Abstract

To fulfill the demand of high saturation magnetization soft magnetic materials for electric motors, Fe82−xCoxSi4B13C1 (x = 0, 5, 10, 15, 20, 25, and 30) amorphous alloys are prepared and effects of Co addition on soft magnetic properties and thermal parameters have been investigated. It shows that Curie temperature increases greatly with the increasing Co content. And the Bs of the low Co content amorphous alloys can be effectively enhanced. Especially, the amorphous alloy with 15 at% Co exhibits a high saturation magnetization of 1.73 T and a maximum permeability as high as 1.37 × 104 by appropriately annealed at 380 °C without magnetic fields for 10 min. Moreover, the relation between the coercivity and magnetic domain structure was investigated. The amorphous alloys are promising for further application in the field of electric motors.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The Fe-based amorphous soft magnetic materials have attracted wide attention because of their high saturation magnetization (Bs), low coercivity (Hc), high permeability (µ), low core losses, high Curie temperature (Tc), and high glass forming ability (GFA) [1,2,3,4]. As a result, they have been widely used in electromagnetic devices such as inductors, transformers, and sensors [5,6,7,8]. However, Bs values of the commercial Fe-based amorphous alloys are merely 1.56 T for Fe78Si9B13 [9] and 1.64 T for Fe82Si4B13C1 [10], which are much lower than the 1.9–2.1 T for the conventional Fe-Si electrical steels [11]. Thus, it is crucial to improve the Bs and numerous efforts have been made to achieve this goal [12,13,14,15,16].

In the view of the alloy composition, the Bs of Fe-based amorphous alloys can be improved by increasing the Fe content [12, 14] and/or partially substituting Fe with Co [13,14,15,16]. However, it has been found that the GFA of the Fe-based amorphous alloys is weaken with the increasing Fe content. According to the Chaos principle [17], complex components make it difficult to precipitate complicated phases, and the competition between different phases can restrain the crystallization process. Therefore, the addition of Co can not only improve Bs, but also improve the GFA of the system. What’s more, Bs and Tc are the intrinsic magnetic properties that depend on elementary composition and crystal structure. As accepted that the Bs of α-Fe(Co) phase (2.45 T) is higher than that of α-Fe phase (2.18 T) [18] and Co element exhibits higher Bs of 1394 K than Fe element (1043 K) [19]. Hence, the addition of Co is beneficial for enhancing GFA, Bs and Tc [20, 21].

Consequently, many efforts have been devoted to develop Fe- and Fe-Co based amorphous alloys. Kong et al. have developed a new amorphous Fe–P–B–Si–C alloy with high Bs of 1.70 T [22]. It has subsequently been reported that the partial replacement of Fe by Co causes a further increase in Bs to 1.74 T for Fe68Co15P3B11Si2C1 [16] and 1.76 T for Fe68Co17P3B8Si4 [23]. However, the P-containing alloys show several disadvantages, such as the difficulty in controlling the alloy composition [24]. Therefore, there is a strong demand to develop P-free Fe-based amorphous alloys. Moreover, it should be noted that the Metglas 2605Co (Fe67Co18B14Si1) with high Bs of 1.80 T and low Hc of 2.0 A/m are only obtained by annealed at magnetic fields [19, 25], which cannot be applied in electric motors.

There is a large demand of high Bs and low core loss amorphous alloys without magnetic-fields annealing serving as the stator core in the field of electric motors. In this study, we try to improve the Bs of the famous commercially applied 2605HB1 [26] amorphous alloy by substituting Fe with Co. The Fe82−xCoxSi4B13C1 (x = 0, 5, 10, 15, 20, 25 and 30) amorphous alloys are synthesized and effects of Co addition on soft magnetic properties and thermal parameters are explored.

2 Experiment

Fe82−xCoxSi4B13C1 (x = 0, 5, 10, 15, 20, 25, and 30) alloys were prepared by melting the mixtures of pure Fe (99.99 wt%), Co (99.95 wt%), Si (99.99 wt%), pre-alloyed Fe-5% C and Fe-20% B in a highly purified argon atmosphere. And the ingots were re-melted to ensure the homogeneity. Amorphous ribbons with a width of 3 mm and thickness of 20 μm were prepared by single roller melt-spinning method with a wheel velocity of 29 m/s. The phase structure of both as-quenched and annealed ribbons was identified by X-ray diffraction (XRD, Bruker D8 Advance) with Cu-Kα radiation. Thermal parameters associated with crystallization was examined by differential scanning calorimetry (DSC, NETZSCH 404 C) at a heating rate of 40 °C/min under an argon flow. Annealing treatment without magnetic fields was carried out at 280 to 440 °C for 10 min in a vacuum atmosphere under a low pressure of 2 Pa. The Hc and µm were tested by a DC B–H loop tracer (EXPH-100, Riken Denshi Co., Ltd) under a field up to 800 A/m. The Bs was measured with a vibrating sample magnetometer (VSM, Lake Shore 7410) under a field up to 800 kA/m. Additionally, the structure of magnetic domain was characterized via the Magneto-optical Kerr Microscope (MOKE, KMPL-Spin-X).

3 Results and discussion

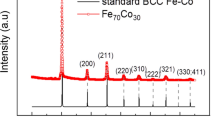

The XRD patterns of Fe82−xCoxSi4B13C1 (x = 0, 5, 10, 15, 20, 25, and 30) as-quenched ribbons are shown in Fig. 1. All patterns exhibit a wide peak near 44.5° without any sharp peak, indicating the amorphous structure of the samples.

Figure 2 shows the DSC curves measured at a heating rate of 40 °C/min of the as-quenched Fe82−xCoxSi4B13C1 (x = 0, 5, 10, 15, 20, 25, and 30) alloy ribbons. All alloy ribbons exhibit two distinct exothermic peaks, which indicates the crystallization process involves two separated crystallization steps. The onset temperatures of the first and second exothermic peaks were denoted as Tx1, Tx2, respectively. And, Tx1 presents a slight change which can be regarded as constant over the whole Co content range, while Tx2 increases with increasing Co content. An endothermic peak can be observed for the ribbons corresponding to the x = 0 and 5 curves before the first exothermic peak, which has been proven to be the result of Curie transition from ferromagnetic state to paramagnetic state of the alloy ribbons. Whereas, no trace of Tc signal can be marked on the curves of x = 10, 15, 20, 25 and 30 alloy ribbons, because the Tc exceeds the Tx and overlaps with the exothermic peak. This result indicates that Tc increases accordingly with the increasing of Co content, which is consistent with previous report [27]. An interesting phenomenon is that the intensity of the first exothermic peak is stronger than that of the second exothermic peak for the Fe82−xCoxSi4B13C1 (x = 0, 5 and 10) alloy ribbons. The reasons might be that (i) the ribbons with a higher melting temperature release more enthalpy during the initial crystallization reaction [28], (ii) in the Fe–Si–B–C system, when the Fe content exceeds 82 at%, the DSC curve exhibits two distinct exothermic peaks. However, as Tx1 increases with decreasing Fe content, when Fe content drops to or below 82 at%, the two exothermic peaks tend to overlap [29]. What’s more, Tx2 increases with increasing Co content. Therefore, in the alloys studied in this paper, where there is either without Co or a small amount of Co, the two exothermic peaks tend to overlap into a single peak.

Variation of Hc with the annealing temperature for Fe82−xCoxSi4B13C1 (x = 0, 5, 10, 15, 20, 25, and 30) alloy ribbons after annealed for 10 min is shown in Fig. 3. On sees that for the alloy ribbons of Co free, the Hc firstly decreases to 5.9 A/m and then increases with the increasing annealing temperature. And the Hc can keep very low value (about 10 A/m) under the annealing temperature from 280 °C to 380 °C. However, the alloy ribbons with Co addition exhibit obviously different phenomenon. For the alloy ribbons of Co addition, the Hc maintains a high value more than 10 A/m and demonstrates a trend of first increasing, then decreasing and finally increasing with increasing annealing temperature. The Hc of all alloy ribbons reaches the minimum value after annealed at 380 °C for 10 min and the Hc at 380 °C exhibits a trend of first increasing and then decreasing with increasing Co content. In conclusion, with the increasing of Co content, the optimal Hc increases, while the optimum annealing temperature interval decreases.

Figure 4 shows the annealing temperature dependence of µm for Fe82−xCoxSi4B13C1 (x = 0, 5, 10, 15, 20, 25, and 30) alloy ribbons. In contrast to the tendency of Hc, the µm decreases with the increasing of Co content. On the one hand, the trend of the µm can be described as an initial increase, followed by a subsequent decrease for the Fe82−xCoxSi4B13C1 (x = 0, 5 and 10) alloy ribbons. On the other hand, the µm of the Fe82−xCoxSi4B13C1 (x = 15, 20, 25, and 30) alloy ribbons nearly keeps a constant value in the whole annealing temperature interval.

Based on the annealing temperature dependence of Hc and µm, Fig. 5 shows the hysteresis loops, soft magnetic properties and corresponding XRD patterns of the Fe82−xCoxSi4B13C1 (x = 0, 5, 10, 15, 20, 25, and 30) alloy ribbons after annealed at 380 °C for 10 min. One sees that from Fig. 5a, b that with the increase of Co, the Bs of the Fe82−xCoxSi4B13C1 (x = 0, 5, 10, 15, 20, 25, and 30) alloy ribbons annealed firstly increase from 1.64 T for x = 0 to 1.73 T for x = 15, and then decrease to 1.63 T for x = 30. The arrows in Fig. 5c present the summit position of the amorphous broad diffraction peak. It is noteworthy that the peak in the XRD patterns shifts significantly to a lower angle until x = 15 and then shifts to the higher angle side with further increasing Co content. According to Bragg’s Law [30], this shift indicates that the nearest neighbor atomic distance in the amorphous structure increases slightly with Co addition until x = 15, and then decreases with further increasing Co content. This compositional dependence has been interpreted a result of free electrons in the outer shell of the 15 at% Co amorphous alloy, which can contribute to the attainment of high Bs. This decrease in the number of free electrons in the outer shell can then contribute to the formation of metallic-like bonding among the constituent elements [31], which may be regarded as one of the reasons for the change in Bs.

In this section, we will discuss the possible reasons for the changes in magnetic properties. Previous studies [32] have shown that the destruction of B, P, and Si on the magnetic moment (ms) in Fe-base amorphous increases successively. P, Si, and Ge are considered as substitutional elements, whereas B and C are interstitial elements. The mass density of substitutional elements decreases significantly when they are added to the alloy, while the mass density of interstitial elements decreases less.

The relationship between the spontaneous magnetization (Ms) and the temperature (T) of amorphous ferromagnets can be treated with traditional effective molecular field approximation. For ferromagnet systems with two kinds of magnetic atoms, it can be expressed as follows [33],

where \({m}_{\text{Fe}}\) and \({m}_{\text{Co}}\) are the magnetic moment of Fe and Co, \(\chi\) relates to the atomic spin quantum number and the exchange integral of the spin.

Due to the stronger exchange interaction between Fe–Co and Co–Co atoms compared to Fe–Fe atoms [34], the addition of Co atom increases the value of \(\chi\). For alloys without Co addition, \(\chi\) < 1, both terms on the right side of the equation are positive. With the increase of Co content, \(\chi\) gradually increases and becomes greater than 1. At this point, the first term on the right side of the equation is positive, but the second term becomes negative. As a result, the absolute value of the sum of the two, Ms decreases.

The Slater-Pauling curve based on the rigid band model [35], also can explain the changes of Bs. According to this model, the ms of Fe70Co30 is the largest. There are holes in both positive and negative spin bands in Fe. With the addition of Co, the excess \(d\) electrons enter the positive spin band with high state density, which increases the positive spin number and ms. However, near 30 at% Co, the positive band is almost filled, then the d electrons begin to enter the negative band, and the \({m}_{s}\) decreases with the increase of d electrons. The same trend was also found in amorphous Fe–Co–B alloys [36]. And the maximum value of Bs corresponding to 10–20 at% Co, which is consistent with conventional amorphous alloys.

The Hc of the amorphous alloys can be expressed as follows [37]:

where δ is thickness of domain wall, Bs is saturated magnetization, K is anisotropy constant, λs is saturated magnetostriction, σ is internal stress. Based on these relations, the lower Hc seems to be dominated by the release of internal stress. The internal stress would be gradually released with the increasing annealing temperature until the optimal temperature. However, higher annealing temperature can lead to the formation of crystalline phase, such as bcc-Fe, which increases the anisotropy and ultimately deteriorates the soft magnetic property.

A notable phenomenon observed is that there is a small hump for the Hc of alloy ribbons annealed at 300 °C with x ≥ 5, which can be explained by the existence of induced anisotropy. When the annealing temperature is much lower than Tc, magnetic softness will not be achieved, and will even be worsened in high-Tc systems [38].

For further understanding soft magnetic properties, magnetic domains were examined. As shown in Fig. 6, for the as-quenched Fe82−xCoxSi4B13C1 alloy ribbons, the magnetic domains direction (see Fig. 6a, c, e) is almost in sensitive direction and all alloy ribbons exhibit small strips. The internal stress distributions within the strips differ due to the influence of the quench curing mode and heat treatment process, resulting in varying magnetoelastic energy and related induced uniaxial anisotropy (Ku) values. The magnetic anisotropy will directly affect the magnetic structure of amorphous crystals without grain boundaries and other defects. Due to the uniaxial properties of Ku, the domain walls in amorphous materials are mainly 180° (see in Fig. 6a–e) [39].

For alloy ribbons without Co, the domain direction and width is more uniform after annealing because of the release of internal stress. However, for 15 at% Co addition alloy ribbons, the annealing treatment makes the domains more wider. Co addition results in a large annealing induced anisotropy due to the well-known pair ordering effect where Ku becomes proportional to the square of Co content [40]. For 30 at% Co addition alloy ribbons, the domain structure does not become uniform so much as change into worse. After annealing, the magnetic domain structure changes from narrow to wide and then to disordered, indicating an increase in Ku and Hc. In summary, the domain structure makes a good explanation for the changes of soft magnetic properties.

Table 1 presents a summary of magnetic properties of the Fe82−xCoxSi4B13C1 (x = 5, 10, and 15) amorphous ribbons, along with other representative alloys reported for comparison [9, 25, 41]. One sees from Table 1 that Fe82−xCoxSi4B13C1 alloy ribbons exhibit a smaller Hc than the traditional non-oriented Fe–Si alloy but a larger Bs than Fe78Si9B13, indicating that they can reduced both the core loss and the device volume. In contrast to Metglas 2605Co (Fe67Co18B14Si1), the Fe82−xCoxSi4B13C1 alloy ribbons do not require the application of magnetic-fields annealing, making them promising for potential applications in the electric motors industry.

4 Conclusion

Effects of Co addition on thermal parameters and magnetic properties of Fe82−xCoxSi4B13C1 (x = 0, 5, 10, 15, 20, 25, and 30) amorphous alloys are investigated. And origin of the changes in soft magnetic properties of these Co-doped FeSiBC amorphous alloys are explored. The results obtained can be summarized as follows:

-

1)

Bs of Fe82−xCoxSi4B13C1 amorphous alloys is effective enhanced from 1.64 T to 1.73 T with Co addition from 0 to 15 at%, and then decrease to 1.63 T with Co addition from 15 to 30 at%. Tc of Fe82−xCoxSi4B13C1 amorphous alloys increases greatly. While Hc and µe deteriorated after Co addition.

-

2)

The high Bs is contributed to the optimum Co/Fe content ratio with the maximum magnetic interaction. The magnetic domain structure changes from narrow to wide and then to disordered, indicating the increase in Hc.

-

3)

Compared to the traditional materials, the Fe82−xCoxSi4B13C1 amorphous alloys with more applicable Hc and Bs without the application of magnetic-fields annealing, making them highly suitable for potential applications in the field of electric motors.

Data availability

Data will be made available on request.

References

G. Herzer, H.R. Hilzinger, Recent developments in soft magnetic materials. Phys. Scripta (1988). https://doi.org/10.1088/00318949/1988/T24/003

R. Hasegawa, D. Azuma, Impacts of amorphous metal-based transformers on energy efficiency and environment. J. Magn. Magn. Mater. 320(20), 2451–2456 (2008). https://doi.org/10.1016/j.jmmm.2008.04.052

T. Fukao, A. Chiba, M. Matsui, Test results on a super-high-speed amorphous-iron reluctance motor. IEEE Trans. Ind. Appl. 25(1), 119–125 (1989). https://doi.org/10.1109/28.18881

C. Suryanarayana, A. Inoue, Iron-based bulk metallic glasses. Int. Mater. Rev. 58(3), 131–166 (2013). https://doi.org/10.1179/1743280412Y. 0000 000007

D.C. Jiles, Recent advances and future directions in magnetic materials. Acta Mater. 51(19), 5907–5939 (2003). https://doi.org/10.1016/j.actamat.2003.08.011

M.E. McHenry, M.A. Willard, D.E. Laughlin, Amorphous and nanocrystalline materials for applications as soft magnets. Prog. Mater. Sci. 44(4), 291–433 (1999). https://doi.org/10.1016/S0079-6425(99)00002-X

B. Dong, Q. Zhi, D. Li et al., Abnormality of magnetic behavior and core loss of nanocrystalline Fe73.5Cu1Nb3Si15.5B7 alloy. Sci. China Technological Sci. 53, 343–347 (2010). https://doi.org/10.1007/s11431-010-0049-9

B. Dong, S. Zhou, J. Qin et al., The prediction of upper limit of copper content in CoBCu glass-forming alloys. Comput. Mater. Sci. 152, 351–354 (2018). https://doi.org/10.1016/j.commatsci.2018.05.016

A. Datta, D. Nathasingh, R.J. Martis et al., Saturation and engineering magnetostriction of an iron-base amorphous alloy for power applications. J. Appl. Phys. 55(6), 1784–1786 (1984). https://doi.org/10.1063/1.333477

F. Kuniyoshi, E. Oda, S. Nakajima et al., Magnetic materials for energy and resource saving. Hitachi Hyoron 95(43), 48 (2013)

A. Inoue, F. Kong, Q. Man et al., Development and applications of Fe-and Co-based bulk glassy alloys and their prospects. J. Alloys Compd. 615, S2–S8 (2014). https://doi.org/10.1016/j.jallcom.2013.11.122

H. Li, A. Wang, T. Liu et al., Design of Fe-based nanocrystalline alloys with superior magnetization and manufacturability. Mater. Today. 42, 49–56 (2021). https://doi.org/10.1016/j.mattod.2020.09.030

R. Parsons, Z. Li, K. Suzuki, Nanocrystalline soft magnetic materials with a saturation magnetization greater than 2 T. J. Magn. Magn. Mater. 485, 180–186 (2019). https://doi.org/10.1016/j.jmmm.2019.04.052

A. Wang, C. Zhao, H. Men et al., Fe-based amorphous alloys for wide ribbon production with high Bs and outstanding amorphous forming ability. J. Alloys Comp. 630, 209–213 (2015). https://doi.org/10.1016/j.jallcom.2015.01.056

C. Parra, F.J. Bolivar, Effect of cobalt addition on the microstructural evolution, thermal stability and magnetic properties of Fe-based amorphous alloys. Vacuum 169, 108911 (2019). https://doi.org/10.1016/j.vacuum.2019.108911

C. Zhao, A. Wang, A. He et al., Correlation between soft-magnetic properties and Tx1-Tc in high bs FeCoSiBPC amorphous alloys. J. Alloys Compd. 659, 193–197 (2016). https://doi.org/10.1016/j.jallcom.2015.11.044

A.L. Greer, Confusion by design. Nature. 366(6453), 303–304 (1993). https://doi.org/10.1038/366303a0

H. Ohno, Properties of ferromagnetic III–V semiconductors. J. Magn. Magn. Mater. 200(1–3), 110–129 (1999). https://doi.org/10.1016/S0304-8853(99)00444-8

F. Wang, A. Inoue, Y. Han et al., Excellent soft magnetic Fe–Co–B-based amorphous alloys with extremely high saturation magnetization above 1.85 T and low coercivity below 3 A/m. J. Alloys Compd. 711, 132–142 (2017). https://doi.org/10.1016/j.jallcom.2017.03.341

B. Shen, A. Inoue, C. Chang, Superhigh strength and good soft-magnetic properties of (Fe, Co)–B–Si–Nb bulk glassy alloys with high glass-forming ability. Appl. Phys. Lett. 85(21), 4911–4913 (2004). https://doi.org/10.1063/1.1827349

C.D. Jr Graham, T. Egami, Magnetic properties of amorphous alloys. Annu. Rev. Mater. Sci. 8(1), 423–457 (1978). https://doi.org/10.1146/annurev.ms.08.080178.002231

F. Kong, C. Chang, A. Inoue et al., Fe-based amorphous soft magnetic alloys with high saturation magnetization and good bending ductility. J. Alloys Compd. 615, 163–166 (2014). https://doi.org/10.1016/j.jallcom.2014.06.093

Y. Han, J. Ding, F. Kong et al., FeCo-based soft magnetic alloys with high bs approaching 1.75 T and good bending ductility. J. Alloys Compd. 691, 364–368 (2017). https://doi.org/10.1016/j.jallcom.2016.08.250

S. Banya, N. Maruyama, S. Fujino, Vapor pressure of phosphorus in liquid Fe–P alloys. Tetsu-to-Hagane 68, 269–276 (1982). https://doi.org/10.2355/tetsutohagane955.68.2_269

F. Wang, A. Inoue, Y. Han et al., Soft magnetic Fe-Co-based amorphous alloys with extremely high saturation magnetization exceeding 1.9 T and low coercivity of 2 A/m[J]. J. Alloys Compd. 723, 376–384 (2017). https://doi.org/10.1016/j.jallcom.2017.06.192

C.H. Hsu, Y.H. Chang, (2009) Impacts of Fe-based amorphous HB 1 core transformers on energy efficiency and environment protection. WSEAS International Conference. Proceedings. Mathematics and Computers in Science and Engineering. World Scientific and Engineering Academy and Society.

Y. Xing, B. Dong, S. Zhou et al., Soft magnetic properties of co-doped FeSiBC amorphous and nanocrystalline alloys. J. Magn. Magn. Mater. 565, 170249 (2023). https://doi.org/10.1016/j.jmmm.2022.170249

Z. Zhu, H. Zhang, H. Wang, B. Ding, Z. Hu, Influence of casting temperature on the thermal stability of Cu- and Zr-based metallic glasses: theoretical analysis and experiments. J. Mater. Res. 23(10), 2714–2719 (2008). https://doi.org/10.1557/JMR.2008.0335

C. Dong, A. Inoue, X. Wang et al., Soft magnetic properties of Fe82 – 83B14–15Si2C0. 5–1 amorphous alloys with high saturation magnetization above 1.7 T. J. Non-cryst. Solids. 500, 173–180 (2018). https://doi.org/10.1016/j.jnoncrysol.2018.07.072

C.J. Humphreys, The significance of Bragg’s law in electron diffraction and microscopy, and Bragg’s second law. Acta Crystallogr. Sect. A: Found. Crystallogr. 69(1), 45–50 (2013). https://doi.org/10.1107/S0108767312047587

G. Herzer, Modern soft magnets: amorphous and nanocrystalline materials. Acta Mater. 61(3), 718–734 (2013). https://doi.org/10.1016/j.actamat.2012.10.040

A. Makino, T. Kubota, C. Chang, M. Makabe, A. Inoue, Fe-metalloids bulk glassy alloys with high Fe content and high glass-forming ability. J. Mater. Res. 23(5), 1339–1342 (2008). https://doi.org/10.1557/JMR.2008.0180

L. Hou, M. Li, C. Jiang et al., Thermal and magnetic properties of Fe (Co) BCCu amorphous alloys with high saturation magnetization of 1.77 T. J. Alloys Compd. 853, 157071 (2021). https://doi.org/10.1016/j.jallcom.2020.157071

J.M. MacLaren, T.C. Schuthess, W.H. Butler, R. Sutton, M. McHenry, Electronic structure, exchange interactions, and Curie temperature of FeCo. J. Appl. Phys. 85, 4833–4835 (1999). https://doi.org/10.1063/1.370036

A. Díaz-Ortiz, R. Drautz, M. Fähnle et al., Structure and magnetism in bcc-based iron-cobalt alloys. Phys. Rev. B 73(22), 224208 (2006). https://doi.org/10.1103/PhysRevB.73.224208

R.C. O’Handley, R. Hasegawa, R. Ray et al., Ferromagnetic properties of some new metallic glasses. Appl. Phys. Lett. 29(6), 330–332 (1976). https://doi.org/10.1063/1.89085

T. Bitoh, A. Makino, A. Inoue, Origin of low coercivity of Fe-(Al, Ga)-(P, C, B, Si, Ge) bulk glassy alloys. Mater. Trans. 44(10), 2020–2024 (2003). https://doi.org/10.2320/matertrans.44.2020

C. Zhao, A. Wang, S. Yue et al., Significant improvement of soft magnetic properties for Fe (Co) BPSiC amorphous alloys by magnetic field annealing. J. Alloys Compd. 742, 220–225 (2018). https://doi.org/10.1016/j.jallcom.2018.01.311

A. Hubert, R. Schäfer, Magnetic Domains (Springer, Berlin, 1998), p.255

K. Suzuki, R. Parsons, B. Zang et al., Nanocrystalline soft magnetic materials from binary alloy precursors with high saturation magnetization. AIP Adv. 9(3), 035311 (2019). https://doi.org/10.1063/1.5079778

A. Inoue, F.L. Kong, Q.K. Man et al., Development and applications of Fe-and Co-based bulk glassy alloys and their prospects. J. Alloys Compd. 615(S2), S8 (2014). https://doi.org/10.1016/j.jallcom.2013.11.122

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No.51971093 and 52192603) and the National Key Research and Development Program of China (No.2022YFB2404102).

Author information

Authors and Affiliations

Contributions

HC: data curation, formal analysis, investigation, writing—original draft. BD: conceptualization, formal analysis, funding acquisition, supervision, writing—review and editing. YX: conceptualization, formal analysis, supervision. YC: visualization, supervision, writing—review and editing. LW: supervision, visualization. SZ: project administration, resources.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

There are no experiments involving human tissue.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cui, H., Dong, B., Xing, Y. et al. Soft magnetic properties of FeCoSiBC amorphous alloys with high saturation magnetization. J Mater Sci: Mater Electron 34, 1801 (2023). https://doi.org/10.1007/s10854-023-11204-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11204-0