Abstract

The sub-micron size anatase TiO2 particles with size about 0.2-0.3 μm were synthesized with basic peptizing agent and hydrothermal method and added into TiO2 film as light scattering center. The addition of the sub-micron size anatase TiO2 particles enhanced light scattering and dye adsorption abilities of the TiO2 film. When the weight proportion of the sub-micron size/nano-size TiO2 particles in the TiO2 film attained to 1.25/10, the highest energy conversion efficiency about 7.41% was obtained, which was 23% enhancement comparing with the TiO2 film containing pure nano-size TiO2 particles. It presented an efficient way for improving the photovoltaic performance of dye-sensitized solar cell.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The dye-sensitized solar cell (DSSC) reported by Grätzel in 1991 promised an easy, low-cost way for fabricating solar cell comparing with the conventional methods [1]. Recently, energy conversion efficiency has been achieved up to 11.18% [2]. Dye-sensitized solar cell usually consists of a meso-porous nanocrystal TiO2 film with a monolayer dye deposited on a transparent conducting glass (TCO), a platinum modified counter electrode, and an electrolyte solution with a dissolved iodide/triiodide redox couples between the electrodes. Among them, the dye-coated meso-porous nanocrystal TiO2 film, which adsorbs dyes, transmits electrons, and scatters light, is one of the most important components in DSSC [3]. Many efforts were made to enhance the photovoltaic performance of TiO2 film, such as preparing appropriate thickness and porosity, multilayer structure with different particle morphologies, TiCl4 or other chemical reagents modification [4–8]. In this study, the sub-micron size anatase TiO2 particles with size about 0.2–0.3 um were synthesized with basic peptizing agent and hydrothermal method and added into TiO2 film as light scattering center. The influences of the sub-micron size anatase TiO2 particles on the light scattering, dye adsorbing properties of the TiO2 film and the photovoltaic performance of DSSC were investigated.

2 Experimental details

2.1 Materials

Titanium isopropoxide, nitric acid, glacial acetic acid, tetramethyl ammonium hydroxide, polyethylene glycol 20,000 (PEG), sodium iodide, tetrabutyl ammonium iodide, iodine, acetonitrile, and 4-tert-butylpyridine were all A. R. grade and all purchased from Sinopharm Chemical Reagent Co., Ltd, China. All reagents were used without further treatment. Conducting glass plates (FTO glass, Fluorine doped tin oxide over-layer, sheet resistance 8 Ω cm−2, purchased from Hartford Glass Co. USA) were used as substrates for precipitating TiO2 films. Sensitizing dye cis-[(dcbH2)2Ru(SCN)2] was purchased from Solaronix SA.

2.2 Assembling of dye-sensitized solar cells

2.2.1 Preparation of 10–20 nm, 200–300 nm nanocrystalline TiO2 particles

About 10–20 nm nanocrystal TiO2 particles were synthesized as the following processes: titanium isopropoxide (20 ml) was rapidly added into distilled water (200 ml) and a white precipitate was formed immediately. The precipitate was filtered by using a glass frit and washed three times with 100 ml distilled water. The filter cake was added into nitric acid aqueous solution (0.1 M, 200 ml) with 10 ml glacial acetic acid under vigorous stirring at 80 °C until the slurry became a translucent blue–white liquid. The resultant colloidal suspension was autoclaved at 200 °C for 12 h to form milky white slurry. The sub-micron size TiO2 particles about 0.2–0.3 μm were synthesized with almost the same method as the above mentioned. The difference is that nitric acid is substituted with tetramethylammonium hydroxide (2.0 M, 150 ml). The paste for depositing TiO2 film contains 10 g 10–20 nm nanocrystal TiO2 particles and 1 g PEG 20, 000 dispersed in deionized water. The sub-micron size TiO2 particles were added into the above paste as light scattering center in the TiO2 film. The added amount of the sub-micron size TiO2 particles were changed from 0/10 to 2/10 as the weight proportion of sub-micron size/nano-size TiO2 particles.

2.2.2 Fabrication of dye-sensitized solar cells

TiO2 films were prepared with the above pastes and the doctor blade method and sintering at 450 °C for 30 min. Then, They were immersed into a 2.5 × 10−4 M absolute ethanol solution of cis-[(dcbH2)2Ru(SCN)2] for 24 h to adsorb dyes. An electrodeposited platinum conductive glass was used as counter electrode [9]. The photo and counter electrodes were clipped together and one drop of liquid electrolyte was kept between the two electrodes. Finally, a piece of cyano acrylate adhesive (15–30 μm) was used as sealant. Bisphenol A epoxy resin was used for further sealing process. The composites of liquid electrolyte are 0.4 M sodium iodide, 0.1 M tetrabutyl ammonium iodide, 0.5 M 4-tert-butylpyridine, and 0.05 M iodine dissolved in acetonitrile.

2.3 Measurements

The morphologies of TiO2 particles and films were analyzed by TEM and SEM. The crystallization of TiO2 particles was measured by X-ray diffractometer using Cu Kα radiation (λ) 1.5405 Å. The diffuse reflectance and dye-adsorption spectra of TiO2 films were measured with UV–visible spectrophotometer. The absorbed dyes were washed from dye-coated TiO2 films with 0.05 M NaOH ethanol solution before measurement. The photovoltaic tests of DSSC were carried out by measuring the J-V characteristic curves under simulated AM 1.5 solar illumination at 100 mW cm−2 from a xenon arc lamp (CHF-XM500, Trusttech Co., Ltd, China) in the ambient atmosphere and recorded with CHI 660 C electrochemical workstation. The thickness of photo electrode and the active area of DSSC were 10 μm and 0.5 cm2 (1 × 0.5 cm2), respectively.

3 Results and discussion

3.1 Morphology and crystallization of TiO2 particles

Figure 1 shows the TEM images of sub-micron size and nano-size TiO2 particles synthesized according to the above processes. It is seen that the nano-size TiO2 particles synthesized in acid aqueous solution show nearly square shape with the size about 10–20 nm, while the TiO2 particles synthesized in basic aqueous solution have ellipsoidal shape with the size about 0.2–0.3 μm, 10–20 times bigger than the former ones. It is demonstrated that the DSSC containing anatase TiO2 nanoparticles shows higher photovoltaic performance than that of other kinds of crystallization of TiO2 nanoparticles such as rutile and brookite, and the pure anatase TiO2 nanoparticles can be obtained by using either nitric acid and glacial acetic acid mixed solution or organic alkali ammonium hydroxide as peptizers [10]. The XRD patterns of the samples in Fig. 2 show that the crystallization of both sub-micron size and nano-size TiO2 particles are all anatase, which is according with the published results. Due to the good transparency of 10–20 nm nano-size TiO2 particles [11], they were used as the main composite in the paste. The sub-micron size ones can scatter light, so they were added into the paste and played as light scattering center in the TiO2 film.

3.2 UV–vis diffuse reflectance and dye-adsorption spectra of TiO2 films

The light scattering properties of the TiO2 films with different weight proportion of sub-micron size and nano-size TiO2 particles were investigated with diffuse reflectance spectra as shown in Fig. 3. With the addition of sub-micron size TiO2 particles into the paste, the obtained TiO2 films turn from transparent to semi-transparent and finally to opaque. The reflecting rate also increased simultaneously. It is seen that the TiO2 film with pure nano-size TiO2 particles also shows a moderate reflecting intensity about 35%. Although the light scattering ability of nano-size TiO2 particles is weak, the pores in the TiO2 film formed through burning of PEG can scatter light, so they mainly answer for the light scattering property of the TiO2 film with pure nano-size TiO2 particles [12].

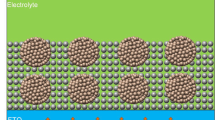

Fig. 4 shows the UV–vis adsorption spectra of dyes washed from TiO2 films with different weight proportion of sub-micron size/nano-size TiO2 particles. It is seen that the intensity of dye absorption peak increases with the addition of sub-micron size TiO2 particles from 0 to 1.25 g per 10 g of nano-size TiO2 particles, later it decreases with the further addition of sub-micron size TiO2 particles. The reason is that the addition of sub-micron size TiO2 particles can introduce many pores into the TiO2 film as shown in Fig. 5, which is benefit for the penetration and soakage of dye solution into the TiO2 film and results in increased dye-loading amount. However, the sub-micron size TiO2 particles have much smaller surface area than that of nano-size ones, they adsorb very few dyes in the TiO2 film [13]. And the introduced pores occupy much space for TiO2 nano-particles formerly, which also decreases the dye-loading in the TiO2 film. The above influences on the dye-loading amount are reverse, so there is an optimal weight proportion of sub-micron size/nano-size TiO2 particles in the TiO2 film for the maximum dye-loading amount. Over it the intensity of dye absorption peak will decrease.

3.3 Photovoltaic performance of dye-sensitized solar cells

Photovoltaic performance of DSSCs with TiO2 films containing different weight proportion of sub-micron size/nano-size TiO2 particles is presented in Fig. 6, their relative parameters are listed in Table 1. The highest energy conversion efficiency about 7.41% is obtained when the TiO2 film containing sub-micron size TiO2 particles with weight proportion of 1.25/10. The value is 23% enhancement comparing with that of DSSC containing pure nano-size TiO2 particles. The improved photovoltaic performance of DSSC is mainly due to the increased current density and fill factor. The increased light scattering, dye-loading properties of the TiO2 film with sub-micron size TiO2 particles answer for the improved current density of DSSC [14]. And the larger pores formed in the TiO2 film with sub-micron size TiO2 particles make for the deep penetration of electrolyte into the TiO2 film, which can decrease the serious resistance and enhance the fill factor [15].

4 Conclusions

The sub-micron size anatase TiO2 particles with size about 0.2–0.3 μm were synthesized and used as light scattering center in fabricating DSSC. It is found that the addition of suitable amount of sub-micron size TiO2 particles in the film can enhance light scattering and dye adsorption abilities, which are benefit for improving the photovoltaic performance of DSSC. The highest energy conversion efficiency about 7.41% is obtained when the film containing sub-micron size TiO2 particles with weight proportion of 1.25/10. The value is 23% enhancement comparing with DSSC containing pure nano-size TiO2 particles.

References

B. O’Regan, M. Grätzel, Nature 353, 737 (1991)

M.K. Nazeeruddin, F. De Angelis, S. Fantacci, A. Selloni, G. Viscardi, P. Liska, S. Ito, B. Takeru, M. Grätzel, J. Am. Chem. Soc. 127, 16835 (2005)

S. Ito, T.N. Murakami, P. Comte, P. Liska, C. Grätzel, M.K. Nazeeruddin, M. Grätzel, Thin Solid Films 516, 4613 (2008)

S. Ito, S.M. Zakeeruddin, R. Humphry-Baker, P. Liska, R. Charvet, P. Comte, M.K. Nazeeruddin, P. Pechy, M. Takata, H. Miura, S. Uchida, M. Gratzel, Adv. Mater. 18, 1202 (2006)

M. Ni, M.K.H. Leung, D.Y.C. Leung, K. Sumathy, Sol. Energ. Mat. Sol. Cells 90, 1331 (2006)

Q. Shen, T. Toyoda, Thin Solid Films 438, 167 (2003)

C. Kim, K.S. Kim, H.Y. Kim, Y.S. Han, J. Mater. Chem. 18, 5809 (2008)

L.H. Hu, S.Y. Dai, J. Weng, S.F. Xiao, Y.F. Sui, J. Phys. Chem. B 111, 358 (2007)

S.C. Hao, J.H. Wu, J.M. Lin, Y.F. Huang, Compos. Interface. 13, 899 (2006)

M. Grätzel, J. Photoch. Photobio. A 164, 3 (2004)

A.F. Nogueira, M.A.D. Paoli, I. Montanari, R.M. House, J. Nelson, J.R. Durrant, J. Phys. Chem. B 105, 7517 (2001)

Z.P. Tian, H.M. Tian, X.Y. Wang, S.K. Yuan, J.Y. Zhang, X.B. Zhang, T. Yu, Z.G. Zou, Appl. Phys. Lett. 94, 031905 (2009)

T. Moritz, J. Reiss, K. Diesner, J. Phys. Chem. B 101, 8052 (1997)

M.K. Nazeeruddin, A. Kay, I. Rodicio, R. Humphrey-Baker, E. Muller, P. Liska, N. Vlachopoulos, M. Gra¨tzel, J. Am. Chem. Soc. 115, 6382 (1993)

M. Quintana, T. Edvinsson, A. Hagfeldt, G. Boschloo, J. Phys. Chem. C. 111, 1035 (2007)

Acknowledgments

The authors would like to acknowledge the support of the National High Technology Research and Development Program of China (No. 2009AA03Z217), the National Natural Science Foundation of China (No. 90922028, 50842027), and the Natural Science Foundation of Hua Qiao University (No. 09BS401).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lan, Z., Wu, J., Lin, J. et al. Preparation of sub-micron size anatase TiO2 particles for use as light-scattering centers in dye-sensitized solar cell. J Mater Sci: Mater Electron 21, 833–837 (2010). https://doi.org/10.1007/s10854-009-0003-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-009-0003-4