Abstract

Buffalo gourd root starch (BGRS) and Mexican oregano essential oil (OEO) were used to obtain bioplastic films. The effect of different concentrations of OEO (0, 0.1, 0.3, 0.5, and 1.0% w/w in relation with starch) on the films physicochemical properties was evaluated. The additive inclusion significatively impacted on optical, mechanical, permeability, thermal, wettability, and morphological properties compared to the control, outstanding this effect on samples at low OEO concentrations (0.1 and 0.3% w/w respect to the BGRS), due to its component’s plasticizer capacity. FTIR analysis evidenced the different degrees of material’s components mixtures integration through the possible formation of hydrogen bonds to which the changes in the physicochemical properties of the obtained films could be attributed. SEM micrography showed an appropriated components integration for 0.1 and 0.5% OEO concentrations. According to their properties, these films may have a greater possibility to have practical applications, including food packaging.

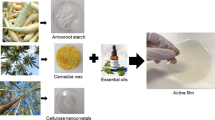

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

To mitigate pollution from single-use plastics, in recent decades prototypes of biobased plastic films have been developed, mainly using starch, a natural and sustainable raw material [1] that can be combined with others, such as essential oils, to improve their properties; these oils help them improve, for example, in terms of hydrophobicity [2], and can provide other capabilities to the materials, such as antioxidants and antimicrobials derived from polyphenols, such as thymol and carvacrol, present in Mexican oregano. (Lippia berlandieri Schauer) [3].

However, although starches are naturally abundant, those obtained from the main sources of calories for humans and animals are mostly used [4], this makes it necessary to evaluate the use of alternative sources, such as crazy squash (Cucurbita foetidissima Kunth), species native to North America, from whose roots up to 52% of starch can be isolated, whose properties are similar to some conventional ones, such as corn and cassava [5].

Based on this, a new generation of biobased materials could be created that, without matching the properties of conventional plastics, compete with them from another point of view, without emphasizing mechanical resistance: as functional materials that could, in theory, help extend the shelf life of food, so studying the result of the combination of crazy zucchini root starch with essential oil of Mexican oregano has been the objective of this research, with the purpose of describing the interaction mechanism and the physicochemical properties of the films obtained, with special focus on the mechanical properties and water vapor permeability, to know their possible feasibility of use, for example, in food packaging.

Materials and methods

Films elaboration

Starch from buffalo gourd roots (BGRS) was obtained according to [5] using Cucurbita foetidissima Kunth roots collected in wild areas at Buenavista, Saltillo, Coahuila, Mexico. Oregano (Lippia berlandieri Schauer) essential oil (OEO) was obtained from a laboratory of Chihuahua state in Mexico. OEO main components were thymol and carvacrol 1:4 relation, respectively. The films were produced by casting method [6] with modifications, using BGRS at 4%, glycerol 2% as plasticizer, and different OEO concentrations (0.0, 0.1, 0.3, 0.5, and 1.0% w/w respect to starch) using 1 mL of absolute ethanol as OEO solubilizer and dispersant. Each filmogenic solution was carried out in a magnetic plate at 600 rpm. The film obtained with 0.0% OEO was considered as control. Molding was carried out in acrylic plates 15 × 15 × 2 cm, with a density of 0.191 g/cm2 of filmogenic solution. Samples were dried in a convection drying sistem for 48 h at 35 ± 1 °C. Later, the films were released and were conditioned at 25 ± 2 °C in a 57 ± 5% relative humidity (HR).

Moisture, solubility, thickness and opacity

Moisture percentage was carried out by gravimetric method [7]. Solubility percentage was done by triplicate following [8] reports, and films thickness analysis, was conducted through a spiral pattern, using a digital micrometer Mitutoyo™ (model H-2780, Mitutoyo Co., Kanagawa, Japan) [9]. Films opacity was determined at by absorbance at 600 nm in a spectrophotometer UV/Vis (Labomed brand, model UVS-2700 Labomed Inc., California, USA), using Ec. (1) reported by [10].

FTIR spectroscopy

The OEO spectrograms obtention was carried out in a FTIR-ATR equipment Perkin Elmer™ (model Spectrum Two, Perkin Elmer Inc., Bucks, UK) according to [3]. The average of 5 spectrograms of each repetition were recorded per sample, with 32 scans per reading with a resolution of 4 cm−1 in the region of 4000 a 550 cm−1. For all films it was used the reported conditions of [11]. The de-convolution of spectrograms of all sample films was also performed with the software SPECTRUM™ 10 version 10.6.2 (Perkin Elmer, Inc., Bucks, UK) to analyze the regions of interest.

Mechanical properties, contact angle (wettability) and water vapor permeability (WVP)

Mechanical properties were evaluated using ten repetitions (tensile strength (TS, in MPa), percentage of elongation at break (%EAB) and elastic module (EM, in MPa)) based on the ASTM D882-10 norm with some modifications. The probes of 1 × 6 cm were previously conditioned at 55 ± 5% RH for 24 h at room temperature (25 ± 2 °C), the assays were performed in a Brookfield™ texturometer (model CT3, Brookfield Engineering Laboratories Inc., Massachusetts, USA), using a load cell of 4 kg and with the software TexturePro CT version 1.9.35 (Brookfield Engineering Laboratories Inc., Massachusetts, USA), and for the corresponding calculations the following equations were used:

where W is the breaking strength (N), Ac is the original contact area of the film specimen (m2), ΔL is the length obtained at the end of the test (mm) and L0 is the probe’s original length (mm). The variable EM was obtained from the resultant slope of the linear region in the deformation effort.

To obtain information about the hydrophobicity of the films, the contact angles (wettability) were determined in triplicate as reported by [12] with modifications: 3 × 3 cm cuts of each film were used, using a goniometer (Krüss, DSA30) at 25 °C and distilled water. The average value of the angle formed between the drop formed by the distilled water in contact with the surface of the film was obtained for each case.

WVP was obtained in triplicate using the procedure based in the norm ASTM E96-00, with some modifications. For so probes of 6 × 6 cm were used, employing permeability cells with films exposition diameter of 50 mm, for moisture chamber keeping a relative moisture of 55 ± 5% at a room temperature (25 ± 2 °C). The WVP value was calculated according to Eq. (4).

where W is the silica’s gel weight increment (g), x is the film’s thickness (m), t is the time (s), A is the film’s permeation area (m2), and ΔP is the pressure difference between the film’s surfaces in Pa.

Thermal properties by differential scanning calorimetry (DSC)

Film’s thermal properties were obtained in triplicated using a differential scanning calorimeter model DSC4000 (Perkin Elmer™, Perkin Elmer, Inc., Bucks, UK), according to [9]. Obtaining the variables of To (onset melting temperature) and Tp (peak melting temperature).

Morphological study by scanning electronic microscopy (SEM)

Materials probes surface micrographs were obtained in a scanning electronic microscope Jeol™ (model JMS-70000S, Jeol Ltd., Tokio, Japón) at a magnification of 500X and 15 kV intensity.

Statistical analysis

A completely random design was carried out. The results were subject to One-way variance analysis (ANOVA), using LSD de Fisher test (p ≤ 0.05) to discriminate among means using the software Statgraphics™ Centurion version XVI (Statgraphics Technologies, Inc., Virginia, USA).

Results and discussions

Moisture, solubility, thickness and opacity

Regarding to the film’s moisture percentage (Table 1), an increase on the water retention was observed at using OEO concentrations of 0.3 and 0.5%, which directly impacted in the films thickness values (Table 1), which indicates these materials retained more moisture. These results agree with the ones obtained by [13] in corn starch films added with oregano essential oil (of a non-specified specie), in which was regarded to the integration a heterogeneous distribution of the hydrophobic film’s fractions. To the film’s solubility, these showed a non-moisture related behavior (Table 1), since higher solubility values were observed in the control films and with OEO 1.0%, which allows infer that between concentrations of OEO at 0.1 and 0.5% a better integration of the materials take place and a consequent lower susceptibility to solve in water media, as reported by [14]. In relation with the opacity, OEO integration gave higher values for treatments with oil intermediate concentrations, mainly for 0.1% OEO, which indicates a gradual integration between the components. Akhter et al. [15] described that the coalescence, the light dispersion, and the creamy effect during film’s dehydration affects these materials.

FTIR spectroscopy analysis

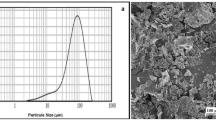

To evidence the presence and integration of OEO, a band analysis was carried out in the infrared spectrograms. The functional groups of interest are shown in Table 2. For the region related to the OH− (Fig. 1a), it was observed and stretching of the band between 3700 and 3000 cm−1 with a slight shift of the peak for this band for the OEO concentrations of 0.1% (3296 cm−1) and 0.3% (3297 cm−1) from 3303 cm−1. This conduct would be caused by the formation of hydrogen bonds between the molecules of starch and glycerol [16, 17]; as well as with this of OEO, united to that the OH- functional group seems to be a strong electron donor in the formation of this type of links [18]. On the other hand, in the characteristic bands of the groups –CH3 (Fig. 1b), it was detected a slight shift and progressive stretching of the wave band number (n) from 2930 to 2925 cm−1 and from 2883 to 2878 cm−1, regarding to the increment of the presence of –CH3 radicals, characteristics of the main components of OEO (thymol and carvacrol), and evidencing for the presence of a low intensity band at n = 2850 cm−1 starting on the concentration of 1.0% of OEO. The movement of these bands is due to the molecular interaction between the OEO and the starch [19, 20] and this may be impacting on the values of the mechanical and thermal properties and on the WVP of these films (Table 3).

Besides it was detected the presence of a low intensity band in the wave number n = 1735 cm−1 (Fig. 1c), which is related with the presence of phenolic compounds [21], increasing in direct proportion with the concentration of OEO in the films. This band can be explained through the interactions generated between the starch’s carbonyl groups and the OH- groups coming from the OEO phenolic compounds forming hydrogen bonds. This information helped to confirm the interaction that the OEO established with the biopolymeric film of the prepared matrix. [15] indicated that the molecular interaction between the phenolic components of the essential oils and the starch chains favor an altered conformation and structural orientation. This behavior coincides with the data obtained for moisture and thickness (Table 1), so it could be deduced that the presence of the essential oil added at these concentrations would cause a structure with greater molecular integration between the films components, which would favor the retention of water in the polymeric matrix and a greater insolubility of the resulting material (Table 1), also causing a lower resistance to water vapor for the 0.3% OEO concentration (Table 3).

Water vapor permeability, mechanical, thermal and wettability properties

It was observed that in the fracture stress (TS), the highest behaviors were obtained when using OEO at 0.1 and 0.3%, respect to rest of the treatments (Table 3). This may indicate a possible plasticizing effect of this concentrations OEO on the material’s tensile strength; an effect on the material’s elasticity (%EAB) was also observed only up to the use of OEO at 1.0%; however, there was no significant impact due to the use of OEO in the elastic modulus (EM) variable. These results coincide with the use of other essential oils [22, 23]. Even in synthetic polymeric materials such as polypropylene, OEO components impart a plasticizing effect, also modifying their mechanical properties by altering their crystalline structure [24].

To the water vapor permeability (WVP), a clear effect of greater resistance to the water passage was observed depending on the increase in the OEO (Table 3), which agrees with that reported by [14], [19] and [25]. The polyphenols can induce certain hydrophobicity to the films in which it was included, favored by the integration at the molecular level of the film’s formulation components.

In relation to the thermal properties, the results showed an important difference between To and Tp in all the treatments, observing a clear effect in the decrease of the values for these variables depending on the increase in the concentration of the OEO until the use of the concentrations of 0.5%. According to [26], a significant difference between To and Tp favors a better adhesion between polymer sheets, so that for the materials obtained, a better performance would be obtained for the films with OEO at 0.1% and 0.3%.

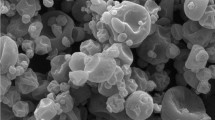

Regarding the contact angle (Fig. 2), which offers information about the hydrophilicity or hydrophobicity of the materials on their surface, a heterogeneous behavior was obtained between the average values of films. According to the difference of means test (p ≤ 0.05), the films that resulted in the highest water repellency were those formulated with 0.1 and 1.0% OEO, in contrast to the control (0.0% OEO), which was the film with the greatest affinity to water. This agrees with the moisture values obtained and contrasts with the solubility and thickness values (Table 1), since the films with the highest contact angle values turned out to be the thinnest, but also the most soluble. Gutiérrez and González [27] refer that higher values of contact angle are related to strong intermolecular hydrogen bonds between the starch and the other components of the films, in this case the OEO components, which have been evidenced in the FTIR study, which could suggest greater interaction between the components of the films through this type of intermolecular bonds, promoting the molecular disaggregation of starch and favoring flatter contact surfaces (Figs. 2 and 3) and, therefore, with greater physical resistance to interacting with water. Karbowiak et al. [28] proposed that the mechanics of the contact angle of biopolymers with water is because the Lewis sites (those most polar sites) would be affected by the formation of hydrogen bonds between the components of the films below their surface, which would lead to the reduction of their surface polarity.

Regarding the comparison against the mechanical and permeability properties (Table 3), the most hydrophobic film (Fig. 3b) turned out to be the most resistant to tension and one of the least permeable to water vapor, together with the film with 1.0% OEO. This could also be a consequence of the formation of hydrogen bonds when the components of the films conjugate [27, 28], mixed in specific proportions, given the heterogeneity of the results in terms of the values of their contact angles.

Surface morphological analysis by SEM

The inclusion of OEO in the BGRS film caused an apparent alteration that can be observed from the surface structure. The film corresponding to the control (without OEO addition) (Fig. 3a) showed uniform continuity on its surface; However, the hydrophilicity of its components allowed greater diffusion of water vapor molecules and lower elasticity and resistance to fracture than the other films added with OEO. The inclusion of 0.1% OEO in the film (Fig. 3b) presented an apparent change in its structure, which indicated a probable loss of homogeneity, similar to what was reported by [29] who observed a change in the appearance of the surface attributed to the hydrophobicity of the essential oil they used, which could have caused an apparent discontinuity in the structure of the resulting materials (Fig. 3b, 3c, 3d, and 3e). Akhter et al. [15] studied the interaction between the essential oil of mint and rosemary and starch in corn and wheat starch films, and found that the interaction between the essential oil and starch chains obeys a complex equilibrium mechanism between the increase of hydrophobic components (in this case OEO) finally adopting this property in the functionalized films due to the effect of said components on the integrity of the microstructure of the films and their possible interaction with the side chains of the starches, with the consequent impact on all the other physicochemical properties of this type of biopolymeric materials.

Conclusions

Biobased films were obtained from the components used in this study. The FTIR analysis indicated that the films with 0.1 and 0.5% OEO presented greater molecular integration between their components, compared to the treatments with 0.3 and 1.0% OEO, which had a positive impact on their physical properties (lower thickness and lower moisture absorbency), mechanical (higher fracture stress than the control film), thermal (lower glass transition temperature), water vapor permeability (higher moisture barrier than the control film), and wettability (higher water repellency), as well as better touch handling than films with 1.0% OEO. Therefore, films with 0.1 and 0.5% OEO could have greater application possibilities compared to the control treatments and with 0.3 and 1.0% OEO, due to a better balance of molecular interaction between the hydrophilic and hydrophobic components in the referred concentrations. In general, the results indicated that the starch obtained from ground buffalo root represents a non-conventional alternative source for its application in films added with OEO, which generated changes in the physicochemical properties of the films obtained.

Data availability

The data obtained during the study are available from the corresponding author upon reasonable request.

Abbreviations

- BGRS:

-

Buffalo gourd root starch

- OEO:

-

Oregano essential oil

References

D. Datta, G. Halder, Process. Saf. Environ. Protect. (2018). https://doi.org/10.1016/j.psep.2017.12.017

L.J. Bastarrachea, D.E. Wong, M.J. Roman, Z. Lin, J.M. Goddard, Coatings (2015). https://doi.org/10.3390/coatings5040771

S.J. Kwon, Y. Chang, J. Han, Food Microbiol. (2017). https://doi.org/10.1016/j.fm.2017.02.004

T. Tesfaye, Clean. Technol. Environ. Policy. (2018). https://doi.org/10.1007/s10098-018-1597-0

F. Hernández-Centeno, H.Y. López-De la Peña, M. Hernández-González, C.A. Rodríguez-González, J.M. Tirado-Gallegos, C. Rios-Velasco, P.B. Zamudio-Flores, Food Measure (2020). https://doi.org/10.1007/s11694-020-00444-x

M. Ghasemlou, N. Aliheidari, R. Fahmi, S. Shojaee-Aliabadi, B. Keshavarz, M.J. Cran, R. Khaksar, Carbohydr. Polym. (2013). https://doi.org/10.1016/j.carbpol.2013.07.026

P.B. Zamudio-Flores, E. Ochoa-Reyes, J.J. Ornelas-Paz, J.M. Tirado-Gallegos, L.A. Bello-Pérez, A. Rubio-Ríos, R.G. Cárdenas-Felix, Agrociencia 49, 483–498 (2015)

J.H. Suh, S.Y. Ock, G.D. Park, M.H. Lee, H.J. Park, Polym. Test. (2020). https://doi.org/10.1016/j.polymertesting.2020.106612

Tirado-Gallegos J.M., Zamudio-Flores P.B., Ornelas-Paz, J.J., Rios-Velasco C., Orozco G.I.O., Espino-Díaz M., Baeza-Jiménez R., Buenrostro-Figueroa J.J., Aguilar-González, M.A., Lardizábal-Gutiérrez D., Hernández-González M., Hernández-Centeno F., López-De la Peña H.Y. Coatings. (2018). https://doi.org/10.3390/COATINGS8110384.

K. Anchundia, S. Santacruz, J. Coloma, Rev Chilena Nutr. (2016). https://doi.org/10.4067/S0717-75182016000400009

X. Yao, Y. Qin, M. Zhang, J. Zhang, C. Qian, J. Liu, Int. J. Biol. Macromol. (2021). https://doi.org/10.1016/j.ijbiomac.2021.04.152

P.N. Manoudis, I. Karapanagiotis, Prog. Org. Coat. (2014). https://doi.org/10.1016/j.porgcoat.2013.10.007

D. Šuput, V. Lazić, L. Pezo, S. Markov, Ž Vaštag, L. Popović, A. Radulović, S. Ostojić, S. Zlatanović, S. Popović, Pol. J. Food Nutr. Sci. (2016). https://doi.org/10.1515/pjfns-2016-0008

J. Li, F. Ye, L. Lei, G. Zhao, Int. J. Biol. Macromol. (2018). https://doi.org/10.1016/j.ijbiomac.2018.04.093

R. Akhter, F.A. Masoodi, T.A. Wani, S.A. Rather, Int. J. Biol. Macromol. (2019). https://doi.org/10.1016/j.ijbiomac.2019.06.214

D. Muscat, R. Adhikari, S. McKnight, Q. Guo, B. Adhikari, J. Food Eng. (2013). https://doi.org/10.1016/j.jfoodeng.2013.05.033

L. Dai, J. Zhang, F. Cheng, Int. J. Biol. Macromol. (2019). https://doi.org/10.1016/j.ijbiomac.2019.03.197

L.J. Bellamy, The Infra-Red Spectra of Complex Molecules (Springer, London, 1975)

A.G. de Souza, N.M.A. dos Santos, R.F. da Silva Torin, D. dos Santos Rosa, Int. J. Biol Macromol. (2020). https://doi.org/10.1016/j.ijbiomac.2020.07.226

C. Cai, R. Ma, M. Duan, Y. Deng, T. Liu, D. Lu, LWT (2020). https://doi.org/10.1016/j.lwt.2020.109700

O. Abbas, G. Compère, Y. Larondelle, D. Pompeu, H. Rogez, V. Baeten, Vib. Spectrosc. (2017). https://doi.org/10.1016/j.vibspec.2017.05.008

E. Arezoo,, E. Mohammadreza, M. Maryam, M.N. Abdorreza, Int. J. Biol. Macromol. (2019). https://doi.org/10.1016/j.ijbiomac.2019.11.244.

A.E. Restrepo, J.D. Rojas, O.R. García, L.T. Sánchez, M.I. Pinzón, C.C. Villa, Food Sci. Technol. Int. (2018). https://doi.org/10.1177/1082013218792133

M. Ramos, A. Jiménez, M. Peltzer, M.C. Garrigós, J. Food Eng. (2012). https://doi.org/10.1016/J.JFOODENG.2011.10.031

R. Aguilar-Sánchez, R. Munguía-Pérez, F. Reyes-Jurado, A.R. Navarro-Cruz, T.S. Cid-Pérez, P. Hernández-Carranza, S.C. Beristain-Bauza, C.E. Ochoa-Velasco, R. Avila-Sosa, Molecules (2019). https://doi.org/10.3390/molecules24122340

M.N. Abdorreza, L.H. Cheng, A.A. Karim, Food Hydrocoll. (2011). https://doi.org/10.1016/J.FOODHYD.2010.05.005

T.J. Gutiérrez, G. González, Food Biophys. (2017). https://doi.org/10.1007/s11483-016-9458-z

T. Karbowiak, F. Debeaufort, D. Champion, A. Voilley, J. Colloid Interface Sci. (2006). https://doi.org/10.1016/j.jcis.2005.07.030

J.A. do Evangelho, G. da Silva Dannenberg, B. Biduski, S.L.M. el Halal, D.H. Kringel, M.A. Gularte, A.M. Fiorentini, E. da Rosa Zavareze, Carbohydr. Polym. (2019). https://doi.org/10.1016/j.carbpol.2019.114981

Acknowledgments

Authors would like to thank Ing. Arturo Ramos Martínez and José Manuel Morales Xicohténcatl for the technical support provided in this work. The present study is a product of the Research Group in Carbohydrates, Packaging and Functional Foods (CEAF-Laboratory) of the CIAD-Cuauhtemoc, Chihuahua, Mexico, led by Dr. Paul Baruk Zamudio-Flores.

Funding

No funding was obtained for this study.

Author information

Authors and Affiliations

Contributions

Conceptualization: Francisco Hernández-Centeno and Paul Baruk Zamudio-Flores; Methodology: Francisco Hernández-Centeno, Paul Baruk Zamudio-Flores, María Hernández-González, Juan Manuel Tirado-Gallegos, Ana Margarita Rodríguez-Hernández and Claudia Alejandra Rodríguez-González. Formal analysis and investigation: Francisco Hernández-Centeno, Haydee Yajaira López-De la Peña, Paul Baruk Zamudio-Flores, Ana Margarita Rodríguez-Hernández and Claudia Alejandra Rodríguez-González; Writing—original draft preparation: Francisco Hernández-Centeno; Writing—review and editing: Paul Baruk Zamudio-Flores, María Hernández-González, Claudio Rios-Velasco and Juan Manuel Tirado-Gallegos. Funding acquisition: Francisco Hernández-Centeno; Supervision: Paul Baruk Zamudio-Flores and María Hernández-González.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest with respect to the work described in this manuscript.

Ethical approval

Not applicable, because this manuscript does not contain any studies with human or animal subjects.

Informed consent

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hernández-Centeno, F., Hernández-González, M., Tirado-Gallegos, J.M. et al. Biobased films from unconventionally sourced starch (Cucurbita foetidissima Kunth) and oregano essential oil (Lippia berlandieri Schauer): A look at their physicochemical properties. MRS Advances 9, 523–530 (2024). https://doi.org/10.1557/s43580-024-00824-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43580-024-00824-1