Abstract

An enhancement in piezoelectric properties of lead-free ceramic materials by compositional engineering is often accompanied by a sacrifice in the temperature-stability of properties. Here we demonstrate that high piezoelectric properties and excellent high-temperature stability are obtained simultaneously in 0.72BiFeO3–0.28Ba1−x Na x TiO3 (BF–BTNx, x = 0–0.035) ceramics. Our results show that the high temperature-stable piezoelectric properties from 26 to 470 °C, combined with room temperature high piezoelectric constant d 33 = 165pC/N and electromechanical coupling factor k p = 0.35 are achieved for x = 0.015 BF–BTNx ceramics. The results suggest Na-doped BF–BT system ceramic is a potential candidate for high temperature harsh environments actuators and sensors applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With increasing needs for high temperature piezoelectric sensors and actuators for applications in automotive vehicles, aerospace, geothermal and space exploration, considerable attention has been paid to searching for high Curie temperature materials with high piezoelectric performance [1–5]. To date, the most widely used piezoelectric ceramics are lead oxide based ferroelectrics, especially lead zirconate titanate (PZT) due to their superior piezoelectric properties in the morphotropic phase boundary (MPB) [6–8]. Nevertheless, the commercial PZT ceramics generally have a Curie temperature (T c) much <380 °C. The corresponding safe operating temperatures are generally limited to a half of their T c to ensure the stability of piezoelectric properties [6–12]. Therefore, PZT-based ceramics are hard to meet the practical requirements for the high-temperature piezoelectric devices. Furthermore, the use of lead-based ceramics will bring serious harm for human and the environment due to the strong toxicity of lead oxide. Therefore, seeking a lead-fee piezoelectric ceramic with excellent piezoelectric properties and high Curie temperature is fairly significant.

In recent decades, BiMeO3–BaTiO3 (Me = Sc, Fe, Mg1/2Ti1/2, Zn1/2Ti1/2, etc.) binary systems have been developed as candidates with superior properties to replace lead-based ceramics [13–17]. Among those available systems, (1 − x) BiFeO3–xBaTiO3 (abbreviated as BF–BT) is regarded as one of the most promising systems due to the high Curie temperature and excellent piezoelectric properties [17–21].

From the viewpoint of the potential technical important of BF–BT ceramics in high temperature applications, it is very important to study the improvement of piezoelectric properties without sacrificing T c and depolarization temperature T d. However, there are few reports on BF–BT ceramics with the simultaneous existence of large piezoelectricity and good high-temperature stability. In other word, the poled piezoelectric ceramics often begin to lose their piezoelectric properties with temperature increasing to a somewhat below the Curie temperature due to the thermal instability of polarization [22–24]. And the piezoelectric properties and Curie temperature (T c) are generally in conflict with each other [22]. That means that the piezoelectric coefficients d 33 can be improved at the expense of T c, and vice versa [22–25].

How to obtain alternative materials with favorable piezoelectric properties with a high Curie temperature and high thermal depolarization stability? Much attention has been given to various doping modification. It has been noted that addition of lithium element is an effective means enhancing the piezoelectric properties and lowing their sintering temperatures of ceramics [26–28]. Therefore, it can be reasonably expected that Na-doping may improve the properties of the BF–BT ceramics. To our knowledge, there is no report on Na-modified BF–BT ceramic and its structure, piezoelectric properties and high-temperature stability. In the present work, the effect of Na-doping on microstructure, electrical properties and their high-temperature stability of the BF–BT ceramics was studied. We observed that the piezoelectric properties have been enhanced by Na addition. At the same time, temperature dependence of piezoelectric properties suggests that the materials have good thermal stability of electrical properties.

2 Experimental procedure

0.72BiFeO3–0.28Ba1−x Na x TiO3 (abbreviated as BF–BTNx, x = 0–0.035 mol fraction) + 5 % Bi2O3 ceramics were prepared by a conventional oxide-mixed method. The excess Bi2O3 was added to compensate for the Bi loss during calcination and sintering. The raw materials of Bi2O3, Fe2O3, BaCO3, TiO2, and Na2CO3 with purities >99 % were weighed according to the stoichiometric formula and ball-milled for 12 h in alcohol medium. After being dried, the powders were calcined at 800 °C for 4 h. Then, the resultant powders were mixed with 7 wt% of polyvinyl alcohol and pressed into pellets of 12 mm in diameter and 1 mm in thickness by uniaxial pressing under a pressure of 100 MPa, following by sintering at 1010 °C for 2 h in a covered alumina crucible. Finally, silver paste was coated on samples and fired at 600 °C for 30 min to form the electrodes.

The crystal structure for the sintered pellets was characterized by X-ray diffraction (XRD, D8-2-Advanced, Bruker AXS, Germany) with Cu Kα radiation and the surface microstructure was examined by scanning electron microscopy (SEM, JSM-5610LV, JEOL, Japan). The direct piezoelectric coefficient d 33 was recorded from 1-day aged samples using a d 33 meter (ZJ-3A, CAS Shanghai China) after poling at 100 °C in a silicone oil bath under a dc field of 6 kV/mm for 10 min. The piezoelectric and dielectric properties were measured with Agilent 4294A impedance analyzer. The temperature-dependent dielectric properties of poled samples were measured in a controlled furnace with a heating rate of 2 °C/min from 26 to 600 °C. The room-temperature polarization versus electric field hysteresis loops (P–E) were recorded with a ferroelectric test system (Precision Premier II, Radiant Technologies, Albuquerque, NM, USA).

3 Results and discussion

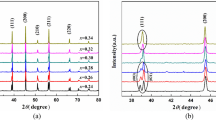

Figure 1 shows the room temperature X-ray diffraction patterns of BF–BTNx ceramics ranging from 20° to 80°. The major diffraction peaks match well with the ABO3-type perovskite phase. However, small additional peaks indexed with a triangle in the XRD patterns are observed, indicating the formation of secondary phase. From the enlarged XRD patterns in Fig. 1b, it is evident for all sintered samples, the peak at 2θ°~39° splits into the (003)/(021) peaks, while the peak at 2θ°~45° is a singlet, meaning that addition of Na has no obvious influence on the crystal structure. Hence, all the samples crystallize into the rhombohedrally distorted perovskite structure.

The surface micrographs of BF–BTNx ceramics are displayed in Fig. 2. The average grain size is seen to initially increase before reaching maximum value of about 9.5 μm (in the case of the x = 1.5 BF–BTNx ceramics). However, when Na content is >0.025, the grain size of the ceramics gradually becomes smaller, which may be attributed to Na gathering in grain boundaries to pin grain boundaries. In addition, some pores could be found for x = 0.035 specimens, meaning that addition of Na has moderate influences on the microstructure and sintering behavior.

Figure 3 shows the room-temperature polarization hysteresis loops of BF–BTNx ceramics measured under an electric field of 6 kV/mm. A well-saturated ferroelectric P–E loop is observed for x = 0 BF–BTNx ceramic. It is generally accepted that Na+ substitutes for higher valence ions (Ba2+), which will result in the formation of oxygen vacancies to retain the charge neutrality, thus causing thermally activated hoping conduction and the absence of proper ferroelectric hysteresis. However, as evidenced by the formation of saturated P–E loops in Fig. 3, Na-doped BF–BT ceramics have not led to higher electrical conductivity. Table 1 shows the coercive field E c and the remnant polarization P r. From Table 1, at the composition of x = 0.015, E c reaches the minimum and P r reaches the maximum.

Figure 4 shows the piezoelectric constant (d 33) and electromechanical coupling factor (k p) of BF–BTNx ceramics as a function of Na content. It can be observed that the piezoelectric properties exhibit strong compositional dependence. Both d 33 and k p increase gradually, reaching maximum at the Na content of 0.015, which are 165 pC/N and 0.35, respectively, then decrease sharply with the increase of Na content. It is well known that the piezoelectric properties are not only attributed to the lattice, crystal structure and polarizability (intrinsic contribution) but also grain size, densification, domain, and defects (extrinsic contribution) [29]. For the present BF–BTNx ceramics, the excellent piezoelectric properties for x = 0.015 composition can be attributed to the multi-effect of intrinsic and extrinsic contribution such as crystal structure, grain size and remnant polarization P r as indicated in Figs. 1, 2 and 3.

The temperature dependence of the relative permittivity (ε r) and dielectric loss tanδ of poled BF–BTNx ceramics at frequencies of 1, 10 and 100 kHz is shown in Fig. 5. It can be seen that all ceramics exhibit only a dielectric peak associated with a phase transition from rhombohedral ferroelectric phase(R) to Cubic paraelectric phase(C). Moreover, the dielectric peaks are very sharp and Curie temperature T c is frequency-independent for all samples, suggesting that the ceramics are ferroelectrics. In addition, the variation of T c of the BF–BTNx ceramics is shown in Table 1. Clearly, the Na-doping has little impact on T c, as shown in Table 1.

From Fig. 5, it can be seen a similar tendency of ε r-temperature curves for all compositions, the values of the ε r increase slightly before a critical temperature (T s) about 450 °C, and then drastically increase to maximum when the temperature near T c. It means that relative permittivity ε r has a relatively good high-temperature stability from room temperature to 450 °C. In addition, obvious dielectric loss peaks are observed near the critical temperature T s.

The thermal depoling of ferroelectric ceramics determines the upper-temperature usage range for the practical applications. Thus, study on the thermal depolarization behavior of piezoelectric properties has great practical significance. The effect of thermal depoling on d 33 and k p of poled BF–BTNx ceramics measured ex situ is shown in Figs. 6 and 7, respectively. From Fig. 6, it can be observed that the values of piezoelectric constants d 33 slightly decrease and then drop dramatically above a critical temperature due to thermal depoling. This critical temperature can be defined as depolarization temperature (T d). The detail depolarization temperature (T d) is also listed in Table 1. Based on the thermal depoling results, all BF–BTNx ceramics display slightly variation of the depolarization temperature (T d) with good high-temperature stability. However, compared with d 33, k p almost remains a constant with increasing temperature, as shown in Fig. 7. As the temperature continues to rise to near T d, the k p dramatically decreases, indicating the induced aligned domains by poling electrical field break up into random state, thus causing loss of piezoelectricity.

Based on the above results, we note that the depolarization temperature (T d) is very close to the critical temperature (T s) in the ε r-temperature curves. Finally, it is important to note that Na-doping can improve the piezoelectric properties, simultaneously combine with good thermal stability. This work therefore provides a simple and cost effective doping method to improve the piezoelectric properties and their high-temperature stability of the BF–BT ceramics.

4 Conclusions

BF–BTNx lead-free piezoelectric ceramics were successfully synthesized using ordinary raw materials and a conventional oxide-mixed method. It has been found that the phase structure of BF–BTNx ceramics is major rhombohedral perovskite phase at study composition range. The piezoelectric properties and their high-temperature stability of BF–BTNx ceramics are improved concurrently. The x = 0.015 BF–BTNx ceramic exhibits a high piezoelectric constant (d 33) of 165 pC/N and an electromechanical coupling factor (k p) of 0.35. At the same time, a high depolarization temperature of T d = 470 °C and Curie temperature of T C = 494 °C are achieved in the x = 0.015 BF–BTNx ceramic. These properties indicate that this system represents a promising lead-free piezoelectric candidate material for harsh environments application.

References

S. Zhang, F. Yu, Piezoelectric materials for high temperature sensor. J. Am. Ceram. Soc. 94(10), 3153–3170 (2011)

J. Chen, J. Cheng, S. Dong, Review on high temperature piezoelectric ceramics and actuators based on BiScO3–PbTiO3 solid solutions. J. Adv. Dielectr. 4(01), 1430002 (2014)

I. Sterianou, D.C. Sinclair, I.M. Reaney, Investigation of high Curie temperature(1−x)BiSc1−yFeyO3–xPbTiO3 piezoelectric ceramics. J. Appl. Phys. 106, 084107 (2009)

Y. Chen, J. Zhu, D. Xiao, B. Qin, Y. Jiang, Bismuth-modified BiScO3–PbTiO3 piezoelectric ceramics with high Curie temperature. Mater. Lett. 62, 3567–3570 (2008)

Z. Pan, J. Chen, L. Fan, Y. Rong, S. Zheng, L. Liu, L. Fang, X. Xing, Enhanced high-temperature piezoelectric properties of traditional Pb(Zr, Ti)O3 ceramics by a small amount substitution of KNbO3. Mater. Res. Express 1(4), 046301 (2014)

R. Guo, L.E. Cross, S.-E. Park, B. Noheda, D.E. Cox, G. Shirane, Origin of the high piezoelectric response in PbZr1−x Ti x O3. Phys. Rev. Lett. 84, 5423–5437 (2000)

B. Jaffe, W.R. Cook, H. Jaffe, Piezoelectric Ceramics (Academic, London, 1971)

B. Noheda, Structure and high-piezoelectricity in lead oxide solid solutions. Curr. Opin. Solid State Mater. 6(1), 27–34 (2002)

R. Theissmann, R.L.A. Schmitt, J. Kling, R. Schierholz, K.A. Schönau, H. Fuess, M. Knapp, H. Kungl, M.J. Hoffmann, Nanodomains in morphotropic lead zirconate titanate ceramics: on the origin of the strong piezoelectric effect. J. Appl. Phys. 102, 024111 (2007)

D.G. Hwang, Y.M. Chae, K.S. Hwang, J.Y. Kang, S.H. Lee, Fabrication and characterization of PZT (lead zirconate titanate) bridge-shaped resonator for mass sensing application. J. Electroceram. 29(3), 225–234 (2012)

T.R. Shrout, S.J. Zhang, Lead-free piezoelectric ceramics: alternatives for PZT? J. Electroceram. 19(1), 113–126 (2007)

A.K. Shukla, V.K. Agrawal, I.M.L. Das, J. Singh, S.L. Srivastava, Temperature dependence of electromechanical properties of PLZTx/57/43 ceramics. Bull. Mater. Sci. 33(4), 383–390 (2010)

H. Ogihara, C.A. Randall, S. Trolier-McKinstry, Weakly coupled relaxor behavior of BaTiO3-BiScO3 ceramics. J. Am. Ceram. Soc. 92(1), 110–118 (2009)

A. Singh, C. Moriyoshi, Y. Kuroiwa, D. Pandey, Evidence for local monoclinic structure, polarization rotation, and morphotropic phase transitions in (1 − x) BiFeO3–xBaTiO3 solid solutions: a high-energy synchrotron X-ray powder diffraction study. Phys. Rev. B 88(2), 024113 (2013)

Q. Zhang, Z. Li, F. Li, Z. Xu, Structural and dielectric properties of Bi(Mg1/2Ti1/2)O3–BaTiO3 lead-free ceramics. J. Am. Ceram. Soc. 94(12), 4335–4339 (2011)

N. Raengthon, D.P. Cann, Dielectric relaxation in BaTiO3–Bi(Zn1/2Ti1/2)O3 ceramics. J. Am. Ceram. Soc. 95(5), 1604–1612 (2012)

S.O. Leontsev, R.E. Eitel, Dielectric and piezoelectric properties in Mn-modified (1−x)BiFeO3–xBaTiO3 ceramics. J. Am. Ceram. Soc. 92, 2957–2961 (2009)

Q. Zheng, L. Luo, K.H. Lam, N. Jiang, Y. Guo, D. Lin, Enhanced ferroelectricity, piezoelectricity, and ferromagnetism in Nd-modified BiFeO3–BaTiO3 lead-free ceramics. J. Appl. Phys. 116, 184101 (2014)

Z. Cen, C. Zhou, H. Yang, Q. Zhou, W. Li, C. Yan, L. Cao, J. Song, L. Peng, Remarkably high-temperature stability of Bi(Fe1−x Al x )O3–BaTiO3 solid solution with near-zero temperature coefficient of piezoelectric properties. J. Am. Ceram. Soc. 96(7), 2252–2256 (2013)

Q. Zhou, C. Zhou, H. Yang, C. Yuan, G. Chen, L. Cao, Q. Fan, Piezoelectric and ferroelectric properties of Ga modified BiFeO3–BaTiO3 lead-free ceramics with high Curie temperature. J. Mater. Sci. Mater. Electron. 25(1), 196–201 (2014)

C. Zhou, A. Feteira, X. Shan, H. Yang, Q. Zhou, J. Chen, W. Li, H. Wang, Remarkably high-temperature stable piezoelectric properties of Bi(Mg0.5Ti0.5)O3 modified BiFeO3–BaTiO3 ceramics. Appl. Phys. Lett. 101(3), 032901 (2012)

H. Ge, Y. Hou, X. Rao, M. Zhu, H. Wang, H. Yan, The investigation of depoling mechanism of densified KNbO3 piezoelectric ceramic. Appl. Phys. Lett. 99(3), 032905 (2011)

J. Chen, J. Li, L. Fan, N. Zou, P. Ji, L. Liu, L. Fang, H. Kang, Enhanced piezoelectric and antiferroelectric properties of high-T c perovskite of Zr-substituted Bi(Mg1/2Ti1/2)O3–PbTiO3. J. Appl. Phys. 112(7), 074101 (2012)

T.Y. Ansell, D.P. Cann, Piezoelectric properties of the high temperature MPB xPbTiO3–(1 − x)[BiScO3 + Bi(Ni1/2Ti1/2)O3] composition. J. Electroceram. 31(1–2), 159–167 (2013)

T. Sebastian, I. Sterianou, I.M. Reaney, T. Leist, W. Jo, J. Rodel, Piezoelectric activity of (1 − x) [0.35Bi(Mg1/2Ti1/2)O3–0.3BiFeO3–0.35BiScO3]–xPbTiO3 ceramics as a function of temperature. J. Electroceram. 28(2–3), 95–100 (2012)

C. Liu, L. Xing, D. Wang, Z. Chen, B. Fang, J. Ding, X. Zhao, H. Xu, H. Luo, Improving piezoelectric property of BaTiO 3 –CaTiO 3 –BaZrO 3 lead-free ceramics by doping. Ceram. Int. 40(7), 9881–9887 (2014)

D. Xu, W.L. Li, L.D. Wang, W. Wang, W.P. Cao, W.D. Fei, Large piezoelectric properties induced by doping ionic pairs in BaTiO3 ceramics. Acta Mater. 79, 84–92 (2014)

X. Huang, W. Zhao, C. Gao, Z. Chen, Influence of Nb2O5 doped amount on the property of BCTZ lead-free piezoelectric ceramics doped with Li2CO3. J. Mater. Sci. Mater. Electron. 25, 505–509 (2014)

C.A. Randall, N. Kim, J.P. Kucera, W. Cao, T.R. Shrout, Intrinsic and extrinsic size effects in fine-grained morphotropic phase boundary lead zirconate titanate ceramics. J. Am. Ceram. Soc. 81(3), 677–688 (1998)

Acknowledgments

This work was supported by the National Nature Science Foundation of China (61361007, 61261012) and Guangxi Key Laboratory of Information Materials (1310001-Z) and Guangxi Experiment Center of Information Science.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fan, Q., Zhou, C., Li, Q. et al. Temperature stability of sodium-doped BiFeO3–BaTiO3 piezoelectric ceramics. J Mater Sci: Mater Electron 26, 9336–9341 (2015). https://doi.org/10.1007/s10854-015-3032-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3032-1