53], we concluded that the polymer was thermally stable.

DSC of extracted PHB

From the DSC thermogram (Fig. 9.), the Tm and the glass transition temperatures were identified. Based on the presence of Tm and Tg, the nature of the polymer was identified. When the heat was applied, the polymer underwent a phase transition. During this phase transition, either more or less heat flow was required to maintain the temperature of the polymer with that of the reference. This heat flow was measured with respect to the temperature. When the polymer was cooled slowly after heating, the melt polymer crystallized at 166.91 °C, and this was found to be the melting point of the polymer. When the polymer was further quench cooled, the melt polymer forms a glass instead of crystallizing. This occurred at − 13.54 °C and this was found to be the Tg of the polymer. However, when the polymer was quench cooled, the melt polymer forms a crystalline intermediate at 225.07 °C known as crystallization temperature. The melting peak at 251.76 °C and 45.80 °C could be due to melting, recrystallization, and re-melting during heating as suggested by Arcos-Hernández et al. [54]. As observed, these two melting endotherms and glass transition peaks were broadly separated and did not converge. So, it can be inferred that the bulk polymer contained many compounds or crystal types. The presence of both Tm and Tg shows that the polymer has both crystalline and amorphous region. Thus, this property of the polymer can be exploited for a wide range of applications like packaging, adhesives, etc. The melting point and crystallinity are similar to that reported previously [24, 43, 44].

Conclusion

In the current study, we are combining principles of waste management and pollution control, to develop a product which is eco-friendly. Cheese whey, after ultrafiltration, can be used as a cheap source of carbon in the growth media, for the production of PHB. B. megaterium NCIM 5472 could utilize this permeate effectively, and after various process parameters were optimized, it was observed that the bacteria could accumulate 75.5% of PHB of its dry weight and could generate a high PHB yield of 8.29 g/L. The polymer produced has a good thermal stability and contains both crystalline and amorphous regions, thus allowing the possibility to exploit its properties for industrial purposes. Cheese whey, being a dairy waste, can be considered for large scale production of PHB as it has the potential to bring about a considerable change in the bio-polymer production industry, whereby, the investments on carbon source can be significantly reduced. Current work focused on small scale studies which showed promising results, but, media optimization needs to be conducted for better understanding and control of PHB production. Scaled-up fermentation studies with better controlled conditions need to be conducted to design a completely sustainable PHB production process. Further modifications can be introduced using chemical reactions (e.g., Cross-linking, double bond hydration, etc.) to generate polymers with varying thermal and mechanical properties. More research is needed to strengthen the expertise in bio-polymer engineering, to produce specifically tailored polymers with desired monomer compositions according to the applications.

References

Povolo S, Casella S (2003) Bacterial production of PHA from lactose and cheese whey permeate. Macromol Symp 197:1–10

Nawrath C, Poirier Y, Somerville C (1995) Plant polymers for biodegradable plastics: cellulose, starch and polydroxyalkanoates. Mol Breed 1:105–122

Wang B, Shivappa RRS, Olson JW, Khan SA (2013) Production of polyhydroxybutyrate (PHB) by Alcaligenes latus using sugarbeet juice. Ind Crops Prod 43:802–811

Ojumu TV, Yu J, Solomon BO (2004) Production of polyhydroxyalkanoates, a bacterial biodegradable polymer. Afr J Biotechnol 3(1):18–24

Chanprateep S, Katakura Y, Visetkoop S, Shimizu H, Kulpreecha S, Shioya S (2008) Characterization of new isolated Ralstonia eutropha strain A-04 and kinetic study of biodegradable copolyester poly(3-hydroxybutyrate-co-4-hydroxybutyrate) production. J Ind Microbiol Biotechnol 35(11):1205–1215

Zhu C, Nomura CT, Perrotta J, Stipanovic AJ, Nakas JP (2010) Production and characterization of poly-3-hydroxybutyrate from biodiesel-glycerol by Burkholderia cepacia ATCC 17759. Biotechnol Prog 26:424–430

Koller M, Bona R, Chiellini E, Fernandes EG, Horvat P, Kutschera C, Hesse P, Braunegg G (2008) Polyhydroxyalkanoate production from whey by Pseudomonas hydrogenovora. Bioresour Technol 99(11):4854–4863

Yellore V, Desai A (1998) Production of poly-3-hydroxybutyrate from lactose and whey by Methylobacterium sp. ZP24. Lett Appl Microbiol 26:391–394

Baldasso C, Barros TC, Tessaro IC (2011) Concentration and purification of whey proteins by ultrafiltration. Desalination 278:381–386

Barile D, Tao N, Lebrilla CB, Coisson JD, Arlorio M, German JB (2009) Permeate from cheese whey ultrafiltration is a source of milk oligosaccharides. Int Dairy J 19(9):524–530

Chee JY, Tan Y, Samian MR, Sudesh K (2010) Expression of Aeromonas caviae polyhydroxyalkanoate synthase gene in Burkholderia sp. USM (JCM15050) enables the biosynthesis of SCL-MCL PHA from palm oil products. J Polym Environ 18:584–592

Bunk B, Schulz A, Stammen S, Münch R, Warren MJ, Rohde M, Biedendieck R (2010) A short story about a big magic bug. Bioeng Bugs 1(2):85–91

Shamala TR, Chandrashekar A, Vijayendra SVN, Kshama L (2003) Identification of polyhydroxyalkanoate (PHA)-producing Bacillus spp. using the polymerase chain reaction (PCR). J Appl Microbiol 94:369–374

Obruca S, Marova I, Melusova S, Mravcova L (2011) Production of polyhydroxyalkanoates from cheese whey employing Bacillus megaterium CCM 2037. Ann Microbiol 61(4):947–953

Kanjanachumpol P, Kulpreecha S, Tolieng V, Thongchul N (2013) Enhancing polyhydroxybutyrate production from high cell density fed-batch fermentation of Bacillus megaterium BA-019. Bioprocess Biosyst Eng 36:1463–1474

Phasakanon J, Chookietwattana K, Dararat S (2014) Polyhydroxyalkanoate production from sequencing batch reactor system treating domestic water mixed with glycerol waste. APCBEE Procedia 8:161–166

Kim YB, Lenz RW (2001) Polyesters from microorganisms. Adv Biochem Eng/Biotechnol 71:51–79

Helm J, Wendlandt KD, Jechorek M, Stottmeister U (2008) Potassium deficiency results in accumulation of ultra-high molecular weight poly-beta-hydroxybutyrate in a methane-utilizing mixed culture. J Appl Microbiol 105(4):1054–1061

Koller M, Hesse P, Salerno A, Reitner A, Braunegg G (2011) A viable antibiotic strategy against microbial contamination in biotechnological production of polyhydroxyalkanoates from surplus whey. Biomass Bioenergy 35(1):748–753

Bugnicourt E, Cinelli P, Lazzeri A, Alvarez V (2014) Polyhydroxyalkanoate (PHA): review of synthesis, characteristics, processing and potential applications in packaging. Express Polym Lett 8(11):791–808

Keshavarz T, Roy I (2001) Polyhydroxyalkanoates: bioplastics with a green agenda. Curr Opin Microbiol 13:321–326

Alkotaini B, Sathiyamoorthi E, Kim BS (2015) Potential of Bacillus megaterium for production of polyhydroxyalkanoates using the red algae Gelidium amansii. Int J Biol Macromol 20:856–860

Irsath H, Santhosh S, Hemalatha V, Vikramathithan M, Dhanasekar R, Dhandapani R (2015) Production and optimization of polyhydroxybutyrate using Bacillus subtilis BP1 isolated from sewage sample. Int J Pure Appl Biosci 3(1):158–166

Ray S, Prajapati V, Patel K, Trivedi U (2016) Optimization and characterization of PHA from isolate Pannonibacter phragmitetus ERC8 using glycerol waste. Int J Biol Macromol 86:741–749

Koller M, Hesse P, Bona R, Kutschera C, Atlicʹ A, Braunegg G (2007) Biosynthesis of high quality polyhydroxyalkanoate co-and terpolyesters for potential medical application by the archaeon Haloferax mediterranei. Macromol Symp 253(1):33–39

Chaudhry W, Jamil N, Ali I, Ayaz MH, Hasnain S (2011) Screening for polyhydroxyalkanoate (PHA)-producing bacterial strains and comparison of PHA production from various inexpensive carbon sources. Ann Microbiol 61(3):623–629

Sathiyanarayanan G, Saibaba G, Kiran GS, Selvin J (2013) Optimization of polyhydroxybutyrate production by marine Bacillus megaterium MSBN04 under solid state culture. Int J Biol Macromol 59:170–177

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275

Mishra SK, Suh WI, Farooq W, Moon MS, Shrivastav A, Park MS, Yang JW (2014) Rapid quantification of microalgal lipids in aqueous medium by a simple colorimetric method. Bioresour Technol 155:330–333

Greenberg AE, Clesceri LS, Eaton AD (1995) Standard methods for the examination of water and wastewater, 19th ed. American Public Health Association, Washington, DC

Yang YH, Brigham CJ, Budde CF, Boccazzi P, Willis LB, Hassan MA, Sinskey AJ (2010) Optimization of growth media components for polyhydroxyalkanoate (PHA) production from organic acids by Ralstonia eutropha. Appl Microbiol Biotechnol 87:2037–2045

Bradstreet RB (1954) Kjeldahl method for organic nitrogen. Anal Chem 26(1):185–187

Jacquel N, Lo CW, Wei YH, Wu HS, Wang SS (2008) Isolation and purification of bacterial poly(3-hydroxyalkanoates). Biochem Eng J 39(1):15–27

Pandian SR, Deepak V, Kalishwaralal K, Rameshkumar N, Jeyraj M, Gurunathan S (2010) Optimization and fed-batch production of PHB utilizing dairy waste and sea water as nutrient sources by Bacillus megaterium SRKP-3. Bioresour Technol 101:705–711

Rodriguez-Contreras A, Koller M, Miranda de Sousa Dias M, Calafell-Monfort M, Braunegg G, Marques-Calvo MS (2013) High production of poly (3-hydroxybutyrate) from a wild Bacillus megaterium Bolivian strain. J Appl Microbiol 114(5):1378–1138

Law JH, Slepecky RA (1961) Assay of poly-β-hydroxybutyric acid. J Bacteriol 82:33–36

Mohapatra S, Samantaray DP, Samantaray SM, Mishra BB, Das S, Majumdar S, Pradhan SK, Rath SN, Rath CC, Akthar J, Achary KG (2013) Structural and thermal characterization of PHAs produced by Lysinibacillus sp. through submerged fermentation process. Int J Biol Macromol 93(Pt A):1161–1167

Li A, Ha Y, Wang F, Li W, Li Q (2012) Determination of thermally induced trans-fatty acids in soybean oil by attenuated total reflectance fourier transform infrared spectroscopy and gas chromatography analysis. J Agric Food Chem 60(42):10709–10713

Gumel AM, Annuar MSM, Heidelberg T (2012) Biosynthesis and characterization of polyhydroxyalkanoates copolymers produced by Pseudomonas putida Bet001 isolated from palm oil mill effluent. PLoS ONE 7(9):1227–1231

Shah KR (2012) FTIR analysis of polyhydroxyalkanoates by a locally isolated novel Bacillus sp. AS 3-2 from soil of Kadi region, North Gujarat, India. J Biochem Technol 3(4):380–383

Bhattacharyya A, Pramanik A, Maji SK, Haldar S, Mukhopadhyay UK, Mukherjee J (2012) Utilization of vinasse for production of poly-3-(hydroxybutyrate-co-hydroxyvalerate) by Haloferax mediterranei. AMB Express 2(1):34

Mitra T, Sailakshmi G, Gnanamani A, Raja STK, Thiruselvi T, Gowri VM, Selvaraj NV, Ramesh G, Mandal AB (2011) Preparation and characterization of a thermostable and biodegradable biopolymers using natural cross-linker. Int J Biol Macromol 48(2):276–285

Babruwad PR, Prabhu SU, Upadhyaya KP, Hungund BS (2015) Production and characterization of thermostable polyhydroxybutyrate from Bacillus cereus PW3A. J Biochem Technol 6(3):990–995

Dhangdhariya JH, Dubey S, Trivedi HB, Pancha I, Bhatt JK, Dave BP, Mishra S (2015) Polyhydroxyalkanoate from marine Bacillus megaterium using CSMCRI’s dry sea mix as a novel growth medium. Int J Biol Macromol 76:254–261

Sharma P, Bajaj BK (2015) Production and characterization of poly-3-hydroxybutyrate from Bacillus cereus PS 10. Int J Biol Macromol 81:241–248

Singh G, Kumari A, Mittal A, Goel V, Yadav A, Aggarwal NK (2013) Cost effective production of poly-β-hydroxybutyrate by Bacillus subtilis NG05 using sugar industry waste water. J Polym Environ 21:441–449

Obruca S, Marova I, Snajdar O, Svoboda Z (2010) Production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by Cupriavidus necator from waste rapeseed oil using propanol as a precursor of 3-hydroxyvalerate. Biotechnol Lett 32:1925–1932

Anjum A, Zuber M, Zia KM, Noreen A, Anjum MN, Tabasum S (2016) Microbial production of polyhydroxyalkanoates (PHAs) and its copolymers: a review of recent advancements. Int J Biol Macromol 89:161–174

Masood F, Hassan F, Ahmed S, Chen P, Hameed A (2012) Biosynthesis and characterization of poly-(3-hydroxybutyrate-co-3-hydroxyvalerate) from Bacillus cereus S10. J Polym Environ 20:865–871

Lathwal P, Nehra K, Singh M, Rana JS (2015) Optimization of culture parameters for maximum polyhydroxybutyrate production by selected bacterial strains isolated from rhizospheric soils. Pol J Microbiol 64(3):227–239

Randria S, Renard E, Guerin P, Langlois V (2003) Fourier transform infrared spectroscopy for screening and quantifying production of PHAs by Pseudomonas grown on sodium octanoate. Biomacromolecules 4:1092–1097

Lopez NI, Pettinari MJ, Stackebrandt E, Tribelli PM, Potter M, Steinbuchel A, Mendelez BS (2009) Pseudomonas extremaustralis sp. nov., a poly(3-hydroxybutyrate) producer isolated from an Antarctic environment. Curr Microbiol 59(5):14–519

Biradar GG, Shivasharana CT, Kaliwal BB (2017) Characterization of polyhydroxybutyrate (PHB) produced by novel bacterium Lysinibacillus sphaericus bbkgbs6 isolated from soil. J Polym Environ 25:1–17

Arcos-Hernández M, Laycock B, Donose BC, Pratt S, Halley P, Al-Luaibi S, Werker A, Lant PA (2013) Value-added bioplastics from services of wastewater treatment. Eur Polym J 49:904–913

Acknowledgements

The authors wish to express their sincere thanks to the management of SRM Institute of Science and Technology and Department of Biotechnology for the research facilities and their constant support throughout this research study. We would also like to thank Dr. M. Venkatesh Prabhu, Assistant Professor (S.G) for his technical help during this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Das, S., Majumder, A., Shukla, V. et al. Biosynthesis of Poly(3-hydroxybutyrate) from Cheese Whey by Bacillus megaterium NCIM 5472. J Polym Environ 26, 4176–4187 (2018). https://doi.org/10.1007/s10924-018-1288-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-018-1288-2