Abstract

The present work reports the construction of polypyrrole (PPy) hydrogels directly with the as-synthesized PPy nanotubes (PPy-NTs) through infiltration of poly vinyl alcohol (PVA) and poly(acrylic acid) (PAA) solutions. This method avoids the time-consuming purification of the in-situ formed conducting hydrogels and provides a facile way to incorporate nanostructured conducting polymers evenly into the hydrogel matrix. PPy-NTs/PVA/PAA hydrogels with dual cross-linking networks were prepared through multiple freeze-thawing cycles followed by coordination with iron (III) ions. The tensile and compression strength of the hydrogels are ca. 54 kPa and 160 kPa, respectively. The PPy-NTs/PVA/PAA hydrogel was mainly electronic conducting dominated, and it showed the highest conductivity of ca. 0.04 S/cm after swollen in 0.2 M HCl (with 2wt% of PPy-NTs). Benefited from the high aspect ratio and high conductivity of PPy nanotubes, it is probable to mediate the PPy content and the integrity of the electronic conducting pathways to develop high-performance hydrogel materials used as strain sensors.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Conductive hydrogels are smart soft materials with self-healing ability, flexibility and electric conduction properties and will be widely used in the area of flexible electronics, soft energy storage devise and tissue engineering (Rong et al. 2018; Turky et al. 2020; Wei et al. 2020), etc. The main idea to develop conducting hydrogels is to incorporate conducting components into a hydrogel matrix, which is usually composed of cross-linking network of hydrophilic polymers. Metallic salts (Rong et al. 2018; Zhang et al. 2019), conducting polymers (Wang et al. 2018a) and carbon nano-materials (An et al. 2019; Uluturk and Alemdar 2019) have all been employed to develop conductive hydrogels. For conductive hydrogels used as strain or stress sensors, conducting components which can easily disperse in aqueous medium, possess high conductivity, and show good compatibility with the hydrogel skeleton are highly desired. Among the numerous conducting components, conducting polymers, including polyaniline (PANI), polypyrrole (PPy) and poly(3,4-ethylenedioxythiophene) (PEDOT), etc. are highly considered since they can be facilely synthesized in the hydrogel matrix, and most importantly, exhibit both the ionic conducting and electronic conducting properties. In recent years, high performance conductive hydrogels based on PANI, PPy and PEDOT have been more and more reported (Chen et al. 2018; Wang et al. 2018b), especially those for strain sensing.

At present, the mostly reported preparation methods for conducting polymer based hydrogels are basically carried out through (1) polymerization of the aniline or pyrrole monomer inside a pre-prepared non-conducting hydrogel matrix, or (2) construct hydrogel network together with the water-soluble polymer solution and a conducting polymer solution or dispersion. In the first way, the pre-prepared hydrogel matrix was soaked in the solution of aniline (or pyrrole) and oxidants such as ammonium persulfate or iron(III) chloride. Since the polymerization takes place simultaneously as the monomer or oxidant diffusing into the hydrogel center, the outer part of the hydrogel will be firstly covered with a layer of the insoluble conducting polymer which in turn inhibits further diffusion of the residual reactants. This method is more applicable to small sized hydrogels and is hard to produce conducting polymers homogenously inside a larger hydrogel samples (Stejskal 2017). Moreover, because the conducting polymer is directly produced inside the hydrogels, dialysis process is usually required to purify the hydrogels in order to remove the byproducts, which is always time-consuming and will lead to swollen of the hydrogels.

As a comparison, the second method seems to be more attractive, since in this case the conducting polymer was incorporated in the form of a solution prior to the formation hydrogel networks, thus a better distribution of the conducting components in the hydrogel network can be achieved. Since PANI and PPy are hardly soluble in water, so PEDOT:PSS solution was more preferred for preparation of conductive hydrogels. For example, Bao et al. used ionic liquid induced gelation of PEDOT:PSS solution and further infiltrate acrylic acid to construct the secondary cross-linking network through radical polymerization (Feig et al. 2018). Rong et al. (2017) obtained anti-freezing hydrogels by co-dissolving PVA and PEDOT:PSS in the mixture of ethylene glycol and water. Nevertheless, the PEDOT:PSS solution is always expensive with a quite low solid content (ca. 1 wt%), which restricts the further improvement of the hydrogel conductivity and their widely application for cheap or single-used flexible electronics. Moreover, for hydrogels in which the conducting components are evenly dispersed in the molecular level, their conductivity is just slightly changed as the hydrogels deforms, i.e., they are usually in-sensitive to the change in strain (Lee et al. 2016), and is not suitable for strain sensors.

Recently, Stejskal et al. (2017) reported a kind of conductive hydrogel formed when the conducting network and hydrogel matrix are simultaneously constructed. This method starts from the dispersion polymerization of aniline in a PVA solution, followed by fast freezing of the reaction mixture. It provides an important direction to incorporate conducting polymer nanostructures evenly into the hydrogel matrix. In early studies, the nanostructures of conducting polymers have been shown to exhibit much more attractive properties than their bulk counterparts (Huang and Kaner 2004; Yang et al. 2005), and the most typical case is polypyrrole. Polypyrrole nanotubes exhibit conductivity nearly two orders of magnitude higher than the conventionally synthesized irregular PPy particles (Li et al. 2017b). Our previous work further manifests the unique roles of sulfonic azo dyes in the morphology control and conductivity improvement of PPy (Li et al. 2020). By finely tuning the synthetic conditions including the type of organic dyes and the polymerization temperature, 1-D PPy nanostructures with conductivity high to 170 S/cm were also reported (Minisy et al. 2020). Most importantly, conducting polymers with one-dimensional morphology are more propitious to form inter-connecting conducting pathways than those isolated nanoparticles or random aggregated molecular strings (Li et al. 2016, 2017a). The highly connecting conducting pathways will probably contribute good electronic conducting properties in hydrogels which are actually a composite system composed of non-conducting matrix and the conducting components. Unfortunately, it is not convenient to directly induce the formation of PPy nanotubes in a hydrogel matrix. Neither the high viscosity of a water-soluble solutions (Li and Jing 2009) nor the elevated temperature usually required for free-radical polymerization of hydrogel matrix polymers is suitable for the formation of conducting polymer nanostructures with high aspect ratio (Minisy et al. 2020). Especially for PPy nanotubes synthesized with sulfonic azo dyes, removal of excess dyes from the hydrogels is quite time-consuming. Therefore, it is highly desired to prepare hydrogels directly from the as-synthesized conductive PPy nanotubes.

In this work, we are trying to prepare conductive hydrogels by employing PPy nanotubes to form the conducting pathways. This idea is proposed based on the fact that well-organized PPy nanotube sponge can be formed during the chemical oxidative polymerization of pyrrole with a much higher reactant concentration. The as-formed porous PPy nanotube sponge can be easily purified through filtration and thus provide naturally conducting framework. By infiltrating water-soluble polymer solutions into the PPy sponge, the hydrogel matrix can be constructed though physical cross-linking or dynamically ionic cross-linking. We believe that this kind of hydrogels in which the electronic conducting pathways are made of 3D network of nanotubes, will display resistance change much more closely dependent on the hydrogel’s geometrical deformation, thus find interesting applications as strain sensor materials.

Experimental

Materials

Pyrrole, polyvinyl alcohol (PVA117, Mw = 145,000), iron(III) chloride hexahydrate and methyl orange (MO) were all purchased from Sigma. Poly (acrylic acid) (PAA, Mw = 240,000, 25 wt%) was purchased from Acros Organics. Citric acid (CA) and hydrochloric acid were purchased from Tianjin Damao Chemical Reagents (Tianjin, China). Pyrrole was vacuum distilled before use and the others were used received.

Synthesis of the PPy nanotube sponge

The PPy nanotube sponge was prepared through the chemical polymerization of pyrrole followed by vacuum filtration. A typical synthetic process was carried out as we reported earlier (Li et al. 2017b), e.g., firstly, dissolve 0.245 g methyl orange (0.75 mmol) into deionized water, into which 1039 μL pyrrole (15 mmol) was added, and the total volume of this mixture solution was mediated to 50 ml; Dissolve 8.109 g iron (III) chloride (0.3 mmol) into deionized water, the total volume of iron (III) chloride solution was also mediated to 50 ml. Secondly, the solution containing pyrrole and MO thus was rapidly mixed with the solution of iron (III) chloride, and the mixture was vigorously shaking for several minutes followed by keeping steady for 24 h. After 24 h of reaction period, the black products became gel-like semi-solid state probably due to the high specific area of PPy nanotubes. Take a certain amount of the semi-solid product mixtures and filtrate it under vacuum, the gel-like products shrink to a sponge and release water containing soluble by-products. Rinse the PPy sponge with 0.2 M hydrochloride acid solution and filtrate again until the filtration solution was colorless and less than 1 mL liquid dropped during 5 min, the PPy sponge was prepared. A piece of the as-prepared PPy sponge is shown in Fig. 1d, the PPy content in the sponge is ca. 6 ± 0.5 wt%.

Construction of hydrogel matrix

PVA solution (12 wt%) in 0.2 M HCl was prepared by dissolving PVA117 into hot water followed by cooled down to room temperature and added the desired amount of concentrated hydrochloric acid. Approximately 2 g of PVA solution and 1 g of the PAA solution (25 wt%) were evenly mixed, into which ca. 2 g of the PPy sponge was put in. The sponge and the mixed solution were put in a closed oven and vacuumed at room temperature with vacuum degree of −0.09–−0.1 MPa for 5–6 min, until the solution was totally absorbed into the PPy sponge. The sponge infiltrated with PVA and PAA solution was filled into a Teflon mold and put in a refrigerator (-18 ℃) for at least five times of frozen and thawing. After that, the de-frosted hydrogel was immersed in to iron (III)/citric acid solution ([Fe3+] = 0.25 M, [Fe3+]/[CA] = 1:2) to induce the cross-linking of PAA with iron (III) ions.

Characterization

The hydrogel was freeze-dried and a thin slice was cut along its cross section direction directly used for morphology examination on a scanning electronic microscope (SEM, Gemini 500). Structure of the freeze-dried PPy-NT/PVA/PAA hydrogel was examined on a Fourier Transform Infrared Spectrometer (Bruker Tensor 27) using ATR mode. Conducting ability of the samples was evaluated using a Keithley 2182 Nanovoltmater and Keithley 6223 current source connected with two graphite rods contacting with each end of the sample. The tensile (10 mm/min) and compression tests (2 mm/min) of the hydrogel were conducted on an electronic universal testing machine (SANS CMT 6503, Shenzhen Sansi, China) by using rectangular hydrogels (7 mm × 60 mm × 2 mm) and cylindrical hydrogels (ϕ10 mm × 10 mm), respectively.

Results and discussion

Formation of the PPy nanotube hydrogels

During pyrrole chemical oxidative polymerization in the presence of sulfonic azo dyes, the high aspect ratio of PPy nanotubes are produced and the multiple non-covalent interactions provide fundamentals for the in-situ formation of 3D polypyrrole skeleton. Both our and the literature results have proved that, for pyrrole polymerization with iron (III) salts as the oxidant and sulfonic azo dyes as the structure directing agents, respectively, highly conducting PPy nanotubes with uniform morphology can be obtained at mild conditions (Kopecka et al. 2014; Li et al. 2017b; Yang et al. 2005). Despite the little differences in their chemical structure or aggregation structures, PPy nanotubes differ oppositely from their irregular particle counterpart in the specific surface area (Li et al. 2017b). As we reported earlier, the specific surface area of PPy nanotubes is almost 8–10 times higher than that of the irregular nanoparticles. Besides, PPy exhibits strong affinity to the sulfonic dyes (Kopecka et al. 2014; Stejskal 2020; Wang et al. 2015). One notable experimental phenomenon is that, when the red-colored MO solution was used for pyrrole polymerization, after 24 h reaction period, the liquid phase almost becomes colorless, indicating MO has been almost totally incorporated into PPy nanotubes. The azo sulfonic dyes were also reported to show strong coordination interactions with metal ions(Chirila et al. 2011). One of our recent works also verified the special interactions between MO and ferric ions (Li et al. 2020). Therefore, under the multiple effects of the high specific surface area of PPy nanotubes, the strong affinity of PPy nanotubes to MO, the coordination interactions between MO and ferric ions, the pyrrole polymerization products become a swollen gel-like bulk block (Fig. 1a) instead of separated precipitates. Some researchers reported that PPy hydrogels were formed after aging of this in-situ formed gel-like products (Dai and Lu 2007; Lu et al. 2014; Pan et al. 2012), whereas the gel-like products are actually fragile.

It is effective to construct strengthened PPy hydrogels by replacing water swollen in the as-formed PPy gel with polymer solutions through filtration. The gel-like polymerization products become a free-standing sponge after vacuum (Fig. 1c, d). Even after several times rinsing with 0.2 M HCl followed by filtration, the sponge structure can still be kept. The apparent density of the as-prepared sponge is ca.18–21 mg/cm3 with water content of 92–95 wt% slightly varied with the vacuum time. The PPy sponge can absorb aqueous polymer solution nearly twice amount of its own weight. This property makes it possible to construct conductive hydrogels based on the purified PPy nanotubes. After infiltration of the PVA and PAA solutions, the sponge becomes flowable and easy to be shaped in a mold. A preliminary PPy hydrogel was formed (Fig. 2) after the infiltrated PPy sponge was repeatedly frozen and de-frosted, due to the crystallization of PVA molecules (Stejskal et al. 2017). After that, the PPy hydrogel was immersed into the mixture solution of iron (III) solution and citric acid, and it was further strengthened by cross-linking the PAA with iron (III) ions (Liu et al. 2019). Thus, hydrogels based on PPy nanotubes with dual cross-linking networks are formed (Fig. 3).

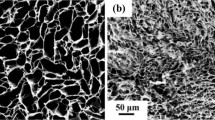

Morphology and structure

The nanotube morphology of PPy is well retained inside the hydrogel and becomes a part of the hydrogel framework with the supporting polymers, e.g., PVA and PAA. As shown in Fig. 4a, nanotubes connect to each other forming 3D porous structure, and the non-conducting polymers (the low brightness region which are less conducting) attach closely with the PPy nanotubes. With this kind of structure, it is probable that the electronic conducting pathways will deform along with the hydrogels matrix, in comparison with hydrogels where the conducting components are evenly distributed in the molecular level in the hydrogel medium. The PPy-NT hydrogels are supposed to display a higher sensitivity to the strain signals.

The FTIR spectrum showed the composite structure features of the PPy-NT/PVA/PAA hydrogels (Fig. 4b). The typical peaks belong to PPy (1530 cm−1 and 1450 cm−1) (Dai et al. 2006), PAA and PVA are all clearly shown in the dried samples. For instance, the peaks at 2090 cm−1 and 1697 cm−1 represent the –C=O in PAA, and the peaks around 3380 cm−1 (hydroxyl groups), 2918 cm−1 (–CH2 groups) can be contributed both to PVA and PAA. The peak at 1400 cm−1 indicates the interaction between the carboxyl group and N–H group of pyrrole ring (Ustamehmetoglu et al. 1999).

Mechanical properties

The PPy nanotube hydrogels with dual cross-linking network show good mechanical properties, which are suitable to handle. The tensile strength and compression strength of the PPy/PVA/PAA hydrogels are ca. 54 kPa and 160 kPa, respectively (Fig. 5), which are higher than some of the literature values where pyrrole polymerization take place inside the hydrogel matrix (Chen et al. 2018; Gu et al. 2018) or PPy (PANI) cryogels (Han et al. 2018; Stejskal et al. 2017) As a matter of fact, the water content, the mass ratio of PPy to the matrix polymer and the cross-linking degree of the matrix network all affect the hydrogels’ mechanical strength. Although PPy nanotube hydrogels can be obtained by employing chemical cross-linking or construct dual cross-linking network, in this work, considering the infiltration process, the viscosity of the matrix polymer solution will restrict the increase in the matrix polymer content. The primary PPy nanotube hydrogels formed through freezing–thawing is fragile and can easily collapse during the installation for mechanical testing. After immersion in iron (III)/CA solution for 6 h, the mechanical strength of the hydrogel is significantly improved and can be successfully tested.

Conducting properties

The PPy-NT/PVA/PAA hydrogels are mainly electronic conducting and show fast response to their strain change (Fig. 6). Their conductivity depends on both the PPy content in the whole hydrogel and the relative content of PPy with respect to the non-conducting polymer matrix. In this work, the PPy content inside the hydrogel is ca. 2 wt%, and relative weight of PPy to that of non-conducting polymers (PVA and PAA) is ca. 19%. Under this condition, the hydrogel shows conductivity of 0.02–0.04 S/cm with the swollen medium of 0.2 M HCl. This conductivity value has achieved the medium level and is even higher than most of the literature values (Stejskal 2017). However, it is still not attractive compared with the high conductivity of dried PPy nanotubes (101–102 S/cm), which can be attributed to the low content of PPy with respective to the non-conducting polymer matrix. For instance, Stejskal reported that hydrogels with 2 wt% of PANI showed conductivity up to 0.105 S/cm, where the relative weight of PANI to PVA is about 40% (Stejskal et al. 2017). Moreover, the conductivity of PPy-NT/PVA/PAA hydrogels changed slightly after it was swollen in 1.0 M HCl or 0.2 M HCl, which indicates that PPy-NTs contribute more to the conductivity than the acidic medium. As a comparison, the PVA hydrogels without PPy-NTs merely showed conductivity of ca. 0.003 S/cm after swollen in 1.0 M HCl. The conductivity of the PPy-NT/PVA/PAA hydrogel can be further improved by carefully improving the intrinsic conductivity of PPy nanotubes and adjusting the relative ratio of PPy-NTs to non-conducting polymer matrix, in order to improve the integrity of the 3D electronic conducting pathways. The detailed work is still under progress. Nevertheless, the PPy-NT/PVA/PAA exhibits smart resistance change by responding their deformation during multiple stretching and recover cycles, which indicates they are attractive for strain sensor applications.

Conclusions

We have developed a facile method to construct conductive hydrogels based on the as-formed PPy nanotubes. This method avoids the time-consuming purification of the pyrrole polymerization products and the inhomogeneous distribution of the conducting polymer inside the hydrogel matrix. The as-formed PPy nanotubes with high specific area and strong affinity to water are susceptive to absorb the water soluble polymers, thus the electronic conducting pathways and the hydrogel matrix networks are well combined. Mechanical property of the infiltrated hydrogels is improved by constructing physical cross-linked (PVA) and chemical cross-linked (PAA/Fe3+) dual networks. Benefited from the high aspect ratio of PPy-NTs, the PPy-NT/PVA/PAA with PPy content of ca.2wt% exhibited the maximum conductivity of 0.04 S/cm in the medium of 0.2 M HCl and showed fast response to the compression strain change. Both the mechanical and conductivity of the PPy-NT/PVA/PAA hydrogels can be improved further, and this kind of facilely prepared hydrogels with dual conducting pathways will play important roles for strain sensing.

References

An R, Zhang BM, Han LL, Wang XD, Zhang YL, Shi LY, Ran R (2019) Strain-sensitivity conductive MWCNTs composite hydrogel for wearable device and near-infrared photosensor. J Mater Sci 54:8515–8530. https://doi.org/10.1007/s10853-019-03438-3

Chen R, Xu XB, Yu DF, Xiao CH, Liu MH, Huang JJ, Mao TY, Zheng C, Wang ZP, Wu X (2018) Highly stretchable and fatigue resistant hydrogels with low Young’s modulus as transparent and flexible strain sensors. J Mater Chem C 6:11193–11201. https://doi.org/10.1039/c8tc02583e

Chirila L, Tutulea DM, Sibiescu D, Rosca I, Cretescu I, Cailean A, Butnaru R (2011) Synthesis and characterization of some metallic combinations with ligands derived from azo dyes. Rev Chim 62:499–503. https://doi.org/10.37358/Rev.Chim.1949

Dai TY, Lu Y (2007) Polypyrrole hydro-sponges built up from mesoscopic scales. J Mater Chem 17:4797–4802. https://doi.org/10.1039/b711790f

Dai TY, Yang XM, Lu Y (2006) Controlled growth of polypyrrole nanotubule/wire in the presence of a cationic surfactant. Nanotechnology 17:3028–3034. https://doi.org/10.1088/0957-4484/17/12/036

Feig VR, Tran H, Lee M, Bao ZA (2018) Mechanically tunable conductive interpenetrating network hydrogels that mimic the elastic moduli of biological tissue. Nat Commun 9:2740. https://doi.org/10.1038/s41467-018-05222-4

Gu ZD, Xu YC, Chen L, Fang RC, Rong QF, Jin X, Jiang L, Liu MJ (2018) Macroporous conductive hydrogels with fatigue resistance as strain sensor for human motion monitoring. Macromol Mater Eng 303:1800339. https://doi.org/10.1002/mame.201800339

Han L, Liu KZ, Wang MH, Wang KF, Fang LM, Chen HT, Zhou J, Lu X (2018) Mussel-inspired adhesive and conductive hydrogel with long-lasting moisture and extreme temperature tolerance. Adv Funct Mater 28:1704195. https://doi.org/10.1002/adfm.201704195

Huang JX, Kaner RB (2004) A general chemical route to polyaniline nanofibers. J Am Chem Soc 126:851–855. https://doi.org/10.1021/ja0371754

Kopecka J, Kopecky D, Vrnata M, Fitl P, Stejskal J, Trchova M, Bober P, Moravkova Z, Prokes J, Sapurina I (2014) Polypyrrole nanotubes: mechanism of formation. RSC Adv 4:1551–1558. https://doi.org/10.1039/c3ra45841e

Lee YY, Kang HY, Gwon SH, Choi GM, Lim SM, Sun JY, Joo YC (2016) A strain-insensitive stretchable electronic conductor: PEDOT:PSS/acrylamide organogels. Adv Mater 28:1636–1643. https://doi.org/10.1002/adma.201504606

Li Y, Jing XL (2009) Morphology control of chemically prepared polyaniline nanostructures: effects of mass transfer. React Funct Polym 69:797–807. https://doi.org/10.1016/j.reactfunctpolym.2009.06.009

Li Y, Bober P, Apaydin DH, Syrovy T, Sariciftci NS, Hromadkova J, Sapurina I, Trchova M, Stejskal J (2016) Colloids of polypyrrole nanotubes/nanorods: a promising conducting ink. Synth Met 221:67–74. https://doi.org/10.1016/j.synthmet.2016.10.007

Li Y, Bober P, Trchova M, Stejskal J (2017a) Colloidal dispersions of conducting copolymers of aniline and p-phenylenediamine for films with enhanced conductometric sensitivity to temperature. J Mater Chem C 5:1668–1674. https://doi.org/10.1039/c6tc05413g

Li Y, Bober P, Trchova M, Stejskal J (2017b) Polypyrrole prepared in the presence of methyl orange and ethyl orange: nanotubes versus globules in conductivity enhancement. J Mater Chem C 5:4236–4245. https://doi.org/10.1039/c7tc00206h

Li Y, Wang YP, Bian C, Stejskal J, Zheng YS, Jing XL (2020) Azo dye aggregates and their roles in the morphology and conductivity of polypyrrole. Dyes Pigments 177:108329. https://doi.org/10.1016/j.dyepig.2020.108329

Liu XY, Xu H, Zhang LQ, Zhong M, Xie XM (2019) Homogeneous and real super tough multi-bond network hydrogels created through a controllable metal ion permeation strategy. ACS Appl Mater Interfaces 11:42856–42864. https://doi.org/10.1021/acsami.9b18620

Lu Y, He WN, Cao T, Guo HT, Zhang YY, Li QW, Shao ZQ, Cui YL, Zhang XT (2014) Elastic, conductive, polymeric hydrogels and sponges. Sci Rep 4:5792. https://doi.org/10.1038/srep05792

Minisy IM, Acharya U, Kobera L, Trchova M, Unterweger C, Breitenbach S, Brus J, Pfleger J, Stejskal J, Bober P (2020) Highly conducting 1-D polypyrrole prepared in the presence of safranin. J Mater Chem C 8:12140–12147. https://doi.org/10.1039/d0tc02838j

Pan LJ, Yu GH, Zhai DY, Lee HR, Zhao WT, Liu N, Wang HL, Tee BCK, Shi Y, Cui Y, Bao ZN (2012) Hierarchical nanostructured conducting polymer hydrogel with high electrochemical activity. Proc Natl Acad Sci USA 109:9287–9292. https://doi.org/10.1073/pnas.1202636109

Rong QF, Lei WW, Chen L, Yin YA, Zhou JJ, Liu MJ (2017) Anti-freezing, conductive self-healing organohydrogels with stable strain-sensitivity at subzero temperatures. Angew Chem Int Ed 56:14159–14163. https://doi.org/10.1002/anie.201708614

Rong QF, Lei WW, Liu MJ (2018) Conductive hydrogels as smart materials for flexible electronic devices. Chem Eur J 24:16930–16943. https://doi.org/10.1002/chem.201801302

Stejskal J (2017) Conducting polymer hydrogels Chem Pap 71:269–291. https://doi.org/10.1007/s11696-016-0072-9

Stejskal J (2020) Conducting polymers are not just conducting: a perspective for emerging technology. Polym Int 69:662–664. https://doi.org/10.1002/pi.5947

Stejskal J, Bober P, Trchova M, Koyalcik A, Hodan J, Hromadkova J, Prokes J (2017) Polyaniline cryogels supported with poly(vinyl alcohol): soft and conducting. Macromolecules 50:972–978. https://doi.org/10.1021/acs.macromol.6b02526

Turky G, Moussa MA, Hasanin M, El-Sayed NS, Kamel S (2020) Carboxymethyl cellulose-based hydrogel: dielectric study, antimicrobial activity and biocompatibility. Arabian J Sci Eng. https://doi.org/10.1007/s13369-020-04655-8

Uluturk C, Alemdar N (2019) Production of reduced graphene oxide-based electrically conductive hydrogel by using modified chitosan. J Appl Polym Sci 136:48008. https://doi.org/10.1002/app.48008

Ustamehmetoglu B, Bayulken S, Ozkara S, Sonmez C, Sarac AS (1999) Interaction of metal ions with polypyrrole on polyacrylic acid matrix. J Polym Sci Pol Chem 37:1115–1123. https://doi.org/10.1002/(SICI)1099-0518(19990415)37:8%3c1115::AID-POLA8%3e3.0.CO;2-P

Wang YQ, Shi Y, Pan LJ, Ding Y, Zhao Y, Li Y, Shi Y, Yu GH (2015) Dopant-enabled supramolecular approach for controlled synthesis of nanostructured conductive polymer hydrogels. Nano Lett 15:7736–7741. https://doi.org/10.1021/acs.nanolett.5b03891

Wang ZW, Chen J, Gong Y, Zhang H, Xu T, Nie L, Fu J (2018a) Ultrastretchable strain sensors and arrays with high sensitivity and linearity based on super tough conductive hydrogels. Chem Mater 30:8062–8069. https://doi.org/10.1021/acs.chemmater.8b03999

Wang ZW, Zhou HW, Lai JL, Yan B, Liu HB, Jin XL, Ma AJ, Zhang G, Zhao WF, Chen WX (2018b) Extremely stretchable and electrically conductive hydrogels with dually synergistic networks for wearable strain sensors. J Mater Chem C 6:9200–9207. https://doi.org/10.1039/c8tc02505c

Wei D, Zhu J, Luo L, Huang H, Li L, Yu X (2020) Fabrication of poly(vinyl alcohol)-graphene oxide-polypyrrole composite hydrogel for elastic supercapacitors. J Mater Sci 55:11779–11791. https://doi.org/10.1007/s10853-020-04833-x

Yang XM, Zhu ZX, Dai TY, Lu Y (2005) Facile fabrication of functional polypyrrole nanotubes via a reactive self-degraded template. Macromol Rapid Commun 26:1736–1740. https://doi.org/10.1002/marc.200500514

Zhang Q, Liu X, Duan LJ, Gao GH (2019) Ultra-stretchable wearable strain sensors based on skin-inspired adhesive, tough and conductive hydrogels. Chem Eng J 365:10–19. https://doi.org/10.1016/j.cej.2019.02.014

Acknowledgements

The authors would like to acknowledge the financial support to this work provided by the National Natural Science Foundation of China through Grant No. 51903200 and the Natural Science Basic Research Plan in Shaanxi Province through Grant No. 2020JQ-037. We also highly appreciate Mr. Zijun Ren from the Instrumental Analysis Center of Xi’an Jiaotong University for his help of SEM examination.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Y., Wang, Y., Liu, X. et al. Facilely prepared conductive hydrogels based on polypyrrole nanotubes. Chem. Pap. 75, 5113–5120 (2021). https://doi.org/10.1007/s11696-021-01559-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-021-01559-1