Abstract

The Ni3Se2 grown on nickel foam (Ni3Se2@Ni) with irregular film, nanowire arrays and microsphere morphologies were successfully synthesized using different reagents via simple one-step hydrothermal method. The as-prepared Ni3Se2@Ni can be used as the electrode for supercapacitor directly without further processing, and the results showed that the Ni3Se2 with the morphologies of irregular film, nanowire arrays and microsphere exhibited the specific capacitance of 1.26 F/cm2 (504 F/g), 1.48 F/cm2 (592 F/g) and 2.04 F/cm2 (816 F/g) at the current density of 10 mA/cm2 in 3 M KOH electrolyte, respectively. Comparing the electrochemical performance of Ni3Se2@Ni electrode with different morphologies, the Ni3Se2 microsphere displayed better electrochemical performance, which exhibited the long-term stability with 85.5% of specific capacitance retention after 1000 cycles. The results indicated that the as-prepared Ni3Se2@Ni can be used as a promising electrode for energy storage devices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, supercapacitors have attracted more and more attention due to its high power density, fast charge/discharge rate and long cycle life [1,2,3]. Therefore, a large number of materials have been explored for supercapacitor electrodes. Generally speaking, the electrode materials of supercapacitors mainly contain carbon-based materials [4,5,6,7], transition metal oxide materials [8] and conductive polymer materials [9, 10]. The carbon-based materials (such as activated carbon, carbon nanotubes, graphene, and so on) exhibit larger specific surface area and longer cycle life. Nevertheless, the lower energy density has limited its development. In contrast, the conductive polymer materials usually present higher specific capacitance than carbon-based materials [11]. However, in the process of charging/discharging, a certain degree of volume expansion or contraction will occur and result in poor stability [12]. Compared with carbon-based materials and conductive polymer materials, the transition metal oxides can not only store charges by electrostatic adsorption but also store more charges by Faraday reaction, thus obtaining higher energy density [13]. Therefore, transition metal oxide materials are undoubtedly a better choice for the supercapacitor electrode. For example, He et al. [14] synthesized the CuO with the three-dimensional flower-like morphology on a copper foam, which achieved a high-specific capacitance of 1641.4 mF/cm2 at the current density of 2 mA/cm2 and good cycling stability with 79% retention after 10,000 charge/discharge cycles. Furthermore, Sun et al. [15] prepared the NiO nanocubes by simple hydrothermal route and assembled the NiO//AC (activated carbon) asymmetric supercapacitor, which exhibited the specific capacitance of 1012 mF/cm2 at the current density of 1 mA/cm2 and good cycle performance with 89.3% of specific capacitance retention after 10,000 charge/discharge cycles.

However, in the process of electrochemistry, the selenium (Se) shows better metallic property than oxygen (O), which indicates the better electronic property of Se [16, 17]. Thus, nickel selenide as one of the transition metal selenides has been widely applied to dye-sensitized solar cells [18], electrocatalyst [19], lithium-ion/sodium-ion battery [20], and supercapacitor [21, 22] due to its excellent physical and chemical properties. As electrode materials for supercapacitors, the NiSe2 prepared by Wang et al. [23] exhibited a high-specific capacitance of 1044 F/g at a current density of 3 A/g. And the Ni0.85Se grown on Ni foam showed the specific capacitance of 1115 F/g at a current density of 1 A/g [21], which can be used as a high-performance electrode for supercapacitors. In addition, other transition metal selenides have also been studied as supercapacitor materials. Tian et al. [24] fabricated the NiSe nanorod arrays by the hydrothermal method and demonstrated its excellent electrochemical performance with areal specific capacitance of 6.81 F/cm2 at a current density of 5 mA/cm2. The high specific capacitance of NiSe can be attributed to the metallic conductivity of nickel selenides, the short ions diffusion length from the electrolyte to electrode materials, and fast electronic transmission path between active materials and collectors. In addition, the Ni3Se2 grown on nickel foam was synthesized for the first time by Jiang et al. [25] via hydrothermal method, exhibiting an excellent specific capacitance of 854 F/g at a current density of 1 A/g. These reports indicated that the nickel selenide would have a promising application prospect as the electrode materials of supercapacitors. Moreover, to improve the electrochemical performance, the morphology of the materials, as one of the significant influencing factors, has also been the research focus in recent years [26]. For example, Ma et al. [27] obtained the flower-like, nanoparticle and ball-like Ni0.85Se by changing the amount of ethylenediamine (EDA) and explored their electrochemical performances. The results showed that the electrochemical performances of flower-like structure Ni0.85Se were better than that of the nanoparticles and ball-like morphology, as the flower-like structure possessing more available sites. Thus, controlling and changing the morphology of Ni3Se2 may improve its electrochemical performance and it can be used as a prospective material for supercapacitors.

In this study, the Ni3Se2 grown on the nickel foam (Ni3Se2@Ni) with different morphologies were designed by a simple one-step hydrothermal method with adding different reagents. The Ni3Se2@Ni with the morphologies of irregular film, nanowire arrays and microsphere were obtained, and the corresponding areal specific capacitance was 1.26 F/cm2, 1.48 F/cm2 and 2.04 F/cm2 at the current density of 10 mA/cm2 in 3 M KOH electrolyte, respectively. The results indicated that the Ni3Se2 microsphere had better electrochemical performance, and the specific capacitance still retained 85.54% after 1000 cycles.

2 Experimental

2.1 Synthesis of Ni3Se2

The Ni3Se2 with different morphologies were synthesized by hydrothermal method. The chemical reagents used were analytical grade and were used without further purification. The nickel foam slices (1.5 × 3.0 × 0.1 cm3) were washed with toluene, acetone, ethanol, 2.4 M HCl and deionized water successively, and then dried in a vacuum oven at 60 °C for 2 h. Typically, 0.1 mmol of Se powder and 2 mL of N2H4·H2O (80 wt%) were dissolved in 13 mL of deionized water in a 25 mL Teflon vessel, then a slice of nickel foam was put into the above Teflon vessel and sealed in a stainless-steel autoclave. Later, it was put in the furnace with temperature of 160 °C for 12 h. After it was cooled down to room temperature naturally, the product was taken out and rinsed with deionized water and ethanol several times and dried in a vacuum oven at 60 °C for 2 h, and finally the irregular film of Ni3Se2 was obtained, which was named as Ni3Se2-A. In addition, nanowire arrays and microsphere of Ni3Se2 were prepared in a similar route by varying the reaction reagents and temperature. The nanowire arrays of Ni3Se2 (named as Ni3Se2-B) can be obtained by increasing the dosage of Se powder to 0.4 mmol and adding 0.2 mmol of Ni(NO3)2 with temperature of 140 °C. Similarly, the Ni3Se2 microsphere (named as Ni3Se2-C) were synthesized by dissolving 0.2 mmol of Se powder, 2 mL of N2H4·H2O and 2 mL of EDA in 11 mL of deionized water with the reaction temperature of 140 °C. The loading masses of Ni3Se2 with different morphologies were measured to be about 2.5 mg/cm2. For comparison, the samples with different temperatures of 140 °C, 160 °C and 180 °C were also investigated (Supplementary material).

2.2 Characterization of the samples

The samples were characterized by X-ray diffraction (XRD, PANalytical X’Pert) with Cu Kα radiation (λ= 1.5406 Å) and field-emission scanning electron microscope (FE-SEM, S-4800) with an energy disperse spectroscopy (EDS, X-max50) attachment. The Brunauer–Emmett–Teller (BET) specific surface areas and the pore size distribution according to the Barrett–Joyner–Halenda (BJH) methods of the samples were performed by the Micromeritics ASAP 2020 HD88 apparatus. And the electrochemical performance was characterized by electrochemical workstation (CHI690) in 3 M KOH electrolyte using three-electrode configuration, where the effective electrode contact area was 1 × 1 cm2, a platinum foil with area of 1 × 1 cm2 and an Hg/HgO electrode were used as the counter and reference electrodes, respectively.

3 Results and discussion

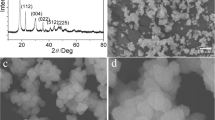

The as-prepared Ni3Se2 on nickel foam with different morphologies were first characterized by XRD and the corresponding XRD patterns were shown in Fig. 1a. Comparing the three diffraction patterns, we can see that the diffraction patterns of Ni3Se2-A (irregular film), Ni3Se2-B (nanowire arrays) and Ni3Se2-C (microsphere) are almost the same. The three strongest diffraction peaks located at 2θ of 44.51°, 51.85° and 76.37° can be assigned to the substrate of nickel foam (JCPDS no. 04-0850) with the corresponding crystal indices of (110), (200) and (220). Except for the peaks of nickel foam, the other diffraction peaks at 2θ of 20.94°, 29.59°, 29.97°, 37.17°, 42.62°, 47.68°, 48.20°, 52.74° and 53.46° were consistent with the rhombohedral phase of Ni3Se2 (JCPDS no. 85-0754) with lattice constant of a = b = 6.03382 Å and c = 7.25102 Å, and the corresponding crystal indices were (101), (110), (012), (003), (202), (211), (113), (122) and (104), respectively. In addition, the EDS of Ni3Se2-A, Ni3Se2-B and Ni3Se2-C were displayed in Fig. 1b–d, respectively. The results showed that all the samples mainly consisted of Se and Ni elements, however, there was also a little O element appearing in the spectra, which was possibly due to the moisture and oxygen adsorbed on the surface of samples [21].

The different morphologies of Ni3Se2 grown on nickel foam were investigated by FE-SEM. Figure 2a–c show the low-magnification FE-SEM images of Ni3Se2-A, Ni3Se2-B and Ni3Se2-C, respectively, and Fig. 2d–f present the corresponding high-magnification FE-SEM images. It can be seen from the low-magnification image of Fig. 2a that the morphology of Ni3Se2-A is a rough film, and the high-magnification image of Fig. 2d shows that the surface of the film is irregular, which looks like angular gravel. Figure 2b, e shows the FE-SEM images of Ni3Se2-B, it is observed that the Ni3Se2 nanowires are grown in-situ on nickel foam surface with the length of ca. 1 μm and diameter of ca. 100 nm, presenting the nanowire arrays morphology. In addition, Fig. 2c shows the low-magnification FE-SEM image of Ni3Se2-C, which exhibits the uniform microsphere morphology with a diameter of ca. 2 μm. However, the microspheres display rough surface in Fig. 2f, which can be inferred that the microsphere might consist of smaller particles. The schematic diagram of the synthesis of Ni3Se2 with different morphology is demonstrated in Fig. 2g. As described in the experimental section, when N2H4·H2O was put in the mixture containing Se, the Se can be rapidly reduced during heating, causing explosive growth of Ni3Se2 to form the irregular film on the surface of nickel foam [27]. And when the Ni2+ was added in the hydrazine hydrate solution, the Ni2+ would react with the Se2+ in solution to construct Ni3Se2 crystal nucleus and grow perpendicular to the nickel foam surface to form the nanowire arrays [24]. However, with the addition of EDA, the interaction between the different crystal faces was enhanced and the thermodynamic stability of the spherical structure will occur [27]. Afterwards, the Ni3Se2 spheres grow isochronously, resulting in the formation of microsphere morphology.

The Ni3Se2 can be obtained in a certain temperature range from 140 to 180 °C in this work. And the XRD patterns and FE-SEM images of the products with different temperatures were shown in the supplementary material. It was clearly observed that all of the samples were consistent with the Ni3Se2 (JCPDS no. 85-0754) in Fig. S1 and the morphology of each group of samples were not significantly changed with different temperatures, as displayed in Fig. S2. To investigate the suitable synthesis temperatures for irregular film, nanowire arrays and microsphere of Ni3Se2 on electrochemical performance, the samples with different morphologies synthesized with 140 °C, 160 °C and 180 °C were also prepared. All the samples were analyzed by galvanostatic charge/discharge (GCD) measurement in 3 M KOH at the current density of 10 mA/cm2, and the results were presented in Fig. 3. Figure 3a shows the GCD curves of Ni3Se2-A with different synthesis temperatures, compared to the 140 °C and 180 °C, the sample with 160 °C exhibits longer discharge time, indicating the suitable synthesis temperature for the irregular film of Ni3Se2 is 160 °C. And the areal specific capacitance (Cs) and gravimetric specific capacitance (Cm) were calculated according to the formula [28]:

where Cs (F/cm2) is the areal specific capacitance, and Cm (F/g) is the gravimetric specific capacitance, and the I, ∆t, S, m and ∆V are the discharge current (A), discharge time (s), the effective area of electrode (cm2), the weight of active material (g) and the voltage variation (V), respectively. Thus, it can be calculated that the Cs of the Ni3Se2-A at 160 °C (1.26 F/cm2) is higher than that of 140 °C (1.19 F/cm2) and 180 °C (0.97 F/cm2). The GCD curves of Ni3Se2-B with different synthesis temperatures are shown in Fig. 3b, it can be clearly observed that the discharge time of the sample with 140 °C is longer than that of 160 °C and 180 °C, and the corresponding areal-specific capacitance is calculated to be 1.48 F/cm2, 1.23 F/cm2 and 1.00 F/cm2, respectively. Meanwhile, the GCD curves of the Ni3Se2-C with different synthesis temperatures are displayed in Fig. 3c. It can be seen that the sample with 140 °C presents the longest discharge time, indicating the Cs of the sample at 140 °C (2.04 F/cm2) is higher than that of 160 °C (1.89 F/cm2) and 180 °C (1.97 F/cm2). From what has been discussed above, we can draw the conclusion that the electrochemical properties of Ni3Se2 with different morphologies are different at different synthesis temperatures. It may be caused by the different crystallinity of the materials with different synthesis temperatures, which would lead to the difference of carrier mobility [29]. However, the performances of electrodes with different morphologies with different synthesis temperature are not very different, which may be due to the small change in crystallinity, as shown in Fig. S1. Besides, to compare the electrochemical performance of the samples with different morphologies and temperatures more intuitively, a histogram between Cs and different samples are performed in Fig. 3d. It can be seen that the optimum temperatures for Ni3Se2-A (irregular film), Ni3Se2-B (nanowire arrays) and Ni3Se2-C (microsphere) are 160 °C, 140 °C and 140 °C, respectively.

The electrochemical performance of Ni3Se2@Ni with irregular film, nanowire arrays and microsphere morphologies synthesized with corresponding optimum temperature is compared in Fig. 4. Figure 4a displays the cyclic voltammetry (CV) curves of Ni3Se2@Ni with different morphologies and bare nickel foam electrode at a scan rate of 30 mV/s. It can be clearly observed that the internal area of the CV curve of nickel foam closes to zero, indicating the capacitance contribution of nickel foam can be neglected. In addition, it can also be seen that the internal area of the CV curve of Ni3Se2-C is larger than that of Ni3Se2-A and Ni3Se2-B, revealing the higher capacitance of Ni3Se2-C. Figure 4b shows the GCD curves of Ni3Se2@Ni with different morphologies at the current density of 10 mA/cm2. It is evident that the Ni3Se2-C presents longer charge/discharge time than that of the Ni3Se2-A and Ni3Se2-B, revealing the better electrochemical performance of Ni3Se2-C, which is consistent with the CV results. The GCD curves of Ni3Se2@Ni with different morphologies under different current densities were performed and the corresponding areal specific capacitances were also calculated, as shown in Fig. 4c. The results show that the specific capacitances of Ni3Se2-C are higher than that of Ni3Se2-B and Ni3Se2-A at the given current densities, revealing that the Ni3Se2 with microsphere morphology (Ni3Se2-C) displays the best electrochemical performance followed by nanowire arrays (Ni3Se2-B) and irregular film (Ni3Se2-A) morphologies. This difference in electrochemical performance may be due to the fact that different morphologies may provide different active sites [27]. Compared with the film and nanowires morphologies, the microsphere can provide more active sites and larger ion channels which is beneficial to improve the electrochemical performance [30]. Furthermore, the electrochemical impedance spectroscopy (EIS) of Ni3Se2 with different morphologies is shown in Fig. 4d with the frequency region of 10–2–105 Hz, which reveals that the internal resistance (Rs) of Ni3Se2-A, Ni3Se2-B and Ni3Se2-C is 0.75 Ω, 0.73 Ω and 0.72 Ω, respectively, which can be clearly seen in the inset in Fig. 4d. The plots in the low frequency region correspond to the diffusion control regions, and the slope of these plots is related to the diffusion resistance. There is no significant difference in the Rs, but the Ni3Se2-C has a maximum slope, indicating the lowest diffusive resistance of the Ni3Se2-C electrode.

Electrochemical performance comparison of Ni3Se2-A, Ni3Se2-B and Ni3Se2-C prepared at 160 °C, 140 °C and 140 °C, and bare nickel foam, respectively: a CV curves at the scan rate of 30 mV/s; b GCD curves at the current density of 10 mA/cm2; c specific capacitance at different current densities; d EIS in the frequency region of 0.01 Hz to 100 kHz, inset is an enlarged view of the high frequency region

Nitrogen adsorption–desorption tests were performed to measure the specific surface area (SSA) and the pore size distribution of Ni3Se2-A, Ni3Se2-B and Ni3Se2-C prepared at 160 °C, 140 °C and 140 °C. As shown in Fig. 5a, all of them exhibited a typical behavior of type IV isotherms according to the IUPAC classification, suggesting that it is consisted predominantly of mesoporous [31]. The BET specific surface area of 4.74 m2/g, 7.17 m2/g and 17.35 m2/g were obtained for Ni3Se2-A, Ni3Se2-B and Ni3Se2-C, respectively. The Ni3Se2-C with microsphere morphology displayed the largest BET SSA compared with Ni3Se2-A and Ni3Se2-B, and the result well agreed with the observation of SEM. The BJH method was used to calculating the pore size distribution of the samples, as shown in Fig. 5b. The average pore size of Ni3Se2-A, Ni3Se2-B and Ni3Se2-C were calculated to be 114.9 nm, 140.4 nm and 79.4 nm, and the pore volume were 0.014 cm3/g, 0.025 cm3/g and 0.034 cm3/g, respectively. The results indicated that the Ni3Se2-C have a suitable mesoporous distribution with more electroactive sites and ion-transport pathways, which is beneficial to improve the electrochemical performance [32].

From the above discussion, it is known that the Ni3Se2 with microsphere morphology (Ni3Se2-C) displays the best electrochemical performance. And thus, the electrochemical performance of Ni3Se2-C was further study in detail, as presented in Fig. 6. The CV curves of Ni3Se2-C at scan rates from 5 to 50 mV/s are shown in Fig. 6a. It can be observed that the CV curves consist of a pair of redox peaks, which may be from the contribution of the redox reaction below [33]:

Moreover, the current response is increased with the increase of scan rate, but the peak shape is still maintained well, indicating the good rate performance. And then the capacitive performance of Ni3Se2-C at different current densities was identified by GCD measurements, as shown in Fig. 6b. According to the GCD curves and Eqs. (1) and (2), the areal specific capacitances of Ni3Se2-C electrode under the current densities of 10, 12, 15, 20 and 30 mA/cm2 is 2.04, 1.95, 1.83, 1.70 and 1.55 F/cm2, and the corresponding gravimetric specific capacitance is 816, 780, 732, 680 and 620 F/g, respectively. Notably, the gravimetric specific capacitance value of Ni3Se2-C at 10 mA/cm2 (corresponding to 4 A/g) is higher than that of the previous report (693.8 F/g at 4 A/g) [25]. And then the specific capacitance of Ni3Se2 in this work and some other NixSey electrode materials with different morphologies are compared, as presented in Table 1. We can see that a series of nickel selenide with ratio of Ni/Se of 1.5, 1, 0.85 and 0.5 [34, 35] exhibits good electrochemical performance. However, the ratio of Ni/Se is not the key factor affecting the electrochemical performance which is mainly affected by morphology and structure. Generally, the larger the specific surface area of nanomaterial is, the better the electrochemical performance will be. As shown in Table 1, the specific capacitance of microspheres of Ni3Se2, denser nanorod arrays of NiSe, ball-like structure of Ni0.85Se and truncated cube-like structure of NiSe2 is higher than that of other morphologies under the corresponding ratio of Ni/Se. Although the specific capacitance of Ni3Se2 in this work is not the best, it is still better than that of NiSe with the same morphology of microspheres [22].

Furthermore, the long-term cycling stability of Ni3Se2-C was studied at a current density of 30 mA/cm2 for 1000 cycles, as shown in Fig. 6c. It can be observed that the Ni3Se2-C exhibits good long-term stability with 85.5% of specific capacitance retention after 1000 cycles. Besides, the EIS was used to investigate the resistance variation before and after 1000 cycles. It has been obtained above that the Rs of Ni3Se2-C with microsphere morphology before cycle is 0.72 Ω, however, the Rs only increases to 0.77 Ω after 1000 cycles, and the corresponding charge transfer resistance (Rct) increases to 7.93 Ω. The increase of charge transfer resistance may be due to the microstructural change effect after 1000 cycles [36]. Thus, the morphology of Ni3Se2-C after 1000 cycles is further investigated in Fig. 7b. To see the changes before and after 1000 cycles clearly, the FE-SEM images of Ni3Se2-C before and after cycles are compared in Fig. 7. It can be observed from the low-magnification image in Fig. 7b that the morphology of Ni3Se2-C after 1000 cycles is still microsphere, however, the diameter of microsphere increases slightly relative to the initial size in Fig. 7a. By further observation of the high-magnification images of inset in Fig. 7, it can be seen that the microsphere surface of Ni3Se2-C after 1000 cycles become rougher, which further verifies that there is a slight change in the microstructure.

4 Conclusions

In a word, the Ni3Se2 with irregular film, nanowire arrays and microsphere morphologies in situ growth on nickel foam were successfully synthesized by a simple one-step hydrothermal method and the electrochemical performance was discussed. The results show that the Ni3Se2 with microsphere morphology (Ni3Se2-C) displays better electrochemical performance with areal-specific capacitance of 2.04 F/cm2 (corresponding gravimetric specific capacitance is 816 F/g) at the current density of 10 mA/cm2 (4 A/g). Meanwhile, the Ni3Se2 with microsphere morphology exhibits good long-term stability with 85.5% of specific capacitance retention after 1000 cycles. The results indicated that the Ni3Se2@Ni could be used as a high-performance electrode for energy storage devices.

References

B.R. Wiston, M. Ashok, Mater. Lett. 235, 76–79 (2019)

S. Thakur, S. Maiti, T. Paul, N. Besra, S. Sarkar, K.K. Chattopadhyay, CrystEngComm 20, 6183–6196 (2018)

A.A. Yadav, Y.M. Hunge, S.B. Kulkarni, J. Mater. Sci. Mater. Electron. 29, 16401–16409 (2018)

Y. Jang, J. Jo, Y.M. Choi, I. Kim, S.H. Lee, D. Kim, S.M. Yoon, Electrochim. Acta 102, 240–245 (2013)

G. Lota, T.A. Centeno, E. Frackowiak, F. Stoeckli, Electrochim. Acta 53, 2210–2216 (2008)

N.G. Sahoo, H.K.F. Cheng, L. Li, S.H. Chan, Z. Judeh, J. Zhao, Adv. Funct. Mater. 19, 3962–3971 (2009)

M.B. Tayel, M.M. Soliman, S. Ebrahim, M.E. Harb, Synth. Met. 217, 237–243 (2016)

K. Wang, X. Dong, C. Zhao, X. Qian, Y. Xu, Electrochim. Acta 152, 433–442 (2015)

F. Wang, X. Lv, L. Zhang, H. Zhang, Y. Zhu, Z. Hu, Y. Zhang, J. Ji, W. Jiang, J. Power Sources 393, 169–176 (2018)

X. Gao, H. Yue, E. Guo, L. Yao, X. Lin, B. Wang, E. Guan, D. Bychanok, J. Mater. Sci. Mater. Electron. 28, 17939–17947 (2017)

V. Gupta, N. Miura, Electrochim. Acta 52, 1721–1726 (2006)

S.R. Sivakkumar, W.J. Kim, J.-A. Choi, D.R. MacFarlane, M. Forsyth, D.-W. Kim, J. Power Sources 171, 1062–1068 (2007)

R. Kotz, M. Carlen, Electrochim. Acta 45, 2483–2498 (2000)

D. He, S. Xing, B. Sun, H. Cai, H. Suo, C. Zhao, Electrochim. Acta 210, 639–645 (2016)

W. Sun, L. Xiao, X. Wu, J. Alloys Compd. 772, 465–471 (2019)

L. Mi, H. Sun, Q. Ding, W. Chen, C. Liu, H. Hou, Z. Zheng, C. Shen, Dalton Trans. 41, 12595–12600 (2012)

C. Tang, Z. Pu, Q. Liu, A.M. Asiri, X. Sun, Y. Luo, Y. He, ChemElectroChem 2, 1903–1907 (2015)

Q. Jiang, R. Chen, H. Chen, J. Jiang, X. Yang, Y. Ju, R. Ji, Y. Zhang, J. Mater. Sci. 53, 7672–7682 (2018)

K.S. Bhat, H.S. Nagaraja, Int. J. Hydrogen Energy 43, 19851–19863 (2018)

X. Li, S. Li, Z. Zhang, C. Liu, B. Qu, J. Pu, Mater. Lett. 220, 86–89 (2018)

C. Gong, M. Huang, J. Zhang, M. Lai, L. Fan, J. Lin, J. Wu, RSC Adv. 5, 81474–81481 (2015)

K. Guo, F. Yang, S. Cui, W. Chen, L. Mi, RSC Adv. 6, 46523–46530 (2016)

S. Wang, W. Li, L. Xin, M. Wu, Y. Long, H. Huang, X. Lou, Chem. Eng. J. 330, 1334–1341 (2017)

Y. Tian, Y. Ruan, J. Zhang, Z. Yang, J. Jiang, C. Wang, Electrochim. Acta 250, 327–334 (2017)

S. Jiang, J. Wu, B. Ye, Y. Fan, J. Ge, Q. Guo, M. Huang, J. Mater. Sci. Mater. Electron. 29, 4649–4657 (2018)

L. Cheng, M. Xu, Q. Zhang, G. Li, J. Chen, Y. Lou, J. Alloys Compd. 781, 245–254 (2019)

S. Ma, S. Zhou, S. Wang, M. Liu, J. Alloys Compd. 728, 592–599 (2017)

Y. Yuan, R. Chen, H. Zhang, Q. Liu, J. Liu, J. Yu, C. Wang, Z. Sun, J. Wang, Electrochim. Acta 294, 325–336 (2019)

I. Shakir, M. Shahid, H.W. Yang, D.J. Kang, Electrochim. Acta 56, 376–380 (2010)

Y. Zhang, J. Zheng, Y. Zhao, T. Hu, Z. Gao, C. Meng, Appl. Surf. Sci. 377, 385–393 (2016)

W. Chen, C. Xia, H.N. Alshareef, ACS Nano 8, 9531–9541 (2014)

G. Zhou, F. Li, H.-M. Cheng, Energy Environ. Sci. 7, 1307–1338 (2014)

H. Huo, Y. Zhao, C. Xu, J. Mater. Chem. A 2, 15111 (2014)

N.S. Arul, J.I. Han, Mater. Lett. 181, 345–349 (2016)

M. Lu, X.-P. Yuan, X.-H. Guan, G.-S. Wang, J. Mater. Chem. A 5, 3621–3627 (2017)

M. Huang, F. Li, Y.X. Zhang, B. Li, X. Gao, Ceram. Int. 40, 5533–5538 (2014)

Acknowledgements

This study was supported by the National Natural Science Foundation of China (51564009), Natural Science Foundation of Guangxi Province (2016GXNSFBA380190, 2018GXNSFAA138041, 2015GXNSFDA139035 and 2018JJA160029), Open Project Fund of Guangxi Ministry-Province Jointly-Constructed Cultivation Base for State Key Laboratory of Processing for Non-ferrous Metal and Featured Materials (14KF-10), the Doctoral Scientific Research Project of Guilin University of Technology and Guangxi Key Laboratory in Universities of Clean Metallurgy and Comprehensive Utilization for Non-ferrous Metals Resources.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wu, L., Xue, Y., Chen, H. et al. Synthesis of Ni3Se2 on nickel foam with different morphologies for high-performance supercapacitor electrode. J Mater Sci: Mater Electron 31, 6140–6149 (2020). https://doi.org/10.1007/s10854-020-03167-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03167-3