Abstract

Electro-Fenton (EF), an advanced oxidation process, can be combined with a biological process for efficient treatment of wastewater containing refractory pollutants such as pharmaceuticals. In this study, a biological process was implemented in a sequencing batch reactor (SBR), which was either preceded or followed by EF treatment. The main goal was to evaluate the potential of two sequences of a combined electrochemical-biological process: EF/SBR and SBR/EF for the treatment of real wastewater spiked with 0.1 mM of caffeine and 5-fluorouracil. The biological removal of COD and pharmaceuticals was improved by extending the acclimation time and increasing concentration of biomass in the SBR. Hardly biodegradable caffeine and COD were completely removed during the EF post-treatment (SBR/EF). During the EF/SBR sequence, complete removal of pharmaceuticals was achieved by EF within 30 min at applied current 800 mA. With a current of 500 and 800 mA, the initially very low BOD5/COD ratio increased up to 0.38 and 0.58, respectively, after 30 min. The efficiency of the biological post-treatment was influenced by the biodegradability enhancement after EF pre-treatment. The choice of an adequate sequence of such a combined process is significantly related to the wastewater characteristics as well as the treatment objectives.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A modern traditional healthcare system is founded on the usage of pharmaceuticals. The circulation of medicinal products is not simply restricted to producers, distributors, and users but has been observed to extend to the total of the environment and became a global concern (Arnold et al. 2014). Pharmaceuticals consumed by humans or animals find their way into all types of surface, ground, and drinking water, and this disturbs not only the natural balance of ecosystems, but has also multiple devastating effects on its inhabitants (Carmona et al. 2014; Houtman et al. 2014; Simazaki et al. 2015).

There is a multitude of sources by which pharmaceuticals enter to water environment, mainly from human excretion and discharge of drug-containing effluents. However, the main cause of pollution remains the ineffective treatment of wastewaters (Komesli et al. 2015; Stackelberg et al. 2007). An apparent solution to the problem is improving the existing treatment technologies, especially for the wastewater from pharmaceutical companies and hospitals. A typical wastewater plant includes a sequence of different stages, where water is gradually decontaminated through physicochemical and biological processes. The core of conventional treatment is typically a biological process, which employs microorganisms for pollutant degradation. Biological processes have several advantages, especially the favorable relation between cost and efficiency. However, as some pharmaceuticals are generally refractory, non-biodegradable, or toxic to bacteria, their biological removal is erratic and inadequate (Belkheiri et al. 2011; Mansour et al. 2012). In order to improve the modern treatment methods, new efficient and cost-effective technologies are needed.

Recently, electrochemical advanced oxidation processes have shown their great efficiency in the destruction of persistent/toxic pollutants (Oturan and Aaron 2014; Trellu et al. 2016). Electro-Fenton (EF) is an advanced oxidation process based on the in situ production of hydroxyl radicals (•OH) through electrochemically assisted Fenton reaction (Brillas et al. 2009; Martínez-Huitle et al. 2015; Vasudevan and Oturan 2013). It is a destructive process, where the strong oxidant •OH is able to degrade non-selectively persistent/toxic organic pollutants, in contrast to the biological processes (Oturan 2014; Rodrigo et al. 2014). EF process has demonstrated its efficiency for the degradation of different pharmaceuticals (Dirany et al. 2011; El-Ghenymy et al. 2014; El-Hanafi et al. 2014), as well as other types of pollutants (Olvera-Vargas et al. 2014; Oturan et al. 2012; Ozcan et al. 2008). The main drawback that holds back its industrial application is the cost-intensive operation due to relatively high energy consumption. Therefore, a combination of electrochemical and biological processes—called “bio-EF”—is supposed to create a synergetic effect by coupling the advantages of both processes. With regard to the order of processes, bio-EF can be performed in two different modes: EF as either pre- or post-treatment. In the first case, the removal of refractory and/or toxic pharmaceutical contaminants can be achieved by means of the electrochemical process, which breaks down mother molecules of pollutants to more biodegradable intermediates facilitating the subsequent biological process (Olvera Vargas et al. 2016). On the contrary, if the influent wastewater is biodegradable, then application of a biological pre-treatment represents an appropriate alternative followed by EF process as a polishing step for the removal of residual refractory pollutants.

The main objective of this study was to evaluate the potential of bio-EF for the removal of pharmaceutical contamination from a real effluent, comparing the two above mentioned configurations, i.e., EF-biological process and biological process-EF. Biological process was performed in a conventional sequencing batch reactor (SBR), which is simple in operation and requires only one reactor, where all the stages of biological treatment take place: (i) wastewater feeding, (ii) biological reaction with microorganisms, (iii) biomass settlement, and (iv) discharge of the treated solution. When the four stages are completed, a new treatment cycle starts in the same reactor.

The research questions that were addressed in this study are (i) to analyze the removal of chemical oxygen demand (COD) as well as pharmaceuticals in a SBR alone and combined to EF post-treatment, (ii) to examine the removal of COD and pharmaceuticals during EF pre-treatment followed by a SBR, (iii) to determine the optimal operating parameters of EF pre-treatment based on biodegradability enhancement and energy consumption, and (iv) to compare the two different treatment strategies (SBR/EF and EF/SBR).

Materials and methods

Chemicals

Analytical grades of 5-fluorouracil (CAS 51-21-8) and caffeine (CAS 58-08-2) were purchased from Sigma-Aldrich. Iron (II) sulfate heptahydrate (CAS 7782-63-0) as a catalyst source and sodium sulfate (CAS 7757-82-6) as supporting electrolyte were obtained from Acros Organics and Sigma-Aldrich, respectively. The solution pH was adjusted using 1 M sulfuric acid as well as 5 M sodium hydroxide. The reagents used for preparation of solutions for analysis of COD and for biodegradability tests as well as for bioreactors are as reported in CEAEQ (2006)) and Rodier et al. (2009)), respectively.

Wastewater characteristics

The real effluent was sampled from a pharmaceutical factory in the Campania region, Italy. Its composition is presented in Table 1. The effluent was spiked with 0.1 mM of psychoactive drug caffeine and 0.1 mM of antineoplastic drug 5-fluorouracil (with the same concentration as in our previous studies; Ganzenko et al. 2015). These two are common pharmaceuticals which are widely used worldwide and are found to be generally refractory pollutants to a certain extent (Kovacs et al. 2015; Zaleska-Radziwill et al. 2014).

Sequencing batch reactor

Two separate bioreactors were maintained for a 3-month period to acclimate the microbial cultures to the real wastewater and subsequently investigate the potential of the SBR/EF and EF/SBR sequences. The biomass was an activated sludge sampled from the municipal wastewater treatment plant in Cassino, Italy. Acclimation of biomass proceeded in two stages. Initially, the microbial activity was stimulated by adding nutrients and sucrose (1 g/L) to the wastewater diluted in 1:1 ratio with tap water in order to minimize the initial shock to the microorganisms. The solution was replaced with a fresh medium twice per week and the dilution with tap water was gradually decreased. Subsequently, caffeine and 5-fluorouracil (0.1 mM each) were added to the microbial culture solution to acclimate the biomass to the presence of these pharmaceuticals. In this case, the replacement with a fresh solution was performed every 5 days.

The operational conditions of both reactors were similar: continuous aeration with air ensured constant oxygen saturation flow rate of 8.7 ± 0.2 mg O2/L, pH and temperature being in the range of 7.8 ± 0.2 and 22 ± 2 °C, respectively. The amount of nutrients was kept within the ratio COD/N/P = 100:5:1. In addition, nutrients (buffer and saline solutions) were prepared and added as reported elsewhere (Rodier et al. 2009). The operation followed the standard steps of an SBR. After pH adjustment, the reactor was fed with the influent and all the nutrients were added. Then, the treatment was performed with continuous mixing and aeration with biological reaction time ranging between 1 and 3 days, which is similar to real-life applications. Finally, after biomass settlement for 30 min, the treated solution was withdrawn from the SBR. This SBR operational design was applied for both SBR/EF and EF/SBR sequences.

In order to investigate the effect of biomass concentration and microbial acclimation time on the biological process, the SBR used in the SBR/EF sequence was maintained under two different operating conditions. Initially, SBR-I was operated with a volatile suspended solids (VSS) concentration of 850 mg/L using a biomass adapted for 2 weeks with the wastewater spiked with pharmaceuticals. A higher VSS concentration (1310 mg/L) and a longer acclimation time (1 month) were used during SBR-II operation. Both parameters were changed simultaneously to enhance significantly the removal efficiency of the SBR.

The working volume of the SBRs used for the SBR/EF and the EF/SBR sequences were 1.5 and 1 L, respectively. The smaller volume for biological treatment in the EF/SBR sequence was because of the fact that the volume of effluent after EF pre-treatment was reduced due to absorption of wastewater by the carbon felt.

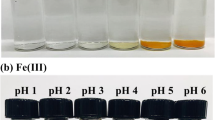

EF setup

An undivided EF reactor of 1.4 L was operated at ambient temperature (T = 22 ± 1 °C) in a batch mode. The reactor was fed with the initial pharmaceutical wastewater spiked with caffeine and 5-fluorouracil for EF/SBR sequence. During the SBR/EF sequence, the EF reactor was fed with the biologically pre-treated solution. In both cases, the EF influent contained 0.05 M sodium sulfate (electrolyte) and 0.2 mM iron sulfate (source of Fe2+ catalyst), according to the optimal operating conditions previously determined (Ganzenko et al. 2015). The pH was adjusted to 2.9 ± 0.1 with 1 M sulfuric acid. A carbon felt cathode with dimensions of 12.5 cm × 38 cm (corresponding immersed area of 475 cm2) was used and placed in order to cover the inner area of the reactor. The boron-doped diamond (BDD) anode with coating on both sides had dimensions of 15 cm × 7.5 cm and immersed area in the solution of 193 cm2. BDD was placed in the center of the reactor on equal distances from the cathode. Continuous stirring at 300 rpm was ensured throughout the process and aeration started 5 min prior to electrolysis in order to saturate the solution with oxygen. The current intensity was applied and monitored in real time with a power supply DM30005E III (MKC, Italy).

Bio-electro-Fenton setup

To ensure proper functioning of both processes as a part of a combined treatment, pH adjustment was needed between the two steps. In the sequence EF/SBR, pH was adjusted from 2.8 to 7.8 ± 0.2 with 5 M NaOH, while for operation of SBR/EF, it was necessary to decrease pH to 2.9 ± 0.1 with 1 M H2SO4. No other transitional actions were taken to approximate the operating conditions to future large-scale setup.

The samples taken during SBR operation were left for 30 min in order to settle the biomass. Afterward, the supernatant was withdrawn and filtered with 0.45 μm Millex cellulose membranes (Merck Millipore, USA) for analysis.

Instruments and analytical procedures

Chemical oxygen demand

A reflux method in a closed system (tubes) and a colorimetric dosage with potassium dichromate was used to determine COD. Digestion and acidic solution were prepared according to the analytical method (CEAEQ 2006) and filled in the tubes. Samples were added to the pre-made tubes and incubated at 148 °C for 2 h. The value of COD was measured at 445 nm by photometric method using a WTW PhotoLab (WTW, Germany) in the range between 0 and 100 mg/L.

Biodegradability tests

These tests were based on measuring biochemical oxygen demand over 5 days (BOD5). The dilution method from Rodier et al. (2009)) was performed with slight modifications. All the solutions (saline, control, phosphate buffer, allylthiourea, and dilution water) were prepared according to the protocol. Biomass was the same activated sludge used to seed the SBR with a VSS concentration of 4.2 g/L.

Prior to analysis, dilution water, samples, and bacterial inoculum were aerated to ensure saturation of oxygen. An OxiTop® control system (WTW, Germany) was used as automated system for BOD5 measurement by respirometric method. Each OxiTop® bottle had a working volume of 432 mL and contained 100 mL of sample, 3 mL of buffer solution (necessary amount to keep the COD/N ratio around 100:5), 5 mL of activated sludge, and 1 mL of allylthiourea solution (to prevent nitrification). The remaining volume (273 mL) was filled with dilution water, prepared as in Rodier et al. (2009)). Before seeding with bacteria, the final pH was ensured to be circumneutral. A rubber sleeve with sodium hydroxide pellets was placed inside each bottle to absorb the carbon dioxide produced during the bacterial respiration. The continuously stirred bottles were incubated in a dark place at 20 ± 1 °C. Each batch of analysis also included one blank and one reference control. The blank control bottle was filled with ultrapure water instead of the sample, in order to evaluate the microbial endogenous respiration, which was thereafter subtracted from the final BOD5 measurements. The control bottle contained glucose and glutamic acid to keep the reference of microbial activity.

High-performance liquid chromatography

Concentration of caffeine and 5-fluorouracil were determined by reverse-phase high-performance liquid chromatography (HPLC). The equipment (Merck Hitachi) consisted of a column Purospher STAR RP-18 end-capped (5 μm), a pump (Elite LaChrome, L-2130), a UV detector (Elite LaChrome, L-2400), and a thermostatic oven (Jetstream Plus, series 140310). Detection limit for both pharmaceuticals was 10−6 M. Temperature was kept at 40 °C, and the mobile phase consisted of a mixture of methanol and ultrapure water both buffered with 1% acetic acid. Detection was performed at 275 nm with an injection volume of 20 μL. Gradient elution was used for the separation of the mixture components with the following order: from the start to 11 min, a 90% water and 10% methanol eluent was used at flow rate of 0.3 mL/min; then, from 11 to 13 min, the conditions were gradually changed to 70% water and 30% methanol at a flow rate of 0.6 mL/min and maintained till 28 min. From 28 to 30 min, the eluent composition was gradually changed to the initial 90% water and 10% methanol at a flow rate of 0.3 mL/min and remained for 5 min before the following injection. Such analytical conditions allowed eluting 5-fluorouracil at 10 min and caffeine at 25.4 min.

Volatile suspended solids

VSS concentration was measured during the SBR operation by using the standard protocol as reported in Rodier et al. (2009)). Filtration of samples was performed with 47-μm glass microfiber filters (Whatman, UK).

Results and discussion

SBR as a pre-treatment

As specified in the “Materials and methods” section, the two bioreactors operated for the SBR/EF sequence differed by the VSS concentration and microbial acclimation time. The experiments performed with SBR-I showed that after a biological reaction time of 24 h, only 43% of COD and 38% of 5-fluorouracil were removed (Fig. 1a). This could be an indication to the fact that these compounds possess low volatility and hydrophobicity, which leads to the conclusion that biodegradation might be the main removal pathway in further experiments. The concentration of caffeine decreased only by 3%, indicating its lower biodegradability compared to 5-fluorouracil. The biologically pre-treated solution was then treated by EF with a current intensity of 500 mA, and the results are presented in Fig. 1b. The residual concentrations of pharmaceuticals were below the detection limit after already 1 h of treatment. The COD removal was 99% after 4 h of EF treatment.

To increase efficiency of pharmaceutical removal, SBR-II was used with a longer microbial acclimation time and a higher biomass concentration. Experimental results are presented in Fig. 2. The evolution of COD and concentration of caffeine and 5-fluorouracil were monitored for a longer biological reaction time up to 3 days. Removal of both pharmaceuticals improved: after 24 h, 5-fluorouracil and caffeine were degraded by 88% and 43%, respectively, showing a significantly higher degradation efficiency compared to SBR-I operation. Both drugs were not detected after 3 days, which is a rather long and cost-intensive reaction time, if compared to the operation of large-scale bioreactors. A slightly enhanced COD removal was observed in SBR-II in comparison with SBR-I. After 24 h, 39% of initial COD remained in SBR-II against 47% in SBR-I. However, a longer retention time of 3 days only resulted in additional 10% of COD removed. This was most likely due to the recalcitrance of some organics to be biologically degraded even after longer microbial acclimation and reaction time.

Figure 3 shows the COD and pharmaceutical profiles obtained when SBR-II was coupled to EF post-treatment.

Evolution of COD and concentration of pharmaceuticals during a batch experiment of a combined treatment: the SBR (a) followed by EF (b): COD (blue square), 5-fluorouracil (green triangle), caffeine (red circle). Operating conditions: [CAF] = [5-FU] = 0.1 mM; COD0 = 120 mg/L, a [O2] = 8.7 mg/L, pH = 7.8, V = 1.5 L, SS = 1000 mg/L; b I = 500 mA, [Fe2+] = 0.2 mM, [Na2SO4] = 50 mM, V = 1.4 L

With this configuration, a biological reaction time of 24 h was used which is more similar to a typical reaction time of a large-scale bioreactor. The removal during biological pre-treatment was similar to the one reported in Fig. 2. COD and caffeine were removed by 52 and 43%, respectively, whereas 5-fluorouracil was below the detection limit (Fig. 3a). The residual amount of caffeine was almost completely degraded by the EF post-treatment after 30 min with a current intensity of 500 mA (Fig. 3b).

EF as a pre-treatment

Removal of COD and pharmaceuticals

The BOD5/COD ratio of the feed wastewater was <0.05, indicating a very low biodegradability. However, 57 and 82% of spiked caffeine and 5-fluorouracil, respectively, were degraded when the biological process was used as pre-treatment with a longer microbial acclimation and a higher biomass concentration. This section presents the results of EF as a pre-treatment, which is considered as a more suitable treatment strategy for non-biodegradable effluents (Comninellis et al. 2008). Initially, the influence of the current intensity on the evolution of COD, caffeine, and 5-fluorouracil was investigated. This operating parameter is extremely important in terms of energy consumption and, consequently, treatment costs (Sires et al. 2014). The range of the studied intensities was 200–800 mA and the results are given in Fig. 4.

The removal of COD and degradation of two pharmaceuticals were strongly influenced by the applied current intensity. After 1 h of EF, COD removal was 44, 68, and 79% at 200, 500, and 800 mA current, respectively. Caffeine and 5-fluorouracil degradation rates were very similar. At 200 mA, both pharmaceuticals were below the detection limit after 3 h, while at 500 and 800 mA, their degradation was faster resulting in complete disappearance after 2 and 1 h, respectively.

Biodegradability enhancement of the EF pre-treated effluent

Biodegradability enhancement is an important condition for proper functioning of a biological post-treatment. In order to optimize EF as economically viable pre-treatment, it is important to evaluate the effects of current intensity and retention time on biodegradability. The results of this analysis are illustrated in Fig. 5. The biodegradability enhancement was higher with longer treatment time and higher current intensities. Nevertheless, the BOD5/COD ratio reached 0.33, a standard level of biodegradability (Rodier et al. 2009), even after only 30 min of EF. Such results can be explained by the transformation of the initially refractory compounds by hydroxyl radicals to more biodegradable intermediates, which are more easily degradable by microorganisms.

Energy consumption

An important parameter for the evaluation of an electrochemical process is energy consumption (EC), which also constitutes a major part of operational costs. It is generally determined in terms of kWh consumed per removal of kg of COD using the following equation (Martinez-Huitle and Brillas, 2009):

where E cell —average cell voltage (V), t—electrolysis time (h), I—applied current (A), (ΔCOD) t —decay of COD (g/L) after time t, and Vs—volume of the solution (L).

Table 2 shows the energy consumption for different treatment durations and current intensities. The lowest current intensity of 200 mA displayed the smallest cell voltage (E cell) and consequently led to lower energy consumption. At the same time, the lowest energy consumption was observed for the shortest treatment time (0.5 h), which can be explained by a changing rate of COD removal during the treatment. Figures 2 and 4 show that COD removal rate was the highest at the beginning of the EF treatment prior to gradually decreasing during the experiments. This was mainly attributed to the decreasing amount of organic matter and the propagation of parasitic reactions between •OH and scavengers (Brillas et al. 2009). Consequently, the efficiency of the process was reduced and the removal of COD slowed down. This made the ratio of energy consumed per unit of COD higher toward the end of treatment for all the intensities. Moreover, it is worthy to note that high currents lead to the high electrical energy consumption due to the enhancement of parasitic side reactions such as O2 evolution at the anode and H2 evolution at the cathode as well as destruction of •OH at the anode and that of H2O2 at both the cathode and the anode (Brillas et al. 2009)

Bio-EF: EF/SBR combination

As shown in the “Removal of COD and pharmaceuticals” section, a complete degradation of pharmaceuticals required different treatment duration depending on the applied current intensity. The effect of two different current intensities (200 and 500 mA) on EF used as pre-treatment stage is illustrated in Fig. 6 At 200 mA, a degradation rate higher than 90% was reached after 2 h of treatment for both pharmaceuticals. Degradation of pharmaceuticals was accompanied by 60% removal of COD (Fig. 6a). Additional 30% of COD was removed during the SBR biological post-treatment with a biological reaction time of 3 days (Fig. 6b). These results highlight that the combined process Bio-EF is able to reach a quasi-complete mineralization rate of the treated effluent.

When 500 mA was used as current intensity, both pharmaceuticals were completely degraded after 30 min of EF treatment (Fig. 7a) and COD was reduced by 48%. Then, during the 24-h biological post-treatment, only 12% of COD was removed. In comparison, 25% of COD was degraded in the first 24 h of the biological post-treatment of the previous EF/SBR combination (Fig. 6a). Such a difference was due to a different biodegradability level reached during the EF pre-treatment step. Figure 5 shows that the BOD5/COD ratio increased up to 0.61 after 2 h of EF at 200 mA, which was higher than 0.38 obtained at 500 mA after 0.5 h. This indicates that, although the pharmaceuticals could not be detected in the solution after both EF pre-treatments, the biodegradability of the solution significantly differed and influenced the effectiveness of the biological post-treatment. In the second case, the biological treatment was less efficient because of the lower biodegradability of the pre-treated solution.

Evolution of COD (blue square) and concentration of pharmaceuticals 5-fluorouracil (green triangle) and caffeine (red circle) during a batch experiment of combined treatment: EF (a) followed by an SBR (b). Operating conditions: [CAF] = [5-FU] = 0.1 mM; COD0 = 120 mg/L, (I) I = 500 mA, [Fe2+] = 0.2 mM, [Na2SO4] = 50 mM, V = 1.4 L; (II) SS = 2330 mg/L, V = 1 L.

Comparison between SBR/EF and EF/SBR sequences

Bio-EF as combined electrochemical-biological treatment can be performed in two modes depending on which process is applied as pre-treatment. The choice of the treatment sequence significantly depends on the type and characteristics of the wastewater to be treated. In this study, the wastewater under investigation was initially non-biodegradable (BOD5/COD <0.05), with a low initial COD (120 mg/L).

Regarding the SBR/EF sequence, microbial acclimation time and biomass concentration significantly affected COD removal during the biological treatment. Almost complete degradation of pharmaceuticals and more than 60% of COD removal was achieved with a biological reaction time of 3 days. When a lower biological reaction time of 24 h was used, COD was removed by 50%; 5-fluorouracil was not detected, while caffeine persisted. EF post-treatment was demonstrated to remove the residual amount of caffeine. At the same time, 2 h of EF post-treatment removed 34% (Fig. 1b) and 23% (Fig. 2b) of COD after pre-treatment in SBR-I and SBR-II, respectively. This discrepancy in terms of COD removal after EF was most likely attributed to the presence of suspended microbial cultures in the EF reactor after SBR-II operation. Part of the hydroxyl radicals produced during EF reacted on the bacteria by attacking their outer membrane and resulting in a lower COD removal (Kimura et al. 2003; Schmalz et al. 2009), meaning that bacteria acted as hydroxyl radical scavengers. A possible solution is represented by the use of “immobilized-cell bioreactors” such as a membrane bioreactor, where the biomass is retained on the membrane surface and is not washed out to the electrochemical post-treatment at significant concentrations. Another question that needs special attention in the future applications is the amount of residual salts after application of electro-Fenton process. As a certain level of conductivity of wastewater is required for operation of electrochemical treatment, the added iron salt should be therefore further removed by precipitation, simply by raising the solution pH to 6.

Further discussion is also needed regarding the way the pharmaceuticals can be biologically removed in an SBR. Here, three mechanisms are possible: biotransformation (degradation of pollutant molecule), volatilization, and biosorption (Dialynas and Diamadopoulos 2012; Yu et al. 2011). The latter process can play an important role in the removal of a pollutant from an aqueous phase, but it is not a desirable outcome. Pharmaceuticals sorbed onto the surface of bacterial cells and extracellular polymeric substances will be disposed with the sludge and, depending on the further sludge treatment (Dialynas and Diamadopoulos 2012; Jiang and Zhang 2007, their contamination will not only affect the hydrosphere but also soils (Gielen 2007). Biosorption of pollutants necessarily requires further attention within future studies on a combined process of bio-EF.

The application of EF as pre-treatment is particularly suitable when the initial wastewater is non-biodegradable. The key concerns here are efficient degradation of pollutants to be removed, biodegradability enhancement of the EF process and minimal energy consumption. In the present work, both pharmaceuticals studied were removed with similar rates depending on the current intensity. Lower intensities required logically longer treatment times for complete removal of caffeine and 5-fluorouracil, as the production of hydroxyl radicals is strongly dependent on the current intensity applied. At the same time, longer treatment times and higher current intensities resulted in an enhanced biodegradability of the effluent, in spite of a higher energy consumption. The key choice was to be made between a higher current intensity/shorter treatment time or a lower intensity/longer treatment time. In this study, both variants were implemented experimentally (500 mA/30 min and 200 mA/2 h). The results revealed that the biological process was more efficient after EF at 200 mA and 2 h of treatment, because of the higher biodegradability enhancement. Therefore, the economic feasibility of EF as pre-treatment can be achieved by applying low current intensities and longer treatment times, making the process more energy saving and ensuring a proper biodegradability level in order to increase the efficiency of a biological post-treatment.

Conclusions

The main findings of this study are related to the combination of EF process and a biological process (SBR) as an example of bio-EF. Both sequences (EF/SBR and SBR/EF) were analyzed in terms of COD removal and degradation of pharmaceutical (fluorouracil and caffeine). Experiments were carried out with a real effluent from pharmaceutical production spiked with 0.1 mM of caffeine and 5-fluorouracil.

The SBR alone demonstrated that an enhanced removal of organic matter and pharmaceuticals was achieved during the biological pre-treatment in case of higher biomass concentration, prolonged acclimation, and longer reaction time. Complete degradation of both pharmaceuticals was observed after 3 days of biological reaction time, whereas COD decreased by 70%. Caffeine was demonstrated to be more recalcitrant than 5-fluorouracil to the microbial degradation. When EF was applied as post-treatment, a lower biological reaction time (1 day) was used. EF treatment removed residual COD and caffeine that remained in solution after SBR operation.

Regarding the EF/SBR sequence, EF was able to completely degrade pharmaceuticals after 0.5–2 h depending on the value of the applied current. The enhancement of biodegradability to a level of BOD5/COD = 0.33 was achieved even after 30 min of treatment at all the current intensities. Calculation of energy consumption revealed that the process was more energy demanding with prolonged treatment time and higher current intensities. The combination of EF/SBR with different operating conditions of EF process (500 mA/30 min and 200 mA/2 h) demonstrated that the bioprocess resulted in higher removal level when EF pre-treatment was performed with a lower current (200 mA) and a longer treatment time (2 h). It was attributed to the higher biodegradability enhancement during EF pre-treatment. Moreover, these operating conditions are less energy-intensive and consequently more economical.

Finally, the novelty of this research addresses future studies on different aspects such as (a) a combined process with the biological step maintained in an immobilized-cell bioreactor, (b) the role of biosorption in pharmaceutical removal, and (c) a continuous-flow combined treatment with possible recirculation of the effluent between EF and biological process.

References

Arnold KE, Brown AR, Ankley GT, Sumpter JP (2014) Medicating the environment: assessing risks of pharmaceuticals to wildlife and ecosystems. Philos Trans R Soc B-Biol Sci 369:11

Belkheiri D, Fourcade F, Geneste F, Floner D, Ait-Amar H, Amrane A (2011) Feasibility of an electrochemical pre-treatment prior to a biological treatment for tetracycline removal. Sep Purif Technol 83:151–156

Brillas E, Sires I, Oturan MA (2009) Electro-Fenton process and related electrochemical technologies based on Fenton’s reaction chemistry. Chem Rev 109:6570–6631

Carmona E, Andreu V, Pico Y (2014) Occurrence of acidic pharmaceuticals and personal care products in Turia River basin: from waste to drinking water. Sci Total Environ 484:53–63

CEAEQ (2006) Détermination de la demande chimique en oxygène dans les effluents: méthode de reflux en système fermé suivi d’un dosage par colométrie avec le bichromate de pottasium, MA. 315—DCO 1.0. Ministère du Développement durable, de l’Environnement et des Parcs du Québec, Centre d’expertise en analyse environnementale du Québec, pp. 12

Comninellis C, Kapalka A, Malato S, Parsons SA, Poulios L, Mantzavinos D (2008) Advanced oxidation processes for water treatment: advances and trends for R&D. J Chem Technol Biotechnol 83:769–776

Dialynas E, Diamadopoulos E (2012) The effect of biomass adsorption on the removal of selected pharmaceutical compounds in an immersed membrane bioreactor system. J Chem Technol Biotechnol 87:232–237

Dirany A, Aaron SE, Oturan N, Sires I, Oturan MA, Aaron JJ (2011) Study of the toxicity of sulfamethoxazole and its degradation products in water by a bioluminescence method during application of the electro-Fenton treatment. Anal Bioanal Chem 400:353–360

El-Ghenymy A, Rodriguez RM, Brillas E, Oturan N, Oturan MA (2014) Electro-Fenton degradation of the antibiotic sulfanilamide with Pt/carbon-felt and BDD/carbon-felt cells. Kinetics, reaction intermediates, and toxicity assessment. Environ Sci Pollut Res Int 21:8368–8378

El-Hanafi N, Mehibel L, Li HZ, Poncin S, Bensadok K (2014) Mineralization of the pharmaceutical β-blocker atenolol by means of indirect electrochemical advanced oxidation process: parametric and kinetic study. Sep Purif Technol 49:2942–2950

Ganzenko O, Oturan N, Huguenot D, van Hullebusch ED, Esposito G, Oturan MA (2015) Removal of psychoactive pharmaceutical caffeine from water by electro-Fenton process using BDD anode: effects of operating parameters on removal efficiency. Sep. Purif, Technol

Gielen GJHP 2007: The fate and effects of sewage-derived pharmaceuticals in soil, University of Canterbury

Houtman CJ, Kroesbergen J, Lekkerkerker-Teunissen K, van der Hoek JP (2014) Human health risk assessment of the mixture of pharmaceuticals in Dutch drinking water and its sources based on frequent monitoring data. Sci Total Environ 496:54–62

Jiang CC, Zhang JF (2007) Personal review: progress and prospect in electro-Fenton process for wastewater treatment. J Zhejiang Univ Sci A 8:1118–1125

Kimura K, Amy G, Drewes JE, Heberer T, Kim T-U, Watanabe Y (2003) Rejection of organic micropollutants (disinfection by-products, endocrine disrupting compounds, and pharmaceutically active compounds) by NF/RO membranes. J Membr Sci 227:113–121

Komesli OT, Muz M, Ak MS, Bakırdere S, Gokcay CF (2015) Occurrence, fate and removal of endocrine disrupting compounds (EDCs) in Turkish wastewater treatment plants. Chem Eng J 277:202–208

Kovacs R et al (2015) Assessment of toxicity and genotoxicity of low doses of 5-fluorouracil in zebrafish (Danio rerio) two-generation study. Water Res 77:201–212

Mansour D, Fourcade F, Bellakhal N, Dachraoui M, Hauchard D, Amrane A (2012) Biodegradability improvement of sulfamethazine solutions by means of an electro-Fenton process. Water Air Soil Poll 223:2023–2034

Martinez-Huitle, CA, Brillas E (2009) Decontamination of wastewaters containing synthetic organic dyes by electrochemical methods: a general review. Appl Catal B Environ 87:105–145

Martínez-Huitle CA, Rodrigo MA, Sirés I, Scialdone O (2015) Single and coupled electrochemical processes and reactors for the abatement of organic water pollutants: a critical review. Chem Rev 115:13362–13407

Olvera Vargas H, Cocerva T, Oturan N, Buisson D, Oturan MA (2016) Bioelectro-Fenton: a sustainable integrated process for removal of organic pollutants from water: application to mineralization of metoprolol. J Hazard Mater 319:13–23

Olvera-Vargas H, Oturan N, Aravindakumar CT, Paul MMS, Sharma VK, Oturan MA (2014) Electro-oxidation of the dye azure B: kinetics, mechanism, and by-products. Environ Sci Pollut Res 21:8379–8386

Oturan MA (2014) Electrochemical advanced oxidation technologies for removal of organic pollutants from water. Environ Sci Poll Res 21:8333–8335

Oturan MA, Aaron JJ (2014) Advanced oxidation processes in water/wastewater treatment: principles and applications. A review. Crit Rev Environ Sci Technol 44:2577–2641

Oturan N, Brillas E, Oturan MA (2012) Unprecedented total mineralization of atrazine and cyanuric acid by anodic oxidation and electro-Fenton with a boron-doped diamond anode. Environ Chem Lett 10:165–170

Ozcan A, Sahin Y, Oturan MA (2008) Removal of propham from water by using electro-Fenton technology: kinetics and mechanism. Chemosphere 73:737–744

Rodier J, Legube B, Merlet N (2009): Analyse de l’eau. Dunod, Paris

Rodrigo MA, Oturan N, Oturan MA (2014) Electrochemically assisted remediation of pesticides in soils and water: a review. Chem Rev 114:8720–8745

Schmalz V, Dittmar T, Haaken D, Worch E (2009) Electrochemical disinfection of biologically treated wastewater from small treatment systems by using boron-doped diamond (BDD) electrodes—contribution for direct reuse of domestic wastewater. Water Res 43:5260–5266

Simazaki D, Kubota R, Suzuki T, Akiba M, Nishimura T, Kunikane S (2015) Occurrence of selected pharmaceuticals at drinking water purification plants in Japan and implications for human health. Water Res 76:187–200

Sires I, Brillas E, Oturan MA, Rodrigo MA, Panizza M (2014) Electrochemical advanced oxidation processes: today and tomorrow. A review. Environ Sci Pollut Res Int 21:8336–8367

Stackelberg PE, Gibs J, Furlong ET, Meyer MT, Zaugg SD, Lippincott RL (2007) Efficiency of conventional drinking-water-treatment processes in removal of pharmaceuticals and other organic compounds. Sci Total Environ 377:255–272

Trellu C, Ganzenko O, Papirio S, Pechaud Y, Oturan N, Huguenot D, van Hullebusch ED, Esposito G, Oturan MA (2016) Combination of anodic oxidation and biological treatment for the removal of phenanthrene and Tween 80 from soil washing solution. Chem Eng J 306:588–596

Vasudevan S, Oturan MA (2013) Electrochemistry: as cause and cure in water pollution—an overview. Environ Chem Lett 12:97–108

Yu TH, Lin AY, Panchangam SC, Hong PK, Yang PY, Lin CF (2011) Biodegradation and bio-sorption of antibiotics and non-steroidal anti-inflammatory drugs using immobilized cell process. Chemosphere 84:1216–1222

Zaleska-Radziwill M, Affek K, Rybak J (2014) Ecotoxicity of chosen pharmaceuticals in relation to micro-organisms-risk assessment. Desalin Water Treat 52:3908–3917

Acknowledgements

The authors thank the EU for providing financial support through the Erasmus Mundus Joint Doctorate Program ETeCoS3 (Environmental Technologies for Contaminated Solids, Soils and Sediments, grant agreement FPA no. 2010-0009). The authors also thank grants from region Ile de France. Special thanks are given to Jessica Soave for her participation in experimental part of the study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Vítor Pais Vilar

Rights and permissions

About this article

Cite this article

Ganzenko, O., Trellu, C., Papirio, S. et al. Bioelectro-Fenton: evaluation of a combined biological—advanced oxidation treatment for pharmaceutical wastewater. Environ Sci Pollut Res 25, 20283–20292 (2018). https://doi.org/10.1007/s11356-017-8450-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-017-8450-6