Abstract

This study reports the effect of Lu addition on the microstructural and superconducting properties of YBa2LuxCu3O7−δ (Y123) superconducting samples with x = 0, 0.1, 0.3, 0.5 and 0.7 by means of X-ray diffraction (XRD) analysis, scanning electron microscopy (SEM), electron dispersive X-ray (EDX), electrical resistivity and transport critical current density (Jc) measurements. The samples prepared by the liquid ammonium nitrate and derivatives are exposed to various annealing time (20, 40 and 60 h) and temperature (950, 960 and 970 °C), and the best ambient for the sample fabrication is determined to be 970 °C for 20 h. Zero resistivity transition temperatures (Tc), critical current densities (Jc), variation of transition temperatures, hole-carrier concentration, grain size, lattice parameter, surface morphology, element distribution, crystallinity and resistivity (at room temperature) values of the bulk superconducting samples prepared at 970 °C for 20 h are compared with each other. Tc and Jc values of the samples are inferred from the dc resistivity and the critical current measurements, respectively. The results show that the Tc value of the pure sample is about 90.6 K while the sample doped with 0.1 wt% Lu has the maximum Tc value (92.5 K). However, beyond x = 0.1, the Tc value is observed to decrease toward to 83.5 K with increment in the Lu addition. Similarly, the Jc values measured are found to reduce from 142 to 76 A/cm2 with the addition. Moreover, XRD measurements show that both pure and Lu-doped samples exhibit the polycrystalline superconducting phase with the changing intensity of diffraction lines and contain Y123 and Y211 phase, confirming the incorporation of Lu atoms into the crystalline structure of the samples studied. At the same time, comparing of the XRD patterns of samples, the intensity ratio of the characteristic (110) and (013) peaks on the sample doped with 0.1 wt% Lu is more than that on the other samples prepared. Additionally, SEM images display that the sample doped with 0.1 wt% Lu obtains the best crystallinity, grain connectivity and largest grain size whereas the worst surface morphology is observed for the maximum doped sample (x = 0.7). Further, EDX results demonstrate that the Lu atoms doped are successfully introduced into the microstructure of the Y123 samples studied and the maximum Cu element level is observed for the sample doped with 0.1 wt%, explaining that why this sample obtains the best superconducting properties compared to others. According to all the results obtained, it is concluded that the 0.1 wt% Lu addition into the Y123 system improves the microstructural and superconducting properties of the samples studied.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

YBaCuO high temperature superconductors obtaining a perovskite structure with bended Cu–O chains [1] have widely been investigated owing to their varying critical transition temperature with oxygen content and strong flux pinning capability in high magnetic field [2]. Moreover, researchers and scientists have endeavored to improve the superconducting, mechanical, electrical, physical, microstructural and flux pinning properties of the superconductor materials to make them suitable for high temperature and magnetic field applications [3–6]. However, the presence of grain and sub-grain boundaries in the materials creates the serious problems in high magnetic field applications [7–9]. As well known, critical current density (is in charge of these applications) is inadequately low in the YBaCuO materials due to the serious weak links and the granularity in these materials [10]. Thus in the last decades, numerous methods including metal doping, chemical substitution, transition metal evaporation and changing preparation condition have been studied to make the effective pinning centers such as planar defects, stacking faults and micro-defects, leading to the improvement of the critical current density [11–15]. The metal doping into the system is one of the most used methods owing to easily controllable mechanism and especially the reproducible process of the samples accomplished quite easily compared to the other methods [16–21]. Besides, this method is useful to investigate the mechanism of high-temperature superconductivity [22–25] because the knowledge of both the location and charge of the doping metals and the microstructural changes in the ceramic superconductors due to the dopants lets us obtain some important clues about the degradation or improvement of the superconducting properties (hole carrier concentration, critical current density, onset and offset critical temperatures, etc.,) [26]. Based on the results in [16–21], it was reported that the superconducting properties of YBCO materials are generally suppressed due to the degradation of the charge carrier numbers, surface morphology and grain connectivity.

According to the literature research, no detailed work has been published on the microstructural and superconducting properties of considerably Lu added YBCO superconductor ceramics. In the present study, after determining the best annealing ambient for the fabrication of the Y123 superconductors, we examine the role of the Lu addition on the microstructural and superconducting properties in detail with the aid of the X-ray diffraction (XRD), scanning electron microscopy (SEM), electron dispersive X-ray (EDX), electrical resistivity and transport critical current density measurements. Lotgering index and hole carrier concentration values for the samples prepared are also discussed clearly. The results show that the Lu addition into Y123 system results in the decrement of the critical transition temperature and current density, and induces an orthorhombic–tetragonal phase transition with the enhancement of the dopant concentration [27–29].

2 Experimental details

The experimental part of this study is composed of two parts. The first part is to determine the best annealing ambient for the fabrication of the YBa2Cu3O7−δ (Y123) superconductor and the second part is to perform the SEM, XRD, EDX, ρ–T and I–V measurements for the investigation of the effect of Lu addition on the microstructural and superconducting properties of Y123 superconductors. For the first part, the best ambient for the sample fabrication is determined to be 970 °C for 20 h (The results obtained will be discussed in detail in electrical resistivity measurements section). For second part, superconducting YBa2LuxCu3O7−δ ceramics with x = 0, 0.1, 0.3, 0.5, and 0.7 are elaborated in air by means of nitrate compounds of Y, Lu, Cu and Ba material. These compounds are weighed in stoichiometric proportion with regard to Eq. (1) to obtain a chemically homogeneous mixture.

The mixture is exposed to heat treatment at 550 °C for 2 h to both release the gasses and obtain the Lu-doped Y123 material. The homogeneous mixture of powders is subjected to calcination process at 800 °C for 24 h in a tube furnace (Protherm-Model PTF12/75/200) at 5 °C per minute heating rate. The resultant powder is mixed in an agate mortar for 2 h and then pressed under 10 tons to make the sample 13 mm in diameter. The sintering process of the samples is conducted at 970 °C (best annealing-temperature) for 20 h (best annealing-time) in the furnace. Both the heating and cooling rates of the furnace are adjusted to be 5 °C/min. The superconductor samples prepared with various Lu stoichiometry (x = 0, 0.1, 0.3, 0.5 and 0.7) will be herein after presented as Lu-0, Lu-1, Lu-3, Lu-5 and Lu-7, respectively.

The dc resistivity and critical current density measurements of the samples are performed on the sample using the conventional four-probe method. Both voltage and current contacts are made with silver paint to get rid of the contact resistance. The electrical resistivity as a function of temperature range from 60 to 130 K is measured by running 5 mA dc current through the sample in a closed-cycle cryostat at low temperatures down to 3 K. A Keithley 220 programmable current source and a Keithley 2182A nano-voltmeter help us to measure the samples’ resistivity. The transport critical current of the samples in zero field at 77 K are measured by man-made system. A programmable temperature controller (Lakeshore 340) helps us take the accurate monitoring of the temperature with a stability and accuracy of ±0.01 K. The current applied parallel to the direction of pressed surface is ramped at a constant rate (1.0 A/ms) for the entire sample. The critical current (I c ) values are defined with the criterion of 1 μV/cm, hence, J c value is computed from I c value and total cross-sectional area of the sample studied. All the data taken were recorded using Labview computer software.

The XRD data are collected using a Rigaku Multiflex + XRD diffractometer with CuKα target giving a monochromatic beam with wavelength 1.5418 Å in the range 2θ = 3°–60° at a scan speed of 3°/min and step increment of 0.02° at room temperature (300 K). Phase purity and lattice parameters are inferred from the XRD patterns and the accuracy in finding the lattice parameters (a and c) is ± 0.0001 Å. At the same time, the average particle size and Lotgering index values of the samples are calculated from the XRD patterns.

Surface morphology, grain connectivity and grain size of the pure and Lu-doped samples are investigated by SEM JEOL 6390-LV, operated at 20 kV in the secondary electron image (SEI) mode with a resolution power of 3 nm. Elemental compositions and distributions in the samples studied in this work are analyzed by means of an Oxford X-ray micro-probe analysis connected to SEM (EDX).

According to the obtained results, the Y123 ceramics fabricated from the nitrate compounds exhibit superconducting behaviour, showing that this production method is useful and easy to manufacture the superconducting samples compared to the other methods such as conventional solid-state reaction [30], sol–gel [31, 32], co-precipitation [33], and micro-emulsion-based techniques [34].

3 Results and discussion

3.1 Electrical resistivity measurements

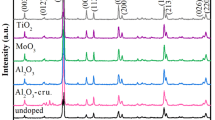

In order to determine the best ambient for the fabrication of Y123 superconductor material, several samples are produced at various annealing temperature (960, 970 and 980 °C) and time (20, 40 and 60 h). The samples annealed at 960 °C shows the characteristic peaks of the green phase Y2BaCuO5 (Y-211) [35, 36] whereas there are voids and signs of melting on the micrograph of the samples fabricated at 980 °C. Thus, the ideal annealing temperature is determined to be 970 °C. On the other hand, the samples are annealed at different time such as 20, 40 and 60 h to find the best annealing time for the fabrication of the superconductors. Dc electrical resistivity, transport critical current density and XRD analysis measurements are performed to characterize the samples produced. Dc electrical resistivity measurements as a function of temperature are conducted using the standard four-probe method in the temperature range 70–120 K and the results obtained are displayed in Fig. 1. It is visible from the figure that the samples prepared at different annealing time exhibit metallic behavior above the Tc value. As for the room temperature resistivity values, the sample annealed at 970 °C for 40 h has the maximum resistivity whereas the sample produced at 970 °C for 60 h obtains the minimum resistivity value. The change of the resistivity value is attributed to the metallic connection between the grains as a result of the optimization of the hole density and possible changes in the lattice vibration [37]. Furthermore, the zero resistivity transition temperatures (R = 0 Ω) inferred from the same figure are found to be about 90.5, 89.1 and 83.2 K for the sample annealed at 970 °C for 20, 40 and 60 h, respectively, being related to not only the deterioration of crystallinity, de-orientation of Y123 grains and the decrease in the grain size and the hole concentration but the increment of the porosity and secondary phases, as well. Moreover, Fig. 2 shows the change of the self field critical current density with regard to the annealing time. As seen from the figure, the sample annealed at 970 °C for 20 h exhibits a J c of 142 A/cm2 that is the maximum value for the critical current density. Furthermore, in Fig. 3 one can see the XRD patterns for the samples prepared at different annealing time. It is found that the most high-intensity peaks belong to Y123 phase for the sample produced at 970 °C for 20 h. According to these results, the preparation condition for the Lu-doped samples is determined to be 970 °C for 20 h. Figure 4a shows the temperature dependence of the electrical resistivity (ρ–T) for YBa2LuxCu3O7−δ with x = 0, 0.1, 0.3, 0.5 and 0.7.

As seen from the figure, the smallest resistivity value is observed for the Lu-1 sample whereas the Lu-7 sample has the greatest value among the samples produced in this work (Table 1), resulting from the shrink of the grains [38]. In other words, when Lu3+ ions incorporate into the Y123 system, the excess Lu3+ fill the holes in the crystal, thus, the hole concentration in the Cu–O plane of the Y123 system reduces, leading to the increment in the normal-state resistivity of the system [39]. Moreover, critical transition (onset and offset critical) temperatures estimated from the normalized resistance graphs (Fig. 4b) are depicted in Fig. 5. It is apparent from the figure that both the onset (T onset c ) and offset (T offset c ) critical temperatures initially increase up to value of x = 0.1 beyond which they start to decrease monotonously. The former (latter) is found to be about 94.6 K (92.5 K) for the Lu-1 sample while for the Lu-7 sample they are obtained to be about 89.7 and 83.5 K, respectively. The decrease in the critical temperature is associated with the increase of the relative percentage of Y211 phase formation, supported by XRD investigations. It is an interesting point from the resistivity measurements that the Lu addition in the Y123 system affects dramatically on the resistive transition of the samples prepared. The variation of ∆T c (T onset c –T offset c ) with regard to the Lu content is listed in Table 1. As seen from the table, the minimum ∆T c is found to be about 2.3 K for the Lu-1 sample whereas the maximum ∆T c is observed to be about 6.2 K for the Lu-7 sample. This phenomenon is in accordance with the presence of impurities in the Y123 system, the weak links between the superconducting grains and grain misorientations [30, 40, 41], supporting the results of the SEM measurements. Based on the results, it is summarized that the 0.1 wt% Lu doping into the Y123 system enhances the critical temperatures, confirming the improvement of the superconducting properties of the Y123 material.

3.2 Hole-carrier concentration calculation

Transition temperature in type II (high-temperature) superconductors depends strongly on the density of mobile holes in the CuO2 planes [42]. The hole-carrier concentrations per Cu ion, P, are calculated by the following relation [43, 44]:

where \( T_{c}^{ \max } \) is taken as 92 K for Y123 phase [45–48] and the T c values are inferred from Fig. 5. The carrier concentrations of the samples studied are also depicted in Table 1. As seen from the table, the Lu-1 sample has the maximum hole carrier concentration value whereas the Lu-7 sample obtains the minimum value, confirming the effect of the carrier concentrations on the Y123 superconducting materials.

3.3 SEM analyses

Figure 6a–e gives SEM images (taken in the SEI mode) of the fractured surface of the Lu-0, Lu-1, Lu-3, Lu-5 and Lu-7 samples prepared in this work, respectively. As seen from the figures that the microstructures of the samples are strongly dependent upon the of Lu addition level. The surface of the Lu-1 sample is much smoother and denser compared to other ones. Furthermore, the sample has more uniform surface appearance with larger grains, better texturing, lower porosity, better crystallinity and connectivity between grains (Fig. 6b), being in good agreement with the Lotgering index data obtained. On the other hand, the Lu-7 sample with randomly oriented and poorly connected grains obtains the worst appearance among the samples (Fig. 6e). Besides, voids and signs of partial melting are observed on the micrograph of this sample.

3.4 EDX analyses

The elemental composition analyses of the Y123 superconductors with and without Lu doping are analytically examined with the aid of the energy dispersive X-ray (EDX) measurements. Figure 7a, b displays the Lu-0 and Lu-7 samples studied, respectively. It is seen from the figure that no differences appear between the samples produced except for Lu peaks observed (Fig. 7), indicating that all the doping (Lu) ions introduce into the crystalline structure of the samples prepared. Furthermore, the Cu element level in the Lu-1 sample is observed to be more than that of the other samples (Fig. 8), confirming that the transition temperatures (both onset and offset) of the sample is greater than the other ones. Additionally, the Y element level is obtained to decrease systematically with the enhancement of the Lu element level while the other element levels in the Y123 samples studied are found to be close to each other. Based on these results, the Lu ions might enter into the crystal structure by replacing Y ions. Hence, it is concluded that the superconducting properties such as T c and J c depend strongly on the Lu content in the system.

3.5 Transport critical current density

As well known, critical current density (Jc) plays an important role to explicate the pinning mechanism in a material [49, 50]. Figure 9a demonstrates the effect of the Lu doping on self field critical current density (J c ) of the Y123 superconductor ceramics. It is found that the self-field J c reduces systematically with the increment in the Lu doping level. The pure (Lu-0) sample exhibits a J c of 142 A/cm2 while the minimum J c measured is 76 A/cm2 for the Lu-7 sample at 77 K (Table 2). This degradation of J c is associated with not only the decrease in the flux pinning centers but the enhancement of the weak links between the superconducting grains, secondary phases, porosity, grain boundaries resistance and de-orientation of Y123 grains with the increase of the Lu content in the system, as well [51–53], supported by the results of the structural investigations. Additionally, Fig. 9b gives the relationship between the offset transition temperatures and critical current densities of the samples. It is apparent from the figure that a drastically decline is observed in the critical current density values compared to the decrement in the transition temperatures, meaning that the critical current density is more sensitive to the change of the Lu-content.

3.6 XRD analyses

The XRD patterns between 20° and 60° for the pure and Lu-doped samples are pictured in Fig. 10. In the diagrams, the corresponding (h k l) Miller indices result from Y123 and green (Y211) phase. It is seen from the figure that all the samples produced in this work indicate the polycrystalline superconducting phase with the changing intensity of diffraction lines and include both the Y123 and Y211 phases. In other words, we observe no secondary phase containing Lu or any other cation in the XRD graphs of the Lu-doped samples, confirming that the Lu enters into the crystal structure of the bulk superconductors. Furthermore, comparing of the XRD patterns of samples, it is apparent that the ratio of the intensity of the characteristic (110) and (013) peaks on the Lu-1 sample is more than that on the other samples while the Lu-7 sample has the minimum intensity ratio, which is attributed to the presence of both the orthorhombic and tetragonal symmetry on the Lu-7 sample [26, 54]. Based on these results, beyond x = 0.1, Y211 phase appears as more dominant in the samples. To illustrate, the peak 131 belonging to Y211 phase is found to decrease for x = 0.1 after which it starts to enhance with the increment of the Lu addition in the system. According to the results, the Y123 phase reduces while the Y211 phase starts to increase with the enhancement of the Lu addition (beyond 0.1 wt%); however, Fig. 10 confirms that the Y123 phase is dominant for all the samples prepared in this work. Moreover, the lattice parameters a and c are calculated using the least square method through d values and (h k l) planes for orthorhombic unit cell structure. The variation of the lattice parameters a and c as a function of the Lu addition is also tabulated in Table 2. A considerable change in cell parameters of the samples is noticed within the experimental limit of 0.001 Å. It is visible from the table that a contraction in both the a and b-axis lengths is obtained while an expansion in the c-axis length is observed with the increment in the Lu doping level up to 0.1 wt% beyond which the a and b-axis lengths start to enhance monotonously whereas the length of the c-axis decreases systematically, illustrating that the role of the Lu addition in the Y123 system on the superconducting properties. Further, Lotgering index [55] is examined to quantify the degree of c-axis orientation in polycrystalline superconductors studied. The Lotgering indexes (F) deduced from the XRD patterns [56] are depicted in Table 2. It is obtained that the texturing of Y123 grains increases with the enhancement of the Lu addition up to x = 0.1 beyond which that of Y211 grains starts to increase systematically. In addition, the broadening nature of the XRD peaks gives that the particle sizes evaluated from the Scherrer–Warren equation are within the nanometer scale [57–62]. Based on the equation, in the broadening region the average grain size of a crystal in the sample is defined as:

where t is the thickness of the crystal, λ presents the wavelength and B denotes the full width at half maximum (FWHM) of the Bragg peak corrected using the corresponding peak in micronized and θ B is the Bragg angle. Also,

where Bs is the half width of the standard material in radians. According to the XRD graphs of the samples, the FWHM value of the Lu-1 sample is smaller than that of the other samples, confirming that the Lu-1 sample has the largest grain size and best crystallinity and connectivity between grains among the samples. The calculations indicate that the largest grain size (71 nm) is obtained for the Lu-1 sample whereas the Lu-7 sample has the minimum value of 43 nm (Table 2), representing that why the microstructural and superconducting properties of the samples produced initially improve and then degrade with the increase of the Lu addition.

4 Conclusion

The aim of this study is to not only determine the best ambient to produce the Y123 superconductor but also investigate the role of Lu doping on the microstructural and superconducting properties of the Y123 superconductor materials with the aid of SEM, XRD, EDX, ρ-T and I–V measurements. According to the results obtained, the best annealing temperature is found to be 870 °C when the duration of 20 h is obtained to be the best annealing time. Moreover, the microstructural and superconducting properties of the samples are observed to depend strongly on the Lu doping and the following findings are summarized:

-

Lu-1 sample has the maximum \( T_{c}^{{\hbox{offset}}} \) and \( T_{c}^{{\hbox{onset}}} \) values whereas the lowest critical temperatures are observed for the Lu-7 sample. Based on these results, the critical temperatures are found to enhance with the addition level up to x = 0.1 beyond which these temperature values are noticed to decrease dramatically. Similarly, the former sample has the greatest hole carrier concentration value while the latter one obtains the smallest value. Furthermore, the smallest ∆T c is noted to be about 2.3 K for the Lu-1 sample while the largest ∆T c is observed to be about 6.2 K for the Lu-7 sample, pointing out the presence of impurities in the Y123 system, the weak links between the superconducting grains and grain misorientations.

-

The surface of the Lu-1 sample exhibits the most uniform surface appearance with largest grains, greatest crystallinity, lowest porosity, best texturing and connectivity between grains whereas the Lu-7 sample with randomly oriented and poorly connected grains obtains the worst appearance among the samples.

-

EDX measurements illustrate that the doping (Lu) ions might enter into the crystal structure by replacing Y ions as a result of the decrement in the Y element level with the increase of the Lu element level in the Y123 system. Additionally, the Cu element level in the Lu-1 sample is found to be more than that of the other samples, explaining that why this sample has the highest the transition (both onset and offset) temperatures.

-

The maximum Jc of 142 A/cm2 are observed for the pure sample as against 76 A/cm2 (minimum value), respectively, for the Lu-7 sample. This suppression of J c is related to not only the reduction of the flux pinning centers but also the increase in the weak links between the superconducting grains, secondary phases, porosity, grain boundaries resistance and de-orientation of Y123 grains with the increment of the Lu content in the system.

-

XRD measurements indicate that all the samples show the polycrystalline superconducting phase with the changing intensity of diffraction lines and contain Y123 and Y211 phase, confirming the introduction of Lu atoms into the crystalline structure of the samples. At the same time, the intensity ratio of the characteristic (110) and (013) peaks on the Lu-1 sample is more than that on the other samples prepared. Based on the results obtained, the Y123 phase reduces while the Y211 phase starts to increase with the enhancement of the Lu addition.

References

M.E. Sagsoz, M. Ertugrul, U. Cevik, Mater. Lett. 60, 1778 (2006)

S. Gupta, R.S. Yadav, N.P. Lalla, G.D. Verma, B. Das, Integr. Ferroelectr. 116, 68 (2010)

P.M. Sarun, S. Vinu, R. Shabna, A. Biju, U. Syamaprasad, Mater. Res. Bull. 44, 1017 (2009)

O. Ozturk, M. Akdogan, H. Aydın, M. Yilmazlar, C. Terzioglu, I. Belenli, Phys. B 399, 94 (2007)

C. Terzioglu, M. Yilmazlar, O. Ozturk, E. Yanmaz, Phys. C 423, 1190 (2005)

C. Terzioglu, O. Ozturk, A. Kilic, A. Gencer, I. Belenli, Phys. C 434, 153 (2006)

P. Diko, Supercond. Sci. Technol. 13, 1202 (2000)

K. Ogasawara, N. Sakai, M. Murakami, Supercond. Sci. Technol. 13, 688 (2000)

A. Koblischka-Veneva, M.R. Koblischka, K. Ogasawara, M. Murakami, Cryst. Eng. 5, 265 (2002)

Y. Feng, L. Zhou, J.G. Wen, N. Koshizuka, A. Sulpice, J.L. Tholence, J.C. Vallier, P. Monceau, Phys. C 297, 75 (1998)

S. Jin, T.H. Teifei, R.C. Sherwood, M.E. Davis, R.B. van Dover, G.W. Kammlott, R.A. Fasrnacht, H.D. Keith, Appl. Phys. Lett. 52, 2074 (1988)

L. Zhou, P. Zhang, P. Ji, K. Wang, X. Wu, Supercond. Sci. Technol. 3, 390 (1990)

K. Salama, V. Selymanickam, L. Gao, K. Sun, Appl. Phys. Lett. 54, 2352 (1989)

H. Fujimoto, M. Murakami, S. Dotoh, N. Koshizuka, S. Tanaka, Adv. Supercond. 2, 285 (1990)

T. Egi, J.G. Wen, K. Koroda, H. Unoki, N. Koshizuka, Appl. Phys. Lett. 67, 2406 (1995)

I. Felner, B. Brosh, Phys. Rev. B 43, 10364 (1991)

T.D. Dzhafarov, M. Altunbas, A. Varilci, U. Cevik, A.I. Kopya, Mater. Lett. 26, 305 (1996)

O. Dogan, M. Ertugrul, U. Cevik, E. Bacaksiz, E. Tirasoglu, A.I. Kobya, H. Erdogan, X-Ray Spectrom. 32, 363 (2003)

C.W. Luo, Phys. C 470, 176 (2009)

J.P. Franck, J. Jung, M.A.K. Mohamed, Phys. Rev. B 36, 2308 (1987)

S.K. Misra, L.E. Misiak, Solid State Commun. 72, 351 (1989)

H. Eisaki, N. Kaneko, D.L. Feng, A. Damascelli, P.K. Mang, K.M. Shen, Z.X. Shen, M. Greven, Phys. Rev. B 69, 064512 (2004)

A. Kapitulnik, A. Fang, C. Howald, M. Greven, J. Phys. Chem. Solids 67, 344 (2006)

C.C. Tsuei, J.R. Kirtley, G. Hammerl, J. Mannhart, H. Raffy, Z.Z. Li, J. Phys. Chem. Solids 67, 64 (2006)

K. Fujita, T. Noda, K.M. Kojima, H. Eisaki, S. Uchida, Phys. Rev. Lett. 95, 097006 (2005)

T.D. Dzhafarov, U. Cevik, J. Mater. Sci. Mater. Electron. 12, 193 (2001)

X.S. Wu, S.S. Jiang, C.C. Lam, D.W. Wang, X.L. Huarg, Z.H. Wu, Y. Yuan, X. Jin, Phys. Status Solidi A 157, 439 (1996)

R. Lal, S.P. Pandey, A.V. Narlikar, Phys. Rev. B 49, 6382 (1994)

C.Y. Yang, A.R. Moodenbaugh, Y.L. Wang, Y. Xu, S.M. Heald, D.O. Welch, M. Suenaga, Phys. Rev. B 42, 2231 (1990)

G. Yildirim, E. Yucel, S. Bal, M. Dogruer, A. Varilci, M. Akdogan, C. Terzioglu, Y. Zalaoglu, J. Supercond. Nov. Magn. 25, 231 (2012)

C.Y. Shieh, Y. Huang, M.K. Wu, C.Y. Huang, Physica C 513, 185 (1991)

S.A. Halim, S.A. Khawaldeh, H. Azhan, S.B. Mohamed, K. Khalid, J.J. Suradi, J. Mater. Sci. 35, 3043 (2000)

Y.T. Huang, D.S. Shy, L.J. Chen, Physica C 294, 140 (1998)

A. Tampieri, G. Celotti, S. Lesca, G. Bezzi, T.M.G. La Torretta, G. Magnani, J. Eur. Ceram. Soc. 20, 119 (2000)

M. Ochsenkiihn-Petropulu, I. Vottea, R. Argyropulu, L. Mendrinos, K.M. Ochsenkiihn, Mikrochim. Acta 130, 289 (1999)

M. François, H.J. Scheel, J. Less Common Metal. 150, 211 (1989)

O. Gorur, C. Terzioglu, A. Varilci, M. Altunbas, Supercond. Sci. Technol. 18, 1233 (2005)

E. Asikuzun, O. Ozturk, H.A. Cetinkara, G. Yildirim, A. Varilci, M. Yılmazlar, C. Terzioglu, J. Mater. Sci. Mater. Electron. 23, 1001 (2012)

S. Bal, M. Dogruer, G. Yildirim, A. Varilci, C. Terzioglu, Y. Zalaoglu, J. Supercond. Novel Magn. 25, 847 (2011)

A. Ianculescu, M. Gartner, B. Despax, V. Bley, Th. Leby, R. Gavrila, M. Modreanu, Appl. Surf. Sci. 253, 344 (1996)

Y. Zalaoglu, G. Yildirim, C. Terzioglu, J. Mater. Sci. Mater. Electron. (2011). doi:10.1007/s10854-012-0723-8

O. Ozturk, E. Asikuzun, M. Erdem, G. Yildirim, O. Yildiz, C. Terzioglu, J. Mater. Sci. Mater. Electron. 23, 511 (2012)

B.F. Azzouz, A. Mchirgui, B. Yangui, C. Boulesteix, B.M. Salem, Phys. C 356, 83 (2001)

J.L. Tallon, C. Bernhard, H. Shaked, R.L. Hitterman, J.D. Jorgensenn, Phys. Rev. B 51, 12911 (1995)

R. Lortz, T. Tomita, Y. Wang, A. Junod, J.S. Schilling, T. Masui, S. Tajima, Phys. C 434, 194 (2006)

J.J. Neumeier, H.A. Zimmermann, Phys. Rev. B 47, 8385 (1993)

C. Meingast, T. Wolf, M. Klaser, G. Muller-Vogt, J. Low Temp. Phys. 105, 1391 (1996)

C. Meingast, O. Kraut, T. Wolf, H. Wuhl, A. Erb, G. Muller-Vogt, Phys. Rev. Lett. 67, 1634 (1991)

G. Yildirim, S. Bal, E. Yucel, M. Dogruer, M. Akdogan, A. Varilci, C. Terzioglu, J. Supercond. Novel Magn. 25, 381 (2012)

A. Biju, R.P. Aloysius, U. Syamaprasad, Supercond. Sci. Technol. 18, 1454 (2005)

P.M. Sarun, S. Vinu, R. Shabna, A. Biju, U. Syamaprasad, Mater. Lett. 62, 2725 (2008)

A.I. Abou-Aly, S.A. Mahmoud, R. Awad, M.M.E. Barakat, J. Supercond. Nov. Magn. 23, 1575 (2010)

R. Shabna, P.M. Sarun, S. Vinu, A. Biju, U. Syamaprasad, J. Alloys Compd. 493, 11 (2010)

M. Kikuchi, Y. Syono, A. Tokiwa, K. Oh-ishi, H. Arai, K. Hiraga, N. Kobayashi, T. Sasaoka, Y. Muto, Jpn. J. Appl. Phys. 26, L1066 (1987)

F.K. Lotgering, J. Inorg. Nucl. Chem. 9, 113 (1959)

W. Gao, J.B. Vander-sande, Supercond. Sci. Technol. 5, 318 (1992)

J. Economy, R. Anderson, Inorg. Chem. 5, 989 (1966)

L. Shi, Y. Gu, L. Chen, Z. Yang, J. Ma, Y. Qitan, Mater. Lett. 58, 3301 (2004)

J. Jiang, Mater. Lett. 61, 3239 (2007)

G. Yildirim, A. Varilci, M. Akdogan, C. Terzioglu, J. Mater. Sci. Mater. Electron. (2011). doi:10.1007/s10854-011-0522-7-0

G. Yildirim, M. Dogruer, O. Ozturk, A. Varilci, C. Terzioglu, Y. Zalaoglu, J. Supercond. Nov. Magn. 25, 893 (2011)

S.B. Guner, O. Gorur, S. Celik, M. Dogruer, G. Yildirim, A. Varilci, C. Terzioglu, J. Alloy. Compd. (2012). doi:10.1016/j.jallcom.2012.06.082

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Turkoz, M.B., Nezir, S., Terzioglu, C. et al. Investigation of Lu effect on YBa2Cu3O7−δ superconducting compounds. J Mater Sci: Mater Electron 24, 896–905 (2013). https://doi.org/10.1007/s10854-012-0846-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-012-0846-y