Abstract

In this work, Fe3O4 magnetic nanoparticles (MNPs) were produced using the co-precipitation method. The surface of the produced MNPs was covered with TEOS and APTES as a shell and the APTES shell is doped with Au nanoparticles (NPs) where Fe3O4@SiO2/APTES–Au nanocomposites were obtained. Catalytic performance of the Fe3O4@SiO2/APTES–Au NPs was assessed for the reduction of 4-nitrophenol (4-NP). The physical structures of the NPs were assessed with microscopic methods such as scanning electron microscopy and transmission electron microscopy. Chemical structures of the nanocomposites were verified using EDX, infrared spectroscopy, and X-ray diffraction. Magnetic properties of the nanostructures were assessed vibrating sample magnetometry. Results indicate that we successfully managed to produce Fe3O4@SiO2/APTES–Au NPs with good magnetic properties. Fe3O4@SiO2/APTES–Au MNPs showed high catalytic activity for the reduction of 4-NP.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Consumption of nitrophenols increased day by day. Nitrophenols were used in the production of different products as raw material and/or side material such as explosives, dyes, pharmaceuticals, pesticides, and rubber products [1, 2]. Such compounds were vastly used in industrial applications. Nitrophenols can contaminate natural freshwaters and soils. Therefore, the uncontrolled release of nitrophenol containing wastewaters affects the food chain and poses a deleterious effect on nature [3, 4]. Nitrophenol compounds can have carcinogenic and mutagenic effects which have a toxic effect on living creatures and microorganisms in freshwaters. Determination and removal of nitrophenol-based compounds, which affect the health of living organisms, are important. Recent researches illustrated that noble metal nanoparticles (NPs) have an outstanding catalytic activity that can be used to reduce nitrophenol to aminophenol in aqueous environments [5,6,7,8,9].

Noble metal NPs have prominent chemical properties which researched by different fields. Data obtained from such researches could be applied to different areas such as energy converging and storage devices, cancer therapy and drug delivery applications, and imaging applications [10,11,12,13]. On contrary, the price of noble materials limits their applicability. A possible solution to overcome the high price is to repetitive usage of the same noble metal NPs in possible applications. To achieve this goal, magnetic characteristics can be given to the noble metal nanomaterials. Therefore, used material can be regained and recollected where reusable materials can be obtained [14, 15]. Hence, using noble NPs with magnetic properties in catalysis applications enhances the efficiency of catalysis reaction; catalyser materials can be recollected with a magnet at the end of the catalysis reaction. Such a case enables NPs to be reused in other reactions. Due to the surface characteristics of Au NPs, direct binding of iron oxide NPs to the Au surface is difficult. Tetraethyl orthosilicate (TEOS), (3-Aminopropyl)triethoxysilane (APTES) dendritic supports can help metallic NPs to overcome various obstacles. For example, TEOS, APTES dendritic supports can be applied to iron NPs, they protect iron NPs from oxidation and can be used in the functionalization of the NPs [16,17,18]. In addition, enhanced biocompatibility and stability were obtained with TEOS and APTES coating. Lu et al. synthesized Fe3O4/Au core@shell nanocubes and nanocrystals [15]. Xia et al. produced Fe3O4 hollow nanospheres and cover the surface of the spheres with APTES. Then, Au nanocomposites were obtained and used for the reduction of 4-NP where catalysis properties were assessed [19].

In this work, we aimed to obtain magnetically collectible and reusable magnetic nanocomposites the surface of which was decorated with Au NPs. The co-precipitation method was used in the production of Fe3O4 magnetic nanoparticles (MNPs), and the surface of the MNPs was covered with TEOS and APTES. Commercially available Au NPs were decorated on the surface of APTES where Fe3O4@SiO2/APTES–Au (See Fig. 1). Reduction of 4-NP in the existence of magnetic nanocomposites were assessed.

2 Materials and methods

2.1 Materials and reagents

FeCl3·6H2O, FeCl2·4H2O, TEOS, APTES, 28% ammonia (NH3), and ethanol were purchased from Sigma-Aldrich. Au NPs (15–19 nm, in 0.1 mM PBS) were obtained from Alfa Aesar.

2.2 Synthesis of Fe3O4@SiO2/APTES–Au MNPs

Fe3O4, Fe3O4@SiO2, Fe3O4@SiO2/APTES magnetic nanocomposites were synthesized according to previous studies [20, 21]. Briefly, under N2 protection, FeCl2·4H2O (1 g) and FeCl3·6H2O (2.6 g) were dissolved in 25 mL of water. The solution obtained was added dropwise to the reaction medium with 28% NH3 (10 mL) solution while stirring vigorously. The solution was stirred at 60 °C for 2 h. The resulting black MNPs were collected with the help of a magnet and washed 2 times with pure water and ethyl alcohol and dried in a vacuum oven at 40 °C for 24 h.

For the surface of Fe3O4 NPs to be covered by the TEOS shell, 20 mL of ethanol was added on 0.1 g of Fe3O4. MNPs were dispersed in the ultrasonic bath for 30 min. 0.5 mL TEOS and 0.5 mL 28% NH3 solution were added dropwise and stirred at room temperature for 12 h. MNPs were collected with the help of a magnet and washed 2 times with water and ethyl alcohol. Fe3O4@SiO2 magnetic nanocomposites were dried in a vacuum oven at 40 °C for 24 h [22].

For the surface of Fe3O4 NPs to be covered by the APTES shell; Fe3O4@SiO2 NPs (0.5 g) were dispersed in 50 mL of ethanol followed by APTES (2 mL). The resulting mixture was stirred at 50 °C for 24 h. The NPs so produced (Fe3O4@SiO2/APTES) were separated using a magnet and washed three times with ethanol. Finally, the solid was dried in a vacuum oven at 40 °C for 24 h [20, 23].

Fe3O4@SiO2/APTES (0.2 g) was dispersed in 20 mL of ethanol for 20 min. Au NPs (3 mL, 15–19 nm, ~ 6.54E + 11 particles/mL in 0.1 mM PBS) were poured into the Fe3O4@SiO2/APTES solution formed and stirred under N2 protection for 24 h. The final product (Fe3O4@SiO2/APTES–Au) was collected with the aid of a magnet, washed with ethanol and distilled water and dried in a vacuum oven at 40 °C for 12 h.

2.3 Catalytic reduction of 4-NP to 4-AP with use of magnetic nanocatalysts

The catalytic activity of Fe3O4, Fe3O4@SiO2, Fe3O4@SiO2/APTES, and Fe3O4@SiO2/APTES–Au were evaluated by the reduction of 4-NP to 4-AP. Reactions were carried out in a quartz cuvette. For this purpose, freshly prepared NaBH4 solution (0.2 M, 0.3 mL) was added to 3 mL of 0.1 mM aqueous 4-NP solution. It was scanned in the wavelength range of 250–600 nm in a UV–vis spectrophotometer. 10 mg of catalyst was added to the mixture and stirred for 1 min at room temperature (25 °C). The conversion of 4-NP to 4-AP was monitored by a UV–vis spectrophotometer.

3 Results and discussion

3.1 Characterization of Fe3O4, Fe3O4@SiO2, Fe3O4@SiO2/APTES, and Fe3O4@SiO2/APTES–Au MNPs

3.1.1 SEM images and EDX analysis of MNPs

Images related to SEM-EDX analysis of Fe3O4, Fe3O4@SiO2, Fe3O4@SiO2/APTES, and Fe3O4@SiO2/APTES–Au MNPs are illustrated in Fig. 2. SEM images of Fe3O4 MNPs illustrated that the particles were in nanosize. NPs were found to be in agglomerated form which was attributed to the magnetic characteristics of the NPs. The shape of NPs was found to be spheric after TEOS and APTES coating of Fe3O4 MNPs. EDX spectra of Fe3O4@SiO2/APTES–Au MNs confirm the existence of Au, Fe, Si, N, and O in the nanocomposite structure.

3.1.2 TEM images of MNPs

TEM images belong to Fe3O4, Fe3O4@SiO2, Fe3O4@SiO2/APTES, and Fe3O4@SiO2/APTES–Au nanocomposites are presented in Fig. 3. TEM images clearly illustrate that TEOS coated MNPs exhibit core@shell structure where light parts were found to be a shell and dark sections were found to be iron oxide core. The size of the Fe3O4 core was assessed using TEM images which was found to be 11.7 nm. TEOS and APTES coat on MNPs increase the overall sizes. Figure 3d illustrates the structure of Fe3O4@SiO2/APTES–Au nanocomposites. Figure 3 illustrates the composite form of the nanostructures dark parts in the centre show Fe3O4 core, light parts illustrate TEOS and APTES coat and dark parts and dots around the periphery illustrate Au NPs. The size of Fe3O4@SiO2/APTES–Au nanocomposites was found to be approx. 60 nm.

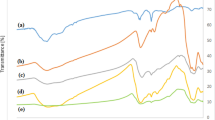

3.1.3 FTIR spectrum of MNPs

Figure 4 illustrates FTIR spectra of Fe3O4, Fe3O4@SiO2, Fe3O4@SiO2/APTES MNPs. Bands observed at 583 and 456 cm−l in the FTIR spectra of Fe3O4 MNPs were attributed to υ(Fe–O) stretching [24]. Bands observed at 1053, 948 and 795 cm−1 in Fe3O4@SiO2 FTIR spectrum confirms that Fe3O4 NPs were coated with TEOS. Vibrations in these wavenumbers show asymmetric Si–O–Si stretching vibrations [25]. FTIR spectrum belongs to Fe3O4@SiO2/APTES MNPs exhibit an apparent band at 1616 cm−1 which was attributed to aliphatic amine groups bending, the band at 2861 cm−1 was attributed to the asymmetric stretching vibrations which belong to methylene (–CH2–) groups in APTES structure. The band at 2939 cm−1 was attributed to asymmetric stretching vibrations of –CH2– groups. The large band observed at 3366 cm−1 belongs to stretching vibrations of aliphatic amine groups [20].

3.1.4 XRD patters of MNPs

XRD patterns of nanocomposites are presented in Fig. 5. It was revealed that the XRD pattern of Fe3O4 NPs illustrate face centred cubic (fcc) structure which corresponds (1 1 1), (2 2 0), (3 1 1), (2 2 2), (4 0 0), (4 2 2), (5 1 1), (4 4 0), (6 2 0), (5 3 3), (6 2 2), and (4 4 4) orientations which corresponds 2θ angles of 18.3°, 30.4°, 35.6°, 37.08°, 43.3°, 53.36°, 57.3°, 62.8°, 70.98°, 74.12°, 74.98°, and 78.94°, respectively [26]. XRD results confirm the structure of Fe3O4 NPs which were pure and well crystallized. TEOS and APTES coats did not change the position of the peaks which indicate that TEOS and APTES coats do not change the crystal structure of the Fe3O4 core [22]. TEOS and APTES coats were broadened the XRD peaks which may be due to the thickness of the coat. However, no Si and N-related peak was observed which indicates that the coating was not in a crystallized form which is what we expect. Unfortunately, an apparent Au-related peak was not observed in the XRD pattern of Fe3O4@SiO2/APTES–Au nanocomposites. Different reasons may be attributed to such a characteristic. The first reason is that Au NPs spread around the surface and the Au load amount was relatively small. Such a case can suppress the Au-related peaks. Another reason might be APTES and TEOS coat which broadens all the peaks. It is highly possible that a small and weak peak can be suppressed by such a broadening effect. Similar cases were previously reported in the literature where Au peaks could not be observed in the XRD diffraction patterns but EDX spectra [19]. In our case, the existence of Au was evidenced by EDX, as well.

3.1.5 Magnetic measurement of MNPs

Magnetic hysteresis plots of Fe3O4, Fe3O4@SiO2, Fe3O4@SiO2/APTES, and Fe3O4@SiO2/APTES–Au MNPs are presented in Fig. 6. Magnetic hysteresis plots revealed that the magnetic saturation value of Fe3O4 MNPs was found to be 63.7 emu/g. It was seen that coating Fe3O4 MNPs with TEOS and APTES coat decreases the magnetic saturation values. Magnetic saturation values for Fe3O4@SiO2 and Fe3O4@SiO2/APTES MNPs were found to be 48.7 emu/g and 35.6 emu/g, respectively. Au doping slightly decreased the magnetic saturation values where magnetic saturation value for Fe3O4@SiO2/APTES–Au was found to be 29.6 emu/g. Results illustrate that increased coat thickness decreased the magnetic saturation values.

3.2 Catalytic activity of magnetic nanocatalysts

Catalytic activities of Fe3O4, Fe3O4@SiO2, Fe3O4@SiO2/APTES, and Fe3O4@SiO2/APTES–Au MNPs were assessed in the presence of NaBH4 for the reduction of 4-NP to 4-AP. The reduction was monitored using UV–vis spectrometry. As can be seen in Figs. 4 and 7-NP solution in neutral and acidic conditions exhibits a strong peak at 317 nm and the colour of the solution was yellowish. The presence of NaBH4 solutions to the 4-NP shifted the absorption peak from 317 to 400 nm where the colour of the 4-NP solution was turned from opaque yellow to bright yellow. In the absence of the catalyser, the reaction could not be completed even if an excessive amount of NaBH4 was presented to the solution which indicates that the catalyser (nanocomposites) was essential to activate the reaction. In the experiments, 10 mg nanoparticle was added to the reactions as catalyser. 10 mg Fe3O4 catalyser reduced 4-NP to 4-AP in 3.5 min. For 10 mg Fe3O4@SiO2/APTES nanocomposites, it took 24 h to complete the reduction process. For the Fe3O4@SiO2/APTES–Au NPs, the catalysis reaction was completed in 2 min.

Efficiency of the catalysis reduction reaction, after induction of catalysers were assessed. Using the results, a time-dependent ln(At/A0) linear graph is obtained and presented in Table 1. The reaction speed was calculated using UV–vis where the reduction of 4-NP concentration was monitored. Figure 8 shows the relation between absorption peak point and the natural logarithm of peak intensity. The slope of the linear plot gives the reaction rate. Reaction rate for Fe3O4, Fe3O4@SiO2, Fe3O4@SiO2/APTES, and Fe3O4@SiO2/APTES–Au magnetic nanocomposites were found to be 9 × 10−3 s−1, 1.29 × 10−2 s−1, 5.1 × 10−3 min−1, and 1.43 × 10−2 s−1, respectively. Results obtained for the reduction of 4-NP indicate that Fe3O4 and Fe3O4@SiO2 magnetic nanocomposites show high catalytic activity. The reaction rate obtained for the Fe3O4@SiO2/APTES MNPs showed the lowest catalytic activity rate which indicates that the APTES shell slows down the catalytic activity. It was concluded that Fe3O4@SiO2/APTES have poor catalytic properties. Fe3O4@SiO2/APTES–Au NPs were obtained by decorating Fe3O4@SiO2/APTES nanocomposites with Au nanoparticle where the reaction rate was found to be significantly high (See Table 1). Such rapid increase may be attributed to Au NPs which was attached to the surface of the APTES coat.

Our results are presented in Table 1. The results reported in the literature are presented in Table 2. It was seen that metallic-based NPs and nanocomposites show good catalytic activity for the reduction of 4-NP. Au containing nanomaterials show outstanding performance. In this regard, our results were found to be coherent with the results reported in the literature. It was seen that APTES coating significantly reduce the catalytic properties of the materials. In our case, the catalytic activity of the Fe3O4@SiO2/APTES nanocomposites exhibits the lowest catalytic performance. Such a case was also reported in the literature. For example, Kurtan et al. and Zhong et al. reported parallel results where APTES coating or APTES-coated nanocomposites were correlated with reduced catalytic performance [27, 31].

4 Conclusions

In this report, Fe3O4@SiO2/APTES–Au magnetic nanocomposites were produced to assess the catalytic properties for the reduction of 4-NP. One of our motivations was to produce magnetically collectible and reusable nanomaterials with good catalytic activities. To achieve this goal, Fe3O4 MNPs were produced and coated with TEOS and APTES, then, the APTES shell was decorated with Au NPs. The chemical and physical properties of the nanocomposites were assessed. It was illustrated that the NPs were successfully produced. TEM images confirm the core@shell structure where Fe3O4, TEOS, APTES, and Au structures were confirmed. Magnetic properties illustrated that Fe3O4 NPs exhibit outstanding ferromagnetic characteristics with a good magnetic saturation rate. Coating Fe3O4 NPs with different shells and NPs reduced the magnetic saturation. All in all, Fe3O4@SiO2/APTES–Au NPs showed good magnetic characteristics which made them a suitable candidate for magnetic filtration applications. The catalytic performance of the NPs was also assessed. It was concluded that Fe3O4 NPs show good catalytic performance, coating MNPs with APTES reduced the catalytic performance of the nanocomposites. Doping the APTES-coated magnetic composites with Au NPs increased the catalytic performance of the NPs.

References

A.F. Mulaba-Bafubiandi, H. Karimi-Maleh, F. Karimi, M. Rezapour, J. Mol. Liq. 285, 430 (2019)

N.H.H. Abu Bakar, A. Ridzwan, W.L. Tan, M. Abu Bakar, N.A. Sabri, Mater. Chem. Phys. 232, 387 (2019)

T. Huang, Y. Fu, Q. Peng, C. Yu, J. Zhu, A. Yu, X. Wang, Appl. Surf. Sci. 480, 888 (2019)

R. Fatima, M.N. Afridi, V. Kumar, J. Lee, I. Ali, K.H. Kim, J.O. Kim, J. Clean. Prod. 231, 899 (2019)

M. Nemanashi-Maumela, I. Nongwe, R.C. Motene, B.L. Davids, R. Meijboom, Mol. Catal. 438, 184 (2017)

J. Fu, S. Wang, J. Zhu, K. Wang, M. Gao, X. Wang, Q. Xu, Mater. Chem. Phys. 207, 315 (2018)

F. Yan, Z. Hu, Q. Tian, B. Wang, Inorg. Chem. Commun. 116, 107896 (2020)

K. Singh, D. Kukkar, R. Singh, P. Kukkar, N. Bajaj, J. Singh, M. Rawat, A. Kumar, K.H. Kim, J. Ind. Eng. Chem. 81, 196 (2020)

T. Endo, T. Yoshimura, K. Esumi, J. Colloid Interface Sci. 286, 602 (2005)

J. Jeevanandam, A. Barhoum, Y.S. Chan, A. Dufresne, M.K. Danquah, Beilstein J. Nanotechnol. 9, 1050 (2018)

M. Pan, J. Yang, K. Liu, Z. Yin, T. Ma, S. Liu, L. Xu, S. Wang, Nanomaterials 10, 209 (2020)

N. Aslan, B. Ceylan, M.M. Koç, F. Findik, J. Mol. Struct. 1219, 128599 (2020)

M.M. Koç, N. Aslan, A.P. Kao, A.H. Barber, Microsc. Res. Tech. 82, 812–848 (2019)

H. Woo, K.H. Park, Catal. Commun. 46, 133 (2014)

Y. Liu, Y.Y.J. Zhang, Q.W. Kou, D.D. Wang, D.L. Han, Z.Y. Lu, Y. Chen, L. Chen, Y.X. Wang, Y.Y.J. Zhang, J.H. Yang, S. Xing, Powder Technol. 338, 26 (2018)

S. Narzary, K. Alamelu, V. Raja, B.M. Jaffar Ali, J. Environ. Chem. Eng. 8, 104373 (2020)

S. Kargar, D. Elhamifar, A. Zarnegaryan, J. Phys. Chem. Solids 146, 109601 (2020)

R. Thekkathu, D. Ashok, P.K. Ramkollath, S. Neelakandapillai, L.P. Kurishunkal, M.S.P. Yadav, N. Kalarikkal, Chem. Phys. Lett. 742, 137147 (2020)

Q. Xia, S. Fu, G. Ren, F. Chai, J. Jiang, F. Qu, New J. Chem. 40, 818 (2016)

N. Kurnaz Yetim, F. Kurşun Baysak, M.M. Koç, D. Nartop, J. Nanostruct. Chem. (2021). https://doi.org/10.1007/s40097-021-00386-w

S. Kulkarni, P. Sawadh, P. Palei, J. Korean Chem. 58, 100 (2014)

N. Kurnaz Yetim, F. Kurşun Baysak, M.M. Koç, D. Nartop, J. Mater. Sci. Mater. Electron. 31, 18278 (2020)

S. Saedi, J.W. Rhim, Food Packag. Shelf Life 24, 100473 (2020)

S. Liu, K. Yao, L.H. Fu, M.G. Ma, RSC Adv. 6, 2135 (2016)

S. Asadbegi, M.A. Bodaghifard, A. Mobinikhaledi, Res. Chem. Intermed. 46, 1629 (2020)

A. Zarei, S. Saedi, F. Seidi, J. Inorg. Organomet. Polym. Mater. 28, 2835 (2018)

U. Kurtan, A. Baykal, Mater. Res. Bull. 60, 79 (2014)

L. Tzounis, S. Logothetidis, in Materials Today: Proceedings. (Elsevier, Amsterdam, 2017), pp. 7076–7082

M. Nasrollahzadeh, Z. Issaabadi, Sep. Purif. Technol. 211, 809 (2019)

H.P. Karki, D.P. Ojha, M.K. Joshi, H.J. Kim, Appl. Surf. Sci. 435, 599 (2018)

Y. Zhong, Y. Gu, L. Yu, G. Cheng, X. Yang, M. Sun, B. He, Colloids Surf. A Physicochem. Eng. Asp. 547, 28 (2018)

Acknowledgements

We would like to present our special thanks to Prof. Dr. Nursen Sari for her support. We also would like to thanks to Assoc. Prof. Dr. Mumin Mehmet KOC.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kurnaz Yetim, N., Hasanoğlu Özkan, E. Synthesis of Au-doped magnetic nanocomposites: structural, magnetic, and catalytic properties. J Mater Sci: Mater Electron 32, 24766–24774 (2021). https://doi.org/10.1007/s10854-021-06922-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06922-2