Abstract

Functional, active and intelligent films were prepared from biopolymeric matrices (plantain starch and pre-gelatinized plantain flour) with and without the addition of a natural filler (blackberry pulp) using the casting methodology. A thorough examination of the physicochemical, antioxidant and antimicrobial properties of the both the matrices used and the developed films was then carried out. The films developed from matrices incorporating the blackberry pulp were more amorphous, thicker, less sensitive to moisture, and with higher melting temperatures than the films made without this natural filler. The degree of substitution, average molecular weight and attenuated total reflectance Fourier transform infrared spectroscopy of the films made with blackberry pulp suggest that the starch chains were cross-linked. This is probably because the citric acid contained in the pulp functions as a cross-linking agent. Films with added blackberry pulp responded to changes in pH, i.e. were pH-sensitive, and also showed antimicrobial activity especially against Escherichia coli. In general, the addition of blackberry pulp improved the physicochemical and mechanical properties of the films developed due to cross-linking, as well as increasing their antioxidant activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The development of new and improved packaging concepts is currently focused on extending food shelf-life, while maintaining and monitoring safety and quality. This differs considerably from traditional packaging, which in principle should be completely inert [1]. With this in mind, “active and intelligent” (A&I) packaging offers numerous innovative solutions for extending shelf-life as well as maintaining, improving and monitoring food quality and safety [2, 3]. The principles behind A&I packaging are based on the intrinsic properties of the polymers used as packaging materials, either alone or with the introduction (inclusion, entrapment etc.) of specific substances within the polymer [4, 5]. However, one of the major risks of these types of packaging materials is the unintentional migration of substances from the packaging towards foodstuffs. For example, antimicrobial systems operation with non-intended migration in contact with foods (e.g. silver or silver based systems, other immobilized or grafted biocides) are known to exhibit some degree of movement [6]. Other hazards associated with A&I packaging could arise from insufficient labelling or non-efficacious. The risk factors mentioned have meant that the penetration of A&I packaging in the European market is limited compared with Japan, USA or Australia [6]. In addition, the high cost of these systems, legislative restrictions and even some reluctant retailers and brand owners have slowed the acceptance of these materials. This last because these systems could reveal possible irregularities, e.g. in the management or control of the cold chain.

Active packaging can be classified into two main types: non-migratory active packaging that acts without intentional migration, and active releasing packaging which allows the controlled migration of non-volatile agents or the emission of volatile compounds into the atmosphere surrounding foods. Intelligent first-generation indicator packaging can be used as an ‘‘indirect indicator’’ of external or internal changes in a food product’s environment, such as the polymerization rate, diffusion, chemical or enzymatic reactions. The most commonly used of these visual indicators are critical pH indicators, temperature indicators, time/temperature indicators and leak indicators [7].

The use of natural dyes for the determination of pH changes in foods has been reported in the literature [8,9,10,11,12]. Color changes in such dyes are due to presence of phenolic or conjugated substances such as anthocyanins, which undergo structural changes when the pH varies [13]. Fruits containing anthocyanins such as blackberry (Rubus glaucus) pulp can thus be used as natural pH indicators.

Moreover, blackberries contain several polyphenolic compounds which, both individually and in synergy, exhibit biological activity beneficial for human health. These include anti-oxidant, anti-microbial, anti-inflammatory and anti-carcinogenic properties [14,15,16,17,18]. In addition, blackberries have been proposed a possible treatment of hyperglycemia and hypertension associated with type two diabetes [19], degenerative diseases such as Alzheimer’s and Parkinson’s, and malaria [20].

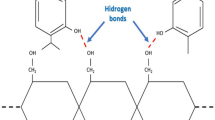

Furthermore, citric acid found in blackberries [21] may produce cross-linking between starch chains [22,23,24,25,26]. Cross-linking reactions increase the average molecular weight of the starch [27] and introduce chemical bridges between different molecules. This makes the starch more resistant to moisture and also helps to enhance both the mechanical and barrier properties [22].

Many natural polymers, such as starchy matrices (starches and flours) and other biopolymers have been used as vehicles of additives in food packaging, due to their biodegradability, non-toxicity and biological properties [28,29,30,31]. Nevertheless, these materials have some drawbacks such as their susceptibility to absorb water, due to their hydrophilic nature [32]. Several alternatives have been proposed to improve the properties of these packaging materials, such as physical and/or chemical modifications [33,34,35,36,37,38]. However, modifications produced by treating the raw materials such as pre-gelatinized plantain flour have not been evaluated.

The incorporation of blackberry pulp in edible films based on native plantain starch and pre-gelatinized plantain flour is an interesting proposal as it could reduce post-harvest losses in fruits. Furthermore, it would help promote fruit marketing, since today’s consumers are interested in foods that provide health benefits (functional foods). The pigments found in blackberries (anthocyanins) could enable us to formulate edible, intelligent, active and biodegradable films that are acceptable to both consumers and legislative bodies.

The aim this study was to develop and characterize food packaging materials based on either native plantain starch or pre-gelatinized plantain flour, with and without the incorporation of blackberry pulp, for their potential application as functional, active and intelligent packaging systems.

Experimental

Materials

Native plantain starch was extracted from a sole variety of plantain (Musa ssp., group AAB, sub-group clone Harton). The plantains used had a degree of ripeness of 1, according to Loesecke’s scale [39] and were acquired at a local market in Caracas, Venezuela. Starch was extracted using the methodology described by Pérez et al. [40] obtaining a yield of approximately 30%. Pre-gelatinized plantain flour was prepared using the method described by Pacheco [41]. Plantains were boiled in water at 100 °C in open containers for 45 min. with their skins on, before peeling and slicing. The plantain slices were then dried in a Mitchell dehydrator (Model 645 159) for 24 h at 45 °C. The dried slices were milled and then passed through a 60-mesh sieve, obtaining a yield of approximately 40% of pre-gelatinized plantain flour. Blackberry (Rubus glaucus) pulp was prepared according to the methodology proposed by Rivero [42]. Commercially ripened fruit was purchased from a local market in the town of Colonia Tovar, Estado Vargas, Venezuela. The fruits were selected discarding diseased or discolored fruits. Blackberry pulp was obtained by liquefying 500 g of fruit without adding water, and then filtering in order to remove fibrous material. The pulp was maintained refrigerated at 5 °C in a dark container whilst the films were developed. This was done on the same day the pulp was prepared in order to avoid oxidative damages. The bacterial strains used in this study were common species: Staphylococcus aureus (ATCC 25923) was selected as an example of Gram positive bacteria, and Escherichia coli (ATCC 25922) of Gram negative bacteria. Both bacteria were obtained from Aldrich. Glycerol from Prolabo, Sweden, was employed as plasticizer in the formation of the films.

Characterization of the Matrices Used and Blackberry Pulp

The chemical composition of the matrices and the blackberry pulp was determined. Moisture content, ash, fat, crude protein (N × 6.25) (obtained by the micro-Kjeldahl method) were calculated using the gravimetric method [43]. Crude fiber was determined by the method proposed by Van Soest and Wine [44], and total amylose content by the differential scanning calorimetry (DSC) method described by Pérez et al. [45, 46]. Starch purity was calculated by subtracting the percent of the ash, crude protein and fatty materials, from 100% of sample. Total carbohydrates were determined by subtracting percent water content, ash, crude protein and fatty materials, from 100% of sample. Total polyphenol content in the matrices and blackberry pulp was determined using the Folin–Ciocalteu method [47] with modifications by Dewanto et al. [48]. Total polyphenols were calculated from a standard gallic acid equivalent (GAE) curve within a concentration range of 5–100 ppm. Absorbance of the patterns and samples was measured at 760 nm. Results were expressed as ppm of total polyphenols. Citric acid content was estimated by the acetic anhydride and pyridine method described by Marier and Boulet [49]. Total anthocyanins were determined according to the method proposed by Hassimotto et al. [50]. Anthocyanin concentration was expressed as mg of pigment/100 g of pulp. Absorbance of the patterns and samples was measured at 532 nm. Color parameters of the starch and flour were obtained using a Macbeth Colorimeter model Color-eye 2445 using the CIE-L*a*b* scale. Water activity (a w ) of the starch and flour was determined using a psychrometric a w meter Aqualab Cx-2 (Decagon Devices, Pullman, USA) previously calibrated with water at 25 °C. The rheological characteristics of the starch and flour were determined through the interpretation of data obtained from a Brabender® Rapid-Visco-Analyser (RVA), Micro Visco-Amylo-Graph model, Duisbur’s, Germany, and examined using the Viscograph program (Version 2.4.9). A suspension of 100 mL of 7% starch solids (dry basis to 14% moisture) was prepared, and then gradually heated in the RVA from 30 to 90 °C at a constant rate (6 °C/min), before cooling at the same rate. Initiation of gelatinization (A), maximum viscosity (B), stability “breakdown” (breakdown = maximum viscosity − viscosity at the end of the heating period at 90 °C), settling “setback” (setback = viscosity at the start of the cooling period at 50°C − maximum viscosity) and consistency (consistency = viscosity at the start of cooling period at 50°C − viscosity at the end of heating period at 90 °C) were then calculated [51]. The morphology of the starch and flour granules was observed by optical microscopy with polarized light [46, 51].

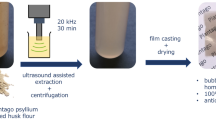

Film Formation

Films containing 2% w/v of either native plantain starch or pre-gelatinized plantain flour, 1.9% w/v glycerol and 500 mL distilled water were prepared following the methodology described by Gutiérrez et al. [52, 53]. For the films with 4% blackberry pulp, this was added 2 min. before the end of the film-forming solution (FFS) process in order to preserve the blackberry pigments, and to ensure a homogeneous distribution. The gel obtained was poured into stainless steel trays 40 × 30 cm and dried in a Mitchell dehydrator (Model 645 159) for 24 h at 45 °C. The resulting thermoplastic starch films and flour films: native plantain starch (TPS-NPS), native plantain starch with added blackberry pulp (TPS-NPSB), pre-gelatinized plantain flour (TPF-PPF) and pre-gelatinized plantain flour with added blackberry pulp (TPF-PPFB) were then carefully removed from the casting molds. The films were then conditioned with a saturated solution of NaBr (a w ∼ 0.575 at 25 °C) for seven days prior to each test. This was done at a set water activity, since it is well known that the properties of biopolymer-based films are modified under different relative humidity conditions [54]. During this period the containers were protected from light in a dark room in order to avoid pigment photodegradation. Films used for determining water activity (a w ) were not conditioned.

Characterization of the Films

Determination of Degree of Substitution (DS) in the Starch Films Esterified with Citric Acid from Added Blackberry Pulp

The amount of citric acid esterified in films with added blackberry pulp was determined by the method described by Klaushofer et al. [55]. This is based on the reaction of citric acid and Cu2+ which forms a stable complex during titration with a solution of copper sulfate. DS was calculated based on the average number of substituent groups per anhydroglucose unit, as follows [56]:

where W (% by weight of substituent) = [bound citrate (g)/sample (g) bound citrate (g)] × 100, and M = molecular weight of the citric acid substituent (175.1 g/mol). Each sample was analyzed in triplicate.

Determination of the Average Molecular Weight (M w) of the Developed Films Using an Ostwald Viscometer

Dimethyl sulfoxide (DMSO) was used as a solvent for preparing solutions at 1% w/v for each film assessed. Successive dilutions were then prepared to give further solutions at 0.125, 0.25 and 0.50% w/v. The resistance time to flow of the prepared solutions was then determined, taking as a reference their passage between two areas marked in the Ostwald viscometer (Cannon–Fenske 200 series, model 120205, IVA, Argentina) at 25.0 ± 0.1 °C. After obtaining the residence times of the different solutions the relationship ηexp/C, empirically demonstrated by Kramer [57] and Huggins [58], was calculated using Eq. 2, which have also been used by Gutiérrez and González [59, 60] and Gutiérrez and Alvarez [61] for similar materials:

where ηexp is the intrinsic viscosity (η–ηo/ηo); ηo is the viscosity of pure solvent; C is the concentration of solutions %w/v; t is the residence time of the solutions and to is the residence time of the pure solvent.

By using Eq. 3:

Graphing ηexp/C versus C, a straight line with a cut point equal to η was obtained. Simultaneously, using the Mark-Houwink-Sakurada-Staudinger equation (Eq. 4):

where η is the intrinsic viscosity, Mw is the polymer molecular weight, K and a constants reported for the solvent used (DMSO); K = 0.0112 mL/g at 25 °C and a = 0.72 at 25 °C.

Finally, the average molecular weight (Mw) of the films tested was calculated from Eq. 5:

Thickness

Film thickness (e) was determined using a digital micrometer (Micromaster®, Mitutoyo, USA) with 0.001 mm accuracy. Measurements were taken from eighteen random positions on each sample. The mean values were utilized for determining the mechanical properties.

Moisture Content

The moisture content of the different films evaluated was determined by initially weighing each sample using a digital weighing scale (Wi). Samples were then dried in an oven at 105 °C for 24 h and reweighed (Wf). Eq. 6 was formulated to calculate the moisture content of each film sample. Tests were carried out in triplicate and the final moisture content of each film recorded as the mean of the results.

Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy (ATR/FTIR)

Infrared spectra of the film samples were recorded on a Nicolet 8700 (Thermo Scientific Instrument Co., Madison, Wisconsin, USA) Fourier transform infrared (FTIR) spectrometer using the single reflection horizontal attenuated total reflectance (ATR) accessory, Smart Orbit, with a diamond crystal at an incident angle of 45°. FTIR spectra were collected by recording 40 scans at a resolution of 4 cm− 1 in a 4000–600 cm− 1 wave range. Each sample was scanned three times, observing good reproducibility.

Water Solubility

Three replicas (~ 0.5 g) from each system evaluated were weighed to determine the initial mass of the films (Wi). Each sample was then immersed in 50 mL of distilled water and kept at 25 °C for 24 h. The insoluble portions of the film samples were separated from the soluble matter in the water and dried in an oven at 105 °C for 24 h. The oven dried samples were then reweighed to measure the weight of the solubilized dry matter (Wf). The water solubility of each film was determined by Eq. 7.

Water Activity (a w)

A psychrometric a w meter Aqualab Cx-2 (Decagon Devices, Pullman, USA) previously calibrated with water at 25 °C was used to determine the water activity of the films. The average value of three measurements was reported.

Scanning Electron Microscopy (SEM)

The morphology of the cryo-fractured surface of each material was investigated using a JEOL JSM-6460 LV instrument. Films were cryo-fractured by immersion in liquid nitrogen. For analysis of the cryo-fractured surface, film samples were mounted on aluminium stubs with double-sided adhesive tapes and sputter coated with a thin layer of gold for 35 s.

Uniaxial Tensile Tests

A Stable Micro Systems texturometer, model TA-XT2i (Stable Micro Systems, Haslemere, Surrey, UK) (5 kg) with a tension grip system (mini tensile grips) was used for determining the force-distance curves. Film were mounted in the tensile grips (A/TG model) and stretched at a rate of 0.01 mm/s until they broke. Tests were conducted in an ambient temperature of 25 °C, and relative humidity around 57%. The force-distance curves were then transformed into stress–strain curves, which enabled calculation of the following parameters: Young’s modulus (E), maximum stress (σ m ), strain at break (ε b ) and toughness (T) as outlined in ASTM D882 [62]. At least ten trials were performed for each film system.

X-Ray Diffraction (XRD)

An X-ray diffractometer (Siemens D 5000) equipped with a copper anode X-ray tube was utilized to obtain X-ray diffraction patterns for each film sample. X-ray diffractograms of films were recorded for 2θ with the scanning region between 3° and 33° at a step size of 0.02° and scan speed of 2 s. XRD analyses of the film samples were conducted with Cu Kα radiation 1.5406 Å, at a voltage of 40 kV and a current of 30 mA. The thicknesses of the samples on the slides were ~ 200 μm. Percent crystallinity was then determined by measuring the relative intensity of the main peaks from the scattering spectrum according to Hermans and Weidinger [63].

Differential Scanning Calorimetry (DSC)

The melting temperature (Tm) of the films were determined using a DSC 823, Mettler Toledo (Schwerzenbach, Switzerland). Temperature and heat flux were calibrated using indium and zinc. Ten milligrams of samples contained in hermetically sealed aluminum pans were heated in the temperature range − 70 to 220 °C at a scanning rate of 10 °C min− 1, under nitrogen atmosphere. Changes of phase or state were determined from the heating thermogram. Tm was obtained from the peak of the heating curve, which was assigned to the middle temperature of the relaxation range [64, 65].

Color

A Macbeth® colorimeter in reflectance mode (Color-Eye 2445 model, illuminant D65 and 10° observer) was used to determine the CIE-L*a*b* coordinates of film surfaces exposed to drying. Lightness (L*), redness (a*) and yellowness (b*) were measured according to the standard test methods [66]. Tests were standardized with a white reference plate (L* = 93.52, a* = − 0.81 and b* = 1.58). Nine measurements were taken for each film.

Response to pH Changes

The response of films to pH changes was examined by placing samples of each system in solutions of pH equal to 1, 7 and 13, prepared from NaOH (0.1 M) and HCl (0.1 M). Film response was then evaluated from images taken with an 8.1 mega pixel Cyber-shot Sony camera; model DSC-H3 (Tokyo, Japan).

Total Polyphenols

The total polyphenol content of the developed films was determined by the Folin–Ciocalteu method [47] with modifications made by Dewanto et al. [48]. For this, ∼ 0.3 g of sample was mixed with 0.5 mL distilled water and 125 µL Folin–Ciocalteu reagent. After 6 min. 1 mL of distilled water and 1.25 mL of a solution of 7% Na2CO3 in water were added, and after a further 90 min. absorbance was measured at 760 nm. A standard gallic acid curve in a concentration range of 5–100 ppm was used to calculate total polyphenol content. Results were expressed as a percentage of total polyphenols.

Antioxidant Capacity

The antiradical capacity was determined by means of the 2,2-diphenyl-1-picrylhydrazyl radical (DPPH·) method [67], which is based on the reduction of the DPPH radical by the antioxidants contained in a sample. The DPPH radical is stable in a 0.025 g L− 1 ethanol solution and has a purple color which is progressively lost as the sample containing antioxidants is added. Radical bleaching was determined at 515 nm and antioxidant activity was quantified using a Trolox calibration curve (water-soluble analogue of vitamin E). This method reflects the activity of antioxidant compounds, which are capable of donating protons for scavenging DPPH radicals [68]. Analyses were done using ~ 0.25 g of each sample, mixed with 975 µL of a DPPH solution (60 µmol in methanol). Absorbance was measured immediately (time 0) and again after 30 min. Results were expressed as percentages of inhibition.

where A o is the absorbance at time 0, and A30 is the absorbance after 30 min.

Antimicrobial Activity

Antimicrobial activity tests were carried out for each edible film system using the agar diffusion method according to Pranoto et al. [69]. Edible films were cut into 20 mm diameter discs and placed on Mueller Hinton agar (Himedia, Mumbai, India) plates, previously seeded with 0.1 mL of inoculum containing approximately 107 CFU/mL of the test bacteria (Staphylococcus aureus and Escherichia coli). The plates were then incubated at 37 °C for 24 h. Observations of the diameter of the inhibitory zone surrounding the film discs, and the contact area of edible film with the agar surface were then made. Experiments were done in triplicate. The activity of the films against the microorganisms used was classified by the diameters of the inhibition halos as follows: not active, diameter less than 8 mm; active, diameter 9–14 mm; very active, diameter 15–19 mm; extremely active, diameter greater than 20 mm [70]. Tests were performed twice: firstly on the day after the films were developed (day 1), and secondly 1 week after the films were developed (day 8).

Statistical Analysis

Statistical analyses of the experimental results obtained were performed by analysis of variance (ANOVA) using Minitab 16 software. Mean comparisons were conducted using Tukey’s test at a 0.05 level of significance.

Results and Discussion

Characterization of the Matrices and Blackberry Pulp Used to Formulate the Films

Table 4 in Appendix shows the chemical composition of the matrices and blackberry pulp. Differences in the moisture content between matrices were statistically significant (p ≤ 0.05). Similar results have been reported by Jay [71] for starchy matrices with a stable lifespan. Lower values of ash, protein, lipids, and crude fiber in the starch compared to the flour shows that these components were extensively extracted during starch preparation, as reported by Pelissari et al. [72]. Starch purity was very high confirming the efficiency of the purification process. This is consistent with Gutiérrez et al. [51] for cassava and cush–cush yam starches. Total amylose content in the starch was ~ 3.5 time higher than that of the flour. This was possibly a consequence of the decrease in other constituents of the starch such as ash, protein, lipids and crude fiber. A direct relationship was observed between moisture levels and the amylose content. This is as expected since amylose has a non-branched molecular structure that easily absorbs moisture from the atmosphere. The polyphenol content was higher in the flour than the starch, possibly due to the loss of these compounds during the extraction and purification of the latter. Fruit generally contains 2 to 3 times the total polyphenols contained in starch matrices [73], which agrees with the polyphenol content measured for the blackberry pulp. The chemical composition of the blackberry pulp, including the presence of citric acid and anthocyanins, was comparable to that reported by other authors [74]. As might be expected these substances were not found in the starch matrices.

Table 5 in Appendix shows the water activity (a w ) values for the matrices examined. A direct relationship between moisture content and a w was found, confirming that the matrices used are not susceptible to the growth of molds and yeasts. Similar results were reported by Gutiérrez et al. [12]. As regards the color parameters (Table 5 in Appendix). Higher L* values were found for the starch compared to the flour. Therefore, it can be said that the flour was darker than the starch. However, lower a* and b* values were obtained for the starch compared to the flour. This may be due to leaching of the pigments during starch extraction. The flour had the highest b* value indicating a tendency towards yellow, probably associated with carotenoids contained in the plantains. The b* and yellow index (Yl) parameters were adequately correlated, and both indicated a greater tendency towards yellow in the flour. Color difference (ΔE) was lower for the starch. Again, this result may be related to pigment loss during starch extraction, resulting in an increase in the whiteness index (WI) and a decrease in the Yl. Based on these ΔE values, starch can be recommended for its use in products requiring a uniform color (e.g., candies, ice creams, juices).

The rheological properties of the matrices used are summarized in Table 6 in Appendix. According to Rasper [75], Hoseney [76] and Zhou et al. [77] the pasting properties are influenced by granular size, the amylose/amylopectin ratio, starch molecular characteristics, the volume fraction of suspended solids, the affinity between hydroxyl groups of molecules, the molecular weight of amylose leached from the starch granules and the conditions of the thermal process used to induce gelatinization. The gelatinization temperature was higher for the flour than the starch, probably due to the higher ash, protein and lipid contents present in the former. In addition, maximum viscosity, breakdown and setback were noticeably higher for the starch compared to the flour.

According to Harper and Tribelhorn [78] starchy matrices with high maximum viscosity values have weak cohesive forces, and show severe swelling and heavy leaching of amylose into the surrounding medium. This fits well with the results obtained since the amylose content was higher in the starch than in the flour. The flour was more resistant to mechanical fragmentation than the refined starch. This behavior was confirmed by the breakdown values which represent granule fragmentation. Retrogradation was also higher in the starch than the flour (see setback values in Table 6 in Appendix). The significant differences in the pasting properties of the flour and the starch (p ≤ 0.05) suggest that interactions between other components in the flour, such as a reaction between the amylose and lipids, or between the protein and starch gel, may influence these properties. Similar results have been reported for banana flour and starch [79], and rice [80]. The paste consistency of the starch was higher than that of the flour. Thus, raw materials made from plantains could have potential applications as thickeners in products requiring sterilization such as sauces and baby foods [81].

Optical micrographs of the matrices used taken under polarized light are shown in Fig. 8 in Appendix. The starch granules contained in the two matrices were elongated and longitudinally oval in shape, and of variable sizes, but within the range reported by Pérez-Sira [82] and Osundahunsi [83], i.e. between 10 and 50 µm. Starch granules revealed no apparent damages, suggesting that the starch preparation technique used was adequate (Fig. 8a in Appendix). Figure 8a in Appendix also shows that starch crystallinity was maintained, since the Maltese cross was not altered. In contrast, the crystalline structure of the pre-gelatinized flour was lost and the disruption of the granules evident (Fig. 8b in Appendix).

Characterization of the Films

Degree of Substitution (DS) by the Titration Method

Table 1 shows the degree of substitution in films with added blackberry pulp. The citric acid found in the blackberry pulp produced the cross-linking of the starch matrices. Similar results were reported by Kapelko-Żeberska et al. [84] for other starches cross-linked with citric acid. The degree of substitution found for the TPS-NPSB film was higher than that of the TPF-PPFB film, suggesting that the systems based on starch sources with a higher amylose content were more susceptible to cross-linking with the blackberry pulp citric acid.

Average Molecular Weight (M w) of the Developed Films

Figure 1 shows the average molecular weights of the different films studied. The pre-gelatinized plantain flour films (TPF-PPF and TPF-PPFB) had the highest molecular weights. This is consistent with results reported by Yoo and Jane [85] for starches with low amylose values. The molecular weight of the developed films increased significantly (p ≤ 0.05) when the blackberry pulp was added. According to Mizoguchi and Ueda [86] an increase in the average molecular weight of these types of materials is related to the cross-linking of polymers. Thus, the organic acids contained in blackberry pulp, in particular citric acid, produce the cross-linking of the starch chains leading to an increase in the average molecular weights of the films. Similar average molecular weight values have been reported by Yoo and Jane [85] for these types of materials.

Thickness

Table 1 shows the thicknesses of the different systems studied. The films based on native plantain starch (TPS-NPS and TPS-NPSB) were thicker than those based on pre-gelatinized plantain flour (TPF-PPF and TPF-PPFB). According to Gutiérrez et al. [87] a greater interaction between the starch and the plasticizer could lead to thicker films. This means that films derived from native plantain starch interact more strongly with the glycerol than the pre-gelatinized plantain flour films (Table 4 in Appendix). This fits well with results reported by Gutiérrez et al. [52] since films with a higher amylose content are generally thicker.

Furthermore, the films with added blackberry pulp (TPS-NPSB and TPF-PPFB) were at least 14% thicker compared those without blackberry pulp (TPS-NPS and TPF-PPF). Pérez et al. [88] reported a significant increase in the thickness of cross-linked starch-based films derived from Dioscorea trífida. Cross-linking apparently strengthens the internal bonds of starch grains. The cross-linking reactions also produce starches with higher molar volumes, as well as higher molecular weights [89]. These factors, together with a greater interaction between the starch and the plasticizer during gelatinization, could result in thicker films [87]. This would fit well with the observed increase in the molecular weight of films with added blackberry pulp (TPS-NPSB and TPF-PPFB, Fig. 1).

Moisture Content

Table 1 shows the moisture contents of the different films studied. This was significantly lower (p ≤ 0.05) in the films with added blackberry pulp (TPS-NPSB and TPF-PPFB) (p ≤ 0.05) compared to films without blackberry pulp (TPS-NPS and TPF-PPF), suggesting that there is a stronger glycerol-matrix interaction in the former. As we know, interactions in these systems occur through polar groups. These could be blocked in developed edible films, thereby reducing their sensitivity to moisture. This behavior could also, however, be due to the cross-linking of the matrices with the blackberry pulp citric acid as this produces strong hydrogen bond interactions between the polymer and the plasticizer, thus limiting water absorption by the polar groups of these matrices [22, 90]. It is also worth remembering that the cross-linking of the starch chains occurs through the hydroxyl groups from this macromolecule, whereby hydroxyl groups become nucleophilic in the addition reaction with the carboxyl group of citric acid. This then causes the loss of the hydroxyl groups, thereby decreasing the susceptibility of the polymer to moisture absorption. Moisture content was notably lower in the TPS-NPSB film, confirming a greater degree of starch cross-linking. It is interesting that starch was the matrix with the highest amylose content, suggesting that cross-linking occurs preferentially in the amylose. These results agree with those reported by Cyras et al. [91] in their study of films based on acetylated potato starch. Similar behavior has also been recently reported by Gutiérrez et al. [92, 93] for edible films derived from cassava, and cush–cush yam starch, as well as films prepared from plantain flour chemically modified by cross-linking with sodium trimetaphosphate (STMP).

Finally, the starch-based films (TPS-NPS) showed a higher moisture content compared to the films made from flour (TPF-PPF). This can be explained by the higher concentrations of amylose contained within it. Amylose is non-branched, a characteristic that makes it more susceptible to water absorption from the environment.

Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy (ATR/FTIR)

Figure 2A shows the ATR/FTIR spectra for the different films studied throughout the absorption range. A significant absorption peak around 3325 cm− 1 (stretching of the OH group contained in the starch, glycerol and water) associated with the stretching vibrations of the C–O groups was observed for all the studied systems [11, 94]. According to González et al. [90] and Gutiérrez et al. [93] materials with OH groups that vibrate more readily and/or form more hydrogen bonds tend to show wider and less intense bands. This fits well with the results obtained, since as can be clearly seen in the region between 3600 and 3000 cm− 1 (Fig. 2B), the transmittance of the films with added blackberry pulp was higher than the other films, i.e. band intensities were lower. This further demonstrates that adding blackberry pulp produces strong hydrogen bond interactions in the developed films. The lower intensities of the bands associated with the OH groups could be also related to the lower moisture content and loss of hydroxyl groups in starch with cross-linked polymeric chains. Similar results were recently reported by González et al. [90] for films based on cassava starch cross-linked with citric acid. The peaks at 2885 and 2934 cm− 1 are associated with C–H stretch vibrations [95] and are characteristic of polymeric matrix materials. The band at around 2893 cm− 1 tended to increase for the films with added blackberry pulp. Other bands that can be identified are those corresponding to C=O bending at ~ 2150 cm− 1 and OH bending at ~ 1644 cm− 1 [94, 96, 97]. In addition, bands appearing between 1300 and 1430 cm− 1 are assigned to C-O angular deformations [98]. Specifically, the band detected at ~ 1415 cm− 1 is associated with the symmetric stretching of carboxyl groups (–COO) [99]. At around 1644 cm− 1 there is an absorbance band that is sensitive to both H-bonding and the number of hydroxyl interactions [100].

A FTIR spectra of the different films studied in all the absorption range: a native plantain starch (TPS-NPS), b native plantain starch with incorporation of blackberry pulp (TPS-NPSB), c pre-gelatinized plantain flour (TPF-PPF) and d pre-gelatinized plantain flour with incorporation of blackberry pulp (TPF-PPFB). B FTIR spectra in the range of absorption corresponding to C–O group (OH stretching) of the different films studied: a native plantain starch (TPS-NPS), b native plantain starch with incorporation of blackberry pulp (TPS-NPSB), c pre-gelatinized plantain flour (TPF-PPF) and d pre-gelatinized plantain flour with incorporation of blackberry pulp (TPF-PPFB)

Specifically, the band located at 1720 cm− 1 in films with added blackberry pulp (TPS-NPSB and TPF-PPFB) could be assigned to C=O groups from esters formed between the citric acid found in the blackberry pulp and the starch-containing matrices, thus confirming the effect of the cross-linking proposed (Fig. 2A). Comparable results were reported by González et al. [90] for films derived from cassava starch cross-linked with citric acid. Finally, the band located at 1720 cm− 1 was more intense for the TPS-NPSB film than the TPF-PPFB film, reinforcing the idea that cross-linking occurs to a greater degree in native plantain starch compared to pre-gelatinized plantain flour.

Water Solubility

Table 1 shows the water solubility values at 25 °C for the different systems studied. The solubility of edible films provides an indication of their integrity in an aqueous medium, such that higher solubility values indicate a lower resistance to water [33]. It can be seen from Table 1 that the plantain starch-based films with added blackberry pulp (TPS-NPSB) were significantly (p ≤ 0.05) less water soluble than the plantain starch-based film without blackberry pulp (TPS-NPS). In a previous study, Gutiérrez et al. [87] found that films made from cross-linked starch were less hydrophilic than native starch-based films. These results are also consistent with the tendency reported by Pérez et al. [88] for native and phosphated Dioscorea trifida white starch-based edible films. The lower solubility of the modified starch films results from an increase in DS. The fact that films with added blackberry pulp are less soluble gives additional weight to the argument that the starch in these systems has undergone cross-linking. This behavior was not statistically significant (p ≥ 0.05) for the pre-gelatinized plantain flour, however, supporting the idea that cross-linking occurred preferentially in the matrix with the highest amylose content (starch). As regards the films without added blackberry pulp, TPS-NPS systems were more soluble than TPF-PPF ones confirming that the former were more hydrophilic.

Water Activity (a w)

The water activity of the films is reported in Table 1. As can be seen, higher a w values were obtained for samples made from the matrices (starch and flour) without added blackberry pulp which correlated positively with their higher moisture content. Pérez et al. [88] and Rojas [101] reported similar results for cross-linked white Dioscorea trifida edible coatings and potato starch-based films, respectively. Based on the results of these authors, the water activity values obtained do not allow microbial growth. In the same manner, a direct relationship between a w and moisture content was found.

Scanning Electron Microscopy (SEM)

Figure 3 shows the SEM images of the cryofractured surfaces of the different films. All the systems examined showed a compact structure, but this was far more marked in the films made from native plantain starch (TPS-NPS and TPS-NPSB). Similar morphologies have been reported by García et al. [102] for cassava starch-glycerol films. According to Miles et al. [103] and Noel et al. [104] these microstructures are associated with a high amylose content. This is consistent with the higher amylose content of the native plantain starch compared to the pre-gelatinized plantain flour (Table 4 in Appendix). In one of the samples of the TPS-NPS film a granular particle of retrograded starch was observed. This fits well with the results of the rheological properties of the starch, since starch had greater tendency to retrograde than the pre-gelatinized plantain flour (Table 6 in Appendix).

SEM micrographs of the cryogenic fractured surface of the films: native plantain starch (TPS-NPS), native plantain starch with incorporation of blackberry pulp (TPS-NPSB), pre-gelatinized plantain flour (TPF-PPF) and pre-gelatinized plantain flour with incorporation of blackberry pulp (TPF-PPFB). At 1.5kX of magnification. Black lines indicate granular particles

According to Pelissari et al. [37] starch-based films with a more compact structure will absorb less water, since interactions between the starch-glycerol and water are less likely. The more compact microstructures of the films developed with added blackberry pulp (TPS-NPSB and TPF-PPFB) compared to the films without added blackberry pulp (TPS-NPS and TPF-PPF) are consistent with the lower moisture values registered for the former (Table 1).

Uniaxial Tensile Strength

The stress–strain curves of each film system studied are shown in Fig. 4. A small linear zone followed by a nonlinear zone until breaking point was observed, regardless of the matrix used. Lourdin et al. [105] and Alves et al. [106] reported that Young’s modulus increases linearly with amylose content. Nevertheless, no statistically significant differences (p ≥ 0.05) in Young’s modulus between the TPS-NPS and TPF-PPF films were found. A significant decrease (p ≤ 0.05) in Young’s modulus was, however, observed for the native plantain starch-based films plus blackberry pulp (TPS-NPSB).

The highest breaking stress values were registered for the TPS-NPS films, possibly due to the retrograded starch grains present in this material (Fig. 3). This agrees with our current understanding that crystalline particles may act as nuclei for inducing the recrystallization (retrogradation) of starch macromolecules [107] leading to a more fragile material [102]. In contrast, the TPS-NPSB films with added blackberry pulp showed the lowest breaking stress values. Similar results were reported by Gutiérrez et al. [12] who compared the breaking stress of native plantain flour-based films with films derived from chemically modified plantain flour by cross-linking with STMP. This further demonstrates that adding blackberry pulp to plantain starch results in a greater degree of cross-linking of the starch matrix.

In general, films with higher amylose content show greater elongation values [108]. This would be in line with the results obtained in this study, since plantain starch-based films showed the highest values of strain at break (Table 4 in Appendix and Table 2). Similarly, the incorporation of blackberry pulp significantly increased (p ≤ 0.05) the strain at break values. Comparable results were by Gutiérrez et al. [52] for films made from cross-linked starches.

Saavedra and Algecira [109] proposed that cassava starch-protein films have higher elasticity values due to their more compact structure. This agrees with our results in which the SEM images obtained for the plantain starch-based films (Fig. 3) correspond to the greater elasticity measured.

As is well known, toughness is a mechanical property associated with the energy existing between molecular bonds within a material. The higher toughness values in the films derived from plantain starch (TPS-NPS and TPS-NPSB) thus indicate stronger intermolecular interactions. This is consistent with all the results obtained here. Materials with high toughness values could prove extremely useful, as they could be used to produce films that absorb more energy without this being transmitted to the packaged foods. This could minimize the damage caused by impacts to the food during transport and storage.

X-Ray Diffraction (XRD)

Figure 5 shows the X-ray diffraction patterns of the developed films. Zullo and Iannace [110] reported that the molecular order within starch granules is destroyed when films are heated during processing, resulting in an amorphous structure. Bearing in mind the work of Rindlav et al. [111], Angellier et al. [112], Kristo and Biliaderis [113] and Tapia et al. [114] it can be said that the films studied were mostly amorphous, with only a small crystalline fraction.

According to Pérez et al. [88] and Tapia et al. [114] the crystallinity of starch films is mainly associated with their amylose content since this has an almost linear structure, unlike amylopectin which is highly branched. The crystallinity percentage values calculated from the surface area under the curves confirmed this (Table 1) namely, that films made from the starch with the highest amylose content showed higher percent crystallinity values. According to the literature, the crystallinity of these systems occurs primarily due to starch retrogradation [88, 114, 115]. This would also agree with the results of the rheological properties of the matrices (Table 6 in Appendix).

A lower degree of crystallinity was observed for the samples with added blackberry pulp. A similar phenomenon was observed by González et al. [90] for films derived from cassava starch cross-linked with citric acid. As has already been indicated, the crystallinity of these systems occurs primarily due to starch retrogradation. This means that films with added blackberry pulp are less susceptible to retrogradation, i.e. are more stable. It is worth emphasizing that this behavior was not statistically significant (p ≥ 0.05) in the case of the TPF-PPFB film, thus further demonstrating that cross-linking is more likely in the presence of amylose.

The peak at 2θ ≅ 17° (Fig. 5) is characteristics of an A-type crystalline structure, and is associated with the glycerol-amylose complex [116,117,118]. According to García-Tejeda et al. [38], however, this signal is also related to interactions between the short external amylopectin chains and the glycerol.

Figure 5 also shows a peak at 2θ ≅ 19.5° corresponding to a V-type crystalline structure [119]. Zobel et al. [119] have suggested that an increase in the development of this structure is related to an increase in the number of amylose-glycerol interactions. This analysis thus agrees with that previously established. Finally, a peak at 2θ ≅ 22° corresponding to a B-type crystalline structure was observed [37].

Differential Scanning Calorimetry (DSC)

Table 1 shows the DSC results of the different films studied. As a general rule, any structural feature that reduces the mobility of polymer chains or the free volume will cause an increase in Tm [37, 93, 120,121,122,123,124]. Thus, high Tm values may be attributed to an increase in the cohesive forces between the polymer chains, resulting from the cross-linking of the starch. An increase in the Tm in the TPS-NPSB and TPF-PPFB films is thus related to cross-linking caused by the blackberry pulp added to these films. The Tm values were higher in the TPS-NPSB film compared to the TPF-PPFB film, thus reinforcing the theory that the blackberry pulp reacts most readily with starch, thus increasing the DS in this material.

On the other hand, lower Tm values were observed in the plantain starch-based film (TPS-NPS) compared to the pre-gelatinized plantain flour-based film (TPF-PPFB). This suggests a stiffening effect in the latter, possibly due to a higher fiber content in this matrix that could act as a natural filler. Similar results were reported by Gutiérrez et al. [12] for films derived from plantain flour chemically modified by phosphation.

Color

Table 1 shows the results of the color parameters of the films studied. The greatest L* value was obtained for the TPF-PPF film, indicating that these systems were the most opaque. Films with added blackberry pulp (TPS-NPSB and TPF-PPFB) showed lower L* values, suggesting that the incorporation of this substance produces more transparent materials. According to Gutiérrez et al. [93] and Fakhouri et al. [125] stronger H-bonding interactions increase transparency. This fits well with the results since we have already seen that the addition of blackberry pulp strengthened the H-bonding interactions. Likewise, the tendency of the blackberry pulp to reduce percent of crystallinity (TPS-NPSB and TPF-PPFB films) suggests that more amorphous materials contain fewer obstacles to the passage of light, resulting in more transparent materials.

The incorporation of the blackberry pulp also increased the a* values, suggesting a tendency towards red probably due to blackberry pulp pigments (anthocyanins). A positive b* value indicates a tendency towards yellow. The films derived from pre-gelatinized plantain flour (TPF-PPF and TPF-PPFB) showed this tendency more significantly.

Response to pH Changes

Figure 6 shows the images of the responses of the films assayed at different pH values. As can be observed, the films with added blackberry pulp (TPS-NPSB and TPF-PPFB) changed in color in both the acid and alkaline mediums. Both films showed a purple-red coloration when exposed to an acid pH, this due to the formation of the flavylium cation (red color) of anthocyanins found in blackberry pulp. However, at an alkaline pH the TPS-NPSB became blue as a product of the quinoidal structure of anthocyanins at pH > 8, whereas the TPF-PPFB film changed to green, possibly as a result of the mix between the yellow color of carotenoids found in the matrix (plantain flour) with the quinoidal structure of anthocyanins (blue). Similar results have been reported by Pereira et al. [11] for films made from chitosan with the incorporation of anthocyanin extracts obtained from red cabbage. Thus films developed with added blackberry pulp show intelligent behavior, as they react to pH changes in the surrounding environment. These intelligent films could be applied in fishery products since the production and accumulation of amines, mainly ammonia, trimethylamine and histamine as a result of microbial growth, create an alkaline medium. This would cause films with added blackberry pulp to change in color, which could indicate a loss in quality of these types of food. Pereira et al. [11] used intelligent films with these same characteristics for packaging pasteurized milk, and Wallach [126] reported that these types of intelligent materials are more versatile than intelligent films activated by enzymatic reactions.

Total Polyphenols and Antioxidant Capacity of the Films

Figure 7 shows the total polyphenols content and antioxidant activity of the developed films. It is worth noting that a direct link between polyphenol content and antioxidant activity was found. Similar results were reported by Chang-Bravo et al. [127]. Both the films with added blackberry pulp (TPS-NPSB and TPF-PPFB) showed higher total polyphenol content and antioxidant capacity than films without pulp, confirming that the blackberries provide polyphenolic compounds and antioxidants to the developed films. Furthermore, the antioxidant activity of the blackberry pulp was maintained demonstrating that the polyphenolic compounds added were stabilized within the matrices. This means that blackberry pulp-containing films could provide large amounts of bioactive substances with potential beneficial health effects.

a Total polyphenols and b DPPH scavenging activity of the films evaluated: native plantain starch (TPS-NPS), native plantain starch with incorporation of blackberry pulp (TPS-NPSB), pre-gelatinized plantain flour (TPF-PPF) and pre-gelatinized plantain flour with incorporation of blackberry pulp (TPF-PPFB)

Regarding the films without blackberry pulp, the pre-gelatinized plantain flour-based film (TPF-PPF) showed a higher polyphenol content compared to the plantain starch-based film (TPS-NPS). This was attributed to the polyphenol content intrinsic to the matrix. Nevertheless, no statistically significant differences (p ≥ 0.05) in antioxidant capacity were observed between these two films.

Antimicrobial Activity

Table 3 shows the results of antimicrobial activity of the films developed against Staphylococcus aureus and Escherichia coli. According to the classification used by Ponce et al. [70], none of the films had significant antimicrobial activity. Nonetheless, they all showed some inhibitory activity against the microorganisms tested after 1 week of storage (day 8). This is consistent with the results of water activity obtained in this study, since lower water activity values in films make microbiological growth very unlikely.

On the other hand, the TPF-PPF film did show a greater inhibitory effect on the two microorganisms tested compared to the TPS-NPS film on day 1. This suggests that the higher polyphenol content of the pre-gelatinized flour could act as an antimicrobial against both microorganisms, although greater activity was registered against E. coli. According to García-Ruiz et al. [128] the inhibition mechanism employed by the citric acid and polyphenols mainly consists of causing damage to the cell walls of the bacteria. Similar results were reported by Raybaudi-Massilia et al. [129] who evaluated edible coatings made from alginate with added maleic acid and essential oils against two groups of microorganisms, one Gram positive and the other Gram negative. However, since the citric acid could all be used up in the cross-linking of the starch chains, it is unlikely to show antimicrobial activity. Thus, it is possible that the polyphenolic compounds are entirely responsible for the antimicrobial activity observed in the developed films.

It is worth highlighting that neither of the films with added blackberry pulp (TPS-NPSB and TPF-PPFB) presented antimicrobial activity after the first day of storage. However, they both showed activity on day 8. This is possibly because starch retrogradation occurred during storage exposing the polyphenolic compounds, which do show antimicrobial activity. Lower antimicrobial activity was found for the TPS-NPSB film compared to the TPF-PPFB film. Based on these results and taking into account the greater tendency to retrograde by part of the plantain starch compared to the pre-gelatinized plantain flour, it is likely that during storage the TPS-NPSB film undergoes retrogradation, exposing polyphenols to the environment. The exposed polyphenols then oxidize, thus losing their antimicrobial characteristics. In contrast, retrogradation of the pre-gelatinized plantain flour occurs at a lower rate, resulting in a less retrograded film, and allowing the polyphenolic compounds to be released over a longer period of time. Higher antimicrobial activity was also observed for the films based on pre-gelatinized plantain flour with and without the incorporation of blackberry pulp. This could be attributed to the higher concentrations of polyphenols provided by the blackberry pulp. Finally, the phenolic compounds in the blackberry pulp show a greater antimicrobial activity against Gram negative microorganisms such as E. coli.

Conclusions

Functional, intelligent and active films based on plantain starch and pre-gelatinized flour with and without added blackberry pulp were developed. The films responded to changes from an acid to an alkaline pH. The addition of blackberry pulp also produced cross-linking of the polymeric chains of the matrices. Films with added blackberry pulp demonstrated anti-microbial activity against the two microorganisms tested (E. coli and S. aureus), although there was greater inhibitory activity against E. coli. Finally, the antioxidant activity of the developed materials was directly related to their polyphenol content.

References

Losada PP, Cacho J, Iglesias MJ, Hernández-Agero TO, de la Puerta CN, Rodríguez RL (2011) Revista del Comité Científico de la AESAN, pp 89–105

Gontard N (2006) Tailor made food packaging concept. IUFoST, 13th World Congress of Food Science and Technology, Food is Life, September 2006, Nantes, France, pp 17–21

Yam KL (2012) Emerging food packaging technologies: principles and practice. Woodhead Publishing, Cambridge, pp 137–152

Gontard N (2000) In: Paris N, Gontard (eds) Les Emballages Actifs. Tech & Doc Editions, Lavoisier, France

Vanderroost M, Ragaert P, Devlieghere F, De Meulenaer B (2014) Trends Food Sci Tech 39:47–62

Dainelli D, Gontard N, Spyropoulos D,, Tobback P, Zondervan-van den Beuken E (2008) Trends Food Sci Tech 19:S103–S112

Restuccia D, Spizzirri UG, Parisi OI, Cirillo G, Curcio M, Iemma F, Puoci F, Vinci G, Picci N (2010) Food Control 21:1425–1435

Terci DBL, Rossi AV (2002) Quím Nova 25:684–688

Chigurupati N, Saiki L, Gayser C, Dash AK (2002) Int J Pharm 241:293–299

Mohd P, Khan A, Farooqui M (2011) J Adv Sci Res 2:20–27

Pereira VA Jr, de Arruda I.N.Q., Stefani R (2015) Food Hydrocolloid 43:180–188

Gutiérrez TJ, Guzmán R, Medina C, Famá L (2016) Int J Biol Macromol 82:395–403

Shahid M, Mohammad F (2013) J Clean Prod 53:310–331

Sharma M, Li L, Celver J, Killian C, Kovoor A, Seeram NP (2009) J Agr Food Chem 58:3965–3969

Adams LS, Zhang Y, Seeram NP, Heber D, Chen S (2010) Cancer Prev Res 3:108–113

Barrajón-Catalán E, Fernández-Arroyo S, Saura D, Guillén E, Fernández-Gutiérrez A, Segura-Carretero A, Micol V (2010) Food Chem Toxicol 48:2273–2282

Kasimsetty SG, Bialonska D, Reddy MK, Ma G, Khan SI, Ferreira D (2010) J Agr Food Chem 58:2180–2187

Sánchez T, Dufour D, Moreno IX, Ceballos H (2010) J Agr Food Chem 58:5093–5099

da Silva Pinto M, de Carvalho JE, Lajolo FM, Genovese MI, Shetty K (2010) J Med Food 13:1027–1035

Dell’Agli M, Galli GV, Bulgari M, Basilico N, Romeo S, Bhattacharya D, Bhattacharya D, Taramelli D, Bosisio E (2010) Malaria J 9:208

Kafkas E, Koşar M, Türemiş N, Başer K.H.C (2006) Food Chem 97:732–736

Olsson E, Hedenqvist MS, Johansson C, Järnström L (2013) Carbohyd Polym 94:765–772

Menzel C, Olsson E, Plivelic TS, Andersson R, Johansson C, Kuktaite R, Jarnstrom L (2013) K Koch Carbohyd Polym 96:270–276

Majzoobi M, Beparva P (2014) Food Chem 147:312–317

Wang S, Ren J, Li W, Sun R, Liu S (2014) Carbohyd Polym 103:94–99

Altamirano-Fortoul R, Hernández-Muñoz P, Hernando I, Rosell CM (2015) J Food Eng 163:25–31

Rutenberg MW, Solarek D (1984) Starch derivates: properties and uses. In: Whistler RL, Bemiller JN, Pachall EF (eds) Starch: chemistry and technology, 2nd edn, pp 312–388

Avella M, De Vlieger JJ, Errico ME, Fischer S, Vacca P, Volpe MG (2005) Food Chem 93:467–474

Fabra MJ, Busolo MA, Lopez-Rubio A, Lagaron JM (2013) Trends Food Sci Tech 31:79–87

Majeed K, Jawaid M, Hassan A, Bakar AA, Khalil HA, Salema AA, Inuwa I (2013) Mater Design 46:391–410

Yoshida CMP, Maciel VBV, Mendonça MED, Franco TT (2014) LWT—Food Sci Technol 55:83–89

Al-Hassan AA, Norziah MH (2012) Food Hydrocolloid 26:108–117

Romero-Bastida CA, Bello-Péreza LA, García MA, Martino MN, Solorza-Feria J, Zaritzky NE (2005) Carbohyd Polym 60:235–244

Zamudio-Flores PB, Bello-Pérez LA, Vargas-Torres A, Hernández-Uribe JP, Romero-Bastida CA (2007) Agrociencia 41:837–844

Sothornvit R, Pitak N (2007) Food Res Int 40:365–370

Pitak N, Rakshit SK (2011) LWT-Food Sci Technol 44:2310–2315

Pelissari FM, Andrade-Mahecha MM, do Sobral A, Menegalli FC (2013) Food Hydrocolloid 30:681–690

García-Tejeda YV, López-González C, Pérez-Orozco JP, Rendón-Villalobos R, Jiménez-Pérez A, Flores-Huicochea E, Solorza-Feria J, Bastida CA (2013) LWT-Food Sci Technol 54:447–455

Loesecke HV (1950) Bananas. Interscience, New York, p 189

Pérez E, Bahnassey Y, Breene W (1993) Starch-Stärke 45:211–214

Pacheco E (2001) Acta Científica Venezolana 52:278–282

Rivero AC (2008) Universidad Nacional de Colombia. Bogotá, Colombia

AACC (2003) Approved methods of the American Association of Cereal Chemists. Methods no. 44-15A, 30-10, 08-01, 46-13, 02-52, and 02-31. American Association of Cereal Chemists, St. Paul

Van Soest PU, Wine RH (1967) J Assoc Off Anal Chem 50:50–55

Pérez E, Gilbert O, Rolland-Sabaté A, Jiménez Y, Sánchez T, Giraldo A, Pontoire B, Guilois S, Lahon M-C, Reynes M, Dufour D (2010) J Agr Food Chem 59:263–273

Pérez E, Rolland-Sabaté A, Dufour D, Guzmán R, Tapia M, Raymundez M, Ricci J, Guilois S, Pontoire B, Reynes M, Gilbert O (2013) Carbohyd Polym 98:650–658

Singleton VL, Orthofer R, Lamuela-Raventos RM (1999) Method Enzymol 299:152–178

Dewanto V, Wu X, Adom KK, Liu RH (2002) J Agr Food Chem 50:3010–3014

Marier JR, Boulet M (1958) J Dairy Sci 41:1683–1692

Hassimotto N.M.A., da Mota RV, Cordenunsi BR, Lajolo FM (2008) Food Sci Technol (Campinas) 28:702–708

Gutiérrez TJ, Pérez E, Guzmán R, Tapia MS, Famá L (2014) J Polym Biopolym Phys Chem 2:1–5

Gutiérrez TJ, Tapia MS, Pérez E, Famá L (2015) Food Hydrocolloid 45:211–217

Gutiérrez TJ, Tapia MS, Pérez E, Famá L (2015) Starch-Stärke 67:90–97

Gontard N, Thibault R, Cuq B, Guilbert S (1996) J Agr Food Chem 44:1064–1069

Klaushofer H, Berghofer E, Steyrer W (1978) Ernährung/Nutrition 2:51–55

Mei JQ, Zhou DN, Jin ZY, Xu XM, Chen HQ (2015) Food Chem 187:378–384

Kramer EO (1938) J Ind Eng Chem 30:1200–1203

Huggins ML (1942) J Am Chem Soc 64:2716–2718

Gutiérrez TJ, .González G (2016) Food Bioprocess Technol 9:1812–1824

Gutiérrez TJ, González G (2017) Food Biophys 12:11–22

Gutiérrez TJ, Alvarez VA (2017) React Funct Polym 112:33–44

ASTM D882. pp 882–888

Hermans PH, Weidinger A (1961) Macromol Chem Phys 44:24–36

Chartoff RP (1981) In: Turi EA (ed) Thermal characterization of polymeric materials. vol 1, Academic Press, New York, pp. C3

Biliaredis CG, Lazaridou A, Arvanitoyannis I (1999) Carbohyd Polym 40:29–47

ASTM D-1925 (1995) Standard Test Method for Yellowness Index of Plastics. American Society for Testing and Materials, Philadelphia

Rincón AM, Tapia MS, Padilla FC (2003) Revista Facultad de Farmacia Universidad Central de Venezuela 66:73–78

Miller NJ, Rice-Evans CA (1997) Free Radical Res 26:195–199

Pranoto Y, Salokhe VM, Rakshit SK (2005) Food Res Int 38:267–272

Ponce AG, Roura SI, Valle CE, Moreira MR (2008) Postharvest Biol Tec 49:294–300

Jay JM (1996) Modern food microbiology, 5th edn. Chapman & Hall Publishing, New York

Pelissari FM, Andrade-Mahecha MM, Sobral PJDA, Menegalli FC (2012) Starch-Stärke 64:382–391

Saura-Calixto F, Goñi I (2006) Food Chem 94:442–447

Kaume L, Howard LR, Devareddy L (2011) J Agr Food Chem 60:5716–5727

Rasper V (1982) Theoretical aspects of amilographology. In: Shuey WC, Tipples KH (eds) The amylograph handbook, AACC, St. Paul

Hoseney (1986) Principles of cereal science and technology. Published by the American Association of Cereal Chemists, Inc., St. Paul

Zhou M, Robards K, Glennie-Holmes M, Helliwel S (1998) Cereal Chem 75:273–281

Harper JM, Tribelhorn RE (1992) In: Kokini JL, Ho CT, Karwe MV (eds) Food extrusion science and technology, Marcel Dekker Inc., New York, pp 653–667

da Mota RV, Lajolo FM, Cordenunsi BR, Ciacco C (2000) Starch-Stärke 52:63–68

Yu S, Ma Y, Menager L, Sun DW (2012) Food Bioprocess Tech 5:626–637

de la Torre-Gutiérrez L, Chel-Guerrero LA, Betancur-Ancona D (2008) Food Chem 106:1138–1144

Pérez-Sira E (1997) Starch-Stärke 49:45–49

Osundahunsi OF (2009) J Food Agric Environ 7:182–186

Kapelko-Żeberska M, Buksa K, Szumny A, Zięba T, Gryszkin A (2016) LWT-Food Sci Technol 69:334–341

Yoo SH, Jane JL (2002) Carbohyd Polym 49:307–314

Mizoguchi K, Ueda M (2008) Polym J 40:645

Gutiérrez TJ, Morales NJ, Tapia MS, Pérez E, Famá L (2015) Procedia Mater Sci 8:304–310

Pérez E, Segovia X, Tapia MA, Schroeder M (2012) J Cell Plast 48:545–556

Sívoli L, Pérez E, Rodríguez P, De Abrisqueta A, Raymúndez MB (2005) Acta Microscópica 14:5–9

González P, Medina C, Famá L, Goyanes S (2016) Carbohyd Polym 138:66–74

Cyras VP, Tolosa Zenklusen MC, Vazquez A (2006) J Appl Polym Sci 101:4313–4319

Gutiérrez TJ, Morales NJ, Pérez E, Tapia MS, Famá L (2015) Food Packag Shelf Life 3:1–8

Gutiérrez TJ, Suniaga J, Monsalve A, García NL (2016) Food Hydrocolloid 54:234–244

Xu YX, Kim KM, Hanna MA, Nag D (2005) Ind Crop Prod 21:185–192

Mathew S, Brahmakumar M, Abraham TE (2006) Biopolymers 82:176–187

Vicentini NM, Dupuy N, Leitzelman M, Cereda MP, Sobral PJA (2005) Spectrosc Lett 38:749–767

Silva-Pereira MC, Teixeira JA, Pereira-Júnior VA, Stefani R (2015) LWT-Food Sci Technol 61:258–262

Reis L.C.B., de Souza CO, da Silva J.B.A., Martins AC, Nunes IL, Druzian JI (2014) Food Bioprod Process 94:382–391

Kizil R, Irudayaraj J, Seetharaman K (2002) J Agr Food Chem 50:3912–3918

Famá L, Bittante A.M.B., Sobral PJ, Goyanes S, Gerschenson LN (2010) Mat Sci Eng C 30:853–859

Rojas C (2008) Trabajo Especial de Grado, Universidad Central de Venezuela. Caracas, Venezuela

García NL, Famá L, Dufresne A, Aranguren M, Goyanes S (2009) Food Res Int 42:976–982

Miles MJ, Morris VJ, Ring SG (1985) Carbohyd Res 135:257–269

Noel TR, Ring SG, Whittman MA (1992) Food Sci Technol Today 6:159

Lourdin D, Valle GD, Colonna P (1995) Carbohyd Polym 27:261–270

Alves VD, Mali S, Beleia A, Grossmann MVE (2007) J Food Eng 78:941–946

Mina JH, Valadez A, Herrera-Franco PJ, Toledano T (2009) Ingeniería y Competitividad 11:95–106

Muscat D, Adhikari B, Adhikari R, Chaudhary DS (2012) J Food Eng 109:189–201

Saavedra N, Algecira N (2010) NOVA-Publicación científica en ciencias biomédicas 8:171–182. ISSN:1794–2470

Zullo R, Iannace S (2009) Carbohyd Polym 77:376–383

Rindlav A, Hulleman S.H.D., Gatenholm P (1997) Carbohyd Polym 34:25–30

Angellier H, Molina-Boisseau S, Dole P, Dufresne A (2006) Biomacromolecules 7:531–539

Kristo E, Biliaderis CG (2007) Carbohyd Polym 68:146–158

Tapia MS, Pérez E, Rodríguez P, Guzmán R, Ducamp-Collin MN, Tran T, Rolland-Sabaté A (2012) J Cell Plast 48:526–544

Morales NJ, Candal R, Famá L, Goyanes S, Rubiolo GH (2015) Carbohyd Polym 127:291–299

Zobel HF (1994) Starch granule structure. In: Alexander RJ, Zobel HF (eds) Developments in carbohydrate chemistry. The American Association of Cereal Chemists, St. Paul, pp 1–36

Farhat IA, Oguntona T, Neale RJ (1999) J Sci Food Agr 79:2105–2112

Manzocco L, Nicoli MC, Labuza T (2003) Italian Food Technol XII:17–23

Zobel HF, French AD, Hinkle ME (1967) Biopolymers 5:837–845

García MA, Martino MN, Zaritzky NE (2000) J Food Sci 65:941–944

García MA, Martino MN, Zaritzky NE (2000) Starch-Stärke 52:118–124

Mali S, Grossmann M.V.E., Garcia MA, Martino MN, Zaritzky NE (2002) Carbohyd Polym 50:379–386

Mitrus M (2005) Int Agrophys 19:237–241

Bonilla J, Fortunati E, Atarés L, Chiralt A, Kenny JM (2014) Food Hydrocolloid 35:463–470

Fakhouri FM, Fontes LCB, Gonçalves PVM, Milanez CR, Steel CJ, Collares-Queiroz FP (2007) Ciencia Tecnol Alime 27:369–375

Wallach DFH (1996) US Patent No. 6495,368

Chang-Bravo L, López-Córdoba A, Martino M (2014) React Funct Polym 85:11–19

García-Ruiz A, Bartolomé B, Cueva C, Rodríguez-Bencomo JJ, Requena T, Martín-Álvarez PJ, Moreno-Arribas MV (2012) 6ª Reunión Red Bal, Tarragona. II. Bacterias Lácticas y Alimentos, p. 27

Raybaudi-Massilia RM, Mosqueda-Melgar J, Martín-Belloso O (2008) Int J Food Microbiol 121:313–327

Acknowledgements

The author would like to thank Dr. Mirian Carmona-Rodríguez, Dr. Judith Sánchez Bruguera, Dr. María B. Raymúndez, Dr. Aura Cova, Prof. Alicia Mariela Rincón and Prof. Edgar del Carpio.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares no conflict of interest.

Rights and permissions

About this article

Cite this article

Gutiérrez, T.J. Active and Intelligent Films Made from Starchy Sources/Blackberry Pulp. J Polym Environ 26, 2374–2391 (2018). https://doi.org/10.1007/s10924-017-1134-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-1134-y