Abstract

In the in situ tensile tests of polymer-GNP nanocomposites, the damage initiation in the interfacial zone is directly related to the surface adhesion in the interface. Adding functional groups to GNP increases the adhesion between polymer and inclusion and significantly reduces damage in the interfacial zone. This research was developed based on hierarchical multiscale modeling to investigate damage initiation in polymer-GNP nanocomposites. In the first step, the effect of functional groups on the surface adhesion between GNP and HDPE at the nanoscale was investigated by MD simulations, and the Pull-out test and force–displacement curve were obtained. A cohesive finite element approach was exploited in the second step to model debonding. The results show that the functional groups (H, OH, and COOH) will cause delayed damage in the interfacial zone, and debonding will begin at higher strains. Also, the damage initiation is directly linked to the type of functional groups. The effect of functional groups in different volume fractions of nanoparticles shows that the damage initiates earlier with an increase in the volume fraction of GNPs in constant percentage coverage of each type of the functional group. However, the effect of the functional groups in reducing effective strain in the damage initiation is more significant than the volume fraction of GNPs. After applying a 20% strain at various volume fractions, the COOH functional groups significantly reduced fully debonded surfaces. Furthermore, we investigated the impact of volume fraction on fully debonded surfaces in both pure and COOH functional groups. A nonlinear trend is apparent as the volume fraction increases from 0.3 to 1.5%. The effects of multiple bonding types are taken into account by creating several RVEs with a constant volume fraction of 1.5 and a different proportion of functional groups.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.References

Ajayan PM, Stephan O, Colliex C, Trauth D (1994) Aligned carbon nanotube arrays formed by cutting a polymer resin—nanotube composite. Science 265:1212–1214. https://doi.org/10.1126/science.265.5176.1212

Thostenson ET, Li C, Chou T-W (2005) Nanocomposites in context. Compos Sci Technol 65:491–516. https://doi.org/10.1016/j.compscitech.2004.11.003

Hu K, Kulkarni DD, Choi I, Tsukruk VV (2014) Graphene-polymer nanocomposites for structural and functional applications. Prog Polym Sci 39:1934–1972. https://doi.org/10.1016/j.progpolymsci.2014.03.001

Potts JR, Dreyer DR, Bielawski CW, Ruoff RS (2011) Graphene-based polymer nanocomposites. Polymer 52:5–25. https://doi.org/10.1016/j.polymer.2010.11.042

Kim J, Cha J, Chung B, Ryu S, Hong SH (2020) Fabrication and mechanical properties of carbon fiber/epoxy nanocomposites containing high loadings of noncovalently functionalized graphene nanoplatelets. Compos Sci Technol 192:101–108. https://doi.org/10.1016/j.compscitech.2020.108101

Karataş MA, Gökkaya H (2018) A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials. Def Technol 14:318–326. https://doi.org/10.1016/j.dt.2018.02.001

A de Oliveira, C Beatrice (2018) Polymer nanocomposites with different types of nanofiller. Nanocomposites—recent evolutions, IntechOpen.chapter 6, London UK

Omanović-Mikličanin E, Badnjević A, Kazlagić A, Hajlovac M (2020) Nanocomposites: a brief review. Heal Technol 10:51–59

Ngo T-D (2020) Composite and nanocomposite materials—from knowledge to industrial applications. IntechOpen, London UK

Rajak DK, Pagar DD, Menezes PL, Linul E (2019) Fiber-reinforced polymer composites: manufacturing, properties, and applications. Polymers 11:1667

Bilisik K, Karaduman NS, Sapanci E (2019) Flexural characterization of 3D prepreg/stitched carbon/epoxy/multiwalled carbon nanotube preforms and composites. J Compos Mater 53:563–577

Bilisik K, Erdogan G, Sapancı E (2018) Flexural behavior of 3D para-aramid/phenolic/nano (MWCNT) composites. RSC Adv 8:7213–7224

Bilisik K, Karaduman NS, Sapanci E (2019) Tensile properties of nanoprepreg/nanostitched 3D carbon/epoxy MWCNTs composites. Mech Mater 128:11–23

Bilisik K, Sapanci E (2018) Experimental determination of fracture toughness properties of nanostitched and nanoprepreg carbon/epoxy composites. Eng Fract Mech 189:293–306

Tang L-C, Zhao L, Guan L-Z (2017) Graphene/polymer composite materials: processing, properties and applications. Advanced composite materials: properties and applications. De Gruyter, Poland, pp 349–419

Li B, Zhong W-H (2011) Review on polymer/graphite nanoplatelet nanocomposites. J Mater Sci 46:5595–5614. https://doi.org/10.1007/s10853-011-5572-y

Bortz DR, Heras EG, Martin-Gullon I (2012) Impressive fatigue life and fracture toughness improvements in graphene oxide/epoxy composites. Macromolecules 45:238–245

Saravanan N, Rajasekar R, Mahalakshmi S, Sathishkumar T, Sasikumar K, Sahoo S (2014) Graphene and modified graphene-based polymer nanocomposites—a review. J Reinf Plast Compos 33:1158–1170

Lawal AT (2019) Graphene-based nano composites and their applications. A review. Biosens Bioelectron 141:111384–111401

Tang B, Hu G, Gao H, Hai L (2015) Application of graphene as filler to improve thermal transport property of epoxy resin for thermal interface materials. Int J Heat Mass Transf 85:420–429

Pawlik M, Le H, Lu Y (2019) Effects of the graphene nanoplatelets reinforced interphase on mechanical properties of carbon fibre reinforced polymer–a multiscale modelling study. Compos Part B Eng 177:107097–107097

Chen L, Jin H, Xu Z et al (2014) A design of gradient interphase reinforced by silanized graphene oxide and its effect on carbon fiber/epoxy interface. Mater Chem Phys 145:186–196

Rafiee MA, Rafiee J, Wang Z, Song H, Yu Z-Z, Koratkar N (2009) Enhanced mechanical properties of nanocomposites at low graphene content. ACS Nano 3:3884–3890

Wei J, Atif R, Vo T, Inam F (2015) Graphene nanoplatelets in epoxy system: dispersion, reaggregation, and mechanical properties of nanocomposites. J Nanomater 2015:1–12

Rohini R, Katti P, Bose S (2015) Tailoring the interface in graphene/thermoset polymer composites: a critical review. Polymer 70:A17–A34

De Cicco D, Taheri F (2019) Effect of functionalized graphene nanoplatelets on the delamination-buckling and delamination propagation resistance of 3D fiber-metal laminates under different loading rates. Nanomaterials 9:1482–1505

Palacios JA, Ganesan R (2019) Reliability evaluation of Carbon-Nanotube-Reinforced-Polymer composites based on multiscale finite element model. Compos Struct 229:111381–111393

Namilae S, Chandra N (2005) Multiscale model to study the effect of interfaces in carbon nanotube-based composites. J Eng Mater Technol 127:222–232

Aghadavoudi F, Golestanian H, Zarasvand KA (2019) Elastic behaviour of hybrid cross-linked epoxy-based nanocomposite reinforced with GNP and CNT: experimental and multiscale modelling. Polym Bull 76:4275–4294

Zeng Q, Yu A, Lu G (2008) Multiscale modeling and simulation of polymer nanocomposites. Prog Polym Sci 33:191–269

Yang B, Shin H, Lee H-K, Kim H (2013) A combined molecular dynamics/micromechanics/finite element approach for multiscale constitutive modelling of nanocomposites with interface effects. Appl Phys Lett 103:241903–241903-4

Gates T, Odegard G, Frankland S, Clancy T (2005) Computational materials: multi-scale modeling and simulation of nanostructured materials. Compos Sci Technol 65:2416–2434

Huang J, Wu Y, Huang L (2021) Evaluation of the mechanical properties of graphene-based nanocomposites incorporating a graded interphase based on isoparametric graded finite element model. Compos Interfaces 28:543–575

Zhao X, Gui Z, Chen X et al (2021) Finite element analysis and experiment study on the elastic properties of randomly and controllably distributed carbon fiber-reinforced hydroxyapatite composites. Ceram Int 47:12613–12622. https://doi.org/10.1016/j.ceramint.2021.01.120

Rémond Y, Ahzi S, Baniassadi M, Garmestani H (2016) Applied RVE reconstruction and homogenization of heterogeneous materials. Wiley, New York USA

Baghani M, Baniassadi M, Rémond Y (2023) Computational Modeling of Intelligent Soft Matter: Shape Memory Polymers and Hydrogels. Elsevier, Amsterdam Netherlands

Montazeri A, Rafii-Tabar H (2011) Multiscale modeling of graphene-and nanotube-based reinforced polymer nanocomposites. Phys Lett A 375:4034–4040

Alian A, Kundalwal S, Meguid S (2015) Multiscale modeling of carbon nanotube epoxy composites. Polymer 70:149–160

Zaccardi F, Santonicola MG, Laurenzi S (2021) Role of interface bonding on the elastic properties of epoxy-based nanocomposites with carbon nanotubes using multiscale analysis. Compos Struct 255:113050–113060

Yang S (2022) Interface and interphase of nanocomposites tailored by covalent grafting of carbon nanotube: hierarchical multiscale modelling. Int J Mech Sci 220:107160–107177. https://doi.org/10.1016/j.ijmecsci.2022.107160

Liu F, Hu N, Ning H et al (2017) Investigation on the interfacial mechanical properties of hybrid graphene-carbon nanotube/polymer nanocomposites. Carbon 115:694–700. https://doi.org/10.1016/j.carbon.2017.01.039

Xiao S, Hou W (2006) Fracture of vacancy-defected carbon nanotubes and their embedded nanocomposites. Phys Rev B 73:115406–115410. https://doi.org/10.1103/PhysRevB.73.115406

Di J, Lei Z, Ren Z et al (2022) Interfacial characterization in defective graphene/PET substrate structure through traction separation models: a molecular dynamics study. Comput Mater Sci 211:111540–111555

Yang D, Sun Y, Yang Z, Chen X, Wang C (2021) Multiscale modeling of unidirectional composites with interfacial debonding using molecular dynamics and micromechanics. Compos Part B Eng 219:108893–108907. https://doi.org/10.1016/j.compositesb.2021.108893

Pan D, Wang H, Zhu K, Tang Z, Hao X (2023) Molecular dynamics simulation and finite element method investigation of PTFE/carbon fiber composite tribological properties. Tribol Int 180:108241–108257. https://doi.org/10.1016/j.triboint.2023.108241

A Fattahi, S Roozpeikar, N Ahmed (2018) FEM modelling based on molecular results for PE/SWCNT nanocomposites. Int J Eng Technol. www. sciencepubco. com/index. php/IJET 7: 1

Lawrimore W, Paliwal B, Chandler M, Johnson K, Horstemeyer M (2016) Hierarchical multiscale modeling of polyvinyl alcohol/montmorillonite nanocomposites. Polymer 99:386–398

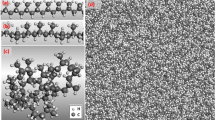

Karimi MR, Abrinia K, Hamdia KM, Hashemianzadeh SM, Baniassadi M (2022) Effects of functional group type and coverage on the interfacial strength and load transfer of graphene-polyethylene nanocomposites: a molecular dynamics simulation. Appl Phys A 128:341–358. https://doi.org/10.1007/s00339-022-05427-x

Plimpton S (1995) Fast parallel algorithms for short-range molecular dynamics. J Comput Phys 117:1–19. https://doi.org/10.1006/jcph.1995.1039

Stukowski A (2009) Visualization and analysis of atomistic simulation data with OVITO–the open visualization tool. Model Simul Mater Sci Eng 18:015012–015020

Sun H (1998) COMPASS: an ab initio force-field optimized for condensed-phase applications overview with details on alkane and benzene compounds. J Phys Chem B 102:7338–7364. https://doi.org/10.1021/jp980939v

Li Y, Seidel G (2014) Multiscale modeling of the effects of nanoscale load transfer on the effective elastic properties of unfunctionalized carbon nanotube–polyethylene nanocomposites. Model Simul Mater Sci Eng 22:025023–025052

L Melro, R Pyrz, LR Jensen (2016) IOP conference series: materials science and engineering, IOP publishing

Algar M (1997) Polymer science dictionary. Polym Test 3:299–1307

A Version (2011) Dassault Systemes Simulia Corp., Providence, RI, USA.

Camanho PP, Davila CG, de Moura MF (2003) Numerical simulation of mixed-mode progressive delamination in composite materials. J Compos Mater 37:1415–1438. https://doi.org/10.1177/0021998303034505

Jin Y, Duan F, Mu X (2016) Functionalization enhancement on interfacial shear strength between graphene and polyethylene. Appl Surf Sci 387:1100–1109. https://doi.org/10.1016/j.apsusc.2016.07.047

Awasthi AP, Lagoudas DC, Hammerand DC (2008) Modeling of graphene–polymer interfacial mechanical behavior using molecular dynamics. Model Simul Mater Sci Eng 17:015002–015039

Choi JY, Zhang X, Nguyen HT et al (2021) Atomistic mechanisms of adhesion and shear strength in graphene oxide-polymer interfaces. J Mech Phys Solids 156:104578–104597104597. https://doi.org/10.1016/j.jmps.2021.104578

Li W, Dichiara A, Bai J (2013) Carbon nanotube–graphene nanoplatelet hybrids as high-performance multifunctional reinforcements in epoxy composites. Compos Sci Technol 74:221–227. https://doi.org/10.1016/j.compscitech.2012.11.015

Reddy CD, Rajendran S, Liew K (2006) Equilibrium configuration and continuum elastic properties of finite sized graphene. Nanotechnology 17:864–870

Dasari A, Misra RDK (2003) On the strain rate sensitivity of high density polyethylene and polypropylenes. Mater Sci Eng A 358:356–371. https://doi.org/10.1016/S0921-5093(03)00330-7

Safaei M, Sheidaei A, Baniassadi M, Ahzi S, Mashhadi MM, Pourboghrat F (2015) An interfacial debonding-induced damage model for graphite nanoplatelet polymer composites. Comput Mater Sci 96:191–199. https://doi.org/10.1016/j.commatsci.2014.08.036

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: Mohammad Naraghi.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Safaei, M., Pourbandari, D., Karimi, M.R. et al. Developing a multiscale approach for damage analysis of functionalized-GNP/PET nanocomposite. J Mater Sci 59, 2907–2923 (2024). https://doi.org/10.1007/s10853-024-09364-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09364-3