Abstract

Developing novel technologies for the effectual treatment of wastewater comprising contaminated organic pollutants is of extraordinary importance across the globe. In the last few years, removal of organic pollutants using various nanocatalysts from aqueous solution by chemical reduction in the presence of NaBH4, as a reducing agent, has become an established route. Nanomaterials show great potential for the improvement of water treatment technologies. Recently, catalytic reduction of dyes by using various nanoparticles has received significant attention due to their effectiveness in degradation and producing less toxic and environmentally benign products. Herein, this comprehensive review discusses the classification of nanocatalysts, mechanisms involved in catalytic degradation of various types of dyes, recyclability of nanocatalysts and characterization techniques for various nanocomposites. We aim to review and summarize the recently published literature and R&D progress in catalytic reduction of various water pollutants. Different nanocatalytic assemblies used for reduction of dyes and their division based on nature of nanoparticles and composition of supporting materials have been described critically. A mechanism for chemical reduction of nitrophenols, methylene blue, Congo red, and methyl orange in the presence of nanocatalysts has been elaborated in this study.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rapid industrialization in recent years has been primarily considered as one of the main causes of the humungous increase in environmental concerns including air, soil, and water pollution [1, 2]. Various environmental factors pose huge impact on quality of life particularly water pollution. The chemicals added to the groundwater reservoirs owing to the working, processing, purification processes of the various industries are causing serious health problems in human beings. Water pollution is caused by addition of various hazardous materials released from different industries and has been considered a major health problem around the globe, especially in developing countries. Keeping in view high population growth along with stringent health-based regulations and economic development, there is more demand for high-quality water (i.e., water that is free of toxic chemicals and pathogens) [3,4,5]. The need for freshwater is of utmost importance for life on earth and its reservoirs are effecting by chemical discharge from industries and agricultural resources as well [6, 7]. The addition of hazardous chemicals in freshwater is attributed to two sources (i) geological, (ii) anthropogenic (i.e., man-made) [8]. The hazardous or toxic materials affecting the quality of water include various dyes, compounds like fertilizers, insecticides, chemical species, heavy metals like Hg, Cu, Cr, Pb, synthetic detergents, oils, solvents, disinfectants, pool chemicals, etc. [9, 10]. So the removal or degradation of hazardous materials and contaminants from wastewater, ground, and surface water is a significant global challenge. Various methods and techniques have been reported for water purification including sedimentation approach, distillation, different chemical methods like coagulation, precipitation, and use of adsorbents, filtration, etc. [11,12,13,14,15,16], where oxidation processes have gained much attention owing to their efficiency.

Dyes are the major source of dangerous contaminants discharged from different companies, such as the paper, textile, paints, cosmetic, printing, food, pulp, and pharmaceutical industries [17,18,19,20,21,22]. Keeping in view the tendency of toxic chemicals and dyes to cause skin problems, coughing, dyspnea, eye irritation, liver and kidney damage, lung disease, ulcers, respiratory problems, and cancer, there is utmost need to improve water quality by removing these hazardous materials [23,24,25,26]. Thus, removal/degradation of toxic chemicals from wastewater is a foremost global challenge because of their potential toxicity, carcinogenic and teratogenic properties toward plants, animals, and humans [27,28,29,30]. Dyes can easily adsorb/reflect sunlight, slow down photosynthesis, and effect aquatic plants in an ecological system [31, 32]. In addition, they are constant threat to natural environment due to low biodegradability; accumulate in natural environment as persistent pollutant. Classification of dyes depends on their basic skeleton or structure, their source, and nature of fiber (i.e., most compatible). They are categorized as, acidic, basic, anthraquinone, azo, and metal complexes [32,33,34,35].

Various sanitization methods have been reported in literature [13, 14, 36,37,38] such as oxidation processes (chemical, biological, or physical), catalysis [39], photocatalysis [40,41,42,43], biological treatment, coagulation, membrane systems, ozonation [24, 44,45,46,47,48,49,50], anodic oxidation [51], catalytic wet air oxidation process [52, 53], chemical reduction [54], electrochemical methods [55,56,57], hydrogenation [58, 59], microbial degradation [60], adsorption [61, 62], Fenton process [63], and so on. These dyes are very resistant and difficult to decompose using conventional methods. Therefore, different approaches are made to minimize the absorption of pollutants into the environment for instance: chemical sedimentation, ion exchange, solvent extraction, evaporation, oxidation, electrochemical treatment, membrane separation, membrane bioreactors, incineration, and absorption [64, 65]. All of these approaches have short comings like incomplete mineralization, chemical consumption, disposal of dense solution, laboratory scale, pH dependence, high consumption of energy, high material costs, sludge treatment, etc.[66, 67]. So, there is dire need to develop new technology for efficient removal of the dyes from the environment.

Among these approaches, chemical reduction has attained great attention because of its high efficiency, easy operation, and low cost. In this approach, dyes are converted into less toxic materials that can be further degraded before release [70,71,72,73,74,75,76,77,78]. Chemical reduction of several dyes by sodium borohydride (NaBH4) as the reducing agent is an economic, safe, highly efficiency, and green alternative approach. Hence, catalytic degradation by NaBH4 is superior to other traditional methods in terms of less time-consuming, simple design, easy operation, and their recyclability is the main motivation to choose this method for review [79,80,81,82,83,84]. However, this process is thermodynamically favorable and kinetically unfavorable in the absence of a catalyst [70,71,72,73]. So, different catalytic system has received considerable attention for variety of applications in several fields as they exhibited tunable physicochemical properties [85,86,87,88,89,90]. Bimetallic catalysts possess better catalytic potential as compared to their individual metal (monometallic analogues) owing to synergistic effects between two metals and degree of freedom that can be adjusted to increase the catalytic efficiency of bimetallic nanomaterials [91,92,93,94,95]. For instance, Mei et al. recently reported the efficient degradation of organic dyes (MO, RhB, and Rh6G) over an organic–inorganic bimetallic catalysts P(St-co-AAM)/PGMA in the presence of NaBH4 reducing agent. The uniform distribution and popcorn like geometry of the prepared catalysts resulted in complete degradation of these dyes within two minutes of working [96]. Moreover, the constituents of bimetallic catalytic system play significant role in reaction and provide a suitable environment for the catalytic performance [97,98,99,100,101,102]. In majority of cases, metal and metal oxide nanomaterials are employed as redox mediator-RM to enhance the degradation rates of electron-accepting priority pollutants [84, 103,104,105,106,107]. Indeed, redox mediators consist of a redox couple accompanied with a high electron transfer rate, which stimulates the interaction between an electron donor (NaBH4) and electron acceptor (dyes) species by acting as an electron shuttle [82, 105, 108,109,110,111]. Pereira et al. demonstrated the effects of thermal treatment on the performance of activated carbon as redox mediator for the degradation of various azo dyes including Direct Blue 71, Reactive Red 2, and Acid Orange 7. The enhancement in surface morphology of activated carbon upon thermal treatment and pH of the medium were reported to be the key factors in the effective degradation of dyes [112]. The transfer of electrons is an important step because a high potential difference between the electron donor and acceptor can hamper electron transfer. Therefore, an effective catalyst with an intermediate redox potential can act as an electron relay to assist electron transfer [70,71,72,73, 113]. Several redox mediators have been employed as catalysts to increase the reductive biotransformation of electron-accepting contaminants [114,115,116,117,118,119,120,121].

Nanotechnology is vital for advancement of various technologies and industrial sectors, particularly environmental sciences, material sciences, energy, information technology, biotechnology, food safety, biomedical sciences, biochips, memory devices, and biosensors. The role of nanotechnology for current development and progress in biotechnology, chemistry, physics, and material sciences is well documented involving design of nanostructures with unique characteristics [122,123,124]. Nanotechnology has attracted scientists around the globe owing to its vast applicability and enables researcher to devise novel strategies for designing, synthesis, and characterization of various nanomaterials with unique characteristics. Nanoparticles being small-sized with significantly improved crystallographic characteristics are of paramount interest in various fields of science. Various surface-dependent applications of nanomaterials are attributed to their exceptionally high surface available for interaction. For instance, heterogeneous catalysis represents one such research approach with wide applications in environmental remediation [118, 125,126,127,128].

Nanomaterial has a main catalytic domain for reaction of reacting species while stabilizing medium serve to immobilize NP or nanomaterial. Nanoparticles deserve a key position among various types of reported nanomaterials with size range 1–100 nm and a high surface: volume ratio [129]. The optical and electromagnetic characteristics of nanoparticles are attributed to high coupling constant among electromagnetic radiations that lead to surface plasmon resonance (SPR) phenomenon. Compatibility of NP’s size and electromagnetic radiations lead to strong coupling between them [130,131,132]. Various types of NPs have been reported in the literature, namely organic and inorganic NPs, metal, and metal oxide NPs, and TM-doped NPs. A very recent study on the biosynthesis of silver NPs was reported by David and Moldovan where they utilized Viburnum opulus L extract as a bioactive source to degrade organic dyes. Highly stable and reducing Ag NPs effectively degraded the Brilliant Blue FCF dye in water [133].

. Although catalytic potential of nanomaterials depends on surface area of nanoparticles still stabilizing medium plays a key role to finalize surface area of NPs [134,135,136,137]. In addition, agglomeration tendency of NPs presents a major issue during synthesis of NPs due to high energy caused by dangling bonds present at their surface. Hence, self-assembly and aggregation facilitate in lowering of surface energy of NPs but decreases surface area of NPs and reduces their applications in various fields. Using stabilizing medium for fabrication of NPs helps to cope with this problem of self-agglomeration and keep size of NPs in desired range [43, 138]. For instance, Joseph and Mathew utilized starch as a stabilizing agent to fabricate Ag NPs via microwave-assisted approach for the degradation of MO and RhB dyes in the presence of NaBH4. Spherical Ag NPs with uniform size were produced I the presence of stabilizing agent which opened new insights in o the commercial fabrication of nanocatalysts [139]. Various characteristics of stabilizing agents including enhanced chemical and thermal stability alongside small density values contribute toward catalytic potential of synthesized NPs, reduce Ostwald ripening tendency, and increase their stability [140, 141]. Keeping in view the significance of various nanocomposite materials for degradation and reduction of hazardous chemicals and dyes here, a detailed review of literature providing information about classification of nanocatalysts, mechanisms involved in catalytic degradation of various types of dyes, and characterization techniques for various nanocomposites is provided.

Classification of catalytic systems

Both nature of synthesized nanoparticles and stabilizing material for any given nanomaterial assembly provide basis for classification of catalytic systems. Following two classification criteria have been reported.

Nature of nanoparticle

Recently, metal nanoparticles have been extensively employed for catalytic degradation of pollutants and organic dyes. Keeping in view, the unique surface properties and chemistry along with small reduction potential values, the metal nanoparticles have been regarded as an attractive catalytic system for various electron transfer reactions. Two categories specified for metal nanoparticles based on their building block’s nature are: (i) monometallic NPs and (ii) bimetallic NPs.

(i) Monometallic metal NPs

Nanoparticles made up of regular array of building blocks of same metal are characterized as monometallic nanoparticles. For instance, silver (Ag), nickel (Ni), gold (Au), copper (Cu), cobalt (Co), etc., have been employed as catalytic systems with potential to catalyze isomeric aromatic nitro phenols [142, 143]. Silver (Ag) NPs being eco-friendly and cost-effective have been used for the catalytic reduction of 2-NP and 4-NP. Various types of stabilizing systems have been reported for nanoparticle fabrication [142, 144,145,146,147,148,149,150,151], like reduction of nitrophenols is achieved successfully using Ag NPs immobilized on microgel. An interesting fact related to use of microgel as a stabilizing medium is its dispersed phase that is water in nature providing an efficient working atmosphere for reduction of 2-NP and 4-NP. Also, changes in the mesh size microgels can facilitate to control and manipulate the size of nanoparticles of interest. Variation in temperature along with other reaction conditions has a major contribution to effect catalytic potential of a given system [134, 142, 145, 147, 151, 152]. Similarly, green synthesis of Au nanoparticles using Breynia rhamnoides plant extract as the stabilizing medium and as reductant is reported by Gangula et al. The stabilization potential of plant extract is attributed to presence of various bioactive constituents like aromatic and phenolic compounds [153]. Although given synthetic approach was quite eco-friendly, simple, and more facile still its characteristic properties were not comparable to NPs synthesized through simple chemical methods. Later, Zayed and Eisa reported same methodology for synthesis of Au NPs using Phoenix dactylifera plant extract as capping agent [154]. Similarly, Guria et al. utilized cultural filtrate Fusarium MMT1 strain for synthesis of protein-stabilized nano-gold particles and used them for reduction of 2-NP and 4-NP [155]. Even though Au nanoparticles have wide applications and unique characteristics still it has limited applications at an industrial scale due to their high cost, as a basic requirement of water purification plants and industries is to provide services at a lower cost. In addition, Ni NPs represent another type of monometallic NPs that have been employed for reduction of 2-NP and 4-NP. For instance, Sahiner et al. reported synthesis of Ni NPs using in situ reduction technique and immobilized on hydrogel system [156]. They reported efficient degradation capacity of Ni NPs immobilized on hydrogel, i.e., poly (2-acrylamido-2-methyl-1-propanesulfonic acid) [p(AMPS)] for 4-NP using sodium borohydride (NaBH4) acting as a reducing agent. Another important feature related to reduction of dyes by NPs system is involvement of stabilizing medium to facilitate electron transfer reaction between reductant and dye. Examples for these systems include usage of graphene, GO, or reduced graphene (RGO) as medium for immobilization of NPs. Jebaranjitham et al. utilized Hummer’s method for production of two types of amino-functionalized graphene oxide and compared their efficiency for nucleation as well as stabilization of Ag nanoparticles. They reported better dispersion potential of alkyl-diamine-functionalized GO for Ag nanoparticles that did not agglomerate in polar solvent [157].

(ii) Bimetallic NPs

Bimetallic nanoparticles have huge significance and have attracted attention of scientists around the globe being better in catalytic performances as compared to the monometallic nanoparticles [158]. Bimetallic nanoparticles are heterogeneous, i.e., composed of different types of metals that enhance their tendency to assemble during synthesis or fabrication. The better efficacy and superior nature of bimetallic nanoparticles are attributed to the combined characteristics of both metals in a given system. The stability, catalytic potential, resistance toward poisoning or degradation, and selectivity features of bimetallic NPs are much better than monometallic NPs [159, 160]. For instance, Ghosh et al. reported better and even more significant performance of bimetallic Pt-Ni nanoparticles for reduction of 4-NP as monometallic Pt NPs investigated under same reaction conditions [161]. Similarly, using core–shell Ag@Pt b-MNPs immobilized on sepiolite nanofibers for reduction of 4-NP showed better catalytic performance as compared to Ag/sepiolite or Pt/sepiolite alone as reported by Ma et al. [162]. Later, Lu et al. [58] reported in situ synthesis of bimetallic Au–Pt NRs supported on core–shell microgel to avoid aggregation of synthesized NPs. The better catalytic potential of Au–Pt NRs for degradation of 4-NP is accomplished due to combined effects of characteristics of both Pt and Au metals in single nano-system [163]. Catalytic potential of any given bimetallic NP assembly is dependent on compatibility of both metals as suggested by Pozun et al. who synthesized different alloys of bimetallic nanomaterials like Pt/copper, palladium (Pd)/Cu, Pd/Au, Pt/Au, and Au/Cu stabilized on G6-OH poly (amidoamine) [PAMAM] dendrimers. They reported Pt/Cu as most efficient nanoparticle system for reduction of 4-NP owing to strong binding tendency of both metals [91], while Au–Ag b-MNPs stabilized on graphene oxide also showed better catalytic performance for reduction of 4-NP as compared to GO-supported monometallic Au and Ag NPs [164]. Furthermore, bimetallic nanowires like Cu@Ni nanowires synthesized through facile liquid-phase reduction technique and graphene as supporting medium has shown enhanced stability along with better catalytic efficiency for 4-NP reduction. Although various multimetallic NPs systems have also been reported very limited literature has been reported in this regard [165]. An example of such multimetallic system was reported by Gao et al. who employed liquid-phase reduction technique for synthesis of multi alloy system comprises of Pd, Ni, and phosphorous (P)[PdNiP/ RGO] catalyst having high stability and catalytic tendency. This higher catalytic potential and performance of multimetallic NPs system is attributed to well distribution of alloy on the surface of RGO [166].

In summary, metal NPs have shown good potential for the catalytic degradation of organic pollutants in wastewater owing to their unique features like small reduction potentials and superior surface chemistry. Although monometallic catalyst have shown great results in the degradation of various organic pollutants such as nitrophenols, another class of catalytic systems named bimetallic nanocatalysts have received much attention lately. This is due the superior stability, chemical potential, and selectivity of bimetallic systems over the traditional monometallic nanocatalysts. Furthermore, the synergism between the two compatible metal components can provide us with a better degradation mechanism which is long lasting as well. However, the traditional synthetic routes for the fabrication of these metallic systems are not environmental friendly and highly costly. Therefore, researchers have diverted their attention to look for environmentally benign fabrication routes like green synthesis and significant developments are being made in this regard.

Stabilizing medium

The surface area of MNPs plays an important part in the catalytic reduction of dyes that is secured by using various stabilization agents including polymers, non-polymers, organic-inorganic compounds, and biogenic compounds. To ensure a better surface morphology, use of various stabilizing agent to fabricate NPs with superior surface properties has become inevitable. Following are some of the conventional stabilizing mediums adopted by the researchers for metal NPS fabrication in the past few years.

Polymers as stabilizing agents

Polymers have been extensively employed for improving properties of various materials particularly their surface characteristics. Previously reported polymer systems employed to enhance stability of metal NPs are dendrimers, polymeric matrix, hydrogels, core–shell or yolk-shell systems that serve as capping agent to perform catalytic activity [167,168,169,170,171,172,173,174,175,176,177,178,179,180,181,182,183]. For instance, dendrimer utilizes steric repulsion while polyelectrolytes involve electrostatic repulsion to fabricate nanoparticles. Dendrimers being neutral have various advantages as compared to polyelectrolytes. Similarly, both homopolymeric and hetero polymeric matrices have been used as capping agent in case of simple polymeric systems. In addition, various polymer matrices have been reported to stabilize and synthesize metal NPs [184], i.e., polystyrene [185], polyvinyl pyridine [186], polydopamine [186], polyvinyl pyrrolidone [187], polyacrylic acid [188], or block copolymer like poly(ethylene oxide)-poly(acrylic acid) [189]. Water-insoluble polymer matrices have been employed for synthesis of NPs with desired shape and size that are easily extracted from medium. For instance, polystyrene-polyvinyl pyridine (PS-PVP) beads have been utilized for synthesis and stabilization of Ag and Ru NPs [185]. Hydrogels represent another important stabilizing agent used for synthesis of metal nanoparticles whose characteristic like change in volume with stimuli alongside electronic, catalytic, and magnetic properties of metal NPs plays pivotal role to manipulate and effect properties of metal NP-hydrogel composites. The synthesis of metal NP-hydrogel composites is accomplished by simple mixing of metal NPs, while in situ method involves use of hydrogel (microreactor). The stability of metal NP-hydrogel composites is attributed to various chemical interactions between both components, i.e., (i) metal NPs and (ii) hydrogel with minimal chance of leakage [190]. In case of porous hydrogel, the reactants can diffuse through pores and reach metal NPs to react at their surface leading to desired product [172] (Figs. 1, 2, 3).

reproduced with permission from Naseem et al.[191]

a Magnetic NPs core-encapsulated polymer impregnated with metal nanoparticles, b metal nanoparticles-immobilized hydrogel network, c metal NPs impregnated fibrous nanosilica composite, d silica nanorattle encapsulated metal NPs core, e metal NPs immobilized on the surface of a hollow silica nanosphere;

reproduced with permission from Bharath G. et al. [196]

TiO2/RGO with plasmonic silver nanoparticles;

reproduced with permission from Abay, A.K., et al. [207]

a UV–Vis spectra of 4-NP before and after the addition of NaBH4 solution and b the time- dependent UV–vis absorption spectra for the reduction of 4-NP over CuNiOS-0.6 catalyst. Plots of c Ct/C0, and d ln (Ct/C0) versus reaction time (s) for reactions without catalyst and with CuOS and CuNiOS catalysts;

Silica particles have attracted much attention from researchers around the globe due to their unique characteristics, i.e., higher surface area, low density, and high stability (both chemical and thermal). Silica nanoparticles have been used as supporting material for metal NPs and also facilitate synthesis. For instance, eight times increase in the catalytic potential of Au NRs has been reported previously when immobilized on silica particle layers [192].

Organic materials have been extensively employed as stabilizing substance for immobilization of synthesized NPs [193]. The most commonly used supporting material is graphene that is 2D layer of carbon atoms arranged in regular array in the form of six-membered rings in-plane. Graphene has unique characteristics in terms of various electrical and mechanical properties along with thermal stability. Combining graphene with TiO2 enhances its potential as supporting material for different nano assemblies. It is also reported that graphene alone has lower catalytic and stabilizing tendency as compared to its oxide form (GO), i.e., more superior in terms of reactivity than graphene. Similarly, reduced form of graphene oxide (rGO) has also been reported as efficient supporting material for immobilization of metal NPs [194] and suitable for potential applications in optoelectronics [195]. Nasrollahzadeh et al. reported combination of GO with TiO2 as stabilizing medium for Ag NPs in the presence of Euphorbia helioscopia plant extract as reducing agent. This TiO2-rGO with Ag NPs hybrid system showed significant catalytic potential for reduction of Congo red dye, and its structural illustration is as follows given in Fig. 4.

reproduced with permission from Abay, A.K., et al. [208]

The possible reaction mechanism for the reduction of 4-nitro phenol (4-NP) by NaBH4 over the CuNiOS-0.6 catalyst into 4-amino phenol (4-AP);

Organic–inorganic compounds

Organic–inorganic hybrid systems represent a novel dopant that has been utilized as supporting material to immobilize nanoparticles of interest for last few decades particularly for systems used in reduction of pollutants. Although this hybrid system is employed with multiple applications still a lot of work is needed for optimization of various concerned parameters. Sravanthi et al. reported a hybrid biological system composed of bentonite clay (inorganic part) and Eucalyptus leaf extract (organic part) with significant catalytic potential for 4-NP reduction [197]. Similarly, gelatin represents another type of natural protein fibers as supporting material for metal NPs and is cost-effective as well. Different metal nanoparticle systems can be functionalized/impregnate on gelatin’s surface and are uniformly distributed, while size of NPs is affected by pH and reaction time [198] Table 1.

Biogenic compounds

Various biological systems have been reported as stabilizing or support material like microorganisms, fungi, and extracts of different parts (i.e., stem, bark, and peal of fruit) for nanoparticle synthesis at large scale. The widespread use of these supporting materials in various systems is attributed to their availability, lower cost, non-toxic nature, eco-friendly, simple methodology, relatively cheap raw material, etc. These biological systems gained exceptional importance due to easier and mild reaction conditions involved in their synthesis. For instance, Dauthal and Mukhopadhyay [199] used fruit extracts of Prunus domestica (plum) as support medium for synthesis of Au NPs that also served as reductant where water-soluble polyols and amino acids are responsible for Au NPs reduction. Similarly, B. rhamnoides extracts serve as reducing agent for synthesis of AgNPs (accomplished reduction of Ag NPs in 2 h).

In conclusion, the application of various stabilizers have become a great necessity in the fabrication of efficient catalytic system and significant developments have been made in the recent years. Different kinds of stabilizing materials have been explored which have yielded outstanding results in the field. Polymeric compounds like dendrimers and hydrogels have been extensively utilized serving as capping agents to stabilize the metal NPs in the catalytic systems. In addition to that, organic–inorganic hybrid systems have also been introduced for this purpose, but still further improvements are required for the optimization of these hybrid systems. Several biogenic stabilizers have also been investigated owing to their eco-friendly nature, low cost, abundant availability, and simple fabrication.

Environmental concerns of nano catalyzed reduction of dye

Various types of catalysts have been reported for degradation of dyes by NaBH4. Mostly, metal NPs have been employed for the reduction of environmental pollutants, but metal NPs themselves have toxic and adverse impacts on aquatic systems [200]. Secondly, NaBH4 itself is a great threat for ecosystem as it is highly toxic and may harm lungs and nervous system. Therefore, an eco-friendly reducing agent (glucose and molecular hydrogen) should be used instead of NaBH4 [201, 202]. Thirdly, it is reported that researchers are reducing toxic dyes into harmless products, but toxic side products are still produced during the degradation reaction that is disturbing the natural environment [203]. Therefore, it is essential to recover nanocatalysts from the reaction mixture and fabricate nanocomposites that are financially feasible, clean, and eco-friendly. In addition, simple capping agents should be used to design efficient catalyst instead of using complex supporting materials that needed a lot of expertise and expensive chemicals. Green synthesized nanocatalysts are widely used for the reduction of organic pollutants being more economic, efficient, and easily recoverable. There is dire need to design environmentally benign and efficient nanocatalyst such as green nanocatalyst, as they are widely used for the reduction of organic pollutants and might be a good alternate to toxic reducing agents. Details over catalytic reduction of various dyes are provided as follows:

Catalytic reduction of nitrophenols

Nitrophenol is a highly poisonous environmental pollutant with carcinogenic and mutagenic effects on humans. To develop natural environment free from nitrophenols, it is necessary to reduce it into less toxic products that have applications in medicines, dye synthesis, photographic film developing methods, etc. Several catalysts like metal nanoparticles (MNPs), impregnated silica, cefditoren, gelatin, graphene, porous glass filter plates, polymer, dextran, hydrogel, and bimetallic nanoparticles have been employed for the reduction of nitrophenols.

A general mechanism for the catalytic reduction of nitrophenols involves the Langmuir–Hinshelwood (L–H) adsorption model. At start of reaction, reactants (dye and NaBH4) get adsorbed on the surface of NPs but NaBH4 dissociates into its ions, and BH4− behaves as electron denoting species that transfer an electron to nitrophenol; later converted into aminophenol molecule. NaBH4 releases hydrogen gas in the reaction mixture that not only increases rate of reaction but also decreases the induction time to activate the NPs by reconstructing its surface. Any impurity on nanocatalyst is removed by this H-flux, and more active site on the surface of NPs is available for the reaction [204,205,206]. The chemical reaction for release of H2 gas can be written as follows:

In May, 2017, Abay et. al. fabricated a noble metal-free nanocatalyst with the structure CuNiOS, via eco-friendly and cost-effective approach, for effective degradation of organic dyes. The boosted catalytic performance of the bimetallic oxysulfide nanocatalysts was attributed to the synergistic effect between Ni and Cu atoms. The catalytic evaluation plots and a proposed degradation mechanism are given in Figs. 3 and 4, respectively.

Figure 3 depicts adsorption of BH4− ion, and transfer of hydride to CuNiOS-0.6-NP leading to the formation of Cu-H on the surface of catalyst. Simultaneously, the nitro group of dye captures H and electrons from Cu-H complex. Eventually, 4-AP is formed by hydrodeoxygenation reactions. The Ni in the catalyst enhances the activity of CuNiOS-0.6 by increasing electron flow, narrow the band gaps of the CuNiOS-0.6 and strong synergetic effect between nickel and copper atoms is one of the possible reasons to improve the catalytic activity of CuNiOS-0.6 as a nanocatalyst [208].

Various catalysts used for the degradation of 4-nitrophenol along with NaBH4 (reducing agent) and degradation time are given in Table 2.

In another study, Chandra et. al. reported for the first time, the biosynthesis of Ag NPs functionalized with amino acid, using Neem gum for catalytic degradation of organic dyes. They utilized different amino acid functional groups like alanine (Ala), tryptophan (Trp), histidine (His), glutamic acid (Glu), asparagine (Asp), and methionine (met) that exhibit strong affinity toward Ag+ ions. Significant degradation of 4-NP was observed for the prepared samples as shown in Fig. 5. The enhanced catalytic activity was ascribed to the thermodynamic favorability offered by the suitable redox potential of Ag atoms lying in between the 4-NP and BH4− ions, hence acting as an electron relay.

reproduced with permission from Chandra et al. [234]

a Time-dependent UV–Visible spectra for the catalytic reduction of 4-nitrophenol by NaBH4 a in the absence of AgNPs and in the presence of 30 μM AgNPs: b AgNP, c Ala-AgNP, d Trp-AgNP, e Met-AgNP, f His-AgNP, g Glu-AgNP, and h Asp-AgNP;

Figure 5 represents the catalytic activity of AgNPs for reduction of 4-NP by NaBH4 where addition of NaBH4 into aqueous solution shifted peak to 400 nm due to formation of phenolate ion, while in the absence of AgNPs, very limited reduction of 4-NP to 4-Aminophenol by NaBH4 was observed. Both AgNP and Trp-AgNP reduced 4-NP.

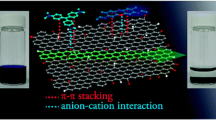

Catalytic reduction of methylene blue

The thiazine group forms the basic skeleton of methylene blue dye with λmax 665 nm in an aqueous medium (due to n–π* transition) [235, 236]. In the absence of NPs, the reduction rate of methylene blue is very slow. Chandra et. al. demonstrated that Ag NPs bleach the methylene blue to colorless solution and their absorption peak (665 nm) is diminished, indicating the conversion of MB to Leuco MB (LMB). This confirmed the catalytic potential of the Ag nanoparticles against MB in aqueous and dodecyltrimethylammonium bromide (DTAB), sodium dodecyl sulfate (SDS), and dioctyl sulfosuccinate sodium salt (AOT) micellar mediums. Negative surface charge on silver NP resulted in significant adsorption of MB (cationic dye), by bringing them close to each other. Hence, strong non-covalent interactions among aromatic rings of the methylene blue (π–π stacking) resulted in increased molecular association [235, 237, 238].

Micellar medium T-20 shows the reverse oxidation of leucomethylene blue in the presence of silver as nanocatalyst and absorbance spectrum (665 nm) increased linearly with time. This observation demonstrated that silver NPs played a vital role in the reverse oxidation of LMB to MB and presented a straight line through positive slope. Thus, rate of reverse oxidation is independent of NPs concentration, whereas it depends on the nature of the silver NPs. The clock reaction revealed significant use of the silver NPs as sensors for oxygen seepage in vacuum packed food and for generating O2 deficient environment in micellar and acidic aqueous mediums, where poisoning of catalyst occurs by oxygen [238] as depicted in Fig. 6.

reproduced with permission from Chandra et al. [234]

Schematic arrangement of MB, Sn2+ ions, and Ag NPs during catalytic reduction of MB by SnCl2 as a reductant in aqueous and aqueous micellar mediums of SDS, AOT, DTAB, and T-20;

In 2016, Saad et. al. fabricated a hybrid Ag-silica composite for the effective degradation of MB into LMB by binding aminopropyltriazole and 2-aminothiazole ligands to trap Ag particles effectively. They overcame the issue of aggregation and high surface energies of Ag NPs by using functional groups, hence improving their stability and efficiency. The reduction of MB to LMB followed the following mechanism; the cationic dye molecules accept electrons and H atoms from BH4− which result in π conjugation breaking the double bond between N and the aromatic rings of dye. The doubly bonded N atom in the dye molecule attaches a H atom by breaking the double bond, while the positively charged N atom receives an electron which result in π conjugation of the dye molecule. The Ag NPs act as an electron relay between the two reactant species since their redox potential lies in between the MB and BH4− molecules. In the absence of Ag NPs, the reduction process was found to be extremely slow and limited [239]. The schematic structure of prepared Ag-silica composite and proposed mechanism for MB reduction are given in Fig. 7.

reproduced with permission from Saad A. et al. [239]

Schematic structure of AMT-SBA-15 and Tr-SBA-15 hybrid supports and mechanism of the catalyzed reduction reaction of MB to LMB in the presence of reducing agent;

Various catalysts used for the degradation of methylene blue along with NaBH4 (reducing agent) and reaction completion time are given in Table 3.

Catalytic reduction of Congo red

Congo red (CR) has linear symmetry with two phenyl rings in the center joined to two terminal naphthalene by diazo bonds [264]. The UV–Vis spectrum confirms (350 and 498 nm) the presence of azo linkages (–N = N–) in its basic structure [254]. It is a high toxic anionic dye that is widely used in paper, rubber, and textile factories and its degradation is needed to avoid its hazards [201] where azo bonds are degraded [70]. Only NaBH4 is not enough for the reduction of CR molecule in an aqueous medium as this process is thermodynamically feasible but not kinetically. Actually, metal NPs provide large surface area for interaction of dye molecules and reducing agents that lead to final product. These nanocatalysts are not only involved in efficient reduction of dye molecules but also make the reaction kinetically feasible (Figs. 8, 9, 10).

reproduced with permission from Ai, L. et al. [258]

a, b SEM images of pure Ag, Fe3O4 and c, d the Ag-Fe3O4 composite, e XRD pattern of the Ag-Fe3O4composite, f the reduction efficiency of RhB: a over Ag-Fe3O4composite in the absence of NaBH4, b in the presence of NaBH4 without Ag-Fe3O4composite, and c over Ag-Fe3O4composite in the presence of NaBH4;

reproduced with permission from Xuan S., et al. [262]

TEM images of the as-prepared Fe3O4@PANI core/shell nanocomposite with the PANI shell thickness of a 0 nm, b 7 nm, c 15 nm, and d 25 nm, e reduction of RhB into Leuco RhB and f M-H curve of the Fe3O4@PANI@Au composite at room temperature;

The catalytic potential of CR depends on different factors such as amount of reducing agent, concentration of catalyst, concentration of dye, a quantity of surfactant, and electrolyte [202, 204, 265,266,267]. A high dosage of catalyst provides large number of active sites for adsorption, increases the rate constant, and decreases the degradation time [203]. Nature of electrolyte also affects the catalytic potential during degradation. It influences the reduction rate in two ways; firstly, electrolytes increase the rate of reduction by transfer of charge from BH4−1 to Congo red via catalyst, and secondly, it decreases rate of reduction as it gets adsorbed on catalysts and block their active sites. Similarly, the catalytic potential of catalyst used for reduction of Congo red is also affected by surfactants due to their large amount in industrial drainage. Generally, they are adsorbed on the surface of MNPs and block their active sites. Some MNPs have negative charges; thus, large number of surfactants with positive charges can adsorb on the surface of catalyst and decrease the reduction rate of CR.

In 2013, Jia et. al. reported the use of palladium (Pd) NPs decorated on porous polypropylene hollow membranes for the catalytic reduction of CR dye. They briefly studied the effect of dye concentration, Pd NPs, and reusability of membranes for catalytic activities. During catalysis, the Pd NPs with large amount of active sites act as electron relay, coordinate with π electrons of CR and surplus hydrogen atoms get adsorbed on catalyst surface. Further interaction of dye molecules with adsorbed surface results in the hydrogenolysis of the dye molecules. BH4− ions release hydrogen by donating an electron to MNPs and then attack CR molecules. Azo groups in Congo red are activated by electron carrying metal nanoparticles. In fact, CR molecules interact with MNPs through their sulfur and oxygen atoms and their azo double bonds are weaken via conjugation that ultimately breaks azo bond. Complete reduction of CR showed colorless solution due to conversion of –N = N– into –HN–NH– and later breaking of –HN–NH– bond. The resulting products separated from surface of MNPs and diffused out into solution. MNPs store electrons after being transferred from BH4− ions during CR reduction [202].

Another study was reported by Rajesh et. al. in 2014, where they stabilized Au and Ag NPs on polyamidoamine (PAMAM) dendrimers functionalized graphene oxide (GO) for efficient catalytic degradation of azo dyes. The enhanced degradation of prepared nanostructures was attributed to larger surface area of GO and hydrophilic nature of PAMAM dendrimers molecules that helps in bringing the dye molecules closer to the active sites of the catalyst [203].

Catalytic reduction of Congo red by metal nanoparticles involves following steps as shown in Fig. 6 [203].

Catalytic reduction of RhB

RhB is another hazardous dye belonging to xanthene family, which is highly soluble in water, gives red color, and shows absorption maximum at 553 nm. Textile and food industries frequently utilize RhB dye as a colorant, and it has been frequently used for water tracing as well. However, RhB is extremely carcinogenic, neurotoxic and causes eye, respiratory tract, and skin irritation [269] Many studies have been reported on the catalytic degradation of this hazardous dyes in the past few years.

Ai et. al. adopted the solvothermal route to fabricate Ag-Fe3O4 for catalytic reduction of Rhb dye in 2011. Furthermore, they gave the advantage of magnetically recycling the nanocatalysts and no significant decrease in catalytic activity was observed after three cycles. A significant increase of 16.8 times magnitude in catalytic rate for the reduction of RhB was reported in the presence of Ag-Fe3O4 in contrast to NaBH4 used alone [257].

Xuan et. al. fabricated a magnetically responsive core–shell Fe3O4@polyaniline@Au nanocomposite via in situ surface polymerization (sound-assisted) method, in 2009. The superparamagnetic Fe3O4 proved to be easily recoverable magnetically, at room temperature. The nanocatalyst showed exceptional degradation of RhB dye where Au NPs acted as electron relay, receiving electrons from the nucleophile reducing agent to the electrophile dye molecules. This results in conversion of RhB to Leuco RhB as demonstrated in Fig. 10 [261].

Various catalysts used for the degradation of Rhodamine B along with NaBH4 (reducing agent) and reaction completion time are given in Table 4.

Catalytic reduction of methyl orange

Du et. al. in 2017 fabricated Fe3O4 NPs coated with polydopamine (Fe3O4@PDA) for catalytic removal of MO dye from wastewater. The prepared nanocomposite acted as a redox mediator due to the synergistic effect of Fe3O4 and PDA during the catalytic reduction of MO dye. In the catalytic reduction, Fe3O4@PDA-NPs act as redox mediators that initiate catalysis by relaying electrons from BH4− to methyl orange. There are two possible ways for catalytic degradation of methyl orange. Firstly, the quinone parts of Fe3O4@PDA-NPs are degraded by NaBH4 and act as electron donors. Secondly, the quinone parts of Fe3O4@PDA-NPs are reduced by NaBH4 and donate electrons for the reduction of Fe+3 to Fe+2 and synergetic effect between Fe+3 and the quinone significantly enhances the catalytic potential of nanomaterial as demonstrated in Fig. 11 [272].

reproduced with permission from Du S., et al. [272]

a Proposed mechanism for the reduction of dyes by NaBH4 in the presence of Fe3O4@PDA-NPs, b TGA curves of Fe3O4@PDA-NPs for the fresh and deactivated catalysts, and c decolorization rate of MO in the presence of Fe3O4@PDA-NPs and NaBH4 with catalyst recycling;

Furthermore, the reusability and stability of the nanocatalysts were also evaluated by magnetically recovering the catalysts and repeating the procedure again and again. An increase in reaction time was observed upon each recycle and possible reason was given for justification. A number of morphological and structural characterizations of samples before and after use were compared which showed no significant changes. However, TGA and ICP-MS analysis depicted a decrease in PDA and Fe3+ content of used catalyst which lead to decreased catalytic activity.

Various catalysts used for the degradation of MO along with NaBH4 (reducing agent) and reaction completion time are given in Table 5.

Various catalysts used for the catalytic degradation of dyes along with preparation method, amount of catalyst, reaction completion time, and value of kapp are given in Table 6.

Recyclability of nanocatalysts

In heterogeneous catalysis, stability and reusability of nanocatalyst are very important from a financial point of view [298]. Mostly, nanocomposites are recycled from the reaction mixture and reused with significant efficiency even after 5 cycles (Atarod et al. 2016). However, a slight decrease in catalytic efficiency of NPs was observed after 5 cycles of usage. Gosh and co-workers have reported the recyclability of Cu-NPs loaded mesoporous silica SBA-15 and found that degradation reduction of dye was the same up to fifth cycle (Table 7).

Nasrollahzadeh et al. studied immobilization of Ag NPs on the surface of rGO-TiO2 and reported a significant increase in recyclability of Ag-RGO-TiO2 nanocomposite catalyst used for Congo red reduction [298]. The catalytic activity and morphology of given nanocomposite material were conserved up to 5th cycle of reusability. FE-TEM analysis and inductively coupled plasma atomic emission spectroscopy (ICP-AES) analysis confirmed that morphology of catalyst did not change and leakage of Ag NPs was also very low up to fifth cycle. Later, Zheng et al. reported even better nanocomposite materials having acrylic acid and chitosan-based hydrogels for impregnation of Ag NPs employed for Congo red reduction in an aqueous medium. They observed that catalytic potential of a given hybrid nanocatalyst composite was maintained up to ten successive cycles [299]. Similarly, shape, morphology, and size of Ag NPs-perlite assembly were maintained up to 4th cycle of reusability (i.e., EDX and TEM analysis) reported by Rostami-Vartooni and co-workers [266]. The increase in recyclability of Au NPs loaded Fe3O4-polyaniline composite material was studied by Chen et al. who reported the catalytic potential of this composite up to 5th cycle of reuse [300]. ICP-MS and TEM analysis confirmed no change in size of nanoparticles while same tendency was observed in case of Au NPs immobilized on tubular Kappa fiber and activity was maintained up to 10th cycle [301]. Furthermore, immobilizing Cu-NPs on surface of chitosan also showed increase recyclability for reduction of Congo red [302]. Plenty of research work has been reported for hybrid nanocomposites used for Congo red degradation [104, 301, 303]. Various other nanocomposites have been reported with natural heterogeneous catalysts that can be separated easily through mild centrifugation. Easy recovery and higher catalytic activity of these nanocomposites have attracted industries to make use of them and replace expensive catalyst for catalytic reduction of Congo red.

Recycling efficiency is the most significant aspect of a catalyst from economical point of view. Ansari et al. carried out recycling study of Co nanocatalysts entangled in p(AAc) networks using p(AAc)-Co composite as catalyst for the reduction of 4-NP up to four consecutive cycles. In this task, composite was removed out of the reaction medium after catalysis via filtration, accompanied by washing with distilled water. Under the same set of conditions, composite was again applied as catalyst for the same reaction [304]. With every cycle, change in activity of catalyst was observed and is depicted in Fig. 12.

reproduced with permission from Ansari et al. [304]

Effect of recycling on catalytic activity in terms % activity of p(AAc)-Co composite catalyst as a function of number of cycle. Reaction conditions; 0.001 M NP = 50 ml, NaBH4 = 0.19 g, Catalyst = 0.03 g of Co, 250 rpm, 30 °C;

Azzam et al. determined the reusability of the TiO2@CNTs/AgNPs/ C10 nanocomposite by employing the same photocatalyst repeatedly for 5 cycles. Figure 13 signifies a decrease in photocatalytic activity of nanocomposite hardly from 100 to 92% within three cycles and then became 77% at the fifth cycle depend on the prescribed environments. Hence, obtained results showed that the synthesized nanocomposite is an efficient and stable photocatalyst within three cycles [305].

reproduced with permission from Azzam et al. [305]

Recycles of TiO2@CNTs/AgNPs/C10 nanocomposite during photodegradation of MB dye [C0 = 20 mg/L, catalyst dose = 0.5 g/L, H2O2 = 0.782 mol/L, pH = 5.8, contact time = 120 min, and T = 25 °C];

Das et al. studied the reusability of magnetic nanocatalyst Fe3O4@PPy-MAA/Ag for reduction of 4-NP. After the reduction of 4-NP, catalyst was disassociated easily from the reaction mixture with a magnet due to its intrinsic magnetism and washed five times by distilled water before reusing in further recycling. Figure 14 reveals that the catalyst was effectively reused in eight successive cycles of 30 min reaction time each. Moreover, it was also monitored that Fe3O4@PPy-MAA/Ag had not showed any remarkable loss of activity after seven cycles. Using nanocatalyst, more than 80% conversion of 4-NP to 4-AP was acquired after eight successive cycles which shows extraordinary stability.

reproduced with permission from Das et al. [306]

Reusability of Fe3O4@PPy-MAA/Ag nanocatalyst over eight successive cycles for reduction of 4-NP;

and robustness of nanocatalyst toward multiple cycles of reuse [306].

Ding et al. studied the photocatalytic stability of Ag/Ag2O/ZnO nanocomposite using visible light irradiation by cyclic degradation of MB for four times. Figure 15 signifies that the synthesized nanocomposite exhibits excellent photocatalytic stability. After 50 min, 99% degradation of MB was observed in the first run. In the second and third run, high degradation efficiency (99%) was monitored till the fourth run down to 85% [307].

reproduced with permission from Ding et al. [307]

The cyclic stability of the Ag/Ag2O/ZnO nanocomposite as a photocatalyst to degrade MB for four cycles under visible light irradiation;

Advanced spectroscopy techniques

In order to understand the interaction mechanism involved between the nanocatalysts and the pollutants to be degraded, several spectroscopic techniques have been adopted by the research community in the past. The interaction mechanisms are highly dependent on the nature of the pollutants/dyes (organic or inorganic, molecular structure, redox conditions, and coordination components), the morphological features of nanocatalysts (porous structure, positive/negative net charge on the surface, attached functional groups and stability), and the atmospheric conditions (pH, temperature, and ionic composition). Depending on these conditions, different kinds of interaction mechanisms including adsorption, precipitation, ion exchange, redox reactions, photocatalytic degradation, and surface complexation, etc., can be followed. Several advanced spectroscopic techniques like X-ray photoelectron spectroscopy (XPS), Fourier transform infrared spectroscopy (FTIR), and X-ray absorption fine structure spectroscopy (XAFS) have been adopted to evaluate the interaction mechanisms. Some semi-qualitative information can be inferred by observing the shift in peaks position (red/blue shifts) or the intensity of the peaks generated in these spectroscopic techniques.

For instance, we can get some useful information regarding the chemical composition, oxidation state, binding energy, and relative content for the surface or near surface interactions through XPS [308, 309]. Recently, Markovic et al. employed XPS analysis to study the chemical composition of the prepared CoAP catalyst and confirmed the oxidation state of cobalt (Co+2) present in the samples [310]. The bond lengths between the metal atoms along with coordination number and valence state can be significantly evaluated by utilizing XAFS analysis. With this information provided by the XAFS, the microstructure can be evaluated molecularly and some interaction information can be inferred semi-qualitatively/quantitatively as well [311]. Mohamed et al. employed the extended EXAFS technique to evaluate the binding and particle size of Cu in TiO2-SiO2 catalyst for the catalytic degradation of Direct Blue dye [312]. In another study, Choi and colleagues evaluated the coordination number of Cu atoms in Cu/Cu2O/CuO-rGO catalysts by applying EXAFS analysis and measured the bond lengths of metal atoms as well [313]. The presence of other relevant phases of Co in Co-B-O nanocatalysts was confirmed by Edla et al. through the EXAFS analysis and no other phases were detected [314]. The EXAFS spectra of prepared catalyst were compared with the pure Co3O4 powder to infer this information as shown in Fig. 16.

reproduced with permission from Elda R., et al. [314]

EXAFS spectrum of Co-B-O coating on glass after annealing in air for 4 h at 600 °C, compared to the very similar spectrum of Co3O4 crystalline powder;

FTIR analysis is extensively employed to evaluate the chemical composition and functional groups present in catalyst in order to understand the interaction mechanisms. For instance, Han et al. confirmed the desulfuration phenomenon by evaluating the diminishing FTIR peak of -SO3Na during the degradation of methyl orange over Cu-MgAl catalysts [315]. In a recent study, Lai and colleagues evaluated the interaction between Ag NPs and dandelion extract molecules with the help of FTIR analysis. The analysis revealed the capping of AG NPs with dandelion extract which acted as a reducing agent in the degradation of MO and RhB dyes [316].

Computational analysis

For better quantitative analysis of the interaction mechanism at molecular level, computational approaches have gained increasing recognition as a power tool in the field of catalysis. This computational modeling allows us to deeply probe the mechanisms occurring at molecular level which cannot be evaluated experimentally. One can explore the dynamics, structure, energetic, and the interaction mechanisms even at atomic scale level by adopting these modeling techniques effectively. Generally, the catalytic systems involve the adsorption of reactant species on the surface of catalyst and undergo different types of interactions including ion exchange, electrostatic interactions, redox reactions, and complexation. The computational analysis can provide a compact information about which of the possible mechanisms are most probable to happen in a given system. Recently, Zhang et al. have demonstrated a density functional theory (DFT) analysis of the degradation mechanism involved in the oxidation of 1, 2-dichloropropane (DCP) over LaMnO3 perovskite catalyst. The DFT modeling revealed that the chemisorption of 1, 2-DCP molecules on the active Mn sites results in the heterogeneous degradation of the organic pollutant into allyl chloride, while the further decomposition of allyl chloride is highly dependent on the reaction conditions [317]. Cherian and colleagues designed a DFT model for the light driven catalytic activity of Co, N, and Co–N-doped MoS2 films and concluded that N-doped films were best candidates for the photocatalytic degradation of dyes. Moreover, the study revealed that stability of MoS2 decreased along with increase in band gap values upon doping [318]. The adsorption energies, equilibrium geometries, and dissociative reactions involved in the degradation of methanol over fullerene like B12N12 catalyst have also been evaluated via DFT modeling [319]. The adsorption of methanol on the B12N12 catalyst also tends to enhance the electric conductivity of the material and O–H bond breaking was proposed as the most probable way of methanol decomposition (Figs. 17, 18).

reproduced with permission from Esrafili et al. [319]

Optimized structures, total density of states, HOMO and LUMO of B12N12 and B12N12ACH3OH complexes. Distances in Å.;

reproduced with permission from Zeng et al.[322]

Dye degradation mechanism along with computational model of ternary CoFeNi-layered double hydroxide catalyst;

Matos and colleagues used DFT modeling to study the photocatalytic degradation mechanism of methylene blue and phenols over C-doped TiO2 catalyst. They concluded that the total electronic charge on oxygen atoms bonded with TiO2 increased after incorporation of carbon in the lattice [320].

Apart from DFT, frontier molecular orbital theory (FMT) has also been adopted by the researchers to understand the interaction mechanisms involved in catalytic degradation of organic pollutants. For instance, Zanjanchi and colleagues studied the adsorption kinetics and reaction of 1-arylazo-2-naphthol dyes with the surface of cellulose. The computational analysis revealed that the singlet-state oxygen (1O2) acts as electrophile and takes part in electrophilic reaction to oxidize the dye molecules [321]. Recently, Zheng et al. studied the interactions of Congo red and RhB dyes with ternary CoFeNi-layered double hydroxide catalysts. The study revealed that the Co(II)-Co(III)-Co(II) cycle effectively generated the radical species that resulted in degradation of dyes. The electronic density in the highest occupied molecular orbital and lowest unoccupied molecular orbitals was also calculated to emphasize on the interaction mechanisms [322]

In short, the computational calculations and modeling provide better in-depth understanding of the various interaction phenomenon at molecular and atomic level to enable the design of efficient experimental setups. In future, significant developments are expected in the computational area which will allow the researchers to explore the dynamics, interaction energy, and structural properties at molecular level, which will significantly improve the catalytic technologies and applications.

Conclusion and future insights

Various nanocomposite assemblies have been reported for reduction of dyes by NaBH4. Mostly, metal nanoparticles are used for reduction of dyes and stabilized for a long time using different supporting materials. This work outlines recent modifications applied to nanocatalysts for the wastewater treatment focused on catalytic reduction reaction of organic dyes, i.e., nitrophenols, methylene blue, Congo red, and methyl orange. Further work can be preceded in the same field but slightly different dimensions by devising methods that involve useful ways for fabrication of metal nanoparticles and maintenance of their activity for a long time. Researchers need to come up with cost-effective ways of synthesizing nanocatalysts used for reduction of dyes by utilizing economic and easily available resources. Such catalysts should be reusable and eco-friendly. This review just addresses the catalytic reduction of dyes by NaBH4 and recent applications in this area, but there is a dire need to develop new methods for the treatment of wastewater contaminants. Furthermore, no significant literature has been reported on the catalytic mineralization of toxic dyes (which is more desirable than mere decolorization) in the presence of NaBH4 reducing agent. However, photocatalytic activities have been reported on various materials for mineralization of several toxic dyes. The applicability of nanocatalysts for water treatment is constrained by different technical problems that require further investigation, from catalytic improvement to reactor design and method optimization. Different catalytic schemes should be employed for the reduction of dyes from wastewater so that water should be cleaned before disposal to water bodies.

References

Chiou J-R et al (2013) One-pot green synthesis of silver/iron oxide composite nanoparticles for 4-nitrophenol reduction. J Hazard Mater 248–249:394–400

Pabbathi NPP et al (2020) Environmental metabolomics: with the perspective of marine toxicology assessment, in environmental biotechnology. Springer, Newyork

Tiwari DK, Behari J, Sen P (2008) Application of nanoparticles in waste water treatment 1.

Jiang J-Q, Ashekuzzaman SM (2012) Development of novel inorganic adsorbent for water treatment. Curr Opin Chem Eng 1(2):191–199

Margalef-Marti R et al (2019) Evaluating the potential use of a dairy industry residue to induce denitrification in polluted water bodies: A flow-through experiment. J Environ Manage 245:86–94

Elimelech M (2006) The global challenge for adequate and safe water. J Water Supply Res Technol–AQUA, 55(1): 3–10.

Tabassum S (2019) A combined treatment method of novel mass bio system and ion exchange for the removal of ammonia nitrogen from micro-polluted water bodies. Chem Eng J 378:122217

Fawell J, Nieuwenhuijsen MJ (2003) Contaminants in drinking water environmental pollution and health. Br Med Bull 68(1):199–208

Kass A et al (2005) The impact of freshwater and wastewater irrigation on the chemistry of shallow groundwater: a case study from the Israeli Coastal Aquifer. J Hydrol 300(1–4):314–331

Al Yaqout AF (2003) Assessment and analysis of industrial liquid waste and sludge disposal at unlined landfill sites in arid climate. Waste Manage 23(9):817–824

Bhatnagar A, Sillanpää M (2009) Applications of chitin-and chitosan-derivatives for the detoxification of water and wastewater–a short review. Adv Coll Interface Sci 152(1):26–38

Bhatnagar A, Sillanpää M (2010) Utilization of agro-industrial and municipal waste materials as potential adsorbents for water treatment–A review. Chem Eng J 157(2):277–296

Bhatnagar A, Sillanpää M (2011) A review of emerging adsorbents for nitrate removal from water. Chem Eng J 168(2):493–504

Qu X, Alvarez PJJ, Li Q (2013) Applications of nanotechnology in water and wastewater treatment. Water Res 47(12):3931–3946

Raza A et al (2019) Enhanced industrial dye degradation using Co doped in chemically exfoliated MoS2 nanosheets. Appl Nanosci 10(5):1535–1544

Ikram M et al (2020) Photocatalytic and bactericidal properties and molecular docking analysis of TiO2 nanoparticles conjugated with Zr for environmental remediation. RSC Adv 10(50):30007–30024

Zollinger H (2000) Azo dyes and pigments. Colour Chem-Syn, Properties Appl Organic Dyes Pigments 1987:92–100

Bafana A, Devi SS, Chakrabarti T (2011) Azo dyes: past, present and the future. Environ Rev 19:350–371

Mark HF et al (1978) Encyclopedia of chemical technology. Wiley, London

Ikram M et al (2020) Dye degradation performance, bactericidal behavior and molecular docking analysis of Cu-doped TiO2 nanoparticles. RSC Adv 10(41):24215–24233

Rafiq A, et al. (2021) Photocatalytic degradation of dyes using semiconductor photocatalysts to clean industrial water pollution. J Ind Eng Chem.

Naz M et al (2018) Bio-inspired synthesis of silver nanoparticles: anticancer drug carrier, catalytic and bactericidal potential. Nanosci Nanotechnol Lett 10(7):889–899

Vanhulle S et al (2008) Decolorization, cytotoxicity, and genotoxicity reduction during a combined ozonation/fungal treatment of dye-contaminated wastewater. Environ Sci Technol 42(2):584–589

Pereira L, Alves M (2012) Dyes—environmental impact and remediation, in Environmental protection strategies for sustainable development. Springer, Newyork

Ikram M et al (2020) Outstanding performance of silver-decorated MoS2 nanopetals used as nanocatalyst for synthetic dye degradation. Phys E Low-dimensional Syst Nanostruct 124:114246

Ikram M et al (2020) Promising performance of chemically exfoliated Zr-doped MoS2 nanosheets for catalytic and antibacterial applications. RSC Adv 10(35):20559–20571

Martínez-Huitle CA, Brillas E (2009) Decontamination of wastewaters containing synthetic organic dyes by electrochemical methods: a general review. Appl Catal B 87(3–4):105–145

Taghizadeh A, Rad-Moghadam K (2018) Green fabrication of Cu/pistachio shell nanocomposite using Pistacia Vera L. hull: An efficient catalyst for expedient reduction of 4-nitrophenol and organic dyes. J Cleaner Prod 198:1105–1119

Ikram M et al (2020) 2D chemically exfoliated hexagonal boron nitride (hBN) nanosheets doped with Ni: synthesis, properties and catalytic application for the treatment of industrial wastewater. Appl Nanosci 10(9):3525–3528

Raza A et al (2020) A comparative study of dirac 2D materials, TMDCs and 2D insulators with regard to their structures and photocatalytic/sonophotocatalytic behavior. Appl Nanosci 10(10):3875–3899

Zhang Z et al (2015) A highly reactive and magnetic recyclable catalytic system based on AuPt nanoalloys supported on ellipsoidal Fe@ SiO 2. J Mater Chem A 3(8):4642–4651

Ikram M et al (2020) Reduced graphene oxide nanosheets doped by Cu with highly efficient visible light photocatalytic behavior. J Alloys Comp 837:155588

Padhi B (2012) Pollution due to synthetic dyes toxicity carcinogenicity studies and remediation. Int J Environ Sci 3(3):940–955

Ajmal A et al (2014) Principles and mechanisms of photocatalytic dye degradation on TiO2 based photocatalysts: a comparative overview. RSC Adv 4(70):37003–37026

Ikram M et al (2020) Hydrothermal Synthesis of Silver Decorated Reduced Graphene Oxide (rGO) Nanoflakes with Effective Photocatalytic Activity for Wastewater Treatment. Nanoscale Res Lett 15(1):95

Srivastava V, Choubey AK (2019) Synthesis of nanostructured silver particles using Citrus limetta peel extract for catalytic degradation of azo dyes through electron relay effect. Adv Nat Sci Nanosci Nanotechnol 10(4):045015

Kaur G et al (2020) Blooming approach: one-pot biogenic synthesis of TiO2 nanoparticles using piper betle for the degradation of industrial reactive yellow 86 Dye. J Inorganic Organometall Polymers Mater 31(3):1111–1119

Mallakpour S, Behranvand V, Mallakpour F (2019) Synthesis of alginate/carbon nanotube/carbon dot/fluoroapatite/TiO2 beads for dye photocatalytic degradation under ultraviolet light. Carbohyd Polym 224:115138

Naz M et al (2017) Green synthesis (A. indica seed extract) of silver nanoparticles (Ag-NPs), characterization, their catalytic and bactericidal action potential. Nanosci and Nanotechnol Lett 9(11):1649–1655

Xiong P et al (2012) Multi-walled carbon nanotubes supported nickel ferrite: a magnetically recyclable photocatalyst with high photocatalytic activity on degradation of phenols. Chem Eng J 195–196:149–157

Rafiq A et al (2019) ZnS–Ni doped nanoparticles served as promising nano-photocatalyst (industrial dye degrader). Nanosci Nanotechnol Lett 11(8):1060–1069

Maurino V et al (1997) The fate of organic nitrogen under photocatalytic conditions: degradation of nitrophenols and aminophenols on irradiated TiO2. J Photochem Photobiol, A 109(2):171–176

Singh J, A.J.E.t. Dhaliwal, (2020) Plasmon-induced photocatalytic degradation of methylene blue dye using biosynthesized silver nanoparticles as photocatalyst. Environmen Technol 41(12):1520–1534

Soler L, Sánchez S (2014) Catalytic nanomotors for environmental monitoring and water remediation. Nanoscale 6(13):7175–7182

Parasuraman D, Serpe MJ (2011) Poly (N-isopropylacrylamide) microgels for organic dye removal from water. ACS Appl Mater Interfaces 3(7):2732–2737

Ahmad M et al (2014) Photocatalytic, sonocatalytic and sonophotocatalytic degradation of Rhodamine B using ZnO/CNTs composites photocatalysts. Ultrason Sonochem 21(2):761–773

Zhou L et al (2016) The roles of conjugations of graphene and Ag in Ag 3 PO 4-based photocatalysts for degradation of sulfamethoxazole. Catal Sci Technol 6(15):5972–5981

Khehra MS et al (2005) Comparative studies on potential of consortium and constituent pure bacterial isolates to decolorize azo dyes. Water Res 39(20):5135–5141

Xiao F et al (2016) Synthesis of akageneite (beta-FeOOH)/reduced graphene oxide nanocomposites for oxidative decomposition of 2-chlorophenol by Fenton-like reaction. J Hazard Mater 308:11–20

Yu F et al (2014) A novel electro-Fenton process with H2O2 generation in a rotating disk reactor for organic pollutant degradation. Environ Sci Technol Lett 1(7):320–324

Donaldson JD et al (2002) Anodic oxidation of the dye materials methylene blue, acid blue 25, reactive blue 2 and reactive blue 15 and the characterisation of novel intermediate compounds in the anodic oxidation of methylene blue. J Chem Technol Biotechnol Int Res Process Environ Clean Technol 77(7):756–760

Apolinário ÂC et al (2008) Wet air oxidation of nitro-aromatic compounds: Reactivity on single- and multi-component systems and surface chemistry studies with a carbon xerogel. Appl Catal B 84(1):75–86

Li Y et al (2020) Preparation of CoFe2O4–P4VP@Ag NPs as effective and recyclable catalysts for the degradation of organic pollutants with NaBH4 in water. Int J Hydrogen Energy 45(32):16080–16093

Narayanan RK, Devaki SJ (2015) Brawny silver-hydrogel based nanocatalyst for reduction of nitrophenols: studies on kinetics and mechanism. Ind Eng Chem Res 54(4):1197–1203

Zhu X, Ni J (2011) The improvement of boron-doped diamond anode system in electrochemical degradation of p-nitrophenol by zero-valent iron. Electrochim Acta 56(28):10371–10377

Singh S, Kumar N, Kumar M, Jyoti Agarwal A, Mizaikoff B (2017) Electrochemical sensing and remediation of 4-nitrophenol using bio-synthesized copper oxide nanoparticles. Chem Eng J 4:283–292

Zaggout FR, Abu Ghalwa N (2008) Removal of o-nitrophenol from water by electrochemical degradation using a lead oxide/titanium modified electrode. J Environ Manag 86(1):291–296

Wu Z et al (2012) Size-controlled synthesis of a supported Ni nanoparticle catalyst for selective hydrogenation of p-nitrophenol to p-aminophenol. Catal Commun 18:55–59

Chen R, et al (2007) Effect of alumina particle size on Ni/Al2O3 Catalysts for p-nitrophenol hydrogenation* *Supported by the Special Funds for Major State Basic Research Program of China (No.2003CB615702), the National Natural Science Foundation of China (No.20636020) and the Natural Science Foundation of Jiangsu Province(No.BK2006722). Chinese J Chem Eng, 15(6): p. 884–888.

Dai R et al (2009) Reduction of nitro phenols using nitroreductase from E coli in the presence of NADH. J Hazardous Mater 170(1):141–143

Li L et al (2013) Transformation of cefazolin during chlorination process: Products, mechanism and genotoxicity assessment. J Hazard Mater 262:48–54

Rodríguez-León E et al (2019) Synthesis of gold nanoparticles using mimosa tenuiflora extract, assessments of cytotoxicity, cellular uptake, and catalysis. Nanoscale Res Lett 14(1): 334

Zhang A et al (2012) Heterogeneous Fenton-like catalytic removal of p-nitrophenol in water using acid-activated fly ash. J Hazard Mater 201:68–73

Ganzenko O et al (2018) Bioelectro-Fenton: evaluation of a combined biological—advanced oxidation treatment for pharmaceutical wastewater. Environ Sci Pollut Res 25(21):20283–20292

Madrakian T, Afkhami A, Ahmadi MJC (2013) Simple in situ functionalizing magnetite nanoparticles by reactive blue-19 and their application to the effective removal of Pb2+ ions from water samples. Chemosphere 90(2):542–547

Luo Y et al (2014) A review on the occurrence of micropollutants in the aquatic environment and their fate and removal during wastewater treatment. Sci Total Environ 473:619–641

da Silva MER, PIM. Firmino ABJBt. (2012) dos Santos, Impact of the redox mediator sodium anthraquinone-2, 6-disulphonate (AQDS) on the reductive decolourisation of the azo dye Reactive Red 2 (RR2) in one-and two-stage anaerobic systems. Bioresource technology. 121: 1–7.

Lichtfouse CG, EJECL, (2019) Advantages and disadvantages of techniques used for wastewater treatment. Environ Chem Lett 17(1):145–155

Robinson T et al (2001) Remediation of dyes in textile effluent: a critical review on current treatment technologies with a proposed alternative. Biores Technol 77(3):247–255

Gupta N, Singh HP, Sharma RK (2011) Metal nanoparticles with high catalytic activity in degradation of methyl orange: an electron relay effect. J Mol Catal A: Chem 335(1–2):248–252

Safavi A, Momeni S (2012) Highly efficient degradation of azo dyes by palladium/hydroxyapatite/Fe3O4 nanocatalyst. J Hazard Mater 201:125–131

Amir M, Kurtan U, Baykal A (2015) Rapid color degradation of organic dyes by Fe3O4@ His@ Ag recyclable magnetic nanocatalyst. J Ind Eng Chem 27:347–353

Zheng L-Q et al (2015) Reversible catalysis for the reaction between methyl orange and NaBH 4 by silver nanoparticles. Chem Commun 51(6):1050–1053

Rostami-Vartooni A, Nasrollahzadeh M, Alizadeh M (2016) Green synthesis of seashell supported silver nanoparticles using Bunium persicum seeds extract: application of the particles for catalytic reduction of organic dyes. J Colloid Interface Sci 470:268–275

Bian S-W, Liu S, Chang L (2016) Synthesis of magnetically recyclable Fe 3 O 4@ polydopamine–Pt composites and their application in hydrogenation reactions. J Mater Sci 51(7):3643–3649. https://doi.org/10.1007/s10853-015-9688-3

Francis S et al (2019) Catalytic activities of green synthesized silver and gold nanoparticles. Mater Today Proc 9:97–104

Zhong X et al (2020) The magnetic covalent organic framework as a platform for high-performance extraction of Cr (VI) and bisphenol a from aqueous solution. J Hazardous Mater 393:122353

Zhu Y et al (2020) Cultivation of granules containing anaerobic decolorization and aerobic degradation cultures for the complete mineralization of azo dyes in wastewater. Chemosphere 246:125753

Zelekew OA, Kuo D-H (2016) A two-oxide nanodiode system made of double-layered p-type Ag 2 O@ n-type TiO 2 for rapid reduction of 4-nitrophenol. Phys Chem Chem Phys 18(6):4405–4414

Ikram M et al (2020) Bimetallic Ag/Cu incorporated into chemically exfoliated MoS2 nanosheets to enhance its antibacterial potential: in silico molecular docking studies. Nanotechnology 31(27):275704

Quiton KGN, Lu M-C, Huang Y-H (2021) Synthesis and catalytic utilization of bimetallic systems for wastewater remediation: a review. Chemosphere 262:128371

Albukhari SM et al (2019) Catalytic reduction of nitrophenols and dyes using silver nanoparticles @ cellulose polymer paper for the resolution of waste water treatment challenges. Colloids Surf, A 577:548–561

Nagarajan D, Venkatanarasimhan S (2019) Copper(II) oxide nanoparticles coated cellulose sponge—an effective heterogeneous catalyst for the reduction of toxic organic dyes. Environ Sci Pollut Res 26(22):22958–22970

Kılıç Depren S et al (2020) Ultra-layered sheet CuCo nanoparticles for optimized application in catalytic reduction of organic dye. Mater Characterization 160:110116

Zhang P et al (2014) A novel approach for the in situ synthesis of Pt–Pd nanoalloys supported on Fe3O4@ C core–shell nanoparticles with enhanced catalytic activity for reduction reactions. ACS Appl Mater Interfaces 6(4):2671–2678

Roberts EJ et al (2019) Continuous flow methods of fabricating catalytically active metal nanoparticles. ACS Appl Mater Interfaces 11(31):27479–27502

Zhang N et al (2020) Efficient oxidative degradation of fluconazole by a heterogeneous Fenton process with Cu-V bimetallic catalysts. Chem Eng J 380:122516

Oseghale CI et al (2019) Gold-based carbon-supported bimetallic catalysts for energy storage and biomedical applications. Microchem J 149:103917

Wang P et al (2020) Nano-hybrid bimetallic Au-Pd catalysts for ambient condition-catalytic wet air oxidation (AC-CWAO) of organic dyes. Separation and Purification Technol 233:115960

Soltani M, Zabihi M (2020) Hydrogen generation by catalytic hydrolysis of sodium borohydride using the nano-bimetallic catalysts supported on the core-shell magnetic nanocomposite of activated carbon. Int J Hydrogen Energy 45(22):12331–12346

Pozun ZD et al (2013) A systematic investigation of p-nitrophenol reduction by bimetallic dendrimer encapsulated nanoparticles. The J Phys Chem C 117(15):7598–7604

Hasnat MA et al (2015) Aggregated Pt–Pd nanoparticles on Nafion membrane for impulsive decomposition of hydrogen peroxide. RSC Adv 5(57):46295–46300

Wang Y-X et al (2020) Ligand-enabled Ni–Al bimetallic catalysis for nonchelated dual C-H annulation of arylformamides and alkynes. Org Lett 22(6):2230–2234

Gu Y et al (2019) Solvent effect on the solvothermal synthesis of mesoporous NiO catalysts for activation of peroxymonosulfate to degrade organic dyes. ACS Omega 4(18):17672–17683

Lee J-SM et al (2019) Homogenized bimetallic catalysts from metal-organic framework alloys. Chem Mater 31(11):4205–4212

Mei S et al (2020) Organic–inorganic bimetallic hybrid particles with controllable morphology for the catalytic degradation of organic dyes. J Hazard Mater 44(20):8366–8378

Park H et al (2017) Hydrogenation of 4-nitrophenol to 4-aminophenol at room temperature: Boosting palladium nanocrystals efficiency by coupling with copper via liquid phase pulsed laser ablation. Appl Surf Sci 401:314–322

Ma, B., et al. (2019) Bimetal–organic-framework-derived nanohybrids Cu0.9Co2.1S4@MoS2 for high-performance visible-light-catalytic hydrogen evolution reaction. ACS Appl Energy Mater, 2(2): 1134–1148.

Zhang K et al (2020) Insights into the active sites of chlorine-resistant Pt-based bimetallic catalysts for benzene oxidation. Appl Catalysis B Environ 279:119372

Rui N et al (2021) Highly active Ni/CeO2 catalyst for CO2 methanation: Preparation and characterization. Appl Catalysis B Environ 282:119581