Abstract

Polyarylene ether nitrile (PEN)/multi-walled carbon nanotubes (MWCNTs)/alumina (Al2O3) micro-nanocomposite material films were fabricated by uncomplicated and accessible method, overcoming the difficulty of bad interaction between MWCNTs and PEN matrix. Scanning electron microscope revealed that MWCNTs were isolated by Al2O3 and realized better dispersion in matrix. Al2O3 particles hindered conductive MWCNTs from bridging with each other, working as dielectric obstacle. In addition, the micro-nanocomposite has excellent thermal stability and possesses high performance in dielectric and mechanical. The investigation results showed that the dielectric constant increased to 100.8 (50 Hz), which is 20 times higher than that of pure PEN while the dielectric loss was only 0.1 with 7 wt% MWCNTs loading. Meanwhile, the mechanical property indicated that the composite with 7 wt% MWCNTs loading reached their highest values. In other words, the composite with 7 wt% MWCNTs loading possess excellent mechanical property simultaneously as it reached the percolation threshold.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

With the maturation of microelectronic and information industry, the miniature and integrated semiconductor devices have been widely applied in dielectric antenna and embedded films conductors. The polymer-based composites become the hot spot in the industry due to their high dielectric constant, low loss and low cost [1–6]. To dielectric composite materials, the characteristic of excellent dielectric properties and better processability is required. Traditional inorganic dielectric materials have disadvantages of great brittleness, high processing temperature and large loss, so they cannot meet the above-mentioned requirements. Polymer materials possess excellent processability and low processing temperature but generally have low dielectric constant [7–11]. Under this circumstance, several different fillers are added into polymer matrix simultaneously to obtain the composite dielectric materials so as to take the advantages of every component of the composites [12, 13]. Therefore, approaches such as loading polymer with high-k (k = dielectric constant) and capacitance particles, synthesizing micro-nanometer particles inside a bulk polymer matrix have been attempted [14–16].

Polyarylene ether nitrile (PEN) has been synthesized in our laboratory. As special engineer polymer resin, it shows excellent temperature stability, radiation resistance and chemical inertia [17–20]. The PEN-based composites turned out to be a new generation of materials with unique properties such as thermal, collaborating enhanced electrical from special microstructure and are widely applied in extreme conditions such as elevated temperature and aggressive chemical environment [21–23]. As a kind of nanomaterials, multi-walled carbon nanotubes (MWCNTs) have large aspect ratio and present a unique combination of electrical and thermal properties, attracting extensive attention worldwide [24, 25]. However, carbon nanotubes naturally form bundles because of very strong intertubular van der Waals attractions, which complicate their use, leading to poor dispersion of MWCNTs in the polymer matrix and high dielectric loss [26–28]. The key issue is to find out appropriate inorganic materials which can isolate MWCNTs. With a blocky structure, micrometer alumina (Al2O3) have good prospect to solve the problem of poor distribution between MWCNTs and PEN matrix.

As the inorganic particle materials aggregate together easily and exhibit phase separation phenomenon in macroscopic view, the objective of this work is to better the interfacial state of polymer and inorganic particle and explore properties of the composite. With the addition of Al2O3, Al2O3 particles hindered conductive MWCNTs from bridging with each other, working as a dielectric obstacle, which can be convinced from SEM images. Besides, to further understand this composite, the dielectric properties were investigated and the thermal, mechanical and micromorphology properties were also characterized as described below.

2 Experimental section

2.1 Materials

N-methylpyrrolidone (NMP, purity 99 %) was supplied by Tianjin Bodi Chemical Holding Co., Ltd., Tianjin, China. Sulfate acid (H2SO4, 98 %) was provided by Shantou Xilong Chemical Factory, Guangdong, China. Nitric acid (HNO3, 65 %) was purchased from Sichuan Xilong Chemical Co., Ltd., Sichuan, China. Provided by Chengdu organic Chemicals Co., Ltd., Chinese Academy of Science, the MWCNTs (purity 95 wt%) is about 50 nm in outer diameter, 20 μm in length, which was purified by H2SO4 and HNO3 (3:1) before use to remove the metal catalyst (Fe, etc.). Al2O3 was purchased from Shanghai Hufeng Chemical Holding Co., Ltd., Shanghai, China. PEN was provided by Union Laboratory of Special Polymers of UESTC-FEIYA, Chengdu, China. PEN (HQ/PP) is synthesized in pilot production via polycondensation of 2,6-dichlorobenzonitrile (DCBN) with phenolphthalein (PP) and hydroquinone (HQ) (molar ratio is 1:1) in the presence of anhydrous K2CO3 as catalyst and NMP as solvent [29].

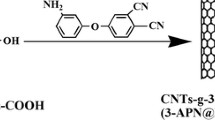

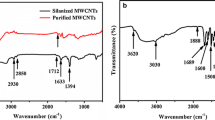

2.2 Preparation of Al2O3/MWCNTs/PEN micro-nanocomposite films

The mixture of MWCNTs, Al2O3 (mass ratio is 2:1) and NMP solvent were added into a 100 mL three necked round bottle flask equipped with a refluxing condenser and mechanical stirrer, keeping ultrasounding for 2 h to make sure that inorganic fillers were dispersed completely. Meanwhile, certain measured of PEN was added into NMP solvent to form a transparent solution. After the PEN completely dissolved, the mixture of MWCNTs and Al2O3 were dispersed into PEN solution and refluxed at the stirring speed of 1,200 rpm for 1 h, and then sonicated for 2 h in a low power ultrasonic bath. The mixture solution was cast on clean glass plates and dried in an oven at 80, 100, 120, 140, 160 and 180 °C, respectively for 1 h, 200 °C for 2 h. After being cooled naturally to room temperature, the films with different MWCNTs loadings (1, 3, 5, 6, 7 and 8 wt%) were obtained. The average thickness of the film is about 75 μm.

2.3 Characterization

The cross-sectional micromorphologies of the films were observed by scanning electron microscope (SEM, JEOL, JSM-5900 LV) and the samples were brittle fractured in liquid nitrogen and then coated with a thin layer of gold before examining. Dielectric properties of the surface modified CCTO/PEN composite films were tested by a TH 2819A precision LCR meter (Tong hui Electronic Co., Ltd.), which was carried out at different frequencies (50 Hz–100 kHz) at room temperature with 40 % humidity. Differential scanning calorimetry (DSC) analysis was performed on a TA Instrument DSC Q100 under nitrogen atmosphere (sample purge flow 50 mL/min) at a heating rate of 10 °C/min from room temperature to 350 °C. Thermogravimetric analysis (TGA) was carried on a TA instrument Q50 series analyzer system under nitrogen atmosphere (sample purge flow 60 mL/min at a heating rate of 20 °C/min) from room temperature to 800 °C. Dielectric properties of the Al2O3/MWCNTs/PEN films were tested by a TH 2819A precision LCR meter (Tong hui Electronic Co., Ltd.), which was carried out at different frequencies (50 Hz–100 kHz) at room temperature with 40 % humidity. Mechanical properties of the films were measured by employing a SANS CMT6104 Series Desktop Electromechanical Universal Testing Machine.

3 Results and discussions

3.1 Morphological properties

According to previous reports, the thermal and dielectric properties of composite films are strongly affected by the dispersity and miscibility between organic and inorganic component [30]. Figure 1 shows the microstructure and dispersion state of the fractured surface of the composite films with 0, 3 and 7 wt% MWCNTs loadings at the magnification of 20,000. From the images, MWCNTs are well isolated by Al2O3 and prevent the direct contact of MWCNTs. The phase interface between MWCNTs and PEN matrix was vague, indicating that Al2O3 and MWCNTs have good compatibility and connection with PEN matrix. Besides, there is no apparent aggregation as MWCNTs loading increases, realizing better dispersity. In the previous researches [31], the combination between MWCNTs and PEN is bad, and MWCNTs can easily agglomerate and pull out from PEN matrix. However, in these images, almost no MWCNTs pull out from matrix and the dispersion of MWCNTs are better, suggesting comparative better combination and interaction between MWCNTs and PEN, overcoming the bad interaction with PEN matrix. For composite materials, this is the precondition for outstanding mechanical and dielectric performances.

3.2 Thermal properties

The melt behavior of pure PEN and the Al2O3/MWCNTs/PEN micro-nanocomposite films were analyzed by DSC and TGA. The results of thermal behavior with different MWCNTs contents are shown in Table 1. According to Fig. 2a, the glass transition temperatures (T g ) of the composite films with different MWCNTs contents are all approximately 224 °C and there is no prominent difference between the curves, indicating that there is no distinct influence on T g of PEN matrix as the addition of MWCNTs and Al2O3 particles. It also shows that the composite films have sound heat-resistant capability. TGA curves show that the initial decomposition temperatures (T id ) and the maximum decomposition rate temperatures (T max ) of pure PEN are 481 and 497 °C, respectively. Above all, the T id and T max of the composite films are all higher than that of pure PEN, suggesting that the addition of MWCNTs and Al2O3 can relieve the thermal decomposition of polymer chain, which is caused by the good dispersion state of the composite films and further approved the results of SEM. Both DSC and TGA curves prove that the composite films possess excellent thermal stability.

3.3 Dielectric properties

The alternating current dielectric constant (Fig. 3a) and dielectric loss (Fig. 3b) as a function of frequency at the room temperature for different MWCNTs loadings are presented in Fig. 3. As can be seen, both dielectric constant and loss are dependent on frequency in the measured scope, especially in low frequency. The decrease tendency in dielectric constant with varying frequency (Fig. 3a) may be caused by the effect of polarization, namely, there is no enough time for electric charge to polarize. The variation tendency of dielectric loss is similar with dielectric constant (Fig. 3b). For the engineering dielectric materials, there always exists vacancies in dielectric and the charged particles can run through the motion of the electrode parallel with the electric field in the external electric field, causing the appearance of leakage current. It can consume energy directly and cause the change of dielectric loss. On the other hand, the variety of dielectric loss is also caused by polarization relaxation and conductivity in the alternating electric field. The speed of electric charge polarization cannot overtake the variety of frequency, consuming less energy and resulting in the decline in dielectric loss [21].

Figure 4 shows the influence of MWCNTs loading on (a) dielectric constant and (b) dielectric loss with 50 Hz, 1 kHz and 10 kHz. Clearly, the dielectric constant exhibits a linear relationship with MWCNTs content when it is below 6 wt%, and then appears a sudden change at 7 wt%. After that, the value doesn’t change obviously between 7 and 8 wt%, suggesting that the percolation threshold is about 7 wt% MWCNTs loading. Whereas, the dielectric loss is still very low as the appearance of sudden change of the dielectric constant (7 wt% MWCNTs loading). The results show the dielectric constant of composite films with 7 wt% MWCNTs loading increases to 100.8, which is 20 times higher than that of pure PEN, while the dielectric loss is just 0.1. This is mainly attributed to the connection and dispersion between polymer and inorganic particles. The conducting MWCNTs are isolated by Al2O3 to form microcapacitors, in other words, Al2O3 particles hindered conductive MWCNTs from bridging with each other, working as a dielectric obstacle. Under this circumstance, in order to form conductive network, more filler will be needed and the effective capacitance can be enhanced accordingly [32]. The percolation theory, ε ∝ (pc − p)−s and tan δ ∝ (pc − p)−t, where pc is theoretical percolation value, p is practical volume fraction value, s and t is critical exponent [33], can explain the exponential relationship between dielectric constant and MWCNTs content. In addition, as shown in Fig. 4b, the dielectric loss of 7 wt% MWCNTs loading is just 0.1. Considering these two aspects together, the composite has realized high-k and low loss simultaneously. This composite will be a good candidate to be used in the field of electronics, motor and cable industry.

3.4 Mechanical properties and flexibility

In most cases, the mechanical properties of composites depend strongly on the amount of fillers and the level of molecular orientation [34, 35]. Figure 5 shows the tensile strengths and modulus of Al2O3/MWCNTs/PEN composite films at varying MWCNTs loading. In the case of the composite, both tensile strength and modulus of the micro-nanocomposite films reach their highest values at the 7 wt% MWCNTs loading, and then decrease with further addition of fillers. This may be attributed to two factors: (1) excessive MWCNTs particles cannot fill in entirely with PEN matrix; (2) the physical entanglement of macromolecular chains centered on MWCNTs particles. Nonetheless, the tensile strengths and modulus of the composite even with 8 wt% MWCNTs loading are also higher than that of pure PEN. In this aspect, the composite can widen their potential application in many special engineering areas.

The breaking elongation of pure PEN and the composite as a fraction of MWCNTs loading is presented in Fig. 6. The breaking elongation gradually decreases with the addition of MWCNTs and Al2O3 particles. This phenomenon can be explained by two mechanisms: (1) the stress concentration and microcracks brought by the particles will seriously affect the breaking elongation; (2) the strong interfacial bonding between polymer and inorganic particles restrict the chain movement. Additionally, the pure PEN and composite possess relatively high breaking elongation, indicating the films cannot break instantly when subjected to external forces, reflecting that the composite have excellent flexibility.

Figure 7 exhibits the digital image of pure PEN and the micro-nanometer composite films which were cured into four layer columns, containing 0, 1, 3 and 7 wt% MWCNTs, respectively. The images testify the high degree of flexibility of the composite films even with 7 wt% MWCNTs loading, further suggesting that they have great potential to be used in film capacitor fields.

4 Conclusions

In summary, the Al2O3/MWCNTs/PEN micro-nanocomposite has been fabricated by uncomplicated and accessible method and obtained better performances. It was found from scanning electron microscope (SEM) that MWCNTs were isolated by Al2O3 and realized better dispersion with PEN matrix. More importantly, Al2O3 particles hindered conductive MWCNTs from bridging with each other, working as a dielectric obstacle, receiving better dielectric property. DSC and TGA showed that the composite films possessed high thermal stability and could meet the demand of practical application. Besides, the investigation of dielectric property proved that the composite films possess excellent dielectric properties. The dielectric constant of the composite film increased to 100.8 (50 Hz), yet the dielectric loss is only 0.1 with 7 wt% MWCNTs loading. Thanks to the features of high-k and low loss, they will attract more attention for practical application in the fields of electronics, cable industry and high energy density storage capacitors. Additionally, the tensile strength and modulus of the composite with 7 wt% MWCNTs reached their highest values, namely, the composite possess excellent mechanical properties simultaneously as it reached the percolation threshold. The outstanding properties of this composite further confirmed the better compatibility and connection between the inorganic fillers and matrix.

References

Z. Dang, Y. Lin, C. Nan, Adv. Mater. 15, 1625 (2003)

L. Wang, Z. Dang, Appl. Phys. Lett. 87, 042903 (2005)

N. Levi, R. Czerw, S. Xing, P. Iyer, D.L. Carroll, Nano Lett. 4, 1267 (2004)

J. Li, Phys. Rev. Lett. 90, 217601-1 (2003)

Q. Zhang, H. Li, M. Poh, F. Xia, Z. Cheng, H. Xu, C. Huang, Nature 419, 284 (2002)

H. Kawai, Jpn. J. Appl. Phys. 8, 975 (1969)

Y. Rao, C. Wong, J. Appl. Polym. Sci. 92, 2228 (2004)

R. Ulrich, Circuit. World 30, 20 (2004)

X. Huang, Z. Pu, L. Tong, Z. Wang, X. Liu, J. Mater. Sci. Mater. Electron. 23, 2089 (2012)

H. Wang, W. Zhong, P. Xu, Q. Du, Macromol. Mater. Eng. 289, 793 (2004)

L. Li, Q. Lu, J. Yin, Z. Zhu, D. Pan, Z. Wang, Mater. Sci. Eng. C 22, 61 (2002)

N. Guo, S.A. Dibenedetto, D.K. Kwon, L. Wang, M.T. Russell, M.T. Lanagan, A. Facchetti, T.J. Marks, J. Am. Chem. Soc. 129, 766 (2007)

J. Li, S.I. Seok, B. Chu, F. Dogan, Q. Zhang, Q. Wang, Adv. Mater. 21, 217 (2009)

A. Maliakal, H. Katz, P.M. Cotts, S. Subramoney, P. Mirau, J. Am. Chem. Soc. 127, 14655 (2005)

Y. Bai, Z. Cheng, V. Bharti, H. Xu, Q. Zhang, Appl. Phys. Lett. 76, 3804 (2000)

R. Schroeder, A.L. Majewski, M. Grell, Adv. Mater. 17, 1535 (2005)

S. Matsuo, T. Murakami, R. Takasawa, J. Polym. Sci. Pol. Chem. 31, 3439 (1993)

J. Yang, H. Tang, Y. Zhan, H. Guo, R. Zhao, X. Liu, Mater. Lett. 72, 42 (2012)

C. Li, X. Liu, N. Gao, X. Liu, Mater. Lett. 62, 194 (2008)

V. Rao, P.U. Sabeena, A. Saxena, C. Gopalakrishnan, K. Krishnan, P.V. Ravindran, K.N. Ninan, Eur. Polym. J. 40, 2645 (2004)

M. Feng, X. Huang, H. Tang, Z. Pu, X. Liu, J. Mater. Sci. Mater. Electron. 24, 3652 (2013)

F. Meng, Y. Zhan, Y. Lei, R. Zhao, M. Xu, X. Liu, Eur. Polym. J. 47, 1563 (2011)

J. Zhong, W. Chen, K. Jia, X. Liu, J. Compos. Mater. 41, 2453 (2007)

X. Xie, Y. Mai, X. Zhou, Mater. Sci. Eng. R 49, 89 (2005)

D. Tasis, N. Tagmatarchis, A. Bianco, M. Prato, Chem. Rev. 106, 1105 (2006)

L. Liu, J.C. Grunlan, Adv. Funct. Mater. 17, 2343 (2007)

B. Yang, K.P. Pramoda, G. Xu, S.H. Goh, Adv. Funct. Mater. 17, 2062 (2007)

M.S. Strano, Nat. Mater. 5, 433 (2006)

H. Tang, J. Yang, J. Zhong, R. Zhao, X. Liu, Mater. Lett. 65, 2758 (2011)

J. Zhong, H. Tang, Y. Chen, X. Liu, J. Mater. Sci. Mater. Electron. 21, 1244 (2010)

X. Liu, S. Long, D. Luo, W. Chen, G. Cao, Mater. Lett. 62, 19 (2008)

Y. Shen, Y. Lin, C. Nan, Adv. Funct. Mater. 17, 2405 (2007)

X. Huang, Z. Pu, M. Feng, L. Tong, X. Liu, Mater. Lett. 96, 139 (2013)

T. Nakinpong, S. Bualeklimcharoen, A. Bhutton, O. Aungsupravate, T. Amornsakchai, J. Appl. Polym. Sci. 84, 561 (2002)

A. Ajji, J. Brisson, Y. Qu, J. Polym. Sci. Pol. Phys. 30, 505 (1992)

Acknowledgments

The authors wish to thank for financial support of this work from the National Natural Science Foundation (Nos. 51173021, 51373028) and “863” National Major Program of High Technology (2012AA03A212).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, M., Huang, X., Pu, Z. et al. Dielectric and mechanical properties of three-component Al2O3/MWCNTs/polyarylene ether nitrile micro-nanocomposite. J Mater Sci: Mater Electron 25, 1393–1399 (2014). https://doi.org/10.1007/s10854-014-1740-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-1740-6