Abstract

This paper describes the preparation, characterization and electrical properties of polyindole (PIN)/phenothiazine (PTZ) blend nanocomposite with different contents of nickel oxide (NiO) nanoparticles. Ultraviolet–Visible spectroscopy and Fourier transform infrared spectroscopic characterizations were carried out to investigate the extent of chemical interactions between PIN/PTZ blend and NiO nanoparticles. Morphological studies carried out using scanning electron microscopy and transmission electron microscopy showed the formation of globular composite particles with a size in 15–25 nm range. X-ray diffraction study of the resultant composites reveals the distribution of sharp crystalline peak of NiO in the blend. Thermogravimetric results confirmed that the rate of degradation of the composite was lower as compared to the pure polymer blend and the thermal stability of the blend increases with the loading of nanoparticles. An investigation of the electrical properties of the prepared nanocomposites revealed that AC conductivity, dielectric constant and dielectric loss of composite increased in proportion to the increase in NiO loading. Current–voltage measurements (I–V curve) showed that the PIN/PTZ/NiO composites have much higher electrical conductivity than pure polymer blend. The gas sensing measurement for PIN/PTZ blend with different contents of NiO nanoparticles toward ammonia gas were investigated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Conjugated polymers become an attractive area of research interest among research community because of its excellent optical, electrical and thermal properties [1,2,3]. The electrical conductivity of conjugated polymers can be tunable and are widely used in the fabrication of electrical and electronic devices [4, 5]. The commonly used conjugated polymers are polyaniline, polyindole, polypyrrole and polythiophene. Among them, polyindole (PIN) can be easily synthesized, good environmental stability and slow degradation rate as compared to polyaniline and polypyrrole [6, 7]. Unfortunately, PIN shows poor mechanical properties and thus poses a processibility problem. This difficulty can be overcome by blending this polymer with other semiconducting organic molecules having reactive functional groups. The blending of two or more polymers is an efficient method to improve the inferior properties of both the components and this technique is commercially more important than the synthesis of homopolymer or copolymer for the fabrication of novel material with desired application at low cost [8,9,10].

Conductive polymer composites are widely used in the fabrication of electrical and electronic devices due to their desired thermal and electrical conductivity. These hybrid systems are mainly used as EMI-shielding material, telecommunications, packaging components in electronics and as electrostatic charge dissipating materials in the pressure-sensitive sensor [11, 12]. Recently several researchers have paid more attention to the investigation of metal incorporated nanocomposites and many interesting works have been extensively reported [13, 14]. The properties of conducting polymer nanocomposites depend mainly on the nature of the association between inorganic and organic components. Nickel oxide (NiO) is a p-type semiconductor with a variety of applications in optical, electronic and magnetic devices and this is because of the presence of Ni+ and Ni++ in the metal oxide [15]. The introduction of NiO nanoparticles into the conjugated polymer greatly enhances the charge storage capacity in comparison to the parent polymer. This is mainly due to the morphology of the hybrid system in which the specific surface area, particle size and size distributions are significantly modified by the incorporation of metal nanoparticles [16].

Phenothiazine (PTZ) is a cheaply available heterocyclic compound, structurally similar to the carbazole unit with an additional sulfur atom. As a more powerful electron-rich molecule, the phenothiazine is extensively used in optoelectronic devices [17]. The presence of hetero atoms such as nitrogen and sulfur in PTZ is not only to improve the solubility but also to enable them for the metal-binding ability [18]. Therefore PTZ is an important semiconducting material for the preparation of low-cost blend with polyindole. The physical and mechanical properties of the polymer blend can further be improved by the incorporation of metal oxide nanoparticles. According to our knowledge, this is the first time we are reporting the preparation of PIN/PTZ/NiO nanocomposites by a simple, inexpensive ball mill mixing technique. The effect of metal oxide nanoparticles in optical, morphological, thermal and electrical properties of PIN/PTZ blend was investigated by FT-IR, UV spectroscopy, SEM, TEM, TGA and impedance analysis. This work also focused on the gas sensing properties of polymer blend nanocomposite at room temperature.

2 Materials and experimental techniques

2.1 Materials

The monomer indole, ferric chloride (FeCl3), chloroform (CHCl3), sodium hydroxide (NaOH), cetyltrimethylammonium bromide (CTAB), ethanol (99.5%), nickel nitrate and were purchased from Merck India. Phenothiazine from Aldrich) and deionized water was used as a solvent for all solution.

2.2 Synthesis of polyindole (PIN)

Polyindole (PIN) was synthesized by using chemical oxidation method. The oxidant FeCl3 (48 mmol) was dissolved in 30 mL of CHCl3 and stirred well at room temperature. Similarly, indole monomer (16 mmol) of was dissolved in 40 mL of CHCl3. The oxidizing agent was added in a dropwise fashion into the indole solution. In order to obtain a total volume of 100 mL solution, additional 30 mL of CHCl3 was added into the indole/FeCl3 solution and the reaction mixture was stirred for 10 h under stirring at room temperature. At the end of the polymerization, the precipitate obtained in brown color was first filtered, washed with 100 mL of chloroform and 100 mL of deionized water, respectively. Finally, powdered PIN samples were dried for 24 h at 60 °C in a vacuum oven.

2.3 Synthesis of NiO nanoparticles

The nickel oxide nanoparticles were synthesized through a simple chemical method [19]. An appropriate amount of nickel nitrate was dissolved in deionized water and stirred at room temperature. About 0.1 g of CTAB in 10 mL deionized water was mixed with nickel nitrate solution. To this 0.5 M NaOH solutions were added slowly with continuous stirring for 12 h. The dark green solution turned into a light green and the precipitate was washed with water several times and finally with ethanol. The precipitate was dried at 50 °C for 24 h and calcined at 300 °C for 2 h.

2.4 Preparation of PIN/PTZ/NiO nanocomposites

Conducting polymer blend nanocomposite was prepared by adding NiO nanoparticle into PIN/PTZ blend using a simple ball milling method. The powdered PIN and PTZ was prepared and then mixed in the ratio 50:50 and ball milled it to get a homogeneous mixture. NiO nanoparticles (0, 3, 5, 7, and 10 wt% for 100 g of polymer) were dispersed with PIN/PTZ blend and the resultant mixture was subjected to a high-energy ball milling for 1 h in an agate jar in order to get a homogeneous mixture.

2.5 Characterizations

Fourier Transform Infrared spectrum (FT-IR) of the powdered PIN/PTZ/NiO nanocomposites was analyzed by a JASCO (Model 4100) spectrometer. The UV–Vis absorption studies of PIN/PTZ blend with different contents of NiO nanoparticles in dimethyl sulfoxide was carried out in a Perkin Elmer Lambda 650 spectroscopy in the wavelength range of 200–800 nm. XRD patterns of the powdered sample were recorded on a Bruker AXS D-8 X-ray diffractometer with CuKα (λ = 1.5407 Å) radiation. The morphology of the fabricated composites (powdered sample) was observed by Hitachi S-3000 H model scanning electron microscopy (SEM). The size and shape of the nanoparticles in the composite was analyzed by high-resolution transmission electron microscopy (HRTEM-JEOL/JEM 2100). The thermal stability of the blend composites was investigated by Hitachi STA7200 thermogravimetric analyzer in an inert atmosphere at the heating rate of 10 °C/min. The AC conductivity and dielectric measurements of the samples were recorded using a Hewlett Packard LCR meter (HP 4284A) at room temperature. DC conductivity of the samples at room temperature was measured using a fully automatic Keithley 2400 device. The experimental setup for the ammonia gas sensing ability of the fabricated composites was illustrated in Fig. 1. The pelletized sample (circular shaped) was placed in a sealed glass chamber of 1000 mL. The chamber contains one inlet port and one outlet port for the gases. Then, the pelletized sample (circular shaped) was placed in the interdigitated silver electrodes in the specially designed glass chamber. The ammonia gas flow rate was regulated by a mass flow controller. The ammonia gas (100 ppm) was passed through the glass chamber and the electrical resistance of the samples was measured by a multi-functional digital system (MECO Meters Pvt. Ltd., Mumbai, India). The gas inside the chamber was evacuated at each cycle and the sensor was placed in atmospheric air for recovery. The response or sensitivity of gas had been measured as (Ri − R0)/R0, where Ri and R0 are the resistance of sensors in ammonia and in the air, respectively. The gas sensitivity performance was carried out three times and average values were used for the study. All sensing measurements were performed at room temperature (25 °C).

3 Results and discussion

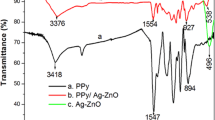

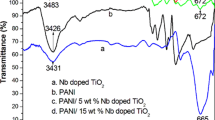

3.1 FTIR spectra

In order to study the specific interactions between PIN/PTZ blend matrix and NiO nanoparticles, FTIR studies of neat blend hybrid, NiO and PIN/PTZ/NiO nanocomposite were carried out and the results are given in Fig. 2. The spectra of NiO shows a strong absorption band at 501 cm−1 is the metallic stretch of Ni–O bond [19]. The additional peaks at 3426 and 1625 cm−1 are the water molecules present in the surface of NiO nanoparticles. As observed in the spectrum of the blend, the strong broad IR band nearly about 3421 cm−1 is resulted by the overlapping of –NH stretching vibration of polyindole and phenothiazine, respectively which specifies the proper mixing of the polymers [20]. The characteristic IR peaks for C=C stretching of the aromatic ring of polymer (1573 cm−1), C–N stretching vibration (1451 cm−1) along with the vibration peak correspond to –CH in-plane motion (1390 cm−1) are revealed in the FT-IR spectra of PIN/PTZ blend. In the FTIR spectrum of PIN/PTZ/NiO nanocomposite, the peaks observed at 598 and 493 cm−1 suggests the presence of a core of NiO nanoparticles in the hybrid structures. Furthermore, if we examine the spectrum of the composite, we can see that the introduction of NiO altered the structure of the blend through a shift in the absorption band. For example, the NH peak in the composite is shifting from 3421 to 3408 cm−1 by the addition of NPs and similarly, the CN bond in the PIN/PTZ blend is shifted from 1179 to 1158 cm−1. The shift and change in intensity of IR bands in the composites impute that the NiO nanoparticles are well incorporated within PIN/PTZ blend matrix.

3.2 UV–visible spectroscopy

The optical properties of PIN/PTZ and PIN/PTZ with different loading of NiO nanoparticles are given in Fig. 3. The UV spectra of PIN/PTZ shows a weak absorption band at 239 nm (n–π* transition) along with a broad UV peak at 414 nm (π–π* transition). The PIN/PTZ blend with 3, 5, 7, 10 and 15 wt% NiO shows the UV peak at 416, 417, 419, 424 and 422 nm respectively. It is evident from the figure that the broadness of the blend is decreased with the loading of NiO nanoparticles. It can be seen that the intensity of the UV peak decreases with a slight shift in the peak position to higher wavelength region. These significant changes in the UV spectra specify that there is a strong interaction between the NiO particles and PIN/PTZ blend. Comparing the UV spectra of 10 wt% composite, the intensity, broadness and the position of UV peak in 15 wt% composite are slightly changed. At higher concentration of fillers (15 wt%), the agglomeration process takes place hence a greater stress developed in the blend matrix, which causes the shift of the UV peak to higher wavelength region. This result is in good agreement with our previous studies [7]

3.3 X-ray diffraction analysis (XRD)

The X-ray diffractometry is a powerful technique to investigate the structure and crystallinity of polymer composites. The X-ray diffraction patterns of pure NiO, PIN/PTZ blend and the blend with different weight fractions of NiO are shown in Fig. 4. Nano-NiO has five crystalline peaks in the XRD spectra at 37.32° (111), 43.45° (200), 62.83° (220), 75.20° (311) and 79.37° (222), confirming the face-centered cubic structure of NiO (JCPDS no. 04-0835). The XRD spectrum of PIN/PTZ blend shows four crystalline peaks at 2θ = 9.82, 18.25, 24.56 and 30.89° indicating well-arranged blend segments in a specific orientation. In the XRD curves of PIN/PTZ/NiO nanocomposites, the characteristic peaks of NiO nanoparticles can be observed besides the crystalline peaks of PIN/PTZ blend. The average crystallite size of PIN/PTZ/NiO has been calculated using Scherrer formula through the reflecting peaks at 2θ = 9.82, 18.25, 24.56 and 30.89°, the average size of filler particle is about 14.2 nm. Comparing the nanocomposite with the pure PIN/PTZ, it is clear that the with increasing NiO content, the intensity of the XRD peak of blend increases indicating the addition of NiO nanoparticles supports the crystallization of the blend matrix. This can be speculated that some interactions between PIN/PTZ blend and NiO particles are existing in the nanocomposites.

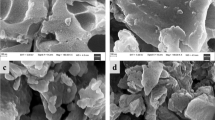

3.4 Scanning electron microscopy (SEM)

Scanning electron microscopy is one of the direct techniques for evaluating the dispersion of nanoparticles in polymers. Figure 5 shows the surface morphology of PIN/PTZ and PIN/PTZ with different contents of NiO nanoparticles. The SEM micrograph of PIN/PTZ (Fig. 5a) reflects a smooth surface with a homogeneous morphology, indicating the miscibility of polyindole/phenothiazine segments. The smooth surface of the polymer blend is destroyed by the incorporation of 5 wt% NiO (Fig. 5b) to PIN/PTZ hybrid with the formation of several hemispherical nanoparticles. As shown in Fig. 5c, several uniformly shaped nanoparticles with good morphology are visible at the nanoparticles concentration of 10 wt%. According to the morphological study of composite images, the optimum condition for the uniform growth of NiO in the blend is 10 wt% loading. The functional NiO nanoparticles with the large surface area can effectively interact with the polar PIN/PTZ which contributes to the encapsulation by growth process of the polymer blend [21]. On increasing the NiO content to 15 wt%, the distribution of the nanoparticles in the polymer blend matrix became coarser and this is because of the agglomeration of nanoparticles. It is well known that the resistance of the composite to external force is large at higher loading of nanoparticles which leads to a poor distribution of filler in the polymer matrix [14]. Therefore, 10 wt% NiO loaded PIN/PTZ blend could be a better candidate for the outstanding electrical conductivity and dielectric performance.

3.5 High-resolution transmission electron microscopy (HRTEM)

The dispersion and structure of the NiO fillers in the PIN/PTZ matrices are observed by analyzing the HRTEM and the images are given Fig. 6. It is clear from the figure that the spherically shaped metal oxide nanoparticles are uniformly inserted into the macromolecular chain of PIN/PTZ. The development of spherically shaped particles in the composite indicates the intermolecular interaction between the nanoparticles and the PIN/PTZ. The micrograph given in Fig. 6a illustrate that the sizes of the NiO particles range from 10 to 18 nm. The TEM study of PIN/PTZ/NiO composite (Fig. 6b) illustrates the formation of aggregates or clusters. These aggregates generate more stress in the fabrication process. The results obtained from HRTEM images are in good agreement with the SEM analysis.

3.6 Thermogravimetric analysis (TGA)

TGA has an important role in determining the thermal stability of polymer composites. Figure 7 shows the TGA curves of PIN/PTZ with different concentrations of NiO nanoparticles. The TGA curves show that the thermal stability of the polymer blend composite changes with increasing NiO contents and the decomposition has completed in two steps. All the samples show small weight loss for the first decomposition step and more significant weight loss for the second degradation step. The initial decomposition up to 250 °C is the removal of surfactant and unreacted oligomers in the polymer blend. The second degradation from 300 to 700 °C is the degradation of the remaining polymer backbone. It is found that the degradation rate of the nanocomposite is slow as compared to the pure polymer blend. The major degradation temperature of the composite with 7 and 15 wt% NiO samples are started at 424 and 439 °C respectively, which is much higher temperature than in pure polymer blend (~ 405 °C). The higher thermal stability of nanocomposite with the addition of nanoparticles is due to the uniform dispersion of fillers in PIN/PTZ matrix. The uniform dispersion generates a protective layer on the surface of polymer blend, which suppress the decomposition of the polymer blend nanocomposites. The final char residue at 580 °C for pure PIN/PTZ is only 33.49% whereas the 58.19 and 67.56% char left for 7 and 15 wt% nanoparticles containing PIN/PTZ at the same temperature. This means that the flame resistance of the polymer blend is increased by the insertion of NiO nanoparticles [22].

3.7 AC conductivity

The frequency dependence AC conductivity of PIN/PTZ blend with different contents of NiO nanoparticles is presented in Fig. 8. The AC conductivity varies slowly at low frequencies and then increases steeply at high-frequency region. The dependence of AC conductivity is due to the relaxation caused by the transport of electrons, hopping or tunneling between equilibrium sites in the polymer matrix. The frequency dependent conductivity is arising from the trapped charges and is active only at higher frequency region. The PIN/PTZ blend shows a lower AC conductivity than NiO incorporated polymer blend and in the composite system, a sudden increase in AC conductivity value is found for a particular concentration of NiO particles (10 wt%). This is the critical concentration in which electrical conductivity has maximum value and on further increase of the concentration of nanoparticles we find a decrease in AC conductivity (for 15 wt% sample) [23]. The higher conductivity of 10 wt% nanocomposite is due to the uniform dispersion of NiO nanoparticles in the polymer blend which provides a smooth conducting path for the flow of current. This is already proved from TEM and SEM analysis which shows the formation of a uniform chain pattern at a critical concentration viz. 10% NiO, provides more number of conductive path and thereby the maximum conductivity. The decrease in conductivity beyond 10 wt% loading is due to the formation of the cluster in the composite which prevents movement of charge carriers through the polymer blend.

3.8 Dielectric analysis

3.8.1 Dielectric constant and dielectric loss

Polymer nanocomposites have been considered as promising candidates for capacitors and charge storage applications. Figures 9 and 10 represent the variation of dielectric constant (εr), and dielectric loss (tan δ) of PIN/PTZ blend with different contents of NiO at various frequencies respectively. Both dielectric constant and dielectric loss values of all the system are higher at lower frequency region and this is attributed to the different polarization effect which enhances the accumulation of charge at the interface of the polymer composite. At higher frequencies, the dipoles are unable to follow the fast changing of the alternative electric field [15] and therefore the polarization due to charge accumulation reduces which results in a depression in the value of εr and tan δ. Such behavior has been observed in many conducting polymer nanocomposites. It is also evident from the figure that the dielectric properties are continuously increases with increasing the loadings of nanoparticles and the maximum properties are observed when the volume fraction of nanoparticles reached 10 wt%. This higher dielectric value of nanocomposite is an indication of the strong interfacial polarization within the polymer blend matrix. However, the dielectric value of 15 wt. % composite is decreased with respect to 10 wt% sample. The nanoparticles have a tendency to undergo self-agglomeration at higher loading. These agglomerated nanoparticles resist the movement of macromolecular chains resulting in lower dielectric properties.

3.8.2 DC conductivity

The mechanism involved in the conductive polymer composites can be investigated by current–voltage (I–V) characteristics. The DC conductivity of PIN/PTZ blend and its composites with various loadings of NiO particles are shown in Fig. 11. The conductivity of nanocomposites is higher than that of the pure polymer blend and the conductivity values increases with the loading of nanoparticles. The conductivity of the polymer-conducting filler composites originates from two mechanisms. One is the Ohmic conduction through direct contact of conductive fillers and the second one is the non-Ohmic conduction through the barrier-tunneling effect between the conducting fillers separated by the polymer layer [24]. The conductivity graph shows a linear variation of electric current with applied voltage up to 10 wt% loading of nanoparticles. The linear I–V relation suggests that direct contact is the dominant mechanism in this case. It can be seen from the figure that the conductivity of the composite is found to decrease at higher loading of NiO (15 wt%). This is due to the formation of aggregates within the polymer blend matrix.

3.8.3 Gas sensing applications

Conducting polymer nanocomposites are good candidates for the elaborations of chemical-vapor sensors by analyzing the change in resistance of the sample by exposure to the gas. The change in electrical resistance with ammonia gas (100 ppm) for pure PIN/PTZ blend and PIN/PTZ/NiO composites at room temperature is given in Fig. 12. The electrical resistance of the sensor increases with the passage of ammonia gas. The higher electrical resistance is observed in the PIN/PTZ blend. The mechanism of the gas sensor is originated from the diffusion of ammonia molecules into PIN/PTZ. This means that the transfer of electron occurs to PIN/PTZ blend through the interaction of ammonia with polymer blend which in turn decreases the electrical conductivity. It can be seen from the figure that the electrical resistance of samples falls to the original value after the passage of ammonia gas and the graph shows a wavy nature. Among the nanocomposites, 10 wt% NiO shows the maximum sensitivity. This is mainly arising from the high surface area of nanoparticles which suppress the interaction between ammonia and uniformly distributed nanoparticles incorporated PINZ/PTZ blend composite [25]. However, as the concentration of NiO reached 15 wt% in the blend, the electrical resistance of the sensor decreased. This is due to the agglomeration of nanoparticles or through the charge compensation by the nanocomposites. The changes in gas sensing properties of PIN/PTZ blend with various contents of NiO particles are given in Fig. 13. There is a linear increase of gas sensing property by the passage of ammonia gas. The maximum sensitivity is observed for 10 wt% sample and beyond this loading the sensitivity is found to be decreasing. Hence it can be suggested the prepared nanocomposite can be used as a promising material for gas sensing applications.

4 Conclusions

We have successfully prepared the PIN/PTZ blend with different contents of NiO nanoparticles. The FTIR and UV spectroscopy of the composite illustrated the characteristic peaks of blend segments and the nanoparticles. XRD pattern confirmed the presence of the crystalline peaks of NiO in the PIN/PTZ blend and the intensity of XRD peaks increased with the loading of nanoparticles. The nanoscale dispersion of inorganic substances within the blend matrix was confirmed by SEM and TEM analysis. TGA analysis shows an enhancement in degradation temperature of the composite with the loading of NiO is due to the effective interaction between nanoparticles and the blend components. The encapsulation of NiO nanoparticles in the blend greatly improved the electrical conductivity (AC and DC), the dielectric constant of the prepared nanocomposites and these electrical properties of the PIN/PTZ blend nanocomposite was higher than that of the pure polymer blend. The response of nanocomposite towards ammonia gas depends on the concentration of nanoparticles in the polymer blend. The experimental results obtained in this study reveals that the PIN/PTZ blend nanocomposites can be used as semiconductor materials for fabricating or improving the properties of nanoelectronic devices.

References

M.G. Murali, U. Dalimba, K. Sridharan, J. Mater. Sci. 47, 8022 (2012)

N.M. Isa, R. Baharin, R.A. Majid, W. Aizan, W.A. Rahman, Polym. Adv. Technol. 28, 1559 (2017)

J. Shi, K.Y. Pu, R. Zhan, B. Liu, Macromol. Chem. Phys. 210, 1195 (2010)

D. Yuping, L. Shunhua, G. Hongtao, J. Compos. Mater. 40, 1093 (2006)

C. Wu, H.M. Xiao, S.Y. Fu, Polymer 54, 4578 (2013)

G.V. Urkmez, B. Sari, H.I. Unal, J. Appl. Polym. Sci. 121, 1600 (2011)

T. Anjitha, T. Anilkumar, G. Mathew, M.T. Ramesan, Polym. Compos. 20, 18 (2018). https://doi.org/10.1002/pc.25088

D.J. Bhagat, G.R. Dhokane, Macromol. Symp. 362, 145 (2016)

J.A. Malmonge, M.A. dos Santos, W.K. Sakamoto, J. Mater. Sci. 40, 4557 (2005)

S. Sakkopoulos, E. Vitoratos, J. Grammatikakis, A.N. Papathanassiou, E. Dalas, J. Mater. Sci. 40, 4557 (2002)

S. Das, P.G.R. Achary, N.C. Nayak, R.N.P. Choudhary, Polym. Compos. 37, 3398 (2016)

K. Suhailath, M.T. Ramesan, J. Vinyl. Addit. Technol. 25, 9 (2019)

S. Palsaniya, H.B. Nemade, A.K. Dasmahapatra, Polymer 150, 150 (2018)

R. Kalyani, K. Gurunathan, J. Mater. Sci.: Mater. Electron. 27, 10634 (2016)

M.T. Ramesan, V. Santhi, Compos. Interfaces 25, 725 (2018)

Y. Xie, X. Sha, Synth. Met. 237, 29 (2018)

G. Kim, H.R. Yeom, S. Cho, J.H. Seo, J.Y. Kim, C. Yang, Macromolecules 45, 1847 (2012)

I.K. Moon, C.S. Choi, N. Kim, React. Funct. Polym. 68, 910 (2008)

M.T. Ramesan, V. Nidhisha, P. Jayakrishnan, Polym. Int. 66, 548 (2017)

V. Hebbar, R.F. Bhajantri, Mater. Sci. Eng., B 224, 171 (2017)

M.T. Ramesan, K. Surya, Polym. Compos. 38, E66 (2017)

J. Feng, J. Hao, J. Du, R. Yang, Polym. Degrad. Stab. 97, 605 (2012)

K. Suri, S. Annapoorni, R.P. Tandon, Bull. Mater. Sci. 24, 563 (2001)

W. Zhou, L. Xu, L. Jiang, J. Peng, Y. Gong, X. Liu, H. Cai, J. Wang, Q. Chen, J. Alloys Compd. 710, 47 (2017)

S.H. Hosseini, J. Appl. Polym. Sci. 101, 3920 (2006)

Funding

The authors (M.T. Ramesan and K. Parvathi) greatly acknowledge for the financial assistance from KSCSTE, Government of Kerala, India (Order No. 566/2017/KSCSTE).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors of this article have no conflict of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ramesan, M.T., Nushhat, K., Parvathi, K. et al. Nickel oxide @ polyindole/phenothiazine blend nanocomposites: preparation, characterization, thermal, electrical properties and gas sensing applications. J Mater Sci: Mater Electron 30, 13719–13728 (2019). https://doi.org/10.1007/s10854-019-01753-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01753-8