Abstract

The polypyrrole (PPy)/graphene oxide (GO) composite hydrogels with hierarchical porous structures were fabricated by one-step self-assembly method. The static oxidation polymerization of pyrrole monomer in GO aqueous solution resulted in the formation of three-dimensional (3D) PPy/GO composite hydrogels, which consisted of one-dimensional PPy nanofibers and two-dimensional GO nanosheets. The as-prepared composite hydrogels exhibited shrinking–swelling behavior with cycles of suction and water-supplying. The effects of GO nanosheets content on the swelling properties were investigated. Results showed that the well-dispersed GO nanosheets in the hydrogel networks resulted in a significant improvement in water absorbencies of the hydrogels. PPy/GO composite hydrogels exhibited unobvious variation in the water absorbency even in saline solutions. Such excellent properties in water absorbencies endow the conducting 3D PPy/GO composite hydrogels with great potential applications in electrochemical sensors or controlled release.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

It is well-known that polymer hydrogels, as soft intelligent materials, possess the feature of phase transition between swelling state and de-swelling state upon exposure to external stimuli, such as temperature, pH, pressure, and solvent [1–5]. In the past few years, conducting polymer hydrogels have attracted great attention because they combine the swelling properties of hydrogels and the specific electrical properties of conducting polymers. Therefore, such unique characteristics of conducting polymer hydrogels endow a broad range of applications in the fields of artificial muscles, supercapacitors, electrochemical sensors, and drug carriers [6–18].

In general, conducting polymer hydrogels are prepared through polymerizing a conducting polymer monomer, such as aniline and pyrrole, within a non-conducting hydrogel matrix. The obtained hydrogels are actually cross-linked polymers containing a semi-interpenetrating network structure. Alternatively, they can be prepared by directly mixing the monomer of aniline or 3,4-ethylenedioxythiophene with the macromolecular sulfonate using multivalent metal ions as the oxidant and cross-linker [19–21]. However, the non-conducting hydrogel matrix and polymers shall inevitably lead to the deterioration of the electrical properties, whereas phase separation between the conducting polymer and non-conducting polymer may occur during the process of swelling and de-swelling under external stimuli.

Graphene, a two-dimensional crystal of carbon atoms, is expected to be an ideal candidate to combine with conducting polymers due to its intrigue electronic carrier mobility, excellent thermal conductivity and strong mechanical properties [22–24]. Graphene oxide (GO) is an important derivative of graphene. Lots of hydrophilic oxygen-containing functional groups on GO nanosheets makes them stably dispersed in water and consequently improve the accessibility and affinity of GO in aqueous solution. Many researchers have demonstrated various strategies on the incorporation of graphene or GO into the conducting polymer matrix to produce the nanocomposites with different morphology [25–27]. Recently, the composites of conducting polymer and graphene with three-dimensional (3D) macrostructures have also been fabricated [28]. Zhao et al. reported a hydrothermal method to synthesize a 3D polypyrrole (PPy)/graphene foam with a remarkable compression tolerance and high specific capacitances [29]. Zhou et al. prepared PPy/graphene composite hydrogels with high supercapacitor performance from high concentration graphene oxide and pyrrole monomers with the aid of Cu2+ ions at 80 °C [30]. Since GO is easily exfoliated in water, it is suitable to be used in the preparation of composite hydrogels. However, there have yet been any reports in regard to the swelling behaviors of conducting polymer/GO composite hydrogels, which is important for fabricating the conducting hydrogel-based devices. Hence, a big challenge still remains to design facile strategy for the fabrication of polypyrrole/graphene oxide 3D macrostructures.

In this paper, we present the fabrication of PPy/GO composite hydrogels via the static polymerization of pyrrole monomer in the presence of GO nanosheets. One-dimensional PPy nanofibers and two-dimensional GO nanosheets constitute the 3D network of the composite hydrogels through the synergetic interaction between the polycations in conjugated backbone of PPy and cations in the GO nanosheets and π–π interactions between PPy and GO. The resulting PPy/GO composite hydrogels exhibited shrinking–swelling behavior with cycles of suction and water-supplying as well as the improved water and saline absorbencies. The highly hierarchical structure and good electrical conductivity of 3D PPy/GO composite hydrogels render them as the attractive candidates for bioelectronics.

2 Experimental

2.1 Materials

Pyrrole was purchased from Aldrich and distilled before use. GO was prepared according to the modified Hummers method [31]. All other reagents were used as received without further purification.

2.2 Fabrication of PPy/GO Composite Hydrogels

In a typical experiment, 5 mL of 0.5 wt% aqueous GO dispersion and 1 mmol of FeCl3 were added into 10 mL of 5 mmol/L methyl orange (MO) aqueous solution. The mixture was immediately stirred for 20 min. Then, 1 mmol of pyrrole monomer was added and stirred for 2 min to obtain uniform blend. The above mixture was then positioned without stirring for 24 h at room temperature to form the PPy/GO composite hydrogels. The as-prepared hydrogels were purified in a large amount of deionized water for at least 1 week in order to remove any residual reactants. To obtain dedoped hydrogels, the hydrogels were immersed in 1 mol/L NaOH aqueous solution for 24 h.

2.3 Characterization

The morphologies of the freeze-dried hydrogels were observed by scanning electron microscopy (SEM) (JSM-5510LV, JEOL Co., Japan) scanning electron microscope. Fourier transform infrared (FTIR) spectrum was recorded on a Nicolet 510 FTIR spectrometer. The electrical conductivity was measured using the four-probe method by inserting four acicular probes into the hydrogels at room temperature.

Through monitoring the volume change of the hydrogels in different states, the swelling–shrinking behaviors with cycles of suction and water-supplying for the PPy/GO composite hydrogels were evaluated. The hydrogel freshly prepared and equilibrated in water was denoted as state a. State b was obtained by suction the water from the hydrogel in state a. State c was obtained by re-supplying an excess amount of water quickly to the hydrogel in state b. The volume change was defined as the ratio of V/V0, in which V0 was the volume of state a and V was the volume of state b or state c.

For water absorbency measurements in distilled water or saline solution, the hydrogels were first freeze-dried under vacuum before measurement. Then the freeze-dried hydrogels were immersed in distilled water or NaCl solution for 48 h. The water absorbency was calculated using the following equation:

in which md and ms were the weight of the dry and re-swollen samples, respectively.

3 Results and Discussion

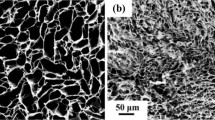

The morphologies of the freeze-dried PPy/GO composite hydrogel are shown in Fig. 1. A well-defined and cross-linked 3D hierarchical porous network structure for PPy/GO composite hydrogels can be observed in Fig. 1a. This porous structure may facilitate the transport of water and thus a better swelling-shrinking property could be expected. Moreover, it is worthy to note that several one-dimensional nanofibers with a diameter of about 150 nm and a length of several micrometers are intertwisted with two-dimensional GO nanosheets, as shown in the SEM image of the hydrogel at high magnification in Fig. 1b. The one-dimensional structure is in agreement with our previous reports about that of PPy prepared by the reactive self-degraded MO–Fe3+ templates [9, 32]. It indicates that in this reaction system, one-dimensional PPy nanofibers can grow via the MO-Fe3+ templates in the presence of GO and eventually form the hydrogels together with the two-dimensional GO nanosheets. FTIR spectrum is carried out to characterize the PPy/GO composite hydrogel. As shown in Fig. 2, the band at 1,732 and 1,639 cm−1 can be assigned to stretching of the C = O bond of carbonyl or carboxyl groups and deformation of O–H band on GO. The bands at about 1,550 and 1,457 cm−1 are attributed to the C=C and C–N stretching vibration of the pyrrole ring, respectively. The C–N stretching wagging vibration is found at 1,172 cm−1. It indicates that GO and PPy exist together in the composite hydrogels.

As shown in Fig. 3a, PPy/GO composite hydrogels obtained without stirring in the presence of MO exhibits a swollen macroscopic appearance after being purified and equilibrated in water for several days, which further confirm the 3D porous network in the hydroges in Fig. 1. For comparison, PPy/GO composites have also been prepared in the absence of MO or with stirring in the process of the reaction. For the former, without the aid of MO, only a black deposit not a whole gel was observed after the reaction. In the case of stirring, only the powders of PPy/GO composites were obtained even in the presence of MO. It is well known that mesoscopic aggregation of the colloids occurs automatically owing to mutual attractions via van der Waals force or chemical bonding [33]. Therefore, external agitation, such as stirring can destroy the aggregation and disrupt the formation of the hydrogels. Our results indicate that the fabrication of PPy/GO composite hydrogels depend strongly on both MO and static conditions. It is concluded that the effective 3D network composed of PPy and GO and the interactions via van der Waals force as well as chemical bonding between the one-dimensional PPy nanofibers and the two-dimensional GO nanosheets are essential for the fabrication of PPy/GO composite hydrogels.

Swelling–shrinking behaviors with suction and water-supplying for PPy/GO composite hydrogel were further observed. After suction, the hydrogel shrank and the ratio V/V0 was about 0.52 (Fig. 3b). It was worth noticing that the shrunk hydrogel swelled again after re-supplying an excess amount of water quickly to the hydrogel in state b and the volume ratio increased to 0.86, as shown in Fig. 3c. Moreover, the PPy/GO composite hydrogel could shrink and swell with the ratio V/V0 varying between 0.51 and 0.87 in the cycles of suction and water-supplying, as shown in Fig. 4. The cycle could be repeated more than ten times. The results indicate that this network in the PPy/GO composite hydrogel is similar to that of reversible hydrogels and will not collapse in the shrinking process. During the process of suction, the combinations of the one dimensional PPy nanoblocks and two-dimensional GO nanosheets were not disrupted and thus the shrunk hydrogel could swell again under the re-supply of water.

Besides the reversibility of volume change, the reversibility of water absorbency is another important property for the hydrogel. Cycles of water absorbencies of PPy/GO composite hydrogels are shown in Fig. 5. The dry samples were immersed into distilled water to reach swelling equilibrium. The hydrogel exhibited a water absorbency of about 38.1 g/g during the experiment of the cycle of water absorbency. It indicates that the network of PPy/GO composite hydrogels is reserved during freeze-drying, resulting in the excellent reversibility in water absorbency.

The effect of GO concentration on the water absorbencies of PPy/GO composite hydrogels is further studied. As shown in Fig. 6, all of the PPy/GO composite hydrogels exhibited larger water absorbency than the pure PPy hydrogel. The introduction of GO nanosheets in the composite increased the water absorbency of the hydrogels. In the case of 1 wt% GO concentration, the water absorbency was enhanced from 25.5 g/g to 39.6 g/g. This result is similar to the previous studies in which the incorporation of hydrophilic filler such as mica into the polymer network can increase the water absorbency of the hydrogel [34]. It is well known that GO nanosheets are highly negatively charged as a result of ionization of the carboxyl and phenolic hydroxyl groups located on GO nanosheets [35]. The two-dimensional GO nanosheets with anionic groups could interact with the one-dimensional PPy nanofibers with positive charges through doping, which leads to a more intact network structure and thus there are more additional space in the network to hold more water. Moreover, these functional groups in GO may interact with water molecules through hydrogen bonding within the hydrogel network, which also resulted in the improvement of water absorbency. It is anticipated to further enhance the water absorbency of PPy/GO composite hydrogels by optimization of several factors, such as the amount of oxidant, the polymerization temperature and the amount of MO in future.

As mentioned above, the conducting polymer hydrogels are potential used in the fields of artificial muscles and drug carriers. In these cases, the external environment contains generally salt aqueous solutions. Therefore, the water absorbency in saline solution is important for their practical applications. It is well known that the conventional hydrogels hold water via the interactions between the polymer chains and water molecules as well as the osmotic pressures of the network [2]. But when the polyelelctrolytic hydrogels are in a saline solution, the water absorbency of polyelectrolyte hydrogels decrease dramatically because of the decrease of the osmotic pressure difference between the polymer network and the external solution [36, 37]. However, in our case, upon exposure to NaCl solutions with concentrations from 0.01 mol/L to as high as 1 mol/L, there was only a slight decrease in water absorbency for PPy/GO composite hydrogels, as shown in Fig. 7. The slight decrease may be ascribed to the screening effect of the counterions (Na+) on the anionic groups on GO nanosheets. It indicates that the interactions between the network of PPy/GO composite hydrogels and the water molecules are the dominant effect through which the hydrogels hold water. Moreover, the PPy/GO composite hydrogel could shrink and swell with the ratio V/V0 varying between 0.49 and 0.83 in the cycles of suction and water-supplying. The 3D network composed of one-dimensional PPy nanofibers and two-dimensional GO nanosheets can effectively improve the stability of the network structures in the hydrogels and resist against the collapse in saline solutions.

The conductivities of PPy/GO composite hydrogels were on the order of 10−4 S/cm, which were similar to those of the conductive polymer hydrogels [38]. With the transfer of water in the cycle of suction and water-supplying, the conductivities of PPy/GO composite hydrogels were altered to 8.7 × 10−3 S/cm and 5.1 × 10−4 S/cm in states b and c, respectively. The shrinkage of the hydrogels in state b is accompanied with the lower storage of water and may cause the conducting polymer chains to be in closer proximity, thus facilitating electron transfer in the network and resulting in the higher conductivity. Moreover, of particular interest, the PPy/GO composite hydrogels soaked in NaOH solution possess the lower electrical conductivities of 10−6 S/cm. The conductivity of the hydrogel could return after being soaked in HCl solution again, as shown in Fig. 8. It could be attributed to the doping/dedoping properties of the conducting polymers. The results indicated that the conductivity of the PPy/GO composite hydrogels could be adjusted by tuning the doping state of the conducting polymers.

4 Conclusions

In summary, we have developed a facile one-step strategy for the fabrication of PPy/GO composite hydrogels. The formation of the hydrogels depended on self-assembly between two-dimensional GO nanosheets and one-dimensional PPy chains. PPy/GO composite possessed the ability of shrinking and swelling with the migration of water in the network. PPy/GO composite hydrogel showed a better water absorbency, which may be attributed to GO nanosheets in the hierarchical hydrogel network. Moreover, the conductivities of PPy/GO composite hydrogels could be adjusted simply by changing pH. Combining the properties of GO and PPy, the as-prepared PPy/GO composite hydrogels may gain potential applications as carriers for controlled drug delivery or electrochemical sensors.

References

J. Kopecek, Nature 417, 388 (2002)

H.B. Bohidar, P. Dubin, Y. Osada, Polymer Gels: Fundamentals and Applications (American Chemical Society, Washington DC, 2002)

L. Chen, B. Kim, M. Nishino, J.P. Gong, Y. Osada, Macromolecules 33, 1232 (2000)

X. Yan, D. Xu, X. Chi, J. Chen, S. Dong, X. Ding, Y. Yu, F. Huang, Adv. Mater. 24, 362 (2012)

H. Izawa, K. Kawakami, M. Sumita, Y. Tateyama, J.P. Hill, K. Ariga, J. Mater. Chem. B 1, 2155 (2013)

S. Rose, A. Prevoteau, P. Elzière, D. Hourdet, A. Marcellan, L. Leibler, Nature 505, 382 (2014)

B. Guo, A. Finne-Wistrand, A.C. Albertsson, Chem. Mater. 23, 1254 (2011)

S.K. Siddhanta, R. Gangopadhyay, Polymer 46, 2993 (2005)

D. Wei, X. Lin, L. Li, S. Shang, M.C. Yuen, G. Yan, X. Yu, Soft Matter 9, 2832 (2013)

B. Pepin-Donat, A. Viallat, J.F. Blachot, C. Lombart, Adv. Mater. 18, 1401 (2006)

Q. Tang, J. Wu, J. Lin, Carbohydr. Polym. 73, 315 (2008)

T.S. Tsai, V. Pillay, Y.E. Choonara, L.C. du Toit, G. Modi, D. Naidoo, P. Kumar, Polymers 3, 150 (2011)

Y.Z. Xu, Z.Y. Sui, B. Xu, H. Duan, X.T. Zhang, J. Mater. Chem. 22, 8579 (2012)

Y. Xiao, L. He, J. Che, J. Mater. Chem. 22, 8076 (2012)

L.J. Pan, G.H. Yu, D.Y. Zhai, H.R. Lee, W.T. Zhao, N. Liu, H.L. Wang, B.C.K. Tee, Y. Shi, Y. Cui, Z.N. Bao, Proc. Natl. Acad. Sci. USA. 109, 9287 (2012)

H. Huang, J. Wu, X. Lin, L. Li, S. Shang, M.C. Yuen, G. Yan, Carbohydr. Polym. 95, 72 (2013)

D. Mawad, E. Stewart, D.L. Officer, T. Romeo, P. Wagner, K. Wagner, G.G. Wallace, Adv. Funct. Mater. 22, 2692 (2012)

P. Asberg, O. Inganas, Biosens. Bioelectron. 19, 199 (2003)

T. Dai, Y. Jia, Polymer 52, 2550 (2011)

T. Dai, X. Jiang, S. Hua, X. Wang, Y. Lu, Chem. Commun. 36, 4279 (2008)

R. Du, Y. Xu, Y. Luo, X. Zhang, J. Zhang, Chem. Commun. 47, 6287 (2011)

Q. Ji, I. Honma, S. Paek, M. Akada, J. Hill, A. Vinu, K. Ariga, Angew. Chem. Int. Ed. 49, 9737 (2010)

M.F. El-Kady, V. Strong, S. Dubin, R.B. Kaner, Science 335, 1326 (2012)

N. Liu, Z. Ma, Biosens. Bioelectron. 51, 184 (2014)

W.P. Li, W.J. Dai, L. Ge, S.G. Ge, M. Yan, J.H. Yu, J. Inorg. Organomet. Polym Mater. 23, 719 (2013)

L. Li, K. Xia, L. Li, S. Shang, Q. Guo, G. Yan, J. Nanopart. Res. 14, 908 (2012)

L. Mao, H.S.O. Chan, J. Wu, RSC Adv. 2, 10610 (2012)

H. Zhou, W. Yao, G. Li, J. Wang, Y. Lu, Carbon 59, 495 (2013)

Y. Zhao, J. Liu, Y. Hu, H. Cheng, C. Hu, C. Jiang, L. Jiang, A. Yuan, L. Qu, Adv. Mater. 25, 591 (2013)

H. Zhou, T. Ni, X. Qing, X. Yue, G. Li, Y. Lu, RSC Adv. 4, 4134 (2014)

N.I. Kovtyukhova, P.J. Ollivier, B.R. Martin, T.E. Mallouk, S.A. Chizhik, E.V. Buzaneva, A.D. Gorchinskiy, Chem. Mater. 11, 771 (1999)

X. Yang, L. Li, Y. Zhao, Synth. Met. 160, 1822 (2010)

R.J. Hunter, Foundations of Colloid Science (Oxford University Press, New York, 1987)

J.M. Lin, J.H. Wu, Z.F. Yang, M.L. Pu, Macromol. Rapid Commun. 22, 422 (2001)

D. Li, M.B. Muller, S. Gilje, R.B. Kaner, G.G. Wallace, Nat. Nanotechnol. 3, 101 (2008)

W.F. Lee, R.J. Wu, J. Appl. Polym. Sci. 64, 1701 (1997)

D. Castel, A. Ricard, R. Audebert, J. Appl. Polym. Sci. 39, 11 (1990)

M.Y. Li, Y. Guo, Y. Wei, A.G. MacDiarmid, P.I. Lelkes, Biomaterials 27, 2705 (2006)

Acknowledgments

The work was supported by the New Century Excellent Talents in University of Ministry of Education of China (NCET-10-0157), Outstanding Youth Scientific Foundation of Hubei Province (2012FFA021) and Outstanding Youth Scientific Innovation Team of Colleges and Universities in Hubei Province (T201406). The authors (P. Sun and Y. Wang) thank for the support of the 9th President Fund for Student of WIT (2014026). The authors also thank Prof. Dongshan Zhou (Nanjing University) for the helpful discussion.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

She, X., Sun, P., Yu, X. et al. Fabrication of 3D Polypyrrole/Graphene Oxide Composite Hydrogels with High Performance Swelling Properties. J Inorg Organomet Polym 24, 884–889 (2014). https://doi.org/10.1007/s10904-014-0062-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-014-0062-8