Abstract

The study found that biodegradable drug delivery membranes that were fabricated from Poly(a-L-alanine) (PLLA) and chlorhexidine (CHX)-gluconate via electrospinning could steadily and continuously inhibit the growth of bacteria. Bacterial growth curves were used to evaluate on a real-time basis the relationship between drug delivery speeds of the membranes and growth rates of bacteria in different phases. The results showed that PLLA/CHX (50:50 in terms of volume) drug delivery membranes could do what drug delivery systems can normally do. SEM morphology observations, FTIR, and Raman spectra analyses were conducted on the drug delivery membranes. This is the first study that confirms that biodegradable CHX delivery membranes fabricated via electrospinning are a rate-preprogrammed drug delivery system by comparing the growth curves of competent cell and plasmid inserted competent cell, bacteria that are of the same strain but grow at different speeds due to the insertion.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Research on controlled release of drugs is a very important process to achieve the highest therapeutic efficiency. Much research has been carried out in order to develop of new and/or improved drug therapies that are more efficient and, most importantly, more cost-effective. The conventional definition of controlled release is a constant level of drugs in suitable systems. Electrospun fibers was a novel process to prepare and the release characteristics should depend on interaction between polymer and drug pair as much as on the sizes of fibers [1].

Polymeric drug delivery systems plays an important role in conventional dosage forms, such as improved therapeutic effect, reduced toxicity, convenience, and so on. In previous study, the drugs can be capsulated directly into electrospun fibers and these systems show nearly zero-order kinetics of drug release [2].

Electrospinning is a simple and versatile method for fibers preparation, which employs electrostatic forces that strength a polymer jet to generate continuous fibers with diameters ranging from micrometers down to several nanometers [3, 4].

Poly(α-l-alanine) (PLLA) is one of the most promising biodegradable polymers owing to its mechanical property profile, thermoplastic processibility and biological properties, such as biocompatibility and biodegradability [5]. Electrospinning is an interesting technique for spinning PLLA. The process offers an excellent opportunity for designing the surface morphology and porosity of the fibers to provide the most appropriate interface for biomedical application [3, 6–8].

Chlorhexidine (CHX) is a bactericidal agent. Its effect on Escherichia coli (E. coli) and S. aureus is dependent on CHX concentration and pH. It’s found that, by using 14C CHX-gluconate, the uptake by bacteria becomes extremely rapid, with a maximum effect occurring within 20 s [9]. Damage to outer cell layers takes place but is insufficient to induce lysis or cell death. The agent then crosses cell walls or outer membranes, presumably by passive diffusion, and subsequently attacks bacterial cytoplasmic or inner membranes. In previous studies, interaction of CHX with carboxyl, sulfate, and phosphate groups was studied in vitro, including factors that might interfere with these interactions. The properties of cetylpyridine in the same systems also were investigated for comparison, as this is a basic antibacterial agent with virtually no plaque inhibiting effect [9–12].

Previous studies fabricated effective bacteria inhibiting fiber membranes from polymer/silver nanoparticles [13, 14] and polymer/chitosan [15–17] via electrospinning. In addition, when it comes to bacteria inhibiting drug, such as CHX [18], CHX-CA [12], CHX-digluconate [11], and CHX-gluconate, only the delivery efficiency of polymer/CHX, or just that of CHX, has been discussed [11, 12]. Tests on the inhibiting capability (Inhibition zone) of polymer/CHX matrix were rarely done. Evaluations of bacteria inhibiting capability based on inhibition zone were only qualitative, not quantitative. This study aimed to discuss whether biodegradable inhibiting drug delivery membranes fabricated from PLLA/CHX via electrospinning possessed the characteristics of drug delivery systems and whether CHX could still inhibit bacteria after being released from PLLA. This experiment quantitatively evaluated bacteria growth in liquid culture by observing optical density (OD) 600 nm at 1 h intervals, and used the growth curves thus derived to evaluate on a real-time the impacts of drug delivery speeds on the growth rates of bacteria in different phases. Competent cell and plasmid inserted competent cell, bacteria that are of the same strain but grow at different speeds were utilized to interact with biodegradable CHX delivery membranes fabricated via electrospinning to determine whether such drug delivery membranes are a rate-preprogrammed drug delivery system.

2 Materials and methods

2.1 Materials

PLLA is a biodegradable, thermoplastic, aliphatic polyester derived from renewable resources, such as corn starch or sugarcanes. PLLA, purchased from Sigma, Taiwan, has a molecular weight of 180–200 kDa with a volume concentration of 12%, i.e. 12 g PLLA dissolved in 100 ml ACS grade >99.8% chloroform. CHX-gluconate, acquired from J.T. Backer, has a volume concentration of 0.5%, i.e. 5 mg CHX-gluconate dissolved in 1,000 ml 70% isopropyl alcohol.

2.2 Bacterial strain and plasmids

The competent cells used in this experiment, XL1-Blue E. coli strain from Stratagene, were purchased from Invitrogene, the same company from which TOPO plasmid was obtained, TOPO Xl1-Blue were XL1-Blue inserted with TOPO plasmid by means of heat shock. XL1-blue E. coli and TOPO XL1-Blue were cultured in Luria–Bertani (LB) broth (from Difico Co Ltd., Taipei, Taiwan) and LB agar plates were supplemented with 100 μg/ml of ampicillin for cloning and maintenance. The cells were grown at 37°C and 200 rpm to mid-logarithmic phase (OD 600 nm of 0.8) growth rates and bacterial concentrations were determined by measuring OD at 600 nm each 30 min (OD of 0.1 corresponds to a concentration of 108 cells per cm3). PLLA, PLLA/CHX (90:10) and PLLA/CHX (50:50) membrane size is 18 × 18 mm, similar to the size of cover slip.

2.3 Fabrication of composite PLLA/CHX fibers

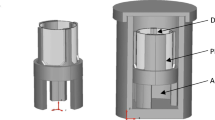

The polymer fibers were injected in by using a 10 ml glass syringe with a 22 needle gauge (0.7 mm OD × 0.4 mm ID) at a flow rate of 0.2 ml/h, which was controlled by using a KDS100 pump from Yeong-Shin Co., Ltd. Hsinchu, Taiwan. The high voltage power supply used was a 30 kV/15 W model purchased from You-Shang Technical Corp. Kaohsiung, Taiwan. The equipment was attached to the needle tip through an alligator clip and voltage difference of 20 kV was used; the tinfoil grounded target was placed at 15 cm away from the needle tip.

First, PLLA, PLLA/CHX (90:10 in terms of volume), and PLLA/CHX (50:50 in terms of volume) solution were injected into 10 ml syringes. Next, a syringe pump was used to control the 10 ml syringes with PLLA/CHX solution to flow at 0.2 ml/h. The syringe needle was stainless steel, while the collector was tinfoil paper. The distance between the syringe tip and the collector was 15 cm. Then, the high power supply was connected to the syringe tip and the collector; the positive electrode was on the syringe tip side, and the negative electrode was on the collector side. The high power supply was turned on to 20 kV to observe the spinning fibers on the collector. The structural and optical properties were investigated by a scanning electron microscope (SEM), micro-Raman system and tensile tests. All the experiments were performed at room temperature, about 25°C.

2.4 Morphology of electrospun fibers

The fibers were examined by a Field Emission Scanning Electron Microscope (FE-SEM) to visualize their morphology by using a JSM-6700F (JEOL Ltd.). The fiber samples were coated with a thin layer of palladium in 100 s at 20 mA by the auto fine coater JFC-1600 (JEOL Ltd.).

2.5 Fourier transform infrared spectroscopy (FTIR)

Perkin-Elmer spectrum one FTIR spectroscopy (from Analytical & Bio Science Instrument Co., Ltd., Taipei, Taiwan) was used and set at absorbance mode, 500–2,000 cm−1 wavelength with a resolution of 4 cm−1.

2.6 Micro-Raman spectroscopy

Raman scattering measurements were performed in the TRIAX 550 micro-Raman system. The 5145 Å line with a power of 0.2 W from the coherent innova argon ion laser was focused to about 2–4 μm on the sample surface. The back-scattered signal was collected by a microscopic system and recorded with a Jobin-Yvon SPEX Spectrum One liquid nitrogen cooled CCD detector. All spectra were recorded by an olympus microscope objective and three accumulations at 300 s integration time with ~50 mW power on the sample for each Raman spectrum. Frequencies were to ±2 cm−1 accurately as determined from plasma emission lines. The frequency of each Raman band reported in this study was obtained using Lorentzian curve fitting.

2.7 Antibacterial test

XL1-Blue and TOPO XL1-Blue were used to evaluate the bacteria/plague inhibiting capability of the CHX releasing membranes by observing their bacteria growth curves. First of all, one colony from the LB agar plate of XL1-Blue and one colony from that of TOPO XL1-Blue were collected and, respectively placed into culture tubes containing 5 ml of LB broth. The tubes were then put in an incubator at 37°C at 200 rpm for 6–8 h (until OD = 0.8). Next, ten 1 l Erlenmeyer flasks containing 500 ml of LB broth medium, sterilized by autoclave at 120°C under 1.2 kgf/cm2 for 15 min, and cooled down for 3 h, were prepared. The ten flasks were divided into two groups of five. One group was added with 0.2 ml of XL1-Blue (OD = 0.8), while the other was added with 0.2 ml of TOPO XL1-Blue (OD = 0.8). In each group, only the first flask (control group) was not added with the drug delivery membranes and PLLA fibers, PLLA/CHX fibers (50:50), PLLA/CHX fibers (90:10), and 100 μg/ml of ampicillin solution were, respectively added into the other four flasks. All of them were placed back into the incubator at 37°C and 200 rpm, and 1 ml of the broth was extracted hourly for 12 consecutive hours to derive bacteria growth curves by observing ODs (OD 600 nm).

3 Results and discussion

It could be observed by the electronic microscope that, in Fig. 1a, the fiber diameter of PLLA was approximately 3–5 μm and on the surface of the fibers were pores at the size of around 10 nm. In Fig. 1b, the fiber diameter of PLLA/CHX was approximately 600–900 nm and the surface was smooth. It was further observed that PLLA/CHX fibers tended to overlap and formed a structure of 2–3 fiber tubes.

In this experiment, the original intent was to understand, by means of FTIR and Raman spectroscopy, if CHX was successfully mixed with PLLA solution to fabricate via electrospinning biodegradable PLLA fiber membranes that contained CHX. FTIR spectra of analyzed polymers were demonstrated in Fig. 2. The band originating from C=O stretching vibrations was situated at 1745 cm−1 for poly lactide [19]. In the range 1,050–1,250 cm−1 C–O and C–O–C stretching vibrations could be attributed. There were three bands in the range 1,300–1,500 cm−1 in PLLA spectrum that might attribute to symmetric and asymmetric deformational vibrations of C–H in CH3 groups [20].

However, in the FTIR experiment, the characteristic IR peaks of CHX were observed between 1,500 and 1,650 cm−1 (C=N stretching and aromatic C=C bending vibrations, respectively) [12] and PLLA demonstrated a very strong peak νC=O at 1,760 cm−1, so we could not confirm via FTIR whether the biodegradable PLLA fiber membranes contained CHX. FTIR could at most confirm that PLLA was used in the experiment. (In the FTIR spectrum of the PLLA film, the most pronounced difference with the spectra of individual homopolymers was the disappearance of the absorption peak at 1,270 cm−1 [19, 20].)

Therefore, to confirm the existence of CHX in the fiber membranes, Micro-Raman spectroscope was utilized to conduct fiber membrane analyses at CH3 and CH bending region. The CH3 asymmetric deformation modes appeared at about 1,450 ± 2 cm−1 as intense Raman and IR bands in all the compounds [19, 21].

In the Raman spectra of the PLLA/CHX fibers, the characteristic CHX peak at 1,604 cm−1, as indicated by an arrow in Fig. 3, was observed. The peak shifted 34 cm−1 to higher wavenumbers compared to that of pure CHX powders (1,570 cm−1) [12, 18], which could be attributed to the interaction between CHX and the polymer matrix in the fibers. As mentioned in previous literature, the I875/I1452 Raman intensity ratio signaled results of bio-degradation and structural differences [19, 21]. In this experiment, although both were bio-degradable membranes, the I875/I1452 Raman intensity ratio of PLLA fiber membranes was 1.494 while that of PLLA/CHX fiber membranes was 1.304.

Figure 4a–c illustrated the interactions between the PLLA/CHX (50:50) drug releasing membranes and XL1-Blue. Figure. 4(d) was the bacteria growth curves derived by observing the ODs (OD 600 nm) of the 1 ml broth extracted from flasks of various conditions at 1 h intervals. As ampicillin, a form of antibiotics, could effectively inhibit the growth of XL1-Blue, no growth was observed (OD 600 nm = 0.002) in XL1-Blue added with ampicillin solution 100 μg/ml. No obvious growth was observed in the zero to third hours in the lag phase. Only PLLA and PLLA/CHX (90:10) experienced some minor growth in OD (OD 600 nm = 0.018, 0.016) in the third hour. The OD of PLLX/CHX (50:50) in the zero to third hours was 0.002, which signaled that the growth of bacteria was effectively inhibited. PLLA/CHX (50:50) PLLA was non-toxic and biocompatible. Even though PLLA/CHX (90:10) contained CHX, the concentration is very low (0.05%). Therefore, bacteria also started to grow in the third hour. In the fourth to ninth hours, the growth curves of PLLA and PLLA/CHX (90:10) entered the log phase, a period featured by exponential multiple growth in terms of the number of XL1-Blue. During this phase, PLLA/CHX (50:50) still could release CHX steadily, maintaining the concentration level of CHX in the flasks and thus inhibiting the growth of XL1-Blue (average OD 600 nm = 0.006), Fig. 4b was a further illustration of the growth curves resulted from the interactions between PLLA/CHX (50:50) membranes and XL1-Blue in the fourth to ninth hours. During the log phase, bacteria could grow in exponential multiples, but as PLLA/CHX (50:50) steadily released CHX, the concentration within the flasks was thus maintained at a level that could effectively inhibit XL1-Blue from growing. In the tenth to twelfth hours, it was observed from the growth curves of PLLA and PLLA/CHX (90:10) that the stationary phase was initiated. During this period of time, PLLA/CHX (50:10) could no longer effectively inhibit the growth of XL1-Blue. The OD (600 nm) was 0.065 in the tenth hour, 0.251 in the eleventh hour, and 0.461 in the twelfth hour. Figure. 4c, the growth curves of PLLA/CHX membranes in the tenth to twelfth hours, further manifested such results. Theoretically, if the concentration of CHX released by PLLA/CHX (50:50) into the flasks was high enough to inhibit bacteria, XL1-Blue would not grow. However, the ODs proved that CHX concentration in the flasks was not high enough to inhibit the growth of XL1-Blue (from the tenth hour and beyond).

a–c Illustrations of interaction between drug released by drug delivery membranes and growth rates of XL1-Blue in the a zero to third hours b fourth to ninth hours c tenth to twelfth hours (yellow membrane:PLLA/CHX(50:50 volume ratio), Green bacterial: Xl1-Blue) d Growth curves of XL1-Blue in LB medium inoculated with 107 CFU of bacteria. The presence of different concentrations of (filled triangle) PLLA/CHX fibers (90:10) and (filled circle) PLLA/CHX fibers (50:50). Another two curves: one is only (filled inverted triangle) poly(l-lactic acid)s fibers; the other is (filled square) ampicillin-added 100 μg/ml

Figure 5a–c were the illustrations of the interaction between PLLA/CHX (50:50) drug release membranes and TOPO XL1-Blue. Figure. 5d was the bacteria growth curves of TOPO XL1-Blue derived by observing the ODs of the 1 ml broth extracted from flasks of various conditions at 1 h intervals. Although antibiotics, ampicillin, could effectively inhibit the growth of E. coli, a section of the genetic sequence of TOPO plasmid which was anti-ampicillion was inserted, and therefore, TOPO XL1-Blue can still grow in broth with ampicillin. Microbial strains with plasmid could stay in the lag phase for 1–2 h more than those without plasmid before they entered into the log phase. This characteristic was what this experiment needed. If the drug delivery membranes fabricated via electrospinning simply released CHX into the flasks through diffusion or permeation at steady rates, the four bacteria growth curves that reflected their interactions with TOPO XL1-Blue as illustrated in Fig. 5d should be in line with Fig. 4d. In the zero to fourth hours in the lag phase, no significant bacterial growth was observed. Only in the fourth hour were minor OD increases observed in PLLA, PLLA/CHX (90:10), and ampicillion solution 100 μg/ml (OD 600 nm = 0.023, 0.016, 0.011); ODs of PLLA/CHX (50:50) from the zero to fourth hours were maintained at the same level (OD 600 nm = 0.003). We can further refer such results to Fig. 5a, the growth curves derived from the interaction between PLLA/CHX membranes and TOPO XL1-Blue. Figure 5d showed that there were not many bacteria in the flasks in the zero to fourth hours, and the release of CHX by PLLA/CHX (50:50) effectively inhibited the growth of bacteria during this period. In the following fifth to tenth hours, it was observed from the growth curves derived from the interaction between TOPO XL1-Blue and PLLA, PLLA/CHX (90:10), and ampicillin solution 100 μg/ml that the log phase was initiated and XL1-Blue E. coli with TOPO plasmid were growing exponentially. However, as PLLA/CHX (50:50) continued to release CHX, the concentration was maintained at a level that inhibited the growth of TOPO XL1-Blue (average OD 600 nm = 0.002). We can further refer such results to Fig. 5b, the growth curves illustrating the interaction between the PLLA/CHX membranes and TOPO XL1-Blue in the fifth to tenth hours. If the PLLA/CHX (50:50) membranes released drug at a steady rate, CHX should be fully released from the membranes into the flasks with XL1-Blue or TOPO XL1-Blue in the ninth to tenth hours. The results should be similar to Fig. 4d, the illustration of the interaction between PLLA/CHX (50:50) and XL1-Blue, where XL1-Blue or TOPO XL1-Blue should start to grow in the tenth hour. However, this was not the case with TOPO XL1-Blue. It was observed in the eleventh to twelfth hours that the growth curves illustrating the interactions between TOPO XL1-Blue and PLLA, PLLA/CHX (90:10), and ampicillin solution 100 μg/ml, still stayed in the log phase. TOPO XL1-Blue continued to grow in exponential multiples and ODs of PLLA/CHX (50:50) in this phase did not show significant increases (OD 600 nm = 0.005), i.e. the growth of TOPO XL1-Blue was still inhibited. We can further refer the results to Fig. 5c, the illustration of the interactions between PLLA/CHX (50:50) and TOPO XL1-Blue. In addition to environmental factors, the concentration level of inhibiting drug was the main element contributing to the inhibiting capability. Given the assumption that the drug was released at a steady rate, the reason PLLA/CHX (50:50) could still effectively inhibit the growth of TOPO XL1-Blue in the eleventh to twelfth hours was TOPO XL1-Blue grew slower than XL1-Blue. Therefore, when CHX was first released into the flasks, there was no TOPO XL1-Blue to interact with. CHX continued to stay in the flasks until XL1-Blue grew to a number that was too many for CHX to suppress (or there was not sufficient CHX to suppress TOPO XL1-Blue) (or until CHX concentration was lower than the effective inhibiting level). Then, it became possible for TOPO XL1-Blue to grow.

a–c Illustrations of interaction between drug released by PLLA/CHX(50:50) membranes and growth rates of topo XL1-Blue in the a zero to fourth hours b fifth to tenth hours c eleventh to twelfth hours (yellow membrane:PLLA/CHX(50:50 volume ratio), Green bacterial: Topo Xl1-Blue). d Growth curves of topo XL1-Blue in LB medium inoculated with 107 CFU of bacteria. The presence of different concentrations of (filled triangle) PLLA/CHX fibers (90:10) and (filled circle) PLLA/CHX fibers (50:50). Another two curves: one is only (inverted filled triangle) poly(l-lactic acid)s fibers; the other is (filled square) ampicillin-added 100 μg/ml

This study made use of bacterial growth curves to evaluate on a real-time basis the impacts of drug delivery speeds on the growth rates of bacteria in different phases. The growth curves of XL1-Blue and TOPO XL1-Blue were used to observe the impacts of drug delivery speeds of PLLA/CHX (50:50). The XL1-Blue growth curves showed that the concentration level of CHX in the ninth hour could no longer inhibit XL1-Blue, and XL1-Blue started to grow exponentially in the tenth to twelfth hours, demonstrating the common characteristics of a drug delivery system. According to Fick’s law of diffusion, PLLA/CHX (50:50) released CHX into the flasks at a steady pace. Even though TOPO XL1-Blue grew slower, PLLA/CHX (50:50) kept on releasing CHX at a steady speed. When TOPO XL1-Blue grew to a number that was too many for CHX to suppress (or there was not sufficient CHX to suppress TOPO XL1-Blue) (or until CHX concentration was lower than the effective inhibiting level), it became possible for TOPO XL1-Blue to grow. there is not sufficient CHX to suppress TOPO XL1-Blue, it becomes possible for TOPO XL1-Blue to grow. Therefore, it could be concluded from this study that the biodegradable CHX delivery membranes fabricated via electrospinning were a rate-preprogrammed drug delivery system.

Polymeric drug delivery systems have numerous advantages compared to conventional dosage forms, such as improved therapeutic effect, reduced toxicity, convenience, and so on. However, the application of drug delivery systems in dentistry is a comparatively new area of research. In addition to applications in wound dressing, PLLA/CHX is also added to mouth-wash and used in periodontal treatments as it not only is bio-degradable membrane but also contains CHX It has been confirmed in pharmacology, microbiology, and toxicology that CHX is very powerful in killing or suppressing germs, such as gram-positive bacteria, gram-negative bacteria, anaerobic or aerobic bacterial, various bacilli, Pseudomonas aeruginosa, albicans, etc. Furthermore, since it is not absorbable by human’s gastrointestinal system, it practically has no systemic toxicity. At present, the practice of guided tissue regeneration (GTR) in treating periodontal diseases aims to stimulate the regeneration of alveolar bone and periodontal tissue. However, the infection of guided tissue regeneration membranes by bacteria often leads to poor surgery results. This explains why anti-bacteria agents, such as antibiotics or CHX, are usually used after surgery. If PLLA/CHX fiber membranes generated via electrospinning can be applied in GTR, the treatment of periodontal diseases can be brought up to another level.

In previous studies, it is known that CHX can effectively inhibit E. coli and S. aureus [9]. This experiment works with E. coli because it has a simpler physiology than other bacteria, and uses TOPO plasmid as control group to confirm that there is no human error during the process. Hence, future work can look into whether biodegradable PLLA/CHX membranes fabricated via electrospin have the same bacteria inhibiting capability on the strains that CHX is known to inhibit.

4 Conclusions

The results of this experiment show that CHX drug delivery membranes fabricated via electrospinning are a typical rate-preprogrammed drug delivery system, which can effectively inhibit the growth of bacteria. In this experiment where bacteria growth curves are used to evaluate the inhibiting capability of CHX releasing membranes, it is found that (1) biodegradable CHX delivery membranes can be fabricated via electrospinning, CHX can effectively inhibit the growth of bacteria, and the concentration level of CHX released by the delivery membranes can have a say over the inhibiting duration; (2) previous studies have focused on the delivery efficiency of polymer/CHX or simply on the drug delivery efficiency. Only a few of them have evaluated the inhibiting capability of polymer/CHX matrix (Inhibition zone), but evaluations of bacteria inhibiting capability based on inhibition zone are only qualitative, not quantitative. Therefore, this experiment proposes to evaluate on a real-time basis the impacts of drug delivery speeds of the membranes on the growth rates of bacteria in different phases; (3) as growth curves of a single bacterium can only conclude whether the membranes possess characteristics of drug delivery systems, bacteria that are of the same strain (competent cells and plasmid inserted competent cells) but grow at different speeds are used to evaluate whether such drug delivery membranes are a rate-preprogrammed drug delivery system.

References

Pornsopone V, Supaphol P, Rangkupan R, Tantayanon S. Electrospun methacrylate-based copolymer/indomethacin fibers and their release characteristics of indomethacin. J Polym Res. 2007;14(1):53–9.

Zeng J, Xu X, Chen X, Liang Q, Bian X, Yang L, et al. Biodegradable electrospun fibers for drug delivery. J Control Rel. 2003;92(3):227–31.

Agarwal S, Wendorff JH, Greiner A. Use of electrospinning technique for biomedical applications. Polymer. 2008;49(26):5603–21.

Reneker DH, Yarin AL. Electrospinning jets and polymer nanofibers. Polymer. 2008;49(10):2387–425.

Tsuji H. Poly(lactide) stereocomplexes: formation, structure, properties, degradation, and applications. Macromol Biosci. 2005;5(7):569–97.

Thakur RA, Florek CA, Kohn J, Michniak BB. Electrospun nanofibrous polymeric scaffold with targeted drug release profiles for potential application as wound dressing. Int J Pharma. 2008;364(1):87–93.

François S, Chakfé N, Durand B, Laroche G. A poly(l-lactic acid) nanofibre mesh scaffold for endothelial cells on vascular prostheses. Acta Biomater. 2009;5(7):2418–28.

Corey JM, Gertz CC, Wang B-S, Birrell LK, Johnson SL, Martin DC, et al. The design of electrospun PLLA nanofiber scaffolds compatible with serum-free growth of primary motor and sensory neurons. Acta Biomater. 2008;4(4):863–75.

Rölla G, Melsen B. On the mechanism of the plaque inhibition by chlorhexidine. J Dent Res. 1975;54(Special Issue B):B57–62.

Riggs PD, Braden M, Patel M. Chlorhexidine release from room temperature polymerising methacrylate systems. Biomaterials. 2000;21(4):345–51.

Yue IC, Poff J, Cortés ME, Sinisterra RD, Faris CB, Hildgen P, et al. A novel polymeric chlorhexidine delivery device for the treatment of periodontal disease. Biomaterials. 2004;25(17):3743–50.

Chen L, Bromberg L, Hatton TA, Rutledge GC. Electrospun cellulose acetate fibers containing chlorhexidine as a bactericide. Polymer. 2008;49(5):1266–75.

Sondi I, Salopek-Sondi B. Silver nanoparticles as antimicrobial agent: a case study on E. coli as a model for gram-negative bacteria. J Colloid Interf Sci. 2004;275(1):177–82.

Xu X, Yang Q, Wang Y, Yu H, Chen X, Jing X. Biodegradable electrospun poly(l-lactide) fibers containing antibacterial silver nanoparticles. Eur Polym J. 2006;42(9):2081–7.

Schiffman JD, Schauer CL. One-step electrospinning of cross-linked chitosan fibers. Biomacromolecules. 2007;8(9):2665–7.

Spasova M, Paneva D, Manolova N, Radenkov P, Rashkov I. Electrospun chitosan-coated fibers of poly(l-lactide) and poly(l-lactide)/poly(ethylene glycol): preparation and characterization. Macromol Biosci. 2008;8(2):153–62.

Xu J, Zhang J, Gao W, Liang H, Wang H, Li J. Preparation of chitosan/PLA blend micro/nanofibers by electrospinning. Mater Lett. 2009;63(8):658–60.

Jones DS, Brown AF, Woolfson AD, Dennis AC, Matchett LJ, Bell SEJ. Examination of the physical state of chlorhexidine within viscoelastic, bioadhesive semisolids using Raman spectroscopy. J Pharm Sci. 2000;89(5):563–71.

Kister G, Cassanas G, Vert M. Effects of morphology, conformation and configuration on the IR and Raman spectra of various poly(lactic acid)s. Polymer. 1998;39(2):267–73.

Tretinnikov ON, Kato K, Iwata H. Adsorption of enantiomeric poly(lactide)s on surface-grafted poly(l-lactide). Langmuir. 2004;20(16):6748–53.

Taddei P, Tinti A, Fini G. Vibrational spectroscopy of polymeric biomaterials. J Raman Spectrosc. 2001;32(8):619–29.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, Y.N., Chang, K.M., Jeng, S.C. et al. Study of release speeds and bacteria inhibiting capabilities of drug delivery membranes fabricated via electrospinning by observing bacteria growth curves. J Mater Sci: Mater Med 22, 571–577 (2011). https://doi.org/10.1007/s10856-011-4249-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-011-4249-z