Abstract

CaO–B2O3–SiO2 (CBS) glass powders are prepared by traditional glass melting method, whose properties and microstructures are characterized by Differential thermal analysis (DTA), X-ray diffraction (XRD) and scanning electron microscopy (SEM). It is found that the pure CBS glass ceramics possess excellent dielectric properties (ε r = 6.5, tan δ = 5 × 10−3 at 10 GHz), but a higher sintering temperature (>900 °C) and a narrow sintering temperature range (about 10 °C). The addition of a low-melting-point CaO–B2O3–SiO2 glass (LG) could greatly decrease the sintering temperature of CBS glass to 820 °C and significantly enlarge the sintering temperature range to 40 °C. The CBS glass ceramic with 30 wt% LG glass addition sintered at 840 °C exhibits better dielectric properties: ε r ≈ 6, tan δ < 2 × 10−3 at 10 GHz, and the major phases of the sample are CaSiO3, CaB2O4 and SiO2.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Low temperature co-fired ceramics (LTCCs) have been widely investigated due to their applications for the multilayer microwave components which can miniaturize the microwave devices [1]. LTCCs offer low loss dielectric characters and are compatible with Au, Ag or Cu, as the best high frequency conductors. Utilization of low dielectric constant LTCC materials and association with high conductivity metallizations are found to have potential applications in the area of wireless communication [2].

Among several LTCC systems [2–6], CaO–B2O3–SiO2 (CBS) glass ceramics have been reported as a promising material for use in microelectronic fields because of its low sintering temperature and excellent dielectric properties [7, 8]. Chia-Ruey Chang et al. [9] studied the crystallization kinetics and mechanism of a commercial CBS glass ceramic (A6, Ferro Co.). Shao-Hong Wang et al. [10] have found that excessive B2O3 in CBS system damages the dielectric properties. Chuang-Chung Chiang et al. [2] studied the compositional effects on the physical properties of CBS glass ceramics.

The pure CBS glass ceramics usually need to be sintered at a higher temperature to achieve high enough density, and the sintering temperatures of CBS in open reports are somewhat too high. How to decline its temperature attracts many researchers’ attentions at present. In this paper, a novel CBS glass ceramic preparation method is presented by sintering two devitrifying CBS glasses, and the microstructures of the CBS glass ceramics are investigated systematically and discussed detailedly.

2 Experimental procedure

The compositions of the glass CBS and a low-melting-point CaO–B2O3–SiO2 glass (LG) were marked in the phase diagram of the CBS system, as is shown in Fig. 1. Compared to CBS glass, LG glass contained less SiO2 but more B2O3. Reagent-grade raw materials of CaCO3, SiO2 and H3BO3 with purities higher than 99 wt% were chosen as the starting materials. After mixed uniformly, the raw materials were put into a platinum crucible and melted by an electric furnace at 1,500 °C for 120 min. The molten glass was quenched into distilled water to form cullet. The cullet was dried and milled with a mixture of agate balls in different diameters of 5–30 mm to an average particle size of less than 5 μm.

Furthermore, the CBS glass and LG glass powders were used as precursors and mixed in accordance with (1−x)CBS-xLG system (0.05 ≤ x ≤ 0.6) by ball milling with deionized water for 2 h. After drying, the powders prepared above were mixed with an amount of polyvinyl alcohol (PVA, 12 wt%), uniaxially pressed under a pressure of 100 MPa to obtain the green compacts with diameter of 13 mm and thickness of 4–10 mm, and then sintered in air at different temperatures for 15 min. The physical properties of those sintered bodies were measured, such as dielectric constant, dielectric loss and microstructure. The phase compositions of the samples were determined by X-ray diffraction with CuKα radiation (XRD ARL X′TRA). The crystal structures were examined by scanning electron microscopy (SEM JSM-5900). The dielectric properties were measured at 10 GHz by Agilent 8722ET network analyzer.

3 Results and discussion

3.1 Characterization of CBS glasses

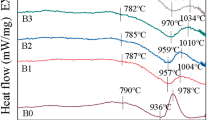

Figure 2 shows the results of DTA measurement of the CBS, LG and 70 wt% CBS + 30 wt% LG glass powders. The DTA curves are obtained in air up to 900 °C by a heating rate of 10 °C min−1 using a STA 449C/6/F analyzer. The exothermic peaks for CBS, LG and the glass composite are at about 870, 825 and 860 °C, respectively. Thus, the crystallization temperature (T c) of the glass composites is just between that of CBS and that of LG glass.

It is found in experiment that the sintering temperature of pure CBS glass is high than 900 °C and the sintering range is about 10 °C. For LG glass, samples become serious deformation when the sintering temperature reaches to 750 °C. This is mainly caused by the formation of too much liquid phase.

3.2 Sintering characterization of CBS glass ceramics

Figure 3 displays the relationship between the bulk densities of CBS glass ceramics and the sintering temperatures. The bulk densities of pure CBS specimens increase from 1.87 to 2.15 g cm−3, and water absorptions decrease only from 12 to 8%, as the sintering temperatures increase from 840 to 880 °C. The CBS glass ceramics doped by 20–50 wt% LG glass exhibit high enough densities at 840–880 °C, because the water absorptions of these samples are all less than 0.8%. The sinterabilities of the green compacts improve dramatically with the increasing amount of LG glass from 5 to 30 wt%, whereas the bulk densities of the glass ceramics all enhance with the rising sintering temperatures.

The sinterability of pure CBS glass is poor with the lack of open porosity, but LG glass could act as the fluxes and increase the liquid fluidity during viscous flow. With the liquid formation, there is a rapid densification due to capillary force exerted by the liquid on the glass particles and filled liquid fluidity to the pores in the samples. In addition, the T c of the LG glass is only 825 °C and about 50 °C lower than that of the CBS glass. Thus, the former crystallization phases of LG glass could induce CBS glass to crystallize. However, when the amount of LG glass is more than 30 wt%, the bulk densities of the glass ceramics decline with the increasing amount of LG glass. For example, the bulk densities of CBS specimens sintered at 840 °C decrease from 2.52 to 2.35 g cm−3, as the amount of LG glass increases from 30 to 50 wt%. It is attributed to the small density of the LG glass, only about 2.23 g cm−3.

3.3 XRD analysis results and SEM observations

Figure 4 shows the XRD patterns of the glass powders and CBS glass ceramics. The XRD patterns of CBS and LG glass powders are basically composed of amorphous glassy phases and no crystalline phases, while the CBS samples sintered at 840 or 900 °C for 15 min are mainly composed of crystalline phases of CaSiO3 (JCPDS no. 75–1,396), CaB2O4 (JCPDS no. 76–747) and SiO2 (JCPDS no. 78–1,252). The maximum peak intensities of samples with 20, 30 and 40 wt% LG glass appear at 2θ = 30, 30 and 27°, respectively. Major crystalline phases of the three samples do not change, but the amount of each crystalline phase varies greatly.

Various microstructures of above samples are examined and the results are illustrated in Fig. 5. The pure CSB glass sintered at 900 °C is more porous (Fig. 5a). With the increasing addition of LG glass, the pore size and porosity decline obviously (Fig. 5b–d) and the grain sizes are all less than 1 μm. Softening and fluidizing of crystal grains bonding each other and filling of liquid phase to the pores are also observed. The more LG glass addition, the more glassy phase formation. The sample with 40 wt% LG glass has the least porosity and the largest glass phase (Fig. 5d). This can be accompanied by the variation of densification (shown in Fig. 3). When the amount of LG glass is less than 30 wt%, the values of densities rise rapidly with the increasing amount of LG glass. However, when the amount of LG glass is more than 30 wt%, values of densities decline caused by the formation of too much liquid phase.

3.4 Dielectric properties of CBS glass ceramics

The dielectric constant (ε r) and dielectric loss (tan δ) of pure CBS glass ceramics sintered at 900 °C are 6.5 and 5 × 10−3 at 10 GHz, respectively. Fig. 6 summarizes ε r and tan δ of the CBS samples with different sintering temperatures. The values of ε r and tan δ vary greatly with increasing of sintering temperatures and amount of LG. The values of ε r and tan δ of CBS glass ceramics decline and the values of ε r are all less than 6.3, as the amount of LG glass increases from 10 to 30 wt%. The ε r of the well-sintered CBS samples are mainly influenced by the major crystalline phases (CaSiO3, CaB2O4 and SiO2) and glassy phases. In this study, the ε r of CaSiO3, CaB2O4, SiO2 and glass phase are about 5.4, 7, 3.8 and 7, respectively. At low LG glass content, the ε r of the samples are primarily affected by crystalline phases. The ε r values of CBS glass ceramics would decrease with the increasing major crystalline phases or the decreasing glass phases, according to the dielectric constant mixing rules [11]:

where x 1, x 2 is the volume fraction of the major crystalline phases and glass phases (x 1 + x 2 = 1), respectively. ε 1, ε 2 is the dielectric constant of the major crystalline phases and glass phases, respectively. However, when LG glass content is more than 40 wt%, glass phases dominate in the ε r of the samples. The ε r values enhance with the increasing amount of LG glass and are high than 6.3. But much poorly conducting glass phases in the dielectric damage the dielectric properties, leading to the tan δ rising with the increasing LG glass content.

4 Conclusions

The pure CBS glass ceramics possess excellent dielectric properties (ε r = 6.5, tan δ = 5×10−3 at 10 GHz), but a higher sintering temperature (>900 °C) and a narrow sintering temperature range (about 10 °C). The addition of a low-melting-point CaO–B2O3–SiO2 glass (LG) could greatly decrease the sintering temperature of CBS glass to 820 °C and significantly enlarge the sintering temperature range to 40 °C. The CBS glass ceramic with 30 wt% LG glass addition sintered at 840 °C exhibits better dielectric properties: ε r ≈ 6, tan δ < 2 × 10−3 at 10 GHz, and the major phases of the sample are CaSiO3, CaB2O4 and SiO2. This material is suitable to be used as the LTCC material for the application in wireless communications.

References

E. Guan, W. Chen, L. Luo, Low firing and microwave dielectric properties of BaTi4O9 with B2O3–ZnO–La2O3 glass addition. Ceram. Int. 33, 1145–1148 (2007). doi:10.1016/j.ceramint.2006.03.017

C.-C. Chiang, S.-F. Wang, Y.-R. Wang, W.-C.J. Wei, Densification and microwave dielectric properties of CaO–B2O3–SiO2 system glass-ceramics. Ceram. Int. 34, 599–604 (2008). doi:10.1016/j.ceramint.2006.12.008

H. Shin, H.-K. Shin, H.S. Jung, S.-Y. Cho, K.S. Hong, Phase evolution and dielectric properties of MgTi2O5 ceramic sintered with lithium borosilicate glass. Mater. Res. Bull. 40, 2021–2028 (2005). doi:10.1016/j.materresbull.2005.04.025

X. Cui, J. Zhou, A simple and an effective method for fabrication of densified glass-ceramics of low temperature co-fired ceramics. Mater. Res. Bull. 43, 1590–1597 (2008). doi:10.1016/j.materresbull.2007.07.038

C.-C. Cheng, T.-E. Hsieh, I.-N. Lin, Microwave dielectric properties of glass-ceramic composites for low temperature co-firable ceramics. J. Eur. Ceram. Soc. 23, 2553–2558 (2003). doi:10.1016/S0955-2219(03)00166-3

Q.-L. Zhang, H. Yang, H.-P. Sun, A new microwave ceramic with low-permittivity for LTCC applications. J. Eur. Ceram. Soc. 28, 605–609 (2008). doi:10.1016/j.jeurceramsoc.2007.07.003

H. Zhu, M. Liu, H. Zhou, L. Li, A. Lv, Preparation and properties of low-temperature co-fired ceramic of CaO–SiO2–B2O3 system. J. Mater. Sci: Mater. Electron. 17, 637–641 (2006). doi:10.1007/s10854-006-0011-6

H. Zhu, M. Liu, H. Zhou, L. Li, A. Lv, Study on properties of CaO–SiO2–B2O3 system glass-ceramic. Mater. Res. Bull. 42, 1137–1144 (2007). doi:10.1016/j.materresbull.2006.09.005

C.-R. Chang, J.-H. Jean, Crystallization kinetics and mechanism of low dielectric, low temperature cofirable CaO–B2O3–SiO2 glass ceramics. J. Am. Ceram. Soc. 82, 1725–1732 (1999)

S.-H. Wang, H.-P. Zhou, Densification and dielectric properties of CaO–B2O3–SiO2 system glass ceramics. Mater. Sci. Eng. B 99, 597–600 (2003). doi:10.1016/S0921-5107(02)00502-0

Z.-D. Guan, Z.-T. Zhang, J.-S. Jiao, Physical Properties of Inorganic Dielectric Materials (Tsinghua University Press, Beijing, 2004), pp. 315–316

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, H., Zhou, H., Liu, M. et al. Microstructure and microwave dielectric characteristics of CaO–B2O3–SiO2 glass ceramics. J Mater Sci: Mater Electron 20, 1135–1139 (2009). https://doi.org/10.1007/s10854-008-9839-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-008-9839-2